Noticias

La revolución del corte por láser de fibra: Liberando precisión y eficiencia

En el ámbito de la fabricación moderna, Un cambio sísmico está en marcha. Imagina la convergencia del arte y la tecnología, Donde la precisión se encuentra con la velocidad, y la eficiencia transforma las posibilidades. Esta revolución, encabezado por corte láser de fibra, está remodelando las industrias, desatar potencial incomparable para innovadores en todo el mundo.

1.The Genesis of Fiber Laser Cutting

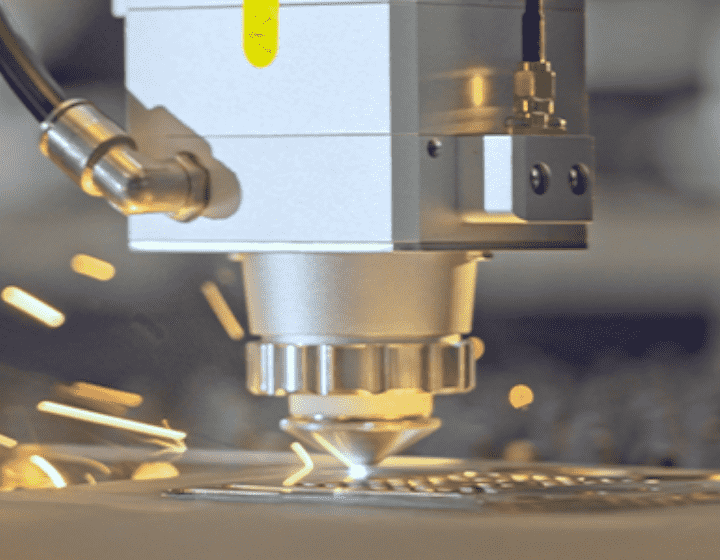

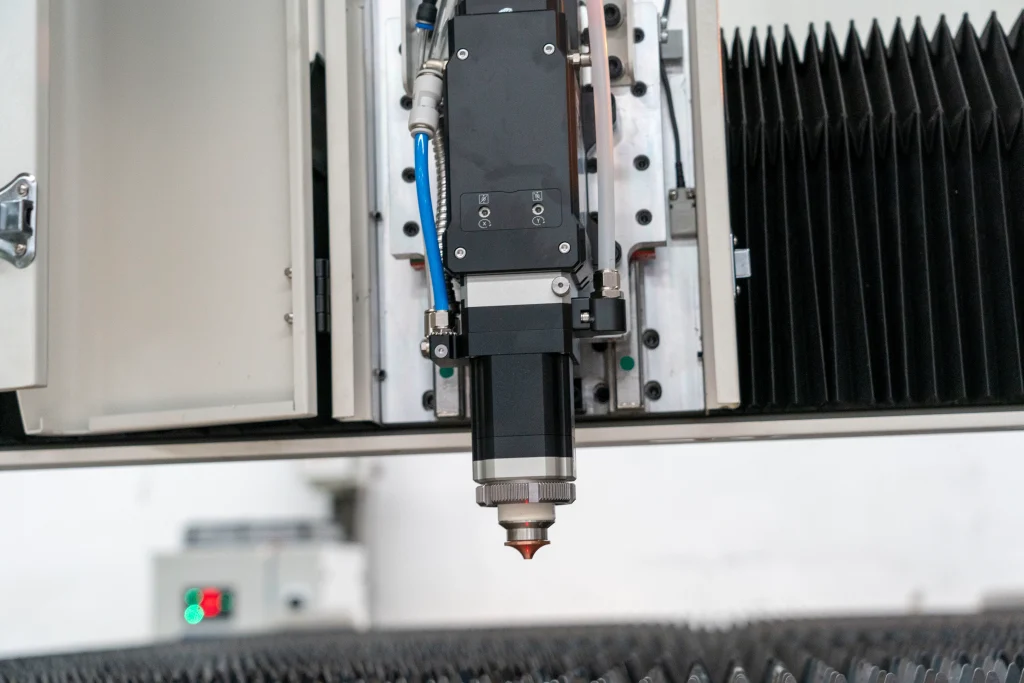

Fiber laser cutting isn’t just a step forward; it’s a leap into the future. Utilizing a high-powered laser beam, it cuts, engraves, and shapes materials with remarkable precision. Unlike conventional methods, fiber laser technology harnesses light through optical fibers, ensuring minimal energy loss and unmatched efficiency.

The innovation doesn’t stop at precision. It is a symphony of speed, rentabilidad, y versatilidad, suitable for industries ranging from aerospace to art design. The advent of KF LASER has further democratized access to these advanced tools, making cutting-edge solutions available to businesses large and small.

- The following video shows KF Laser 6kw cutting 10mm aluminum plate.

2.Why Fiber Laser Cutting Outshines Traditional Methods

- Unparalleled Precision

Fiber laser cutting achieves micron-level accuracy, far exceeding traditional mechanical tools. El rayo láser, controlled with pinpoint precision, can carve intricate designs and handle complex geometries effortlessly. This capability makes it the go-to solution for applications demanding exceptional accuracy, such as medical equipment and microelectronics.

- Enhanced Speed and Efficiency

Time is money, and fiber lasers deliver unmatched cutting speeds. By focusing a high-energy beam with extreme precision, these machines reduce production time without compromising quality. Whether cutting thick steel sheets or intricate patterns, the efficiency is unrivaled.

- Versatilidad del material

From metals like aluminum, acero inoxidable, and titanium to non-metallic materials like wood and plastic, fiber lasers excel across a wide spectrum. Their adaptability empowers industries to explore creative and functional designs without limitations.

- Reduced Maintenance Costs

Unlike CO2 lasers or mechanical cutters, fiber lasers require minimal maintenance. With fewer moving parts and longer operational lifespans, businesses save significantly on repair and downtime costs.

3.Core Applications of Fiber Laser Cutting

- Industrial Manufacturing

Fiber lasers are the backbone of precision manufacturing, enabling efficient production of automotive components, industrial machinery, and intricate aerospace parts.

- Custom Fabrication

Artisans and designers leverage fiber lasers to create custom furniture, intricate jewelry, and bespoke signage, elevating aesthetic value with precision.

- Medical Innovations

Medical devices demand flawless accuracy, and fiber lasers are essential for producing surgical tools, prótesis, and implant components with unparalleled precision.

- Green Energy

As the world shifts toward renewable energy, fiber lasers are pivotal in manufacturing solar panels, wind turbines, and other sustainable technologies.

4.How Fiber Lasers Drive Sustainability

In an era where sustainability is paramount, fiber lasers stand out as an eco-friendly alternative. They consume less energy than traditional cutting methods and produce minimal waste. Además, the precision of fiber lasers reduces material wastage, contributing to cost savings and environmental conservation.

5.The Cutting-Edge Technology Behind Fiber Lasers

Fiber lasers derive their power from optical fibers, amplifying light into an intense beam. This innovation ensures:

– Eficiencia energética: High power-to-light conversion reduces electricity consumption.

– Calidad del rayo: A narrow beam diameter enables precise cuts.

– Minimal Downtime: The robust construction leads to fewer breakdowns and higher reliability.

KF LASER exemplifies these advancements, delivering machines equipped with user-friendly interfaces and cutting-edge features to meet the diverse needs of global industries.

6.Debunking Myths About Fiber Laser Cutting

Mito 1: Fiber Lasers Are Costly

While the initial investment may seem high, fiber lasers prove cost-effective over time due to reduced maintenance, faster production cycles, and energy efficiency.

Mito 2: Limited to Specific Materials

Contrary to this belief, fiber lasers are highly versatile and capable of cutting various materials with precision.

Mito 3: Complex to Operate

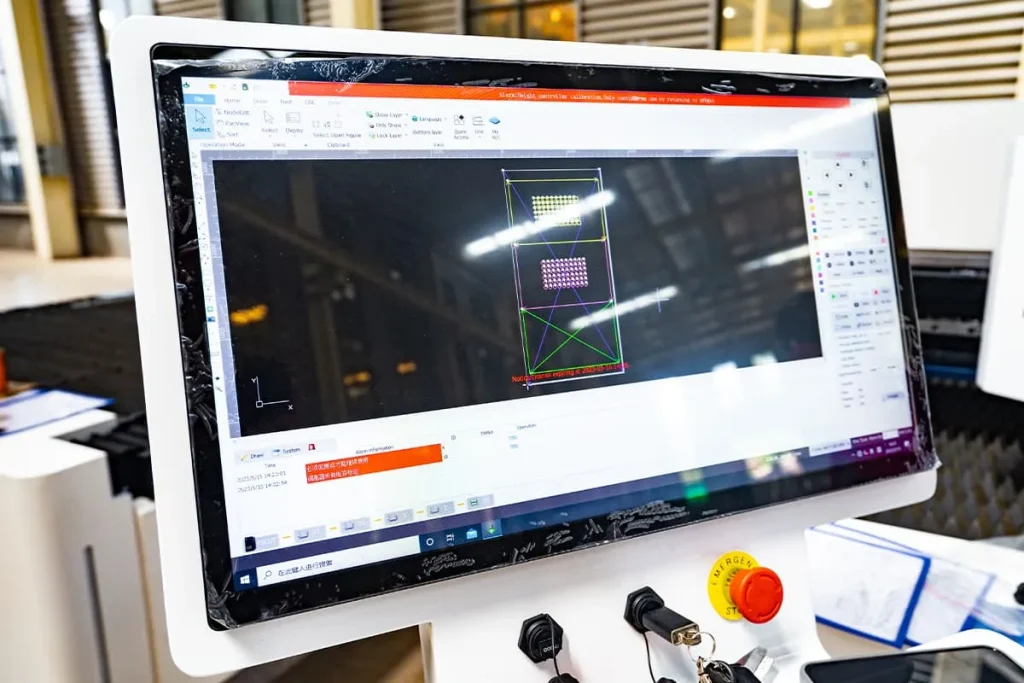

Modern fiber laser systems, such as those by KF LASER, feature intuitive software and user-friendly controls, making them accessible even to operators with minimal experience.

7.Future Trends in Fiber Laser Cutting

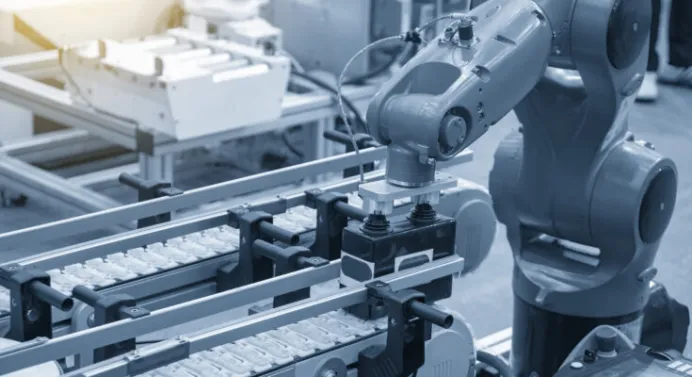

1. Integración de automatización

The integration of automation and AI will enhance the speed, exactitud, and adaptability of fiber laser systems, enabling smarter manufacturing processes.

2. Advanced Material Applications

With continued R&D, fiber lasers will handle an even broader range of materials, unlocking new opportunities for innovation.

3. Compact and Portable Systems

The evolution of portable fiber laser machines will empower smaller businesses and artisans, democratizing access to cutting-edge technology.

4. Customization Through Software

Advanced software will allow greater customization, enabling businesses to adapt machines to specific applications seamlessly.

8.How to Choose the Right Fiber Laser Cutting Machine

When selecting a fiber laser system, consider the following:

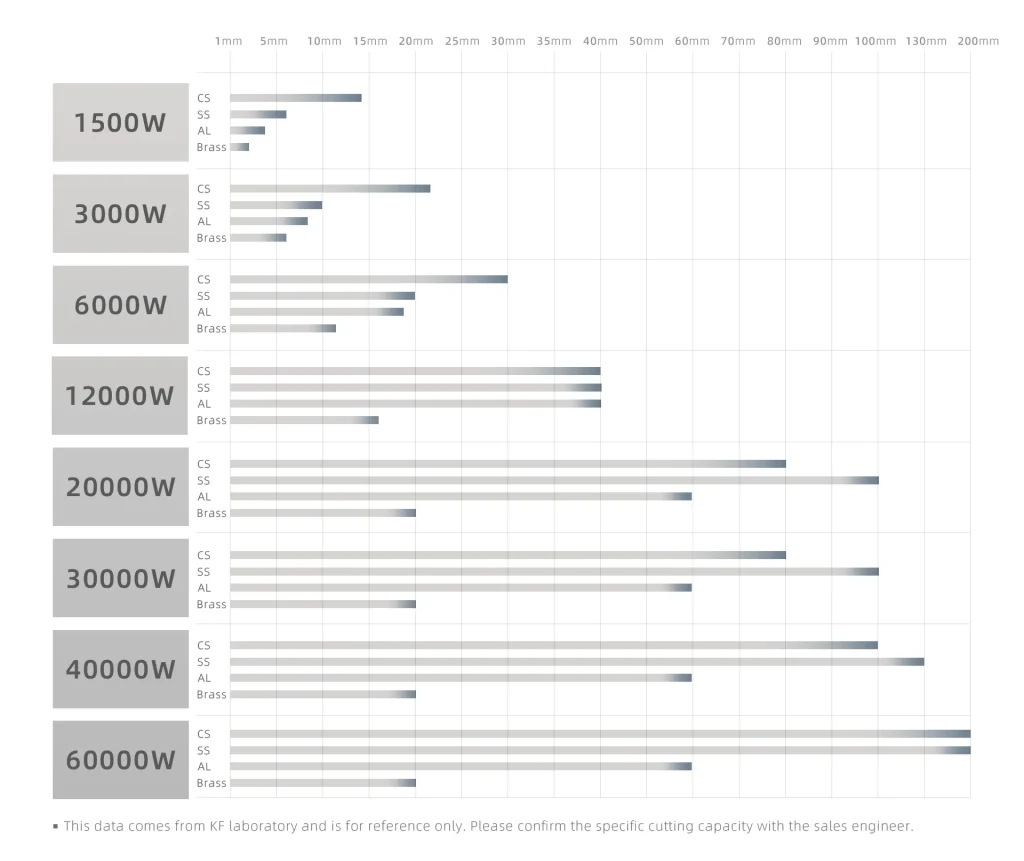

1. Requisitos de energía: Choose a machine with appropriate wattage for your material and application needs.

2. Velocidad de corte: Evaluate speed capabilities to ensure optimal productivity.

3. Compatibilidad de software: Opt for systems with robust software for design and control flexibility.

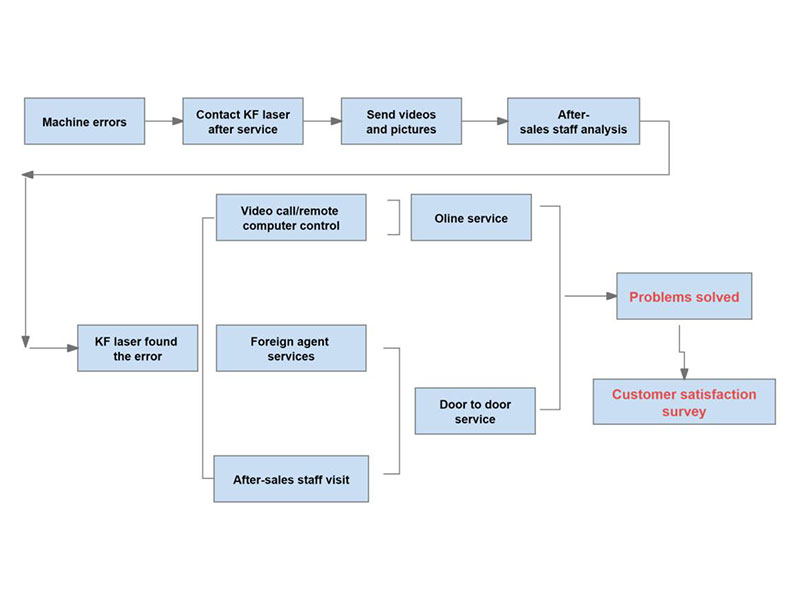

4. Customer Support: Partner with trusted providers like KF LASER for reliable service and support.

9.The Competitive Edge of LÁSER KF

As a leader in fiber laser innovation, KF LASER provides state-of-the-art solutions tailored to diverse industries. From robust machines to unparalleled customer support, KF LASER empowers businesses to achieve their goals with confidence.

Conclusión: The Fiber Laser Era Has Begun

Fiber laser cutting is more than a technology; it’s a gateway to the future. By combining precision, eficiencia, y sostenibilidad, it enables industries to redefine what’s possible. Whether you’re a manufacturer, designer, or innovator, embracing fiber laser technology will propel your operations to new heights.

Join the revolution with KF LASER, and unlock the full potential of fiber laser cutting. The future awaits, and it’s illuminated by the precision of light.

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora