Noticias

Dominar el aluminio cortado con láser: Precisión, Velocidad, y posibilidades infinitas

Imagine a world where cutting aluminum isn’t limited by jagged edges or slow processes. Instead, think of razor-sharp precision, diseños intrincados, and blazing speed. This isn’t just a fantasy—laser cut aluminum has turned it into a modern-day reality. From aerospace to art, this cutting-edge technology has unlocked new frontiers, enabling industries to redefine quality and creativity.

1.The Science Behind Laser Cut Aluminum

Aluminio, prized for its lightweight, corrosion resistance, and thermal conductivity, is a cornerstone material in modern industries. Cutting it, sin embargo, has traditionally posed challenges due to its reflectivity and heat-conductive nature. Enter laser technology: a transformative solution that tackles these challenges with finesse.

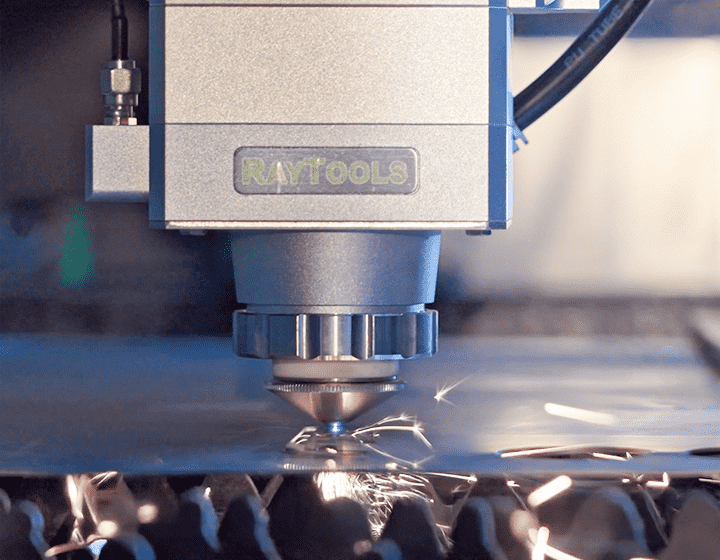

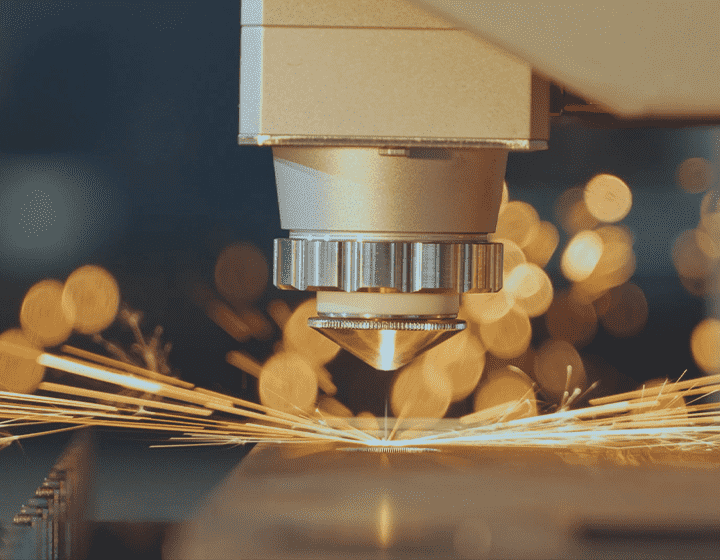

Laser cutting aluminum involves directing a concentrated laser beam onto the material’s surface. This high-energy light rapidly heats and vaporizes the metal, leaving a clean, precise cut. Unlike mechanical tools, which often cause deformation or rough edges, laser cutting delivers unparalleled smoothness and accuracy.

2.Why Choose Laser Cutting for Aluminum?

1. Flawless Precision

When working with aluminum, accuracy is critical. Laser cutting achieves micro-level precision, making it ideal for intricate designs or parts requiring tight tolerances. Whether crafting aerospace components or delicate decorative panels, the results are consistently flawless.

2. Unmatched Efficiency

Speed is a game-changer in today’s competitive manufacturing landscape. Laser cutting not only accelerates production but also minimizes downtime. Advanced systems, such as those provided by KF LASER, ensure seamless operation and optimized workflow.

3. Versatility in Thickness

From ultra-thin sheets to thick aluminum plates, laser cutting adapts to a range of material thicknesses. This flexibility expands its applicability across diverse industries, from automotive manufacturing to architectural design.

4. Eco-Friendly and Cost-Effective

Laser cutting minimizes waste by delivering precise cuts with minimal material loss. Además, its energy-efficient systems reduce operational costs, making it both economically and environmentally sustainable.

3.Applications of Laser Cut Aluminum

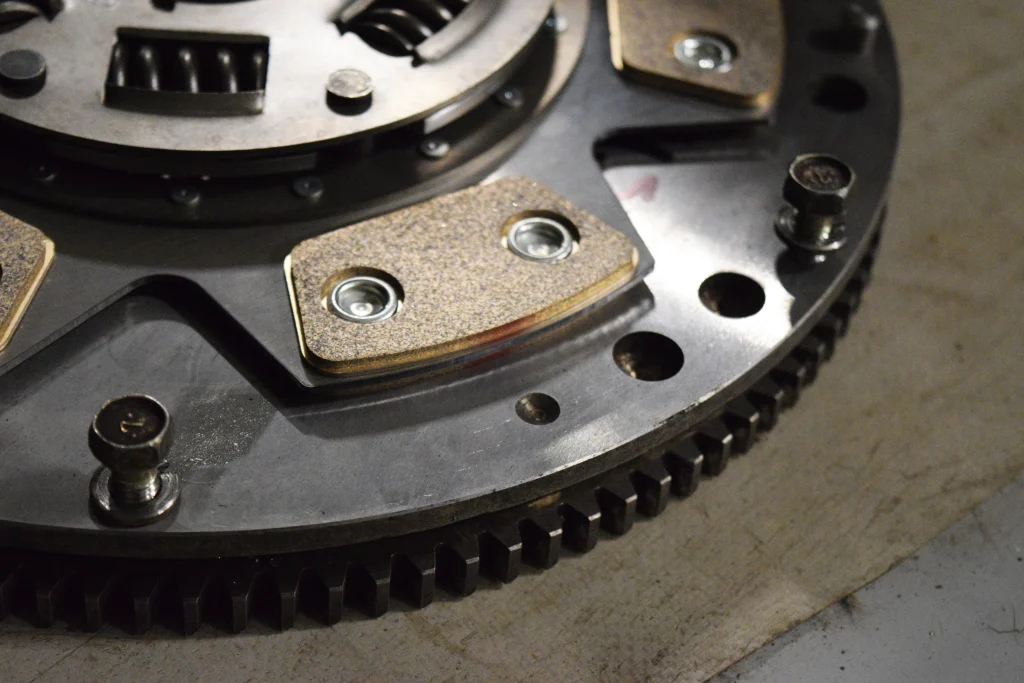

1. Aerospace and Automotive Industries

The lightweight properties of aluminum make it a go-to material for transportation industries. Laser cutting enables the production of aerodynamic structures, componentes del motor, and body panels with impeccable accuracy.

2. Architectural and Decorative Design

Architects and designers leverage laser-cut aluminum for everything from building facades to intricate interior decor. The technology facilitates creative freedom, allowing the transformation of aluminum sheets into stunning, functional art.

3. Electronics and Technology

In electronics, precision is paramount. Laser cutting allows the production of heat sinks, trampas, and circuit boards, ensuring that every component meets exacting standards.

4. Energía renovable

As the world embraces sustainable energy solutions, aluminum plays a crucial role in solar panels and wind turbine components. Laser cutting ensures these parts are produced with the precision needed for optimal performance.

4.How Laser Cutting Handles Aluminum’s Challenges

Aluminum’s reflectivity and thermal conductivity might seem like barriers to laser cutting, but advanced systems have overcome these obstacles:

– Anti-Reflective Coatings: Modern machines are equipped to handle reflective surfaces, ensuring consistent performance.

– Controlled Heat Input: By adjusting laser intensity and focus, systems prevent material warping and ensure clean edges.

LÁSER KF excels in providing cutting systems that seamlessly address these challenges, delivering reliable results for even the most demanding applications.

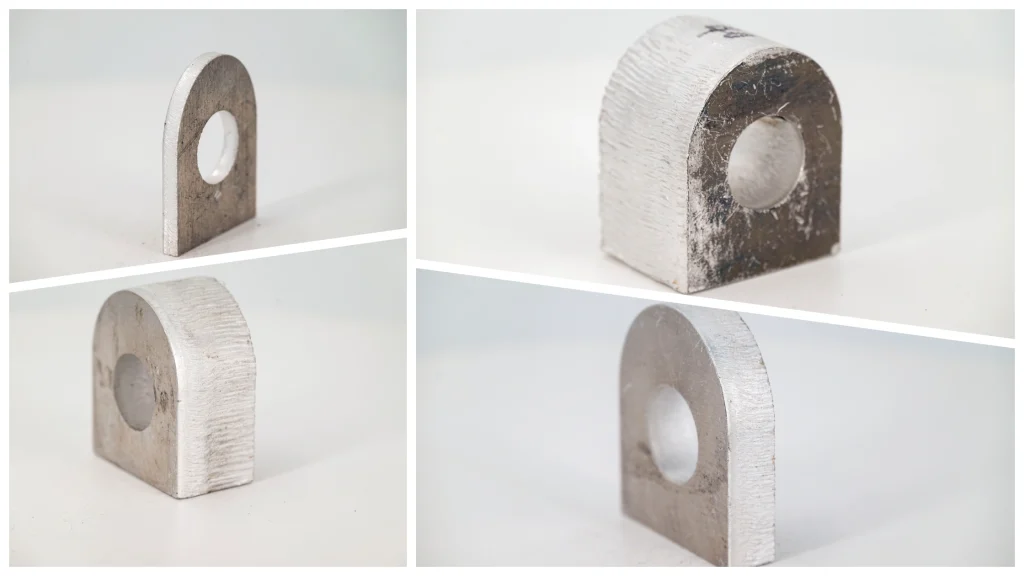

KF Laser cutting machine cuts aluminum plate samples of different thicknesses as shown below:

5.Key Factors for Successful Laser Cutting of Aluminum

1. Potencia del láser

The power of the laser directly affects cutting speed and material thickness capabilities. High-powered systems are better suited for thicker aluminum plates, while lower-powered machines excel in cutting thin sheets with fine details.

2. Assist Gas

Using the right assist gas—typically nitrogen or oxygen—plays a crucial role. Nitrogen prevents oxidation for a polished finish, while oxygen enhances cutting speed for thicker materials.

3. Calidad de enfoque y haz

A well-focused laser beam ensures precision and reduces thermal damage. Systems with superior beam quality deliver sharper cuts and smoother edges.

4. Software Precision

Advanced software optimizes cutting paths, reducing material waste and enhancing productivity. KF LASER systems come equipped with intuitive software to streamline operations.

6.The Environmental Edge: Sustainability in Laser Cutting

As industries pivot toward greener practices, laser cutting stands out as an eco-conscious choice. Its precision reduces material waste, while energy-efficient machines lower carbon footprints. Aluminio, being 100% recyclable, further aligns with sustainability goals, making laser cutting a cornerstone of eco-friendly manufacturing.

7.Future Innovations in Laser Cutting Aluminum

1. Integración con IA y automatización

The future of laser cutting lies in smart systems. AI-driven automation will enhance precision, optimize processes, and predict maintenance needs, Reducción del tiempo de inactividad.

2. Expanded Material Applications

As R&D progresses, laser systems will be able to handle even more aluminum alloys, broadening their use in specialized industries.

3. Portable Laser Systems

Compact and portable laser machines are on the horizon, enabling smaller businesses and workshops to access high-quality cutting solutions.

4. Hybrid Cutting Technologies

Combinando el corte láser con otras tecnologías, such as waterjet or plasma cutting, will further enhance versatility and efficiency.

8.How to Choose the Right Laser Cutting Machine for Aluminum

Selecting the perfect machine depends on your specific requirements. Here’s a checklist to guide your decision:

1. Espesor del material: Match the laser power to the thickness of the aluminum you work with.

2. Production Volume: Choose a system that meets your speed and efficiency needs.

3. Cutting Accuracy: Ensure the machine delivers the precision required for your projects.

4. Support and Maintenance: Partner with a trusted provider like KF LASER to ensure long-term reliability.

9.El LÁSER KF Advantage

As a leader in laser technology, KF LASER offers cutting solutions designed to meet the highest standards of precision and efficiency. With user-friendly interfaces, robust software, and unparalleled customer support, KF LASER empowers businesses to elevate their operations.

10.Conclusión: Redefining Possibilities with Laser Cut Aluminum

Laser cut aluminum isn’t just a technological advancement—it’s a paradigm shift. By combining precision, velocidad, y sostenibilidad, it opens doors to innovation across industries. From aerospace to architecture, this technology is transforming visions into reality.

Con LÁSER KF, you don’t just cut aluminum; you craft excellence. Embrace the future of manufacturing, where precision and creativity converge to shape a brighter tomorrow. The possibilities are endless, and they begin with the power of laser cutting.

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora