Noticias

Revolutionizing Precision: The Power of Small Fiber Laser Cutting Machines

Revolutionizing Precision: The Power of Small Fiber Laser Cutting Machines

Introducción: Why Small Máquinas de corte por láser de fibra are Game-Changers

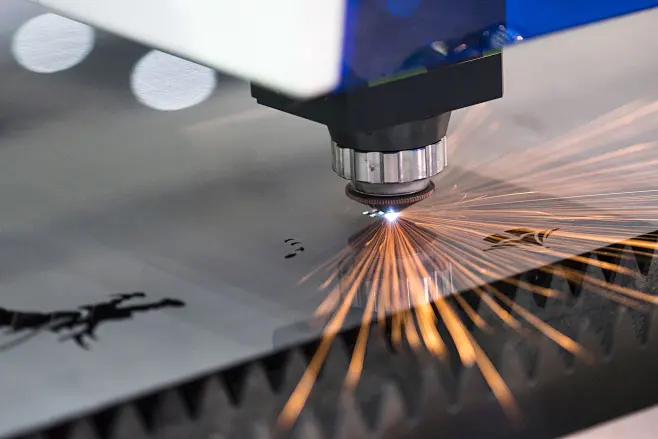

In today’s fast-paced industrial world, cutting-edge technology is no longer just a luxury but a necessity. When it comes to achieving precision and efficiency in manufacturing, small fiber laser cutting machines have become a vital tool across numerous industries. From intricate designs in metalworking to high-precision cuts in the automotive sector, these machines provide unmatched accuracy while maintaining a compact, user-friendly design.

Small in size but big in performance, these machines are redefining what it means to achieve quality without compromise.

But how exactly do these machines work, and why are they becoming a preferred choice for industries seeking cost-effective, resultados de alta calidad? En esta guía completa, we will delve into the benefits, características, and considerations involved in integrating small fiber laser cutting machines into your manufacturing process.

☟ You can share this article to:

1. What is a Small Fiber Laser Cutting Machine?

◆ The Technology Behind Fiber Laser Cutting

A small fiber laser cutting machine uses a láser de fibra to generate a concentrated beam of light capable of cutting through various materials with extreme precision. Unlike traditional CO₂ lasers, fiber lasers use fiber-optic technology, resulting in higher energy efficiency, improved beam quality, and faster cutting speeds.

✔ The following two videos can help you understand.You are also welcome to follow our YOUTUBE homepage.

◆ Key Components of the Small Fiber Laser Cutting Machine

● Fuente láser – The heart of the machine, responsible for generating the laser beam.

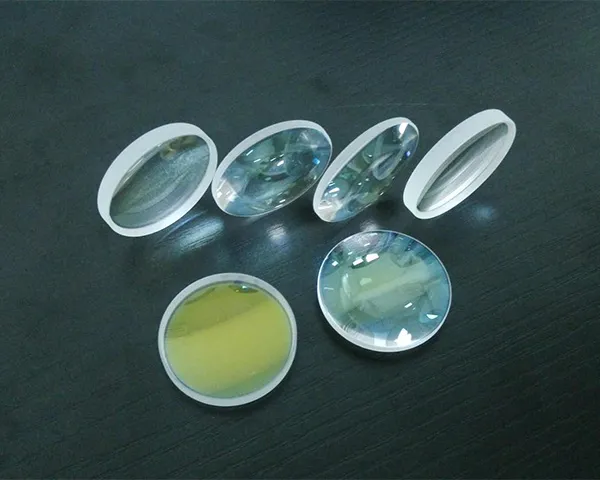

● Focusing Lens – Focuses the laser onto the material for cutting.

● CNC Controller – Enables automated and precise movement during the cutting process.

● Cutting Bed – Holds the material in place during the operation.

● Sistema de enfriamiento – Maintains an optimal temperature for efficient performance.

◆ How it Works

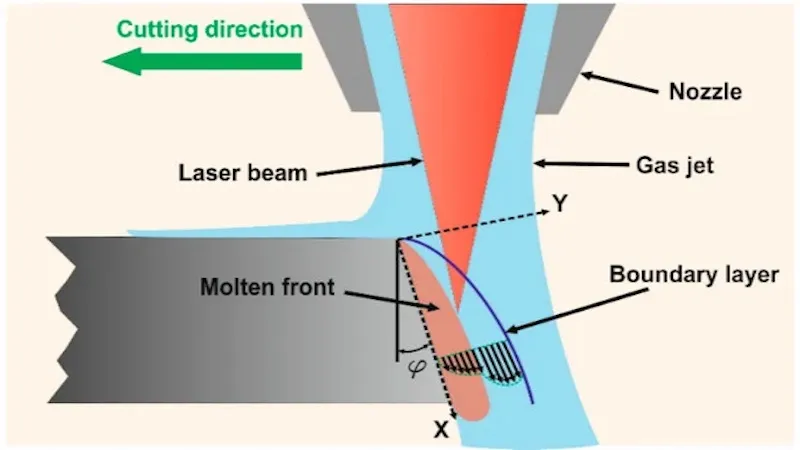

The laser beam travels through fiber-optic cables, and is directed to the material using mirrors and lenses. The laser is focused on the surface, where the heat melts or vaporizes the material, leaving a clean, precise cut.

☞ The picture on the right can give you a more intuitive understanding of the working principle of the laser cutting machine.

2. Advantages of Small Fiber Laser Cutting Machines

◆ Compact and Space-Saving Design

One of the standout features of small fiber laser cutting machines is their compact size. This design makes them an ideal solution for businesses with limited space. Despite their size, these machines deliver the high-powered cutting performance expected from larger models, providing flexibility and efficiency without compromising on quality.

◆ Energy Efficiency and Lower Operating Costs

Small fiber laser cutting machines are known for their energy efficiency. The fiber-optic technology significantly reduces the energy consumption compared to traditional laser systems. With lower power consumption, these machines are also more cost-effective to operate, making them an excellent investment for small to medium-sized enterprises (SMEs).

◆ Precision and Clean Cuts

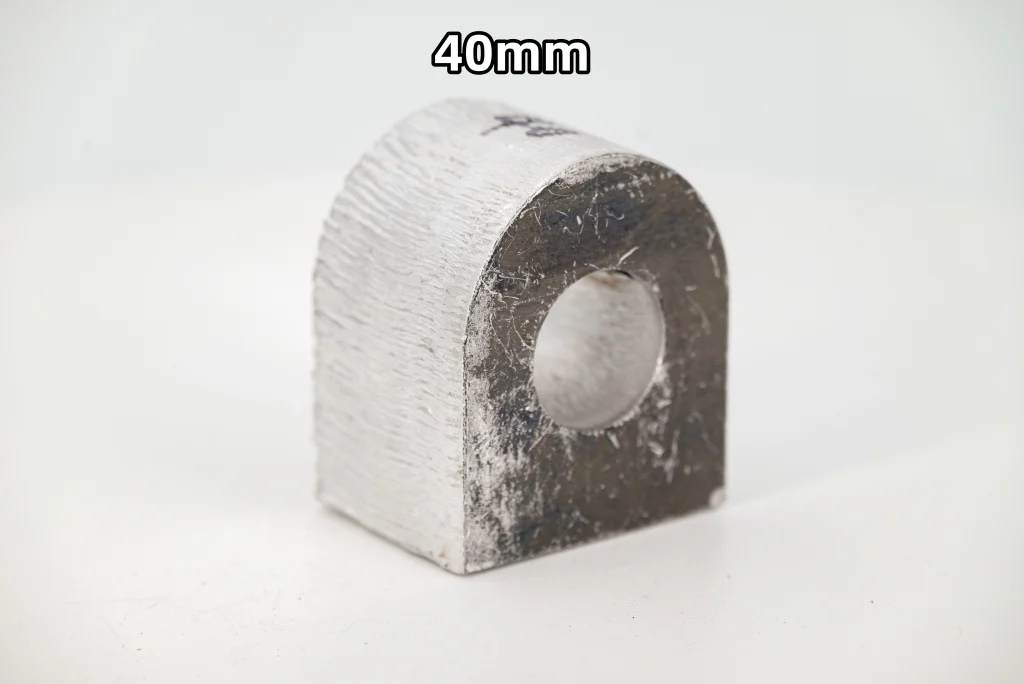

Precision is critical in industries that require high-quality cutting. Small fiber laser machines are capable of cutting thin and thick materials with remarkable accuracy. The beam is focused tightly, producing clean, burr-free edges, reducing the need for additional finishing work.

◆ Versatility in Material Processing

These machines can handle a variety of materials, including metals like acero inoxidable, acero carbono, aluminio, latón, y cobre. Their versatility makes them suitable for applications across multiple sectors, incluido automotor, aeroespacial, señalización, y fabricación de metal.

3. Applications of Small Fiber Laser Cutting Machines

◆ Automotive Industry

En la fabricación de automóviles, precision and speed are key. Small fiber laser cutting machines provide the ideal solution for cutting metal parts for vehicles, ensuring that each piece fits perfectly in the assembly process. The speed and accuracy reduce manufacturing time, allowing for better efficiency and lower production costs.

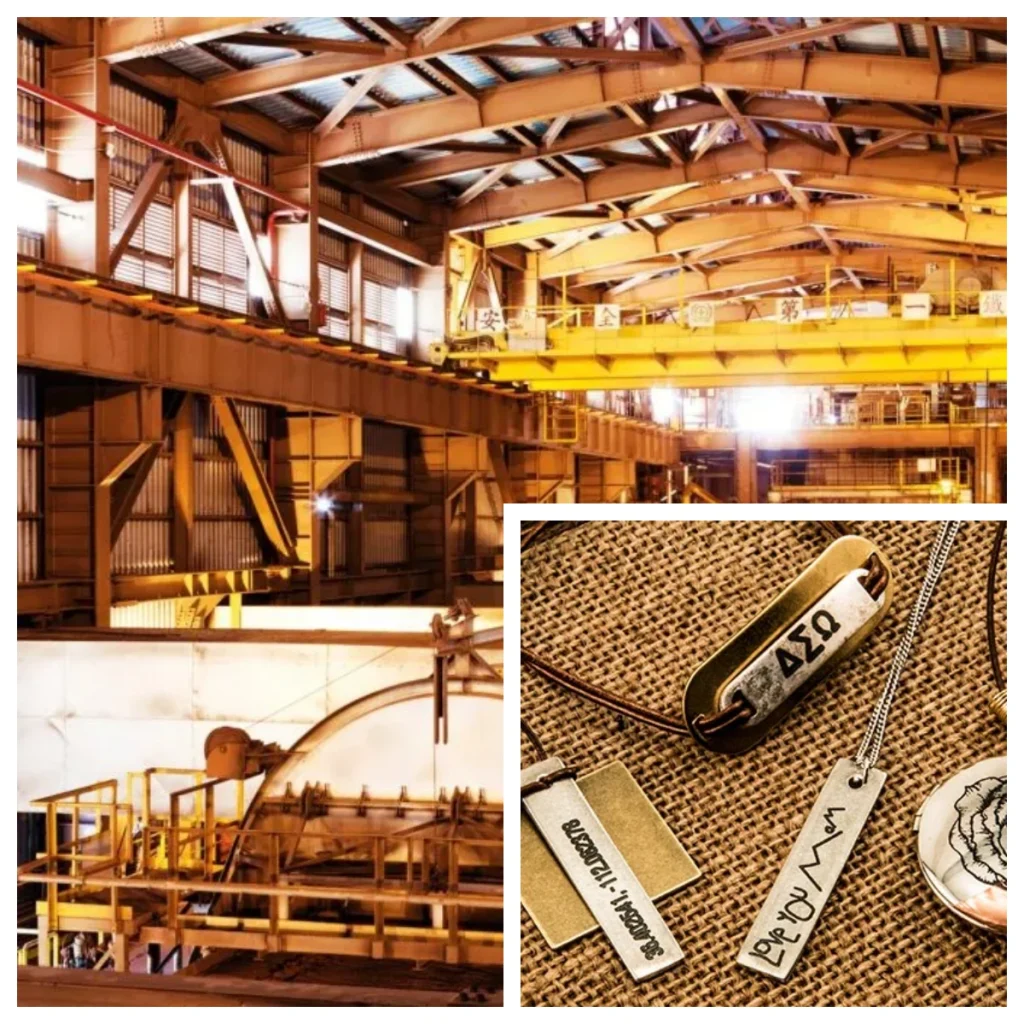

◆ Signage and Metal Fabrication

Small fiber lasers are widely used in the production of custom metal signs y engraved materials. The ability to make cortes intrincados with high precision allows businesses in the signage industry to meet the growing demand for bespoke, detailed designs.

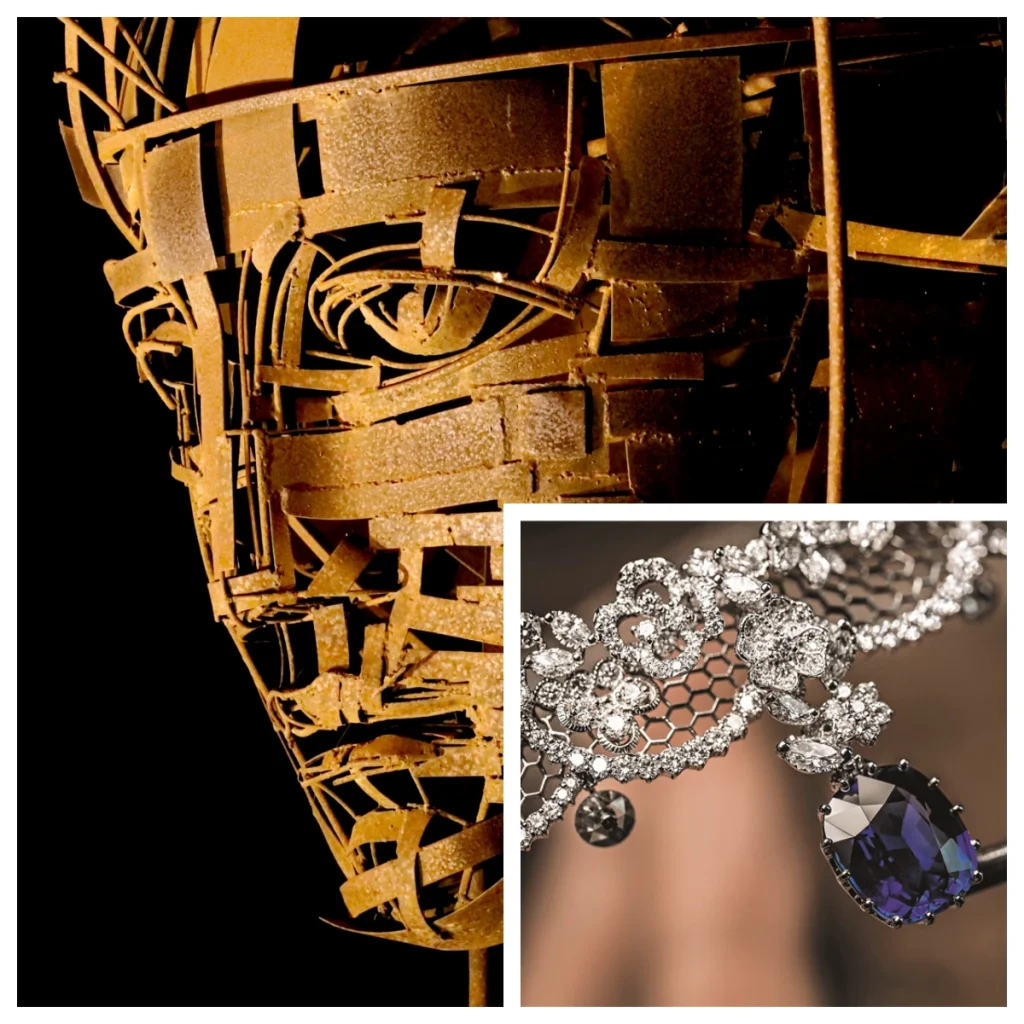

◆ Jewelry Making and Fine Arts

For industries such as jewelry making, where fine details are paramount, small fiber lasers provide the necessary precision for cutting intricate patterns and designs. The clean cuts are essential for ensuring high-quality finished products with minimal post-processing.

◆ Aerospace and Electronics

In aerospace and electronics, the precision of small fiber laser cutting machines makes them perfect for cutting thin metals and components for advanced machinery.

4. Key Considerations When Choosing a Small Fiber Laser Cutting Machine

◆ Power and Performance

When selecting a small fiber laser cutting machine, one of the first considerations is the potencia láser. The power level determines the machine’s ability to cut through various thicknesses of material. For light or thin materials, lower power may suffice, while thicker materials require higher wattage to maintain speed and precision.

◆ Cutting Area Size

The size of the cutting bed is another critical factor. Small fiber lasers typically offer a smaller bed compared to their larger counterparts, but it’s important to choose one that aligns with your operational requirements.

◆ Speed and Efficiency

Look for machines that strike the right balance between velocidad de corte y precisión. Faster cutting speeds can improve productivity, but without sacrificing the clean quality of the cut.

◆ Durability and Maintenance

Opt for a machine that is known for its durability and requires minimal maintenance. This will reduce downtime and extend the machine’s lifespan.

5. Future Trends in Small Fiber Laser Cutting Machines

The future of small fiber laser cutting machines is bright, with technological advancements paving the way for smarter, more efficient sistemas. With integration of features like automated loading/unloading, Optimización impulsada por IA, y remote monitoring capabilities, these machines are becoming even more powerful and intuitive.

As industries across the globe continue to demand faster, more efficient solutions, the adoption of small fiber laser cutting technology is expected to grow exponentially, offering unparalleled precision and flexibility.

ncorporating small fiber laser cutting machines into your operations can dramatically enhance your production capabilities. Whether you’re involved in manufacturing, fabricación de metal, or signage, these machines offer a cost-effective y precise cutting solution. By selecting the right machine for your needs, you can improve quality, reducir costos, and elevate your business’s competitiveness in the marketplace.

Ready to upgrade your manufacturing process with a small fiber laser cutting machine? Reach out for expert guidance and discover how this technology can benefit your business today!

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora