Noticias

Flat Sheet Laser Cutting: Revolutionizing Precision and Efficiency in Manufacturing

Introducción: Why Flat Sheet Laser Cutting is Changing the Game

In the world of precision manufacturing, one technology stands out for its remarkable accuracy and efficiency: flat sheet laser cutting. This advanced cutting method has transformed industries that rely on cutting sheet metal for their products, ofreciendo una precisión inigualable, velocidad, y versatilidad. Whether you’re creating intricate designs, custom components, or simple cuts, flat sheet laser cutting ensures a level of accuracy that traditional cutting methods simply can’t match.

But what exactly is flat sheet laser cutting, and why is it becoming a go-to solution for manufacturers worldwide? En esta guía completa, we will explore the technology, its benefits, and the industries that rely on it for their production needs.

1. What is Flat Sheet Laser Cutting?

◆ The Basics of Flat Sheet Laser Cutting

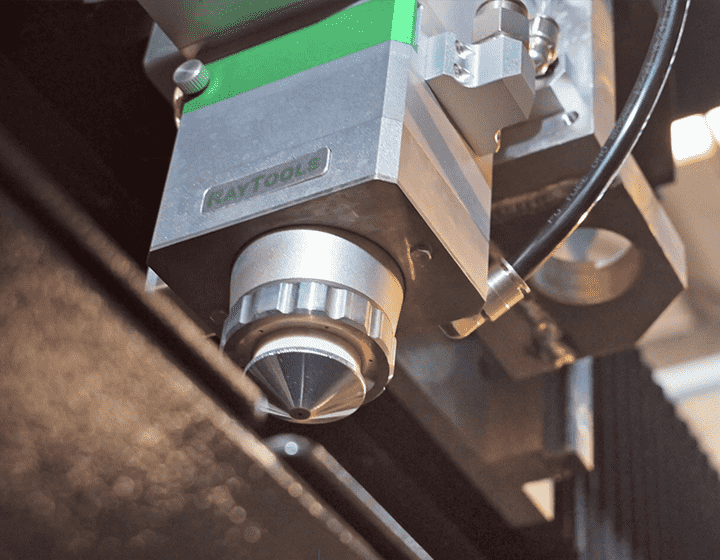

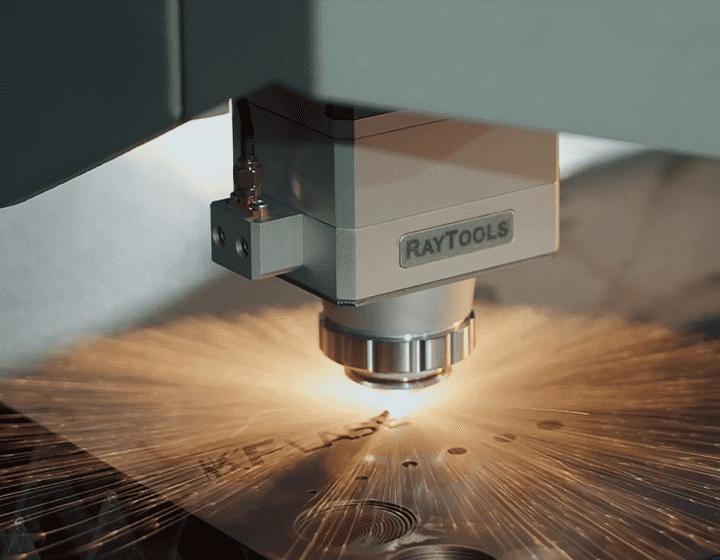

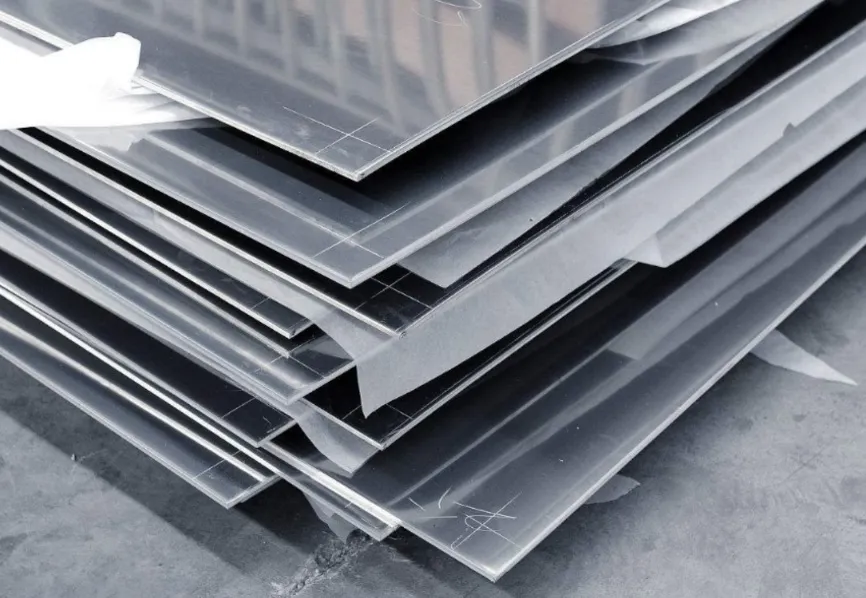

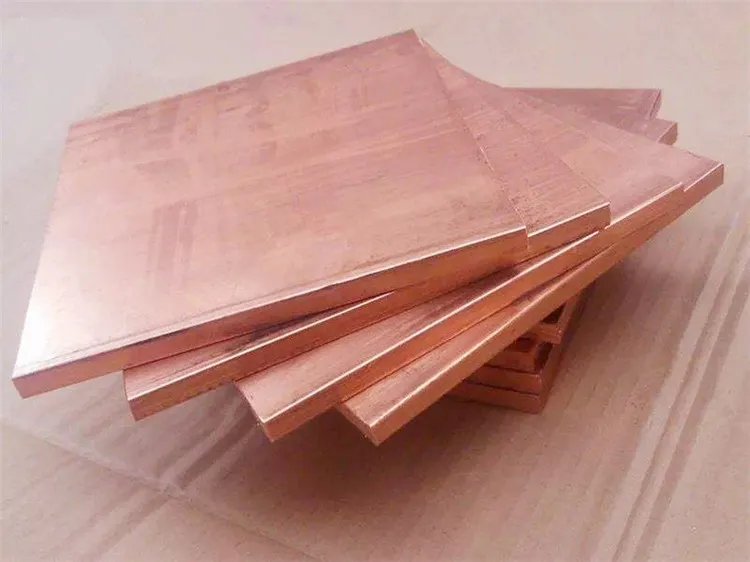

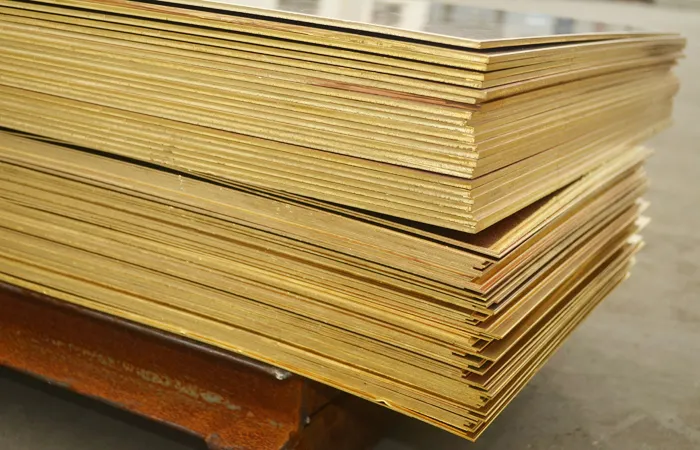

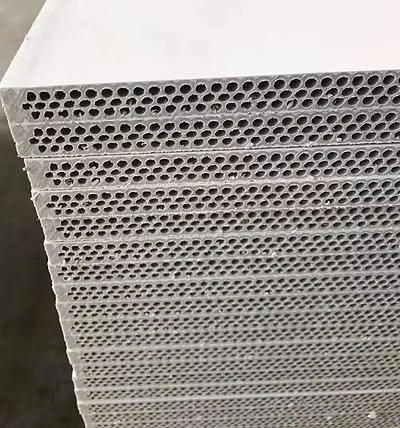

Flat sheet laser cutting is a high-precision cutting method that uses a focused laser beam to cut or engrave flat sheets of metal, plástico, madera, and other materials. El rayo láser, typically emitted from a fiber laser, is directed onto the material’s surface, where it melts, quemaduras, or vaporizes the material at the point of contact. El resultado es un limpio, precise cut with minimal waste.

◆ How Does Flat Sheet Laser Cutting Work?

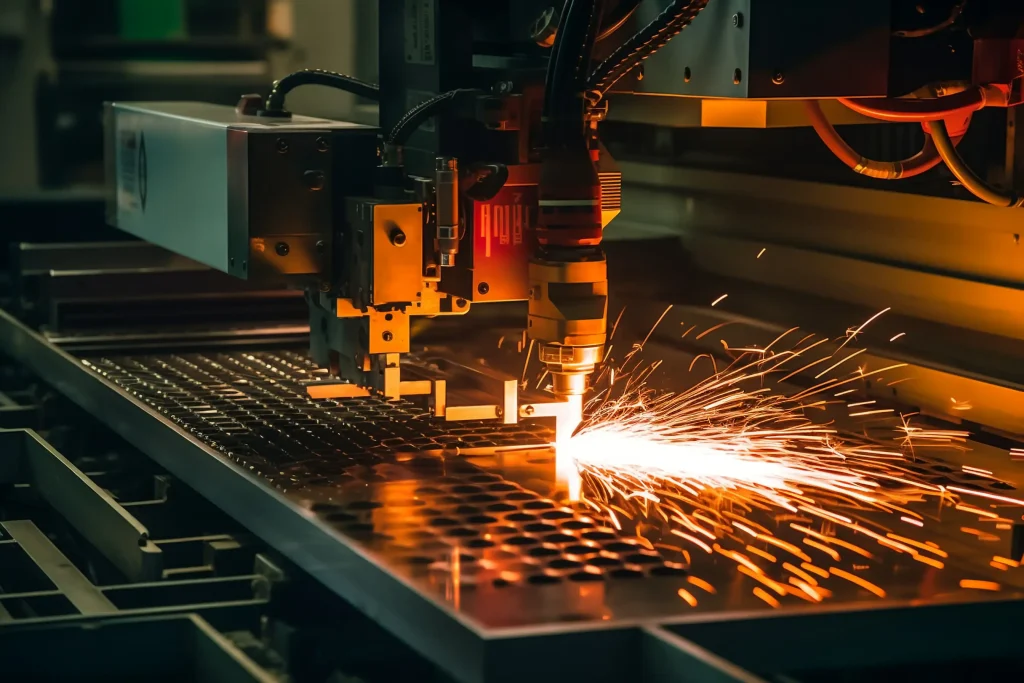

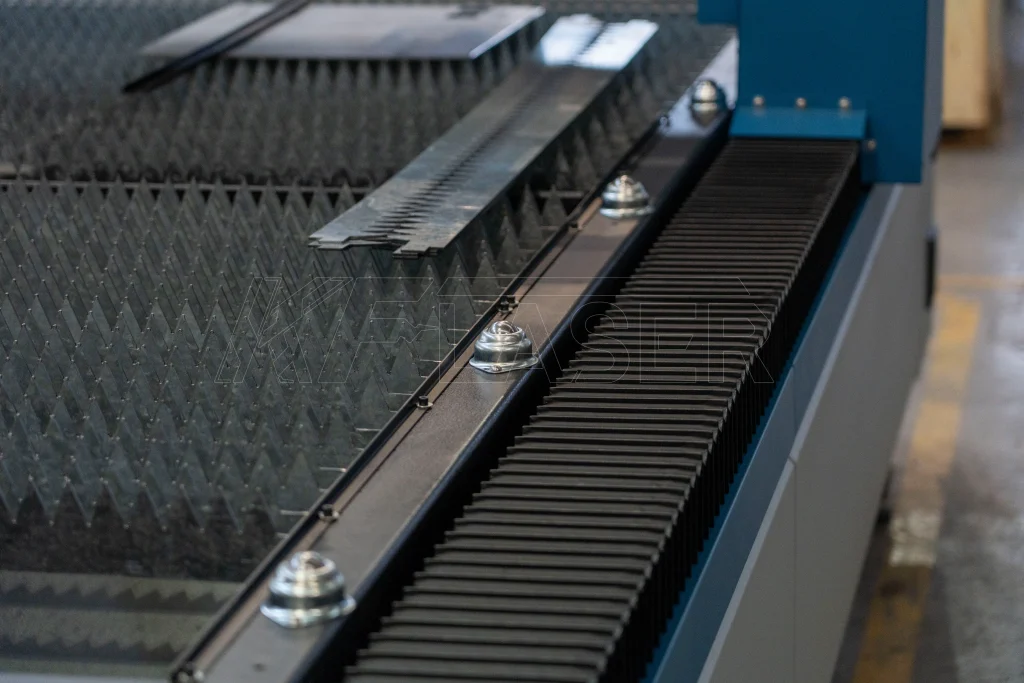

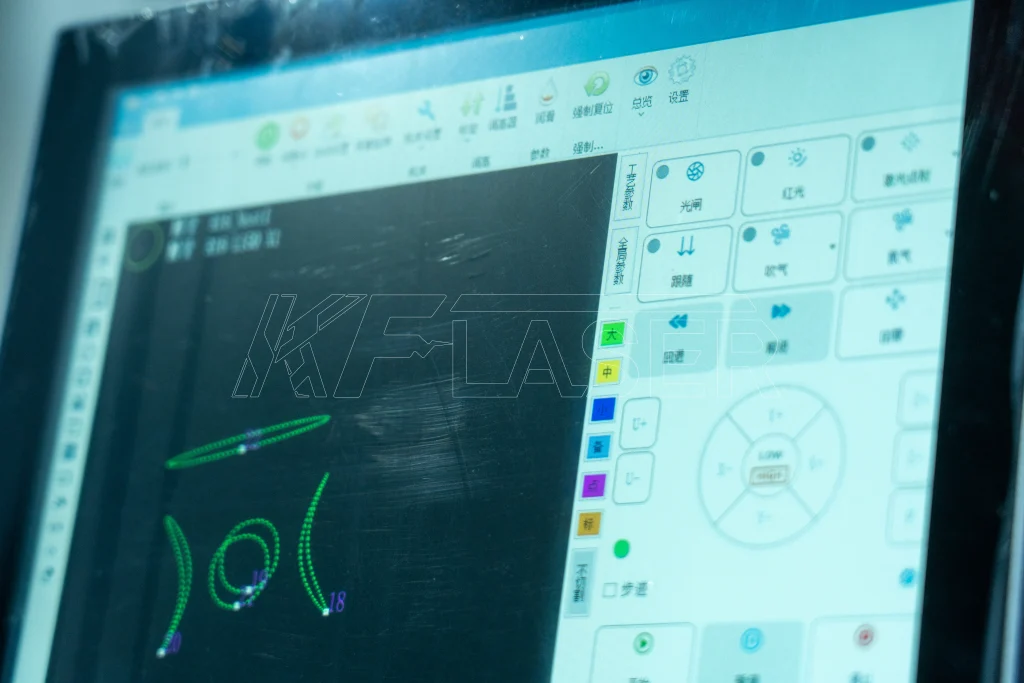

The process begins with a CNC-controlled laser cutting machine. The sheet material is loaded onto a cutting bed, and the laser beam is directed by mirrors and lenses to focus on the material. The machine’s software controls the movement of the laser beam, ensuring the exact cutting path. The laser’s heat melts or vaporizes the material, leaving a sharp edge that requires little to no post-processing.

The following video will give you a more intuitive understanding of the working principle of the flat sheet laser cutting.

2. Advantages of Flat Sheet Laser Cutting

◆ Unmatched Precision

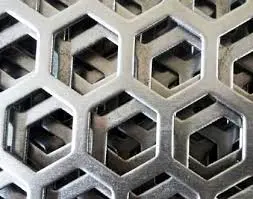

One of the primary reasons businesses choose flat sheet laser cutting is its extreme precision. The laser beam can cut to the exact specifications required, producing sharp, smooth edges with minimal deviation. This precision makes it ideal for intricate designs and complex geometries.

◆ Faster Turnaround Times

Flat sheet laser cutting machines are known for their velocidad. Since the laser beam moves quickly and accurately, it can cut multiple sheets in a fraction of the time it would take with traditional methods. This speed increases production efficiency, reducing turnaround times and helping businesses meet tight deadlines.

◆ Minimal Material Waste

The focused nature of the laser beam means that material waste is minimized. Unlike traditional methods that may involve mechanical cutting, which creates more offcuts, flat sheet laser cutting allows manufacturers to optimize the use of each sheet, leading to reduced costs.

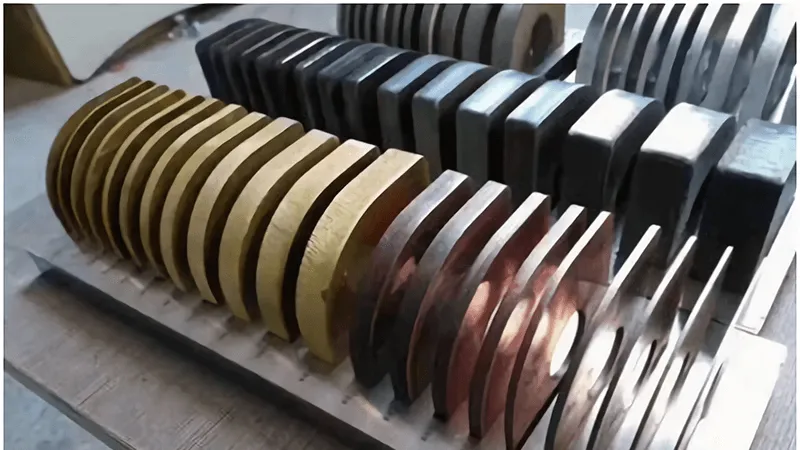

◆ Versatility in Material Cutting

Flat sheet laser cutting is highly versatile and can be used on a wide range of materials, incluido:

● Stainless steel

● Aluminum

● Mild steel

● Copper

● Brass

● Plastics

This versatility makes it suitable for industries ranging from automotive to aerospace and architecture.

◆ Cost-Effectiveness

Though the initial investment in a laser cutting machine may be high, the long-term savings are significant. El precisión y velocidad of the laser cutting process reduce labor costs and waste, making it a cost-effective choice in the long run.

3. Industries That Benefit from Flat Sheet Laser Cutting

◆ Automotive Industry

The automotive industry heavily relies on flat sheet laser cutting to manufacture components such as paneles de cuerpo, paréntesis, y exhaust parts. The precision and speed of the process are crucial in meeting the industry’s demanding production requirements.

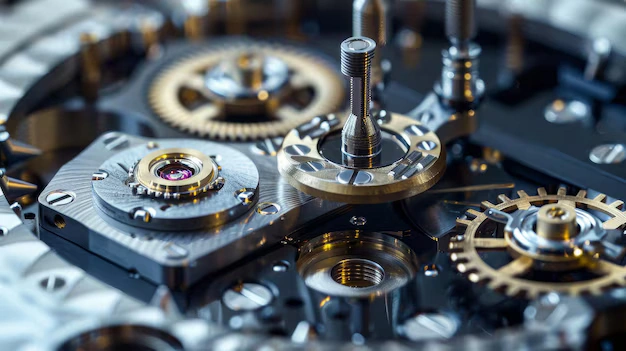

◆ Aerospace and Defense

In aerospace and defense, the need for high-precision parts is paramount. Flat sheet laser cutting allows manufacturers to produce complex components used in aircraft, spacecraft, and defense systems, with tight tolerances and minimal waste.

◆ Architecture and Construction

Flat sheet laser cutting is also widely used in the construction industry to create intricate architectural features, como facades, paneles decorativos, y structural components. The ability to cut precise shapes from metal sheets makes it ideal for architectural designs.

◆ Metal Fabrication

For metal fabricators, flat sheet laser cutting provides a way to create custom parts for various applications, including machinery, industrial equipment, and consumer products. The accuracy and flexibility of laser cutting make it a preferred method for fabricating metal

components.

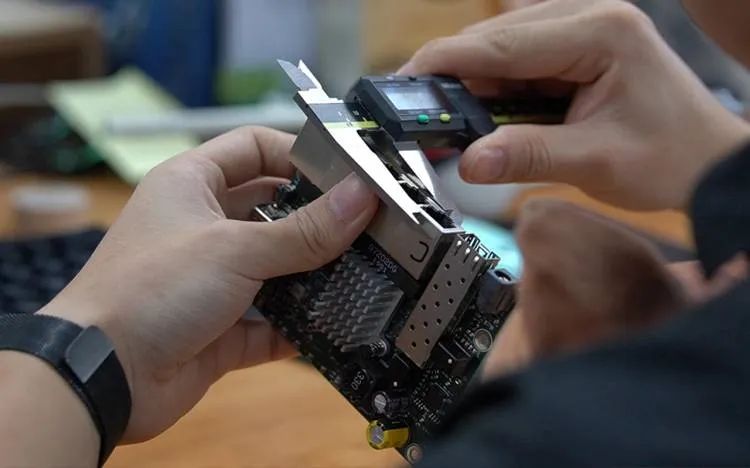

◆ Electronics and Electrical

In the electronics and electrical industries, flat sheet laser cutting is used to create metal housings, placas de circuito, y electrical enclosures, offering both precisión y velocidad for small to medium production runs.

4. How to Choose the Right Flat Sheet Laser Cutting Machine

◆ Laser Power and Capacity

El potencia láser of a machine determines how thick the material can be and how quickly the machine can cut. For most general-purpose cutting, machines with láser de fibra ranging from 500W a 4000W are sufficient. For thicker materials or more demanding applications, higher-power machines are required.

◆ Cutting Bed Size

El size of the cutting bed determines how large a sheet can be processed. Depending on the type of projects you handle, choose a machine that can accommodate the dimensions of your materials without limiting your cutting capabilities.

◆ Automation and Software

Many modern flat sheet laser cutting machines come with advanced software and automation options, como automatic loading and unloading y optimización de la ruta de corte. These features can enhance productivity, reduce errors, and improve the overall efficiency of your operation.

◆ Maintenance and Support

Look for machines that come with reliable support y maintenance services. Regular maintenance is crucial to ensure the longevity of your laser cutting machine and keep it running at optimal performance.

5. The Future of Flat Sheet Laser Cutting

A medida que avanza la tecnología, so does the capability of flat sheet laser cutting machines. The integration of AI, IoT, y smart technologies into laser cutting systems is making them even more efficient, preciso, and adaptable. In the coming years, we can expect even faster cutting speeds, better automation, and lower operating costs, making flat sheet laser cutting more accessible and beneficial for manufacturers of all sizes.

Investing in flat sheet laser cutting technology can dramatically improve the precisión, velocidad, y eficiencia of your production processes. Whether you’re in automotor, aeroespacial, o fabricación de metal, this cutting-edge method can help you achieve exceptional results while reducing waste and lowering costs. As this technology continues to evolve, its capabilities and applications will expand, providing even more opportunities for businesses to innovate and thrive.

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora