Noticias

Tubo de aluminio con láser: Técnicas y beneficios explicados

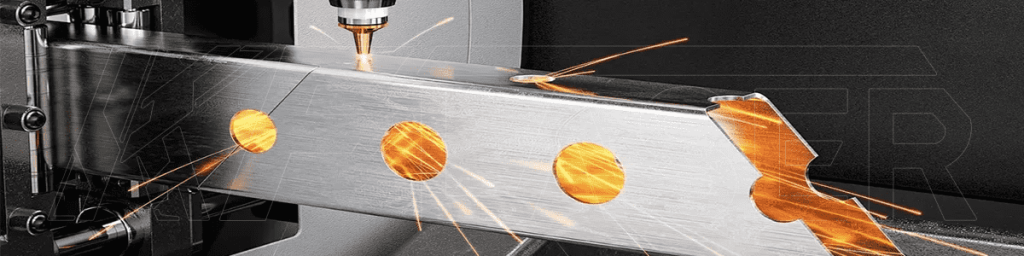

El corte de tubos de aluminio por láser es una técnica avanzada que ha revolucionado la forma en que los fabricantes abordan el corte de precisión.. Ya sea para automoción, aeroespacial, o aplicaciones estructurales, La eficiencia y precisión que proporciona la tecnología láser la convierten en la solución ideal para cortar tubos de aluminio.. Este método utiliza rayos láser de alta potencia enfocados sobre la superficie de aluminio., fundir el material a lo largo de un camino predeterminado para crear diseños intrincados y bordes limpios. A diferencia de los métodos de corte tradicionales, El corte por láser ofrece notables ventajas., incluyendo una reducción del desperdicio de material y tiempos de producción más rápidos.

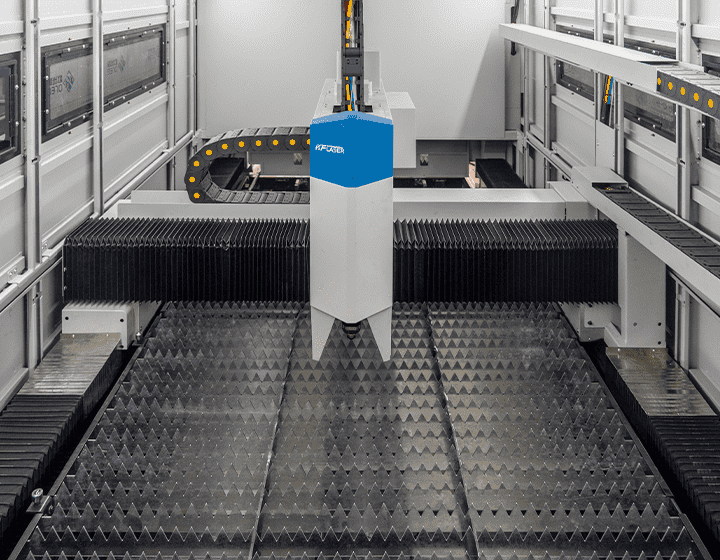

Comprender la tecnología de corte por láser

El corte por láser es un método de procesamiento de materiales de alta precisión que implica el uso de un rayo láser enfocado para cortar o grabar varios materiales., incluyendo metales como el aluminio. Esta técnica permite una precisión extrema., y cuando se aplica al corte de tubos de aluminio., Permite la creación de formas complejas con tolerancias estrictas.. Los sistemas de corte por láser suelen utilizar láseres de CO2 o de fibra., dependiendo del espesor del material y de la velocidad de corte deseada.

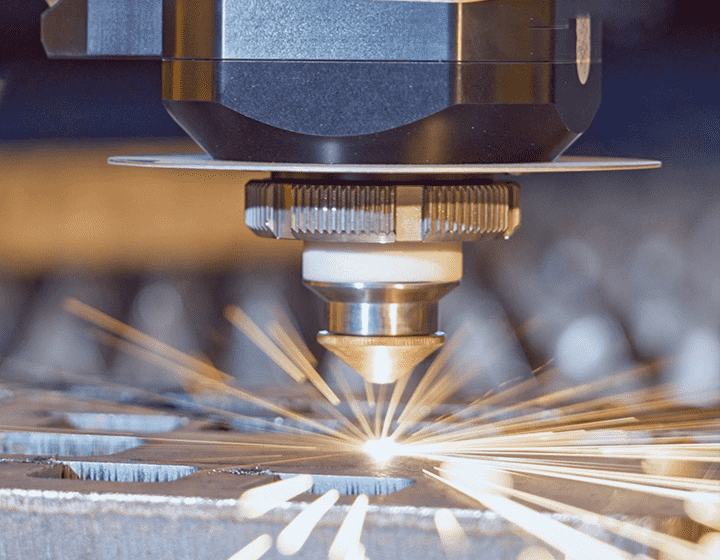

Cómo funciona el corte por láser

En su núcleo, El corte por láser funciona concentrando un rayo láser de alta intensidad en la superficie del material.. El calor del láser hace que el tubo de aluminio se derrita y se vaporice., creando un corte limpio. El láser se puede ajustar para diferentes espesores de material., asegurando que los cortes sean suaves y precisos. Además, El proceso de corte por láser está controlado por un sistema CNC., que permite la creación de formas y diseños complejos sin necesidad de mano de obra.

Beneficios del corte por láser de tubos de aluminio

El corte por láser de tubos de aluminio ofrece varias ventajas clave sobre los métodos de corte tradicionales.. Estos incluyen:

Precisión y exactitud:

El corte por láser proporciona una precisión inigualable, permitiendo a los fabricantes cortar formas complejas con tolerancias estrictas. Este nivel de precisión es esencial para industrias donde el detalle importa, como en los sectores aeroespacial y automotriz.

Desperdicio mínimo de material:

A diferencia de los métodos tradicionales que pueden involucrar sierras u otras herramientas que dejan desechos residuales., El corte por láser minimiza el desperdicio de material gracias a su estrecha anchura de corte.. Esto da como resultado menores costos de material y una mejor eficiencia de producción..

Velocidad y eficiencia:

El corte por láser es un proceso rápido y eficiente. Con un tiempo de preparación mínimo y velocidades de corte más rápidas, los fabricantes pueden completar los trabajos más rápido, lo que lleva a una mayor productividad y a una reducción de los plazos de entrega..

Versatilidad:

Este método se puede utilizar para cortar una variedad de formas y perfiles., haciéndolo ideal para una amplia gama de aplicaciones. Si el diseño es simple o complejo, El corte por láser se adapta a los proyectos más desafiantes..

Necesidad reducida de posprocesamiento:

El corte por láser a menudo deja una superficie suave, Borde limpio que requiere un posprocesamiento mínimo., reduciendo el tiempo y el coste invertido en el acabado.

Aplicaciones del tubo de aluminio cortado por láser

El corte por láser se utiliza en diversas industrias., ofreciendo soluciones para diferentes aplicaciones:

Industria aeroespacial:

El sector aeroespacial a menudo requiere componentes ligeros pero duraderos fabricados en aluminio.. El corte por láser permite la creación de piezas complejas que cumplen con estrictos requisitos de peso y rendimiento..

Industria automotriz:

En la fabricación de automóviles, La precisión es clave. El corte por láser de tubos de aluminio permite la producción de piezas personalizadas para vehículos, desde sistemas de escape hasta estructuras de carrocería, todo con alta precisión y mínimo desperdicio de material.

Arquitectura y Construcción:

El aluminio se utiliza habitualmente en elementos estructurales., y el corte por láser permite la fabricación precisa de elementos arquitectónicos como barandillas, marcos, y paneles.

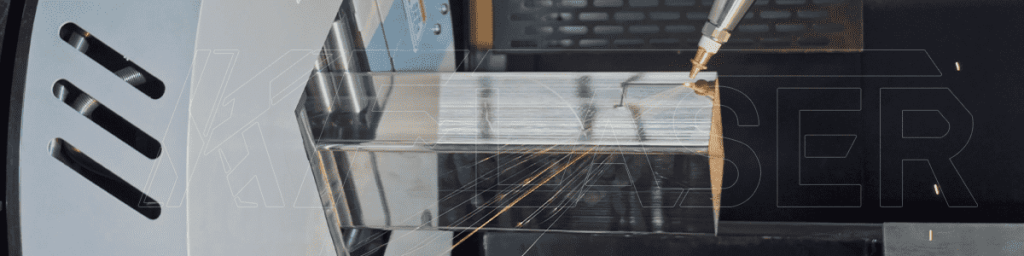

Electrónica y dispositivos médicos:

El corte por láser también se emplea en la creación de carcasas y componentes para dispositivos electrónicos y médicos., asegurando alta precisión y confiabilidad.

Elegir el servicio de corte por láser adecuado para tubos de aluminio

Al seleccionar un servicio de corte por láser para corte de tubos de aluminio, es crucial considerar los siguientes factores:

Tipo de láser y tecnología:

Diferentes tipos de láseres (CO2 frente a. láser de fibra) Ofrecen diferentes beneficios dependiendo del espesor del material y la complejidad del diseño.. Elija un proveedor de servicios que utilice tecnología avanzada adecuada para el corte de tubos de aluminio..

Velocidad y precisión de corte:

Evaluar la velocidad de corte y precisión del proveedor de servicios.. Para fabricación de gran volumen, La velocidad y la precisión son claves para garantizar una entrega oportuna y resultados de alta calidad..

Servicios de poscorte:

Algunos proveedores de servicios ofrecen servicios de poscorte, como desbarbado., refinamiento, o revestimiento. Dependiendo de sus necesidades, Puede ser beneficioso elegir un proveedor que ofrezca servicios integrales..

Experiencia con corte de tubos de aluminio.:

Asegúrese de que el proveedor de servicios tenga experiencia específicamente en el corte de tubos de aluminio.. Las propiedades del material del aluminio requieren conocimientos especializados para obtener resultados óptimos..

Conclusión: El futuro del corte por láser de tubos de aluminio

A medida que la tecnología de corte por láser continúa evolucionando, Ofrece un potencial aún mayor de eficiencia y precisión en el corte de tubos de aluminio.. Con innovaciones como la automatización láser y fuentes láser mejoradas., el proceso es cada vez más rápido, más eficiente energéticamente, y rentable. Las industrias que dependen de tubos de aluminio pueden seguir beneficiándose de la precisión, desperdicio mínimo, y velocidad que ofrece el corte por láser. Ya sea para producción en masa o proyectos personalizados, Este método de corte avanzado seguirá siendo un elemento básico en diversas industrias en los años venideros..

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora