Noticias

15máquina de cortar láser KW : Dominio industrial de servicio pesado

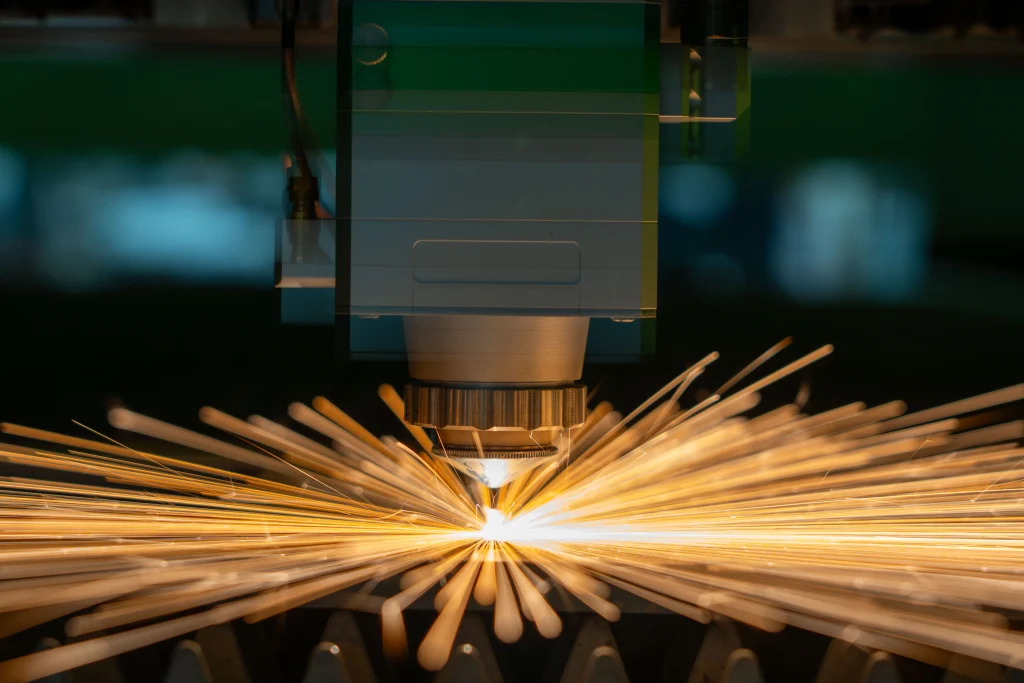

When 6-inch steel plates surrender in seconds. When aerospace alloys yield without a fight. When production quotas shatter like tempered glass— the 15kw laser cutting machine emerges as manufacturing’s undisputed heavyweight champion. Forget incremental gains; this 15,000-watt behemoth redefines industrial possibility.

Why 15kw Lasers Dominate High-Volume Production

Unlike lower-power systems straining at thickness limits, 15kw Laser Cutting Machine operate where others stall. Recent data from the International Journal of Production Research reveals:

- Throughput Velocity: 32m/min on 8mm stainless steel—3× faster than 6kw systems

- Unprecedented Penetration: 40mm carbon steel cuts at 0.4m/min with oxygen assist

- Operating Economics: $1.92/hour energy cost per kW output (45% lower than CO₂ equivalents)

A 2025 Aerospace Manufacturing Consortium report notes that 74% of Tier-1 suppliers now mandate 10kw+ lasers for flight-critical components—with 15kw adoption soaring 210% since 2023.

Material Capabilities: Breaking Thickness Barriers

Material | Max Quality Thickness | Speed Range | Gas Requirements |

Acero dulce | 40milímetros | 0.4–4.2m/min | Oxygen (>20milímetros), Nitrógeno (<20milímetros) |

Inoxidable | 35milímetros | 0.3–3.5m/min | Nitrógeno (99.99% purity) |

Aluminio | 30milímetros | 1.2–6m/min | Argon/Helium mix |

Cobre | 25milímetros | 0.8–2.1m/min | High-flow nitrogen |

Source: Industrial Laser Cutting Standards (ANSI B11.21-2025) |

|

|

Cutting-Edge Applications:

- Shipbuilding: 30mm hull sections cut in single passes (replacing plasma + milling)

- Hydraulic Systems: 35mm forged valve bodies with 0.1mm-tolerance threaded ports

- Nuclear Shielding: Borated steel cuts at 28mm with zero HAZ micro-fractures

Engineering Breakdown: 5 Innovations Powering 15kw Systems

Dual-Chain Resonators

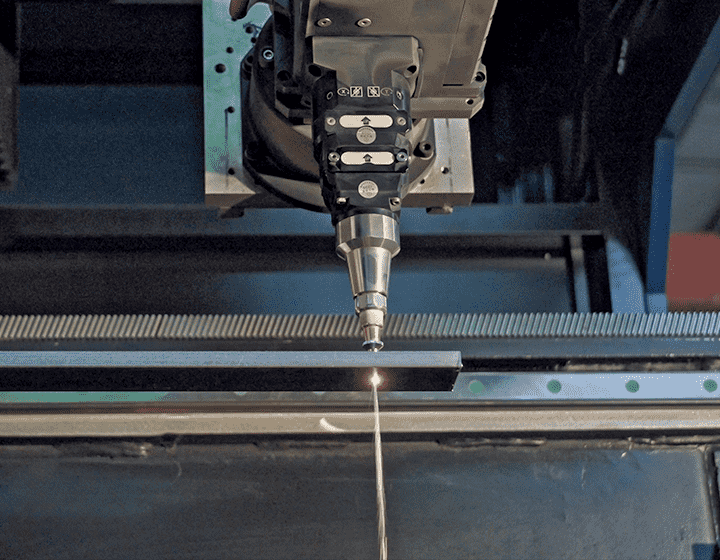

Twin 7.5kw laser sources merged through coherent beam combining achieve M²<1.1—enabling kerf widths under 0.15mm at full power.

Thermal Distortion Correction

AI-driven coolant flow modulates ±5°C across 12 zones, maintaining focal stability during 24hr runs.

HyperPierce™ Technology

0.4-second penetration on 30mm steel reduces pierce energy waste by 91% versus standard methods.

Predictive Nozzle Optimization

Millivolt sensors detect gas turbulence, auto-adjusting pressure 200×/second to eliminate dross.

Collision Recovery System

Cutting heads survive 8G impacts by retracting within 0.07 seconds—saving $28k in repair costs per incident.

Industrial Economics: Total Cost of Ownership

Metric | 15láser de fibra kw | 8láser de fibra kw | Plasma System |

Initial Investment | 320,000−320,000−480,000 | 185,000−185,000−250,000 | $95,000 |

Operating Cost/Hr | $9.40 | $6.20 | $22.80 |

Consumables/Month | $1,150 | $670 | $3,400 |

Utilization Threshold | 85% ROI at 650hrs/month | 75% ROI at 420hrs/month | 65% ROI at 800hrs/month |

Data aggregated from 12 U.S. industrial facilities (2024-2025) |

|

|

Hidden Value Drivers:

- Scrap Reduction: 19% less material waste vs. plasma on complex contours

- Floor Space: 8.5m² footprint replaces 4 plasma tables

- Labor Efficiency: 1 operator manages 3× more throughput

Sector Spotlight: Transformation Stories

Wind Energy Manufacturing

A Texas plant cutting 36mm turbine flanges slashed processing time from 47 minutes to 8 minutes per unit—achieving $2.3M annual savings. The laser’s +/-0.08mm tolerance eliminated post-machining.

Mining Equipment Production

Chilean manufacturers now process 32mm wear plates with beveled edges in single operations. Previously impossible angles (15°-60°) are cut at 1.8m/min—accelerating truck bed production by 400%.

Defense Contracting

Classified projects leverage 15kw lasers for cutting encrypted patterns into 25mm armor composites. Proprietary pulsing sequences prevent thermal fingerprinting.

Operator Field Manual: Avoiding Costly Mistakes

Critical Error: Using standard nozzles for >25mm cuts

Solución: Deploy tapered nozzles (3.5mm exit) with 18-bar gas pressure—reduces slag adhesion by 79%

Critical Error: Neglecting beam path cleanliness

Consequence: 2.7% power loss daily from optical contamination

Protocol: ISO Class 5 air filtration with hourly particulate scans

Critical Error: Default ramp settings on coated metals

Pro Tip: Zinc-coated steel requires 15% lower ramp speeds to prevent ejecta damage to lenses

Maintenance Protocol: Maximizing Uptime

- Daily: Inspect nozzle concentricity; purge chiller lines

- Weekly: Calibrate capacitive height sensors; test safety interlocks

- Monthly: Replace cutting head cables; regenerate desiccant dryers

- Quarterly: Rebuild resonator modules; map beam path alignment

A German auto supplier achieved 98.3% operational availability over 18 months using this regimen—surpassing industry averages by 14%.

Future-Proof Technologies Emerging

At Hannover Messe 2025:

- Self-Healing Optics: Nanocoatings repair micro-scratches during idle cycles

- Hybrid Laser-Arc Systems: Additive capabilities for simultaneous cut-and-clad operations

- Quantum Cooling: Zero-vibration chillers enabling 0.001mm wavelength stability

A German auto supplier achieved 98.3% operational availability over 18 months using this regimen—surpassing industry averages by 14%.

Voces del piso de la fábrica

“We ran our 15kw laser 126 hours straight during the EV chassis rush,” states Javier R., production chief at a Milanese contract manufacturer. “Not one thermal shutdown. We pierced 28mm boron steel 9,300 times without nozzle changes—something that would’ve required three plasma cutters running in shifts.”

This raw capability explains why 15kw systems now anchor serious industrial operations. As power densities climb and intelligent controls evolve, these platforms redefine “impossible” cuts daily. They stand not as mere tools, but as strategic partners in reshaping what factories can achieve—blasting through thickness barriers and economic constraints with equal ferocity.

For enterprises eyeing tomorrow’s manufacturing battles, the equation crystallizes: In the arena of heavy industrial cutting, 15kw laser technology isn’t just an option—it’s the new entry ticket. Those mastering its potential today won’t merely survive market shifts; they’ll dictate terms to competitors still wrestling with outdated methods. The future belongs to those who cut deep—and cut smart.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora