Noticias

Láser cortando aluminio con oxígeno: Aumento de la precisión y la eficiencia

Laser cutting aluminum with oxygen is a groundbreaking technology that continues to transform industries worldwide. The use of oxygen in the cutting process offers several advantages, from speed and efficiency to cost reduction and enhanced precision. Whether you’re in manufacturing, aeroespacial, or automotive industries, understanding the intricacies of laser cutting with oxygen can elevate your production quality while maintaining optimal performance.

What Makes Laser Cutting Aluminum with Oxygen Different?

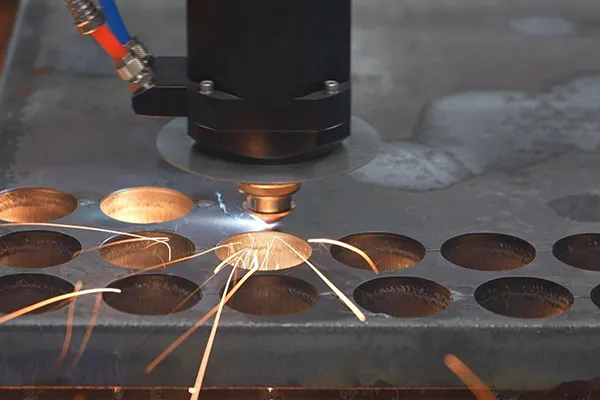

Laser cutting has long been recognized as a precise and effective method for cutting metals, including aluminum. But when oxygen is introduced into the mix, something unique happens. Oxygen accelerates the cutting process and increases the heat generated during the operation, allowing for faster cutting speeds. The high-temperature reaction between aluminum and oxygen helps create a smoother, cleaner cut, particularly on thin aluminum sheets.

In contrast to other methods, oxygen-assisted laser cutting can enhance cutting efficiency while reducing operational costs. This is especially important for industries that require high-volume production with minimal errors. Oxygen reduces the power consumption compared to using nitrogen, ultimately making the process more energy-efficient.

Why Oxygen Is a Game-Changer in Laser Cutting

- Enhanced Cutting Speed

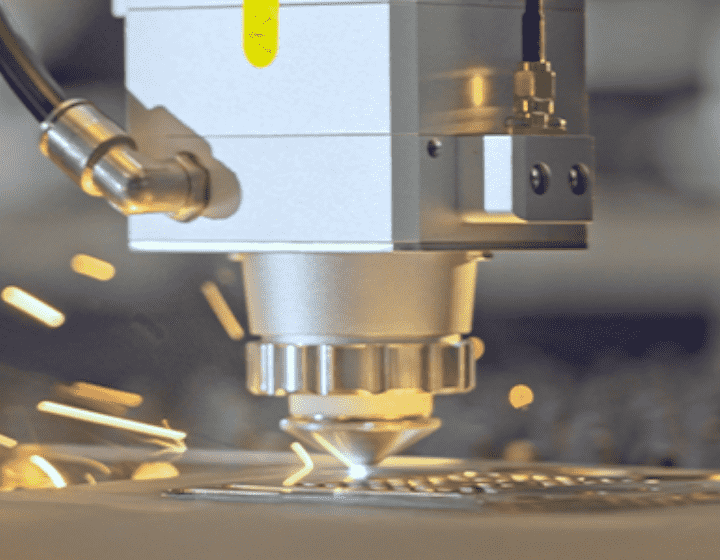

Oxygen acts as an assist gas during the laser cutting of aluminum, promoting an exothermic reaction that heats the metal further. This speeds up the cutting process significantly. Unlike nitrogen, which is typically used as a neutral assist gas, oxygen contributes additional energy, accelerating the entire operation. This means manufacturers can process more parts in less time, improving productivity and throughput. - Cost-Effective and Efficient

With oxygen, the cutting process becomes not only faster but also more cost-effective. Since oxygen is readily available and relatively inexpensive compared to other gases like nitrogen, manufacturers can achieve higher output at a lower cost. Oxygen also reduces the need for post-processing work, such as cleaning or deburring, which further cuts down on expenses. - Superior Cut Quality

One of the biggest advantages of using oxygen for laser cutting aluminum is the exceptional cut quality. While nitrogen provides clean, smooth cuts, oxygen-assisted cutting creates high-quality edges with a distinctive surface finish. The cut is typically brighter and more polished, reducing the amount of post-cutting work necessary and improving the overall aesthetic appeal of the parts. - Ideal for Thin and Thick Materials

Oxygen-assisted laser cutting works effectively for both thin and thick aluminum sheets. For thin materials, the rapid cutting speed enables faster and cleaner cuts. For thicker sheets, the exothermic reaction caused by the oxygen ensures a more efficient and powerful cut, even through denser materials. This versatility makes oxygen an ideal choice for a wide range of aluminum cutting applications.

Key Considerations When Using Oxygen for Laser Cutting

While oxygen offers numerous benefits, there are a few considerations to keep in mind when using it for laser cutting aluminum:

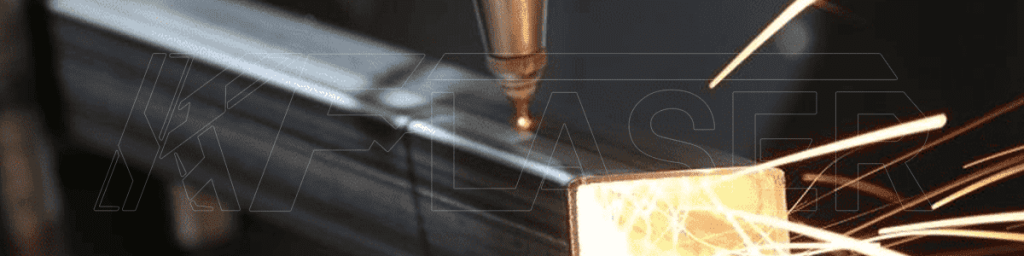

Espesor del material: Oxygen is best suited for cutting aluminum sheets of varying thicknesses. Sin embargo, for ultra-thin materials, nitrogen may still be preferred due to the lower heat input, which could reduce the risk of warping.

Surface Quality: While oxygen can improve cut quality, excessive oxygen levels can lead to oxidation at the cut edges, especially on higher-aluminum alloys. It’s essential to fine-tune the oxygen flow rate to maintain high-quality cuts without over-oxidizing the material.

Fume and Gas Management: Oxygen-assisted laser cutting generates more fumes than nitrogen-based cutting due to the exothermic reaction. Adequate ventilation and extraction systems should be in place to ensure worker safety and maintain optimal cutting performance.

Applications of Laser Cutting Aluminum with Oxygen

The versatility of laser cutting aluminum with oxygen makes it applicable in numerous industries, incluido:

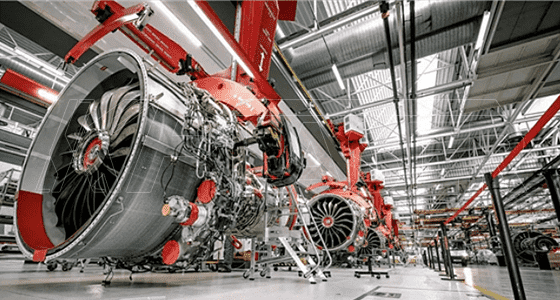

- Aeroespacial: The aerospace industry demands high-quality, lightweight components that require precision cutting. Laser cutting with oxygen ensures that aluminum parts are cut with minimal distortion, ensuring the safety and performance of aircraft parts.

- Automotor: En el sector del automóvil, laser cutting plays a crucial role in manufacturing body parts, marcos, y componentes del motor. Oxygen-assisted laser cutting helps create clean edges that fit precisely during assembly, contributing to overall vehicle safety and reliability.

- Electrónica y bienes de consumo: From smartphones to home appliances, laser cutting is used to manufacture complex components for electronic devices. The ability to cut aluminum with oxygen ensures that intricate designs are executed efficiently while maintaining a high level of detail.

- Sheet Metal Fabrication: In sheet metal fabrication, where large quantities of parts are produced, laser cutting with oxygen provides a cost-effective, fast solution for manufacturers looking to optimize production without sacrificing quality.

Pensamientos finales

Laser cutting aluminum with oxygen is an advanced technique that offers a wide range of benefits, from increased cutting speed and reduced costs to superior edge quality and greater material versatility. It is no wonder that many industries are turning to this method for their high-performance cutting needs. A medida que la tecnología continúa avanzando, oxygen-assisted laser cutting will likely play an even more integral role in shaping the future of manufacturing and precision metalwork.

By understanding the advantages and applications of laser cutting aluminum with oxygen, businesses can improve their operational efficiency, reducir costos, and ensure the highest quality outcomes in their production lines. This technology is not just a trend but a powerful tool that continues to evolve and benefit industries globally.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora