Noticias

Máquinas de cortador de tubería láser de fibra: Precisión definitiva para la fabricación de metales industriales

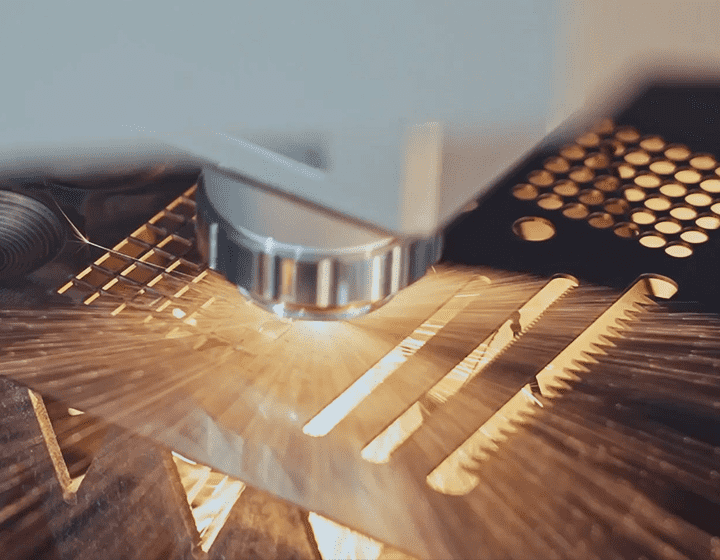

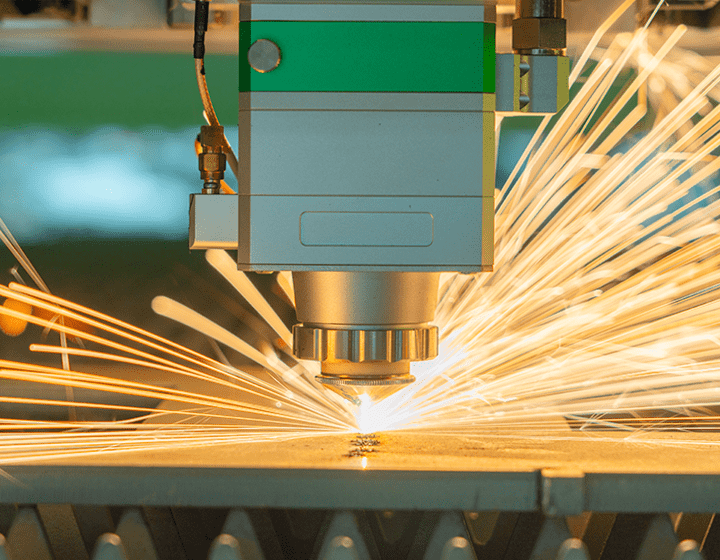

The fiber laser pipe cutter machine stands as a tectonic shift in industrial manufacturing – a fusion of light-speed accuracy and unyielding durability that vaporizes the limitations of conventional metalworking. Where plasma torches struggle with distortion and waterjets drown in operational costs, this photon-powered marvel delivers surgical precision on hardened steel, reflective copper, and aerospace alloys alike. Imagine slicing through a 6-inch carbon steel pipe like warm butter, leaving a mirror-finish edge thinner than a human hair, all while consuming less energy than a commercial oven. That’s the silent revolution reshaping factories worldwide.

1. Core Technology: Photons Over Mechanics

Unlike mechanical blades or thermal torches, fiber laser pipe cutter machines channel amplified light through flexible optical fibers. The laser beam’s wavelength (typically 1070nm) is absorbed by metals with exceptional efficiency, causing instantaneous localized vaporization. Key innovations include:

Adaptive Beam Control: Dynamic focal adjustments maintain intensity across varying pipe diameters (8mm to 600mm), eliminating taper on angled cuts.

Collision Avoidance Systems: 3D sensors map pipe curvatures in real-time, preventing head crashes during complex contouring.

Pulse Modulation Technology: Burst modes pulverize oxidation layers on aluminum, while continuous waves slice stainless steel at 15 meters/minute.

Operational Impact: A shipbuilding plant in Rotterdam reduced bevel-cutting time for hydraulic pipelines by 70% using programmable laser angles, negating secondary milling operations.

2. Economic Transformation: Beyond Cutting Costs

► Material Efficiency Revolution

Laser kerfs (cut widths) as narrow as 0.15mm maximize raw material utilization. Nesting software arranges components like 3D puzzles, achieving 95%+ material yield versus 65–75% with plasma. For titanium pipe networks in chemical plants, this saves $18,000/ton in scrap reduction alone.

► Energy & Maintenance Arithmetic

- Power Consumption: 8kW laser vs. 45kW plasma cutter for equivalent output

- Consumables: Zero gas/sharpening costs vs. $12/hour for waterjet abrasives

- Lifetime: 100,000+ laser hours vs. 3,000-hour plasma electrode lifespan

Estudio de caso: An automotive exhaust manufacturer slashed per-unit production costs by 33% within 8 months of adoption.

3. Cross-Industry Dominance: Sector-Specific Breakthroughs

Industria | Application | Precision Gain |

Aeroespacial | Titanium fuel lines | ±0.05mm tolerance on thin-wall tubes |

MedTech | Implantable device scaffolds | Micro-perforations <50μm diameter |

Energy | Offshore rig piping nests | 45° bevel cuts at 10mm/sec |

Emerging Frontier: Nuclear decommissioning teams now deploy portable fiber laser cutters for remote slicing of contaminated pipes, minimizing human exposure.

4. Technical Evolution: Next-Gen Capabilities

► Hybrid Additive Manufacturing

Leading systems integrate laser deposition heads, enabling cut-and-clad workflows. A damaged valve flange can be trimmed and rebuilt with corrosion-resistant alloys in a single setup – reducing repair timelines from weeks to hours.

► AI-Driven Process Optimization

Machine vision algorithms now detect material defects mid-cut, dynamically adjusting speed/power to avoid waste. Siemens’ test units achieved 99.2% first-pass yield on galvanized steel pipes with variable zinc coatings.

5. Implementation Mastery: Avoiding Critical Pitfalls

Success requires more than hardware purchase:

- Gas Selection Intelligence: Nitrogen delivers oxide-free cuts on stainless steel but raises operational costs 30%. Compressed air systems now achieve comparable quality at 1/10th the expense.

- Vibration Damping Protocols: Floor-mounted models require seismic isolation for micron-level accuracy. Inadequate foundations caused resonant distortion in 43% of failed installations.

- Operator Skill Mapping: Cross-training mechanical engineers in CNC programming reduces setup errors by 68% versus traditional machine operators.

Strategic Outlook

The fiber laser pipe cutter machine market will pivot toward modular mobile units for field service (2026–2028), followed by green wavelength lasers (515nm) for ultra-reflective copper in EV battery plants. Forward-thinking fabricators are already:

- Retrofitting legacy equipment with fiber laser heads

- Building digital twins for predictive maintenance

- Stocking thinner-walled pipes to leverage laser speed advantages

Those dismissing this technology as “just another cutter” risk obsolescence. As Boeing’s lead engineer noted in Manufacturing Today: “We’ve entered an era where cutting isn’t a process – it’s a strategic asset.”

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora