Noticias

Láser industrial CNC: Revolucionando la precisión y la eficiencia

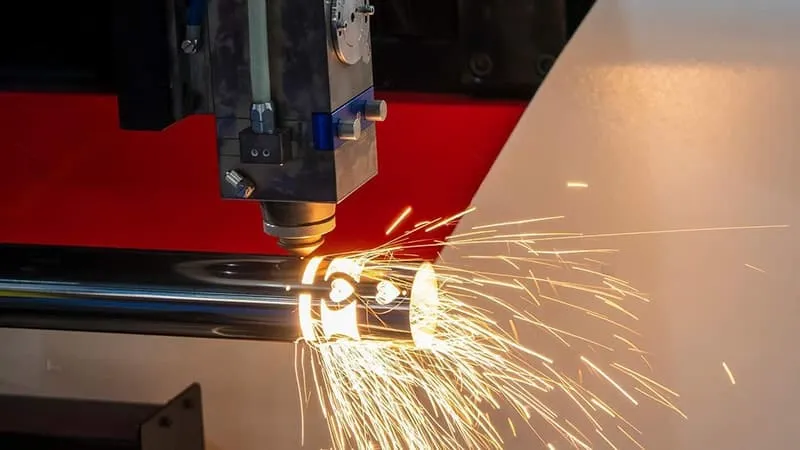

El industrial CNC laser has become a pivotal tool in modern manufacturing and fabrication industries. Renowned for its accuracy and speed, this advanced technology has revolutionized how businesses approach cutting and engraving tasks. As industries strive for higher precision and reduced costs, the demand for CNC laser machines is skyrocketing. Whether you’re cutting thin sheet metals or engraving intricate designs, understanding the true potential of these machines can help you make informed decisions about integrating them into your operations.

What is an Industrial CNC Laser?

An industrial CNC laser machine is a sophisticated piece of equipment used in various industries, desde la automoción hasta la aeroespacial, to cut and engrave materials with unparalleled precision. CNC, or Computer Numerical Control, refers to the use of computers to control the movement of the laser. By directing a high-powered laser beam onto a workpiece, these machines can achieve exceptionally detailed cuts, shapes, and designs.

The precision of CNC lasers enables manufacturers to produce intricate parts and components that would be impossible to achieve with traditional cutting methods. Además, CNC lasers can operate continuously, reducing the need for human intervention and improving productivity.

Key Benefits of Industrial CNC Lasers

1. Precisión inigualable

One of the main reasons why industries invest in CNC laser technology is its ability to offer extreme precision. The laser beam’s controlled movement ensures that every cut is sharp and accurate, even for complex designs. This level of accuracy is crucial in industries such as aerospace and electronics, where even the slightest deviation can lead to significant issues.

2. Velocidad y eficiencia

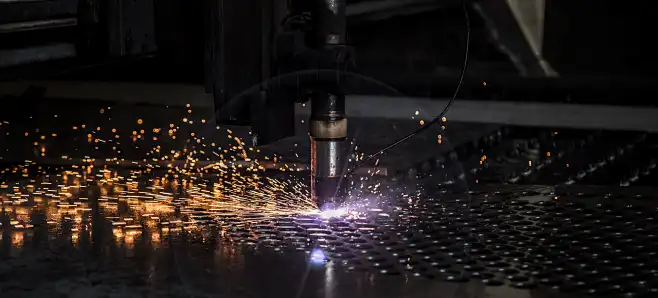

CNC lasers are designed for fast production, making them ideal for high-volume manufacturing. Unlike traditional cutting methods that involve physical tools, the laser’s light beam moves at incredible speeds, slicing through materials with ease. This increased speed leads to higher output rates and a quicker turnaround time, boosting overall production efficiency.

3. Reduced Material Waste

Laser cutting is known for its ability to minimize material waste. The precision of the beam allows for tight cuts with minimal kerf (the width of the cut), which reduces the amount of scrap produced during the process. This efficiency translates into cost savings for manufacturers, making it an attractive choice for businesses seeking to reduce their environmental footprint and material expenses.

4. Versatility of Materials

Industrial CNC lasers are not limited to just one material. They can cut a wide variety of materials, incluyendo metales, plástica, and even wood. This versatility allows businesses in different sectors to use CNC lasers for a variety of projects. Por ejemplo, in the automotive industry, CNC lasers can be used to cut steel and aluminum, while in the signage industry, they can engrave acrylic and wood.

5. Lower Labor Costs

With CNC technology, the need for manual labor is drastically reduced. These machines can operate autonomously with minimal human oversight, cutting down on labor costs. Moreover, the automation of the cutting process allows employees to focus on more complex tasks, further optimizing the overall workflow.

Factors Influencing the Cost of Industrial CNC Lasers

While industrial CNC lasers offer significant advantages, it’s essential to consider the cost factors before making a purchase decision. Below are some of the primary elements that influence the price of these machines:

1. Laser Power and Wattage

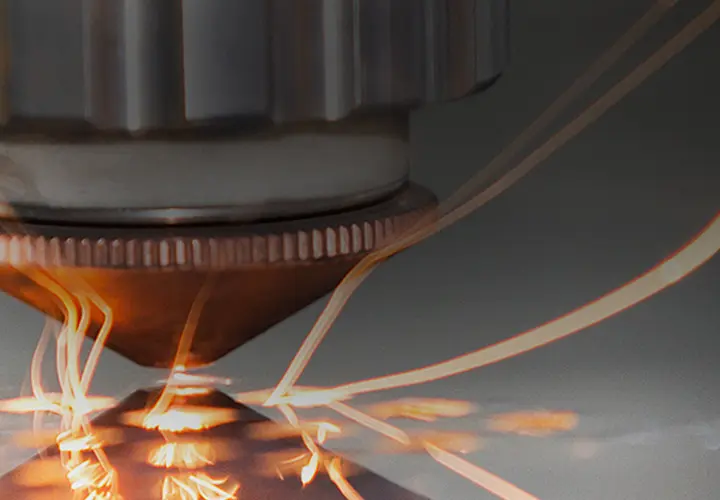

The power of the laser is one of the main determinants of the cost of the machine. Higher wattage lasers are capable of cutting through thicker materials and performing more complex tasks, but they come at a premium price.

Lower-Power Lasers: These machines are designed for precision cutting of thinner materials, and they tend to be more affordable. They are suitable for industries dealing with thin metals or plastic components.

Láseres de alta potencia: These are ideal for cutting thicker materials, such as stainless steel or titanium. Naturally, these machines cost significantly more, but they provide the capability to handle large-scale and demanding projects.

2. Size and Bed Capacity

The size of the cutting bed and the machine itself is another factor that impacts the overall cost. Machines with larger bed capacities can handle larger materials, but they tend to be more expensive. Businesses that deal with large sheets of material or need to process multiple items simultaneously should invest in larger machines to maximize productivity.

3. Características de automatización

Some industrial CNC lasers come with automated features such as automatic material loading and unloading systems, robotic arms, and integrated software for design and operation. These additional features enhance the efficiency of the machine but also increase the upfront cost. For companies looking to streamline operations, investing in fully automated systems can yield long-term savings by reducing manual labor.

4. Marca y fabricante

The brand and manufacturer of the CNC laser machine can significantly influence the price. Well-established brands with a reputation for quality and reliability may cost more initially but offer better long-term durability, support, and performance. On the other hand, lesser-known brands may offer lower prices but could come with trade-offs in terms of after-sales support or reliability.

5. Maintenance and Running Costs

Beyond the initial purchase price, it’s crucial to consider the ongoing maintenance and running costs. High-powered industrial CNC lasers can consume a significant amount of electricity, which adds to operational expenses. Además, regular maintenance is necessary to keep the machine running efficiently, which includes replacing parts like the laser tube, optics, y otros componentes.

Choosing the Right Industrial CNC Laser for Your Business

When selecting an industrial CNC laser, businesses must evaluate their specific needs. Factors such as the material types you cut, the thickness of materials, production volume, and available budget will guide your decision. Además, the level of automation and the power of the laser should be tailored to your workflow requirements.

It’s also essential to factor in the machine’s future scalability. A medida que su negocio crece, you may need a machine that can handle increased production and larger material sizes. Choosing a machine with scalable features ensures that your investment continues to serve your needs in the long term.

Conclusión

El industrial CNC laser is a powerful and versatile tool that can dramatically improve precision, eficiencia, and productivity in manufacturing processes. By understanding the various factors that contribute to the cost of these machines, businesses can make more informed decisions about their investment in this advanced technology. Whether you’re looking to cut metal, plástico, or other materials, industrial CNC lasers offer a solution that enhances both quality and profitability in production.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora