Noticias

Fabricante de la máquina de corte de tubo láser de fibra: Su guía para seleccionar lo mejor

In today’s fast-paced manufacturing world, the need for precision and efficiency is paramount. Fiber laser tube cutting machine manufacturers play a crucial role in providing businesses with the cutting-edge technology necessary for achieving perfect cuts and enhancing production speed. These machines have gained widespread popularity in industries such as automotive, aeroespacial, y construcción, where high-quality, precision cuts are required.

But how do you select the right manufacturer for fiber laser tube cutting machines? Con tantas opciones disponibles, it’s essential to understand the key features that separate top-tier manufacturers from the rest. Whether you’re an experienced industry player or new to the world of laser cutting technology, this guide will help you navigate the choices to find the best fiber laser tube cutting machine manufacturer for your needs.

What Is a Fiber Laser Tube Cutting Machine?

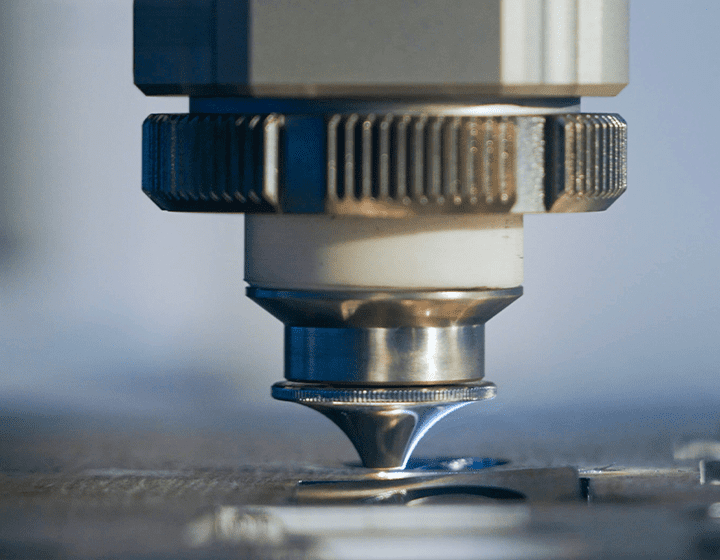

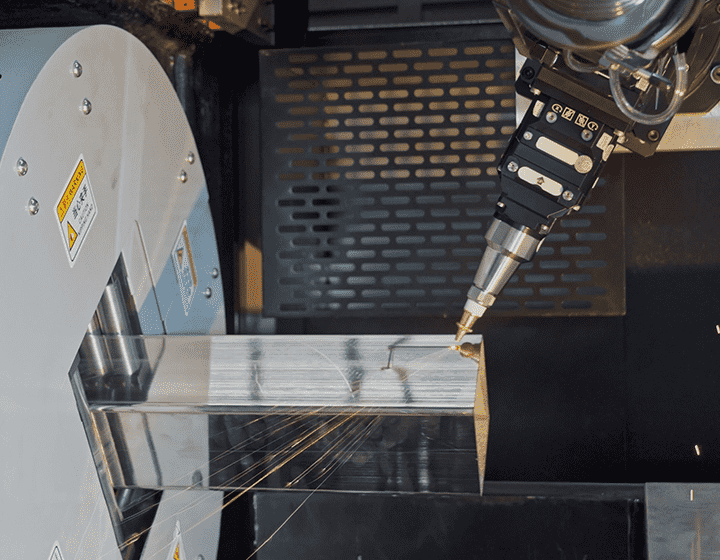

A fiber laser tube cutting machine is a state-of-the-art device used in the fabrication of metal tubes. It uses a focused fiber laser beam to cut through metal with extreme precision. A diferencia de los métodos de corte tradicionales, fiber lasers are able to provide higher speeds, cleaner cuts, and better material utilization, making them a preferred choice in many industrial applications.

Fiber laser technology has revolutionized tube cutting, allowing for clean, fast cuts on materials such as stainless steel, aluminio, and mild steel. These machines are used in a wide variety of industries, from furniture production to aerospace and automotive parts manufacturing. The key advantages of fiber laser tube cutting machines include:

High precision and accuracy

Increased speed and efficiency

Reduced material waste

Ability to cut complex designs with ease

Why Choosing the Right Manufacturer Matters

When it comes to fiber laser tube cutting machines, the manufacturer you choose plays a critical role in the quality and performance of the equipment. A reputable manufacturer will ensure that the machine operates optimally, delivers the desired results, and offers long-term reliability. Here are some reasons why selecting the right manufacturer is essential:

1. Machine Quality and Durability

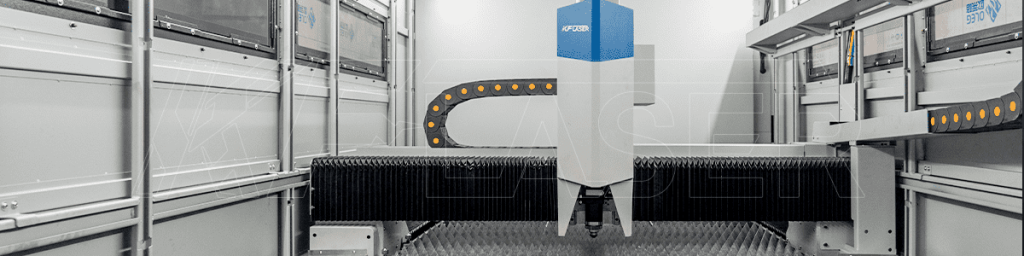

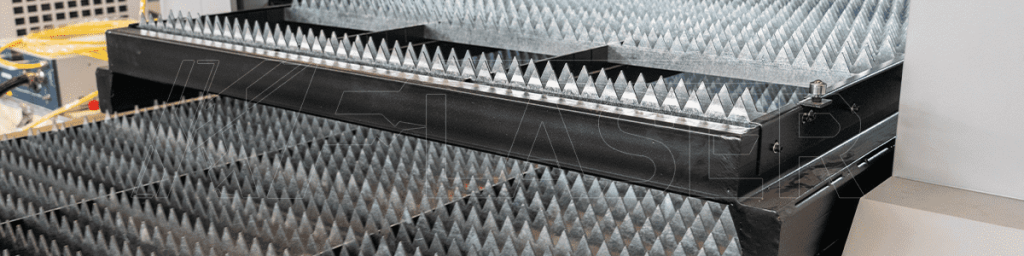

The reliability and longevity of your fiber laser tube cutting machine will directly affect your bottom line. High-quality machines are built with durable components and undergo rigorous testing to ensure they can handle heavy workloads and provide consistent performance. An experienced manufacturer will offer machines that meet high standards for durability and longevity.

2. Technological Innovation

The best manufacturers are committed to staying ahead of the curve by integrating the latest technological advancements into their products. From advanced control systems to automation features, technology is a driving factor in the performance of fiber laser tube cutting machines. When you choose a top-tier manufacturer, you’re ensuring that your machine comes equipped with the latest technology to boost efficiency and reduce production costs.

3. Customization and Flexibility

Every business has unique needs, and a reliable manufacturer will offer solutions that can be tailored to your specific production requirements. Whether you need a machine with higher wattage for thicker materials or one that can handle specific tube sizes, a manufacturer that provides customizable options will help you achieve the best results.

4. Support and After-Sales Service

Fiber laser tube cutting machines are complex and require regular maintenance to keep running at peak efficiency. A good manufacturer will not only provide the machine but also offer robust after-sales support. This includes providing training for operators, offering troubleshooting assistance, and delivering timely maintenance services to ensure your machine stays operational with minimal downtime.

Factors to Consider When Choosing a Fiber Laser Tube Cutting Machine Manufacturer

When evaluating potential manufacturers for your fiber laser tube cutting machine, there are several key factors to keep in mind. These elements will ensure you make an informed decision that supports your production goals:

1. Experience and Reputation

The experience of a manufacturer is often a clear indicator of their ability to deliver high-quality products. A well-established manufacturer with years of experience in the field is likely to have the expertise needed to design and build fiber laser tube cutting machines that meet industrial standards.

Además, checking the manufacturer’s reputation through reviews, testimonials, and case studies can provide valuable insights into their customer service, machine quality, and overall performance.

2. Machine Specifications and Features

Different manufacturers offer machines with varying capabilities. Depending on your specific needs, you may require a machine with high wattage for thick material cutting or one that supports high-speed operation. Antes de tomar una decisión, carefully review the specifications and features of the machines offered by the manufacturer to ensure they align with your requirements.

3. Price and Value for Money

While price is an important consideration, it should not be the sole deciding factor. A cheaper machine may not always deliver the best value in the long run. Consider factors such as durability, velocidad, mantenimiento, and overall efficiency when evaluating the price of a fiber laser tube cutting machine.

Top manufacturers will offer machines that strike a balance between competitive pricing and high-quality performance, providing you with the best value for your investment.

4. Warranty and Support

A reliable manufacturer will offer a solid warranty that guarantees machine performance and protects you from any defects or malfunctions. Además, they should provide excellent customer support, including technical assistance and quick response times in case of any issues.

How Fiber Laser Tube Cutting Machines Boost Efficiency and Productivity

One of the most significant benefits of fiber laser tube cutting machines is their ability to boost efficiency in production. These machines enable manufacturers to cut tubes and pipes with high precision and speed, drastically reducing cycle times compared to traditional methods. Moreover, the automation capabilities of these machines allow for continuous operation with minimal human intervention, resulting in increased productivity.

Además, the clean, precise cuts produced by fiber lasers reduce the need for post-cutting operations like deburring or grinding, further streamlining the production process and reducing material waste. These factors contribute to lower operational costs and enhanced profit margins for businesses.

Conclusión

Choosing the right fiber laser tube cutting machine manufacturer is a crucial decision for businesses looking to improve their manufacturing processes. By evaluating the manufacturer’s reputation, the specifications of their machines, and the support they provide, you can ensure that you make an informed choice that aligns with your production goals. Investing in high-quality machines from a reputable manufacturer will pay off in the form of increased precision, eficiencia, and cost savings over time.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora