Noticias

Máquinas de corte láser para metal: Revolución de la fabricación moderna

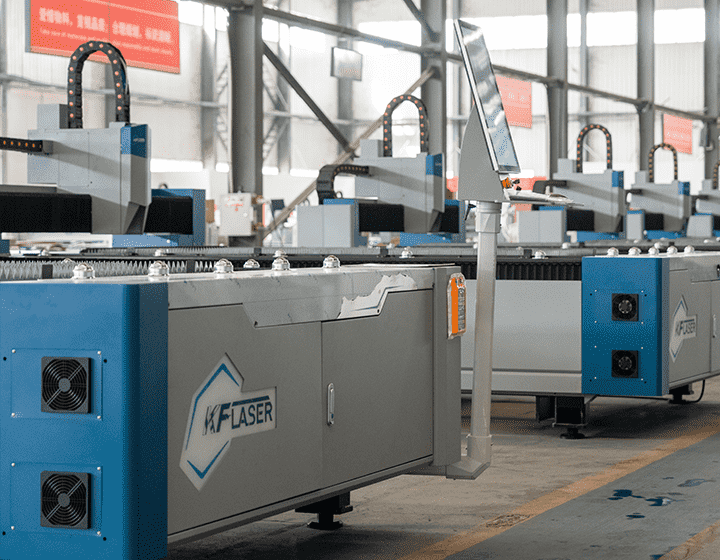

★In the fast-evolving world of industrial fabrication, laser cutting machines for metal are playing an essential role in transforming the way materials are processed. These machines offer a combination of precision, velocidad, and efficiency that traditional methods simply can’t match. Whether it’s for manufacturing intricate automotive parts, cutting thick metal sheets for construction, or producing medical equipment, the versatility and accuracy of laser cutting technology are driving innovation across industries.

As industries demand increasingly complex designs, tiempos de producción más rápidos, and higher-quality cuts, laser cutting machines are stepping up to meet these challenges. Let’s explore how these machines work, their benefits, aplicaciones, and the technology behind them.

Ⅰ.What Are Máquinas de corte láser para metal?

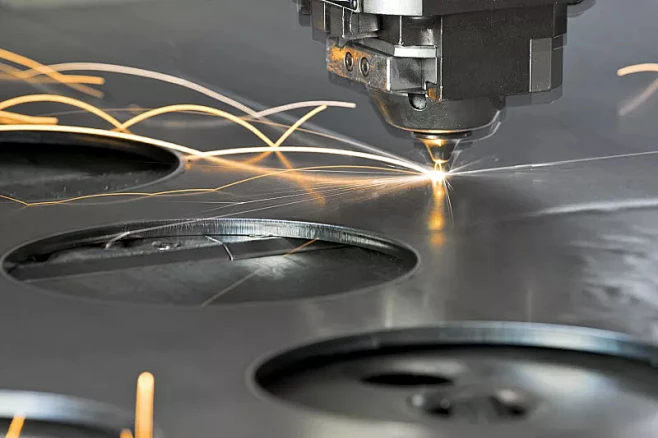

Laser cutting machines for metal are industrial-grade machines that use a high-powered laser beam to cut through metal materials. The process works by focusing the laser beam onto a small point of the material, where intense heat melts, quemaduras, or vaporizes the metal to form precise cuts. The machine is guided by computer numerical control (CNC), allowing it to execute highly accurate, complex cutting patterns with minimal human intervention.

Unlike mechanical cutting methods, which rely on physical contact, laser cutting involves no direct contact between the tool and the material.

This unique feature reduces wear on the machine and avoids the distortion or damage typically caused by friction or heat from traditional tools.

Ⅱ.Why Use Laser Cutting Machines for Metal?

▼Exceptional Precision and Accuracy

One of the primary advantages of laser cutting machines for metal is their ability to make incredibly fine, precise cuts. This level of accuracy is especially crucial when working with metal, where even the smallest error can lead to significant quality issues or component failure. Laser cutting machines can handle complex shapes and tight tolerances, making them indispensable in industries like aerospace, automotor, y electrónica.

▼Increased Efficiency and Speed

In industries where time equals money, laser cutting machines significantly speed up the production process. These machines can operate at much faster speeds compared to traditional cutting methods, while still maintaining high levels of accuracy. This increased efficiency means that more parts can be produced in a shorter amount of time, contributing to reduced production costs and faster turnaround times.

▼Minimal Material Waste

Laser cutting is one of the most material-efficient cutting methods available. Because the laser beam can make precise cuts with little kerf (the width of the cut), less material is wasted. This is particularly beneficial when working with expensive metals, as it reduces scrap and lowers material costs. Además, because the cutting process generates minimal heat, there is less distortion and no need for additional processing steps like welding or grinding.

▼Cleaner Cuts and Better Quality

Laser cutting machines for metal are known for producing smooth, clean edges that often require little to no post-processing. This is especially important when working with metals like stainless steel, aluminio, y titanio, where burrs and rough edges can affect both the appearance and functionality of the final product. The reduced need for additional finishing steps also speeds up production time and reduces labor costs.

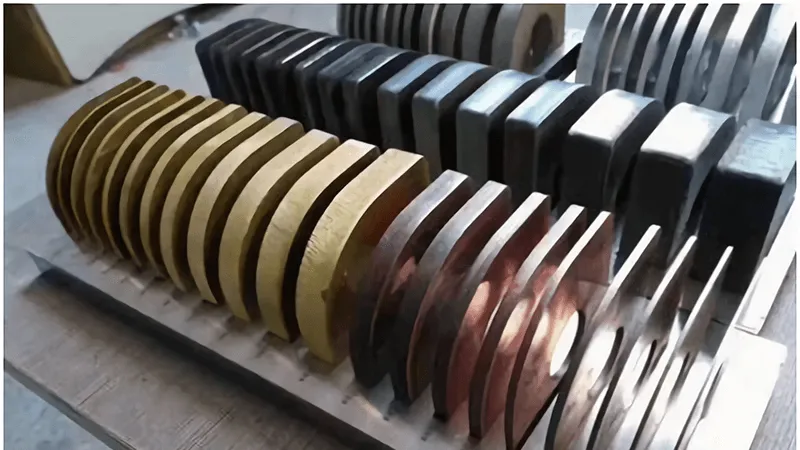

▼Versatility in Material Thickness and Types

Laser cutting machines for metal can handle a wide range of metal types, desde láminas finas hasta placas más gruesas. This versatility makes them suitable for a broad spectrum of applications, whether you’re working with delicate, thin aluminum for electronics or thick steel for heavy-duty machinery. Además, modern lasers can handle materials such as stainless steel, acero carbono, cobre, latón, y titanio, providing unparalleled flexibility for manufacturers.

Ⅲ.Applications of Laser Cutting Machines for Metal

The versatility and precision of laser cutting machines for metal make them invaluable across many industries. Here are some of the most common applications:

●Automotive Industry

En la industria automotriz, laser cutting is used to manufacture a wide range of parts, from body panels to engine components. The ability to produce complex shapes with high precision is crucial for meeting safety standards and ensuring optimal performance. Laser cutting machines also help reduce production times, enabling faster turnarounds for high-demand automotive manufacturing.

●Aerospace and Defense

Aerospace manufacturers rely on laser cutting machines for metal to produce high-precision parts, including turbine blades, wing structures, and frames. The aerospace industry demands extremely tight tolerances and the ability to handle complex geometries, making laser cutting an ideal solution for these high-performance applications.

●Fabricación de dispositivos médicos

The medical device industry uses laser cutting to create surgical instruments, implantes, and diagnostic equipment that require strict adherence to quality standards. Laser cutting offers the precision needed for the small, complex parts that are common in medical devices, ensuring that the components meet regulatory requirements for safety and performance.

●Construction and Heavy Machinery

Laser cutting machines for metal are used to create parts for construction equipment, heavy machinery, y componentes estructurales. These parts often require the ability to handle tough materials, such as steel and titanium, and laser cutting offers the necessary precision and power to cut through these materials effectively.

●Fabricación de productos electrónicos

In electronics manufacturing, laser cutting is used to produce delicate parts such as heat sinks, conectores, and enclosures. The ability to handle thin materials with high precision ensures that the components fit together correctly and perform optimally.

Ⅳ.The Future of Laser Cutting Machines for Metal

The future of laser cutting machines for metal is bright, with ongoing advancements in technology pushing the boundaries of what’s possible. One of the most exciting developments is the continued improvement in fiber laser technology. Fiber lasers offer greater energy efficiency, velocidades de corte más rápidas, and the ability to cut thicker materials with greater precision.

As automation continues to advance, the integration of artificial intelligence (AI) and machine learning will further enhance the capabilities of laser cutting machines. These technologies will allow the machines to optimize cutting paths, predict maintenance needs, and adapt to changes in the manufacturing process, ensuring maximum efficiency and uptime.

Conclusión

The role of laser cutting machines for metal in modern manufacturing is undeniable. By offering unmatched precision, velocidad, and material efficiency, these machines are changing the way metal fabrication is done, helping companies meet the increasing demands of today’s industries. Whether you’re cutting delicate parts for electronics or heavy-duty components for construction equipment, laser cutting machines provide the ideal solution for accurate, high-quality production.

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora