Noticias

Máquina de cortar láser para aluminio: Revolución de la fabricación de metales

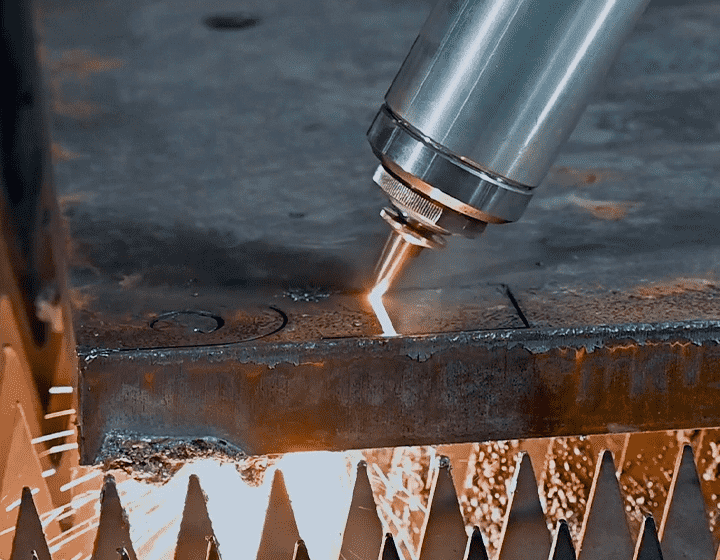

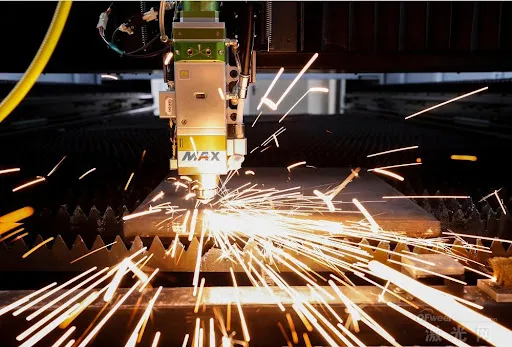

In the world of metal fabrication, precision is the key to success. When it comes to cutting materials like aluminum, laser cutting machines are the industry’s top choice. Known for their efficiency and ability to produce incredibly clean cuts, laser cutting machines for aluminum are indispensable in a variety of sectors—from aerospace to automotive. This technology is not just a passing trend; it’s a fundamental shift that allows businesses to meet the growing demands of precision and cost-effectiveness.

1. What Makes Máquinas de corte con láser Ideal for Aluminum?

Aluminio, due to its lightweight yet sturdy properties, is widely used in various industries. Sin embargo, cutting it can be challenging without the right technology. Laser cutting machines stand out because they combine high-energy beams with precise control to deliver clean, sharp cuts in aluminum. Let’s explore why they are preferred for this purpose.

◆ High Precision and Clean Cuts

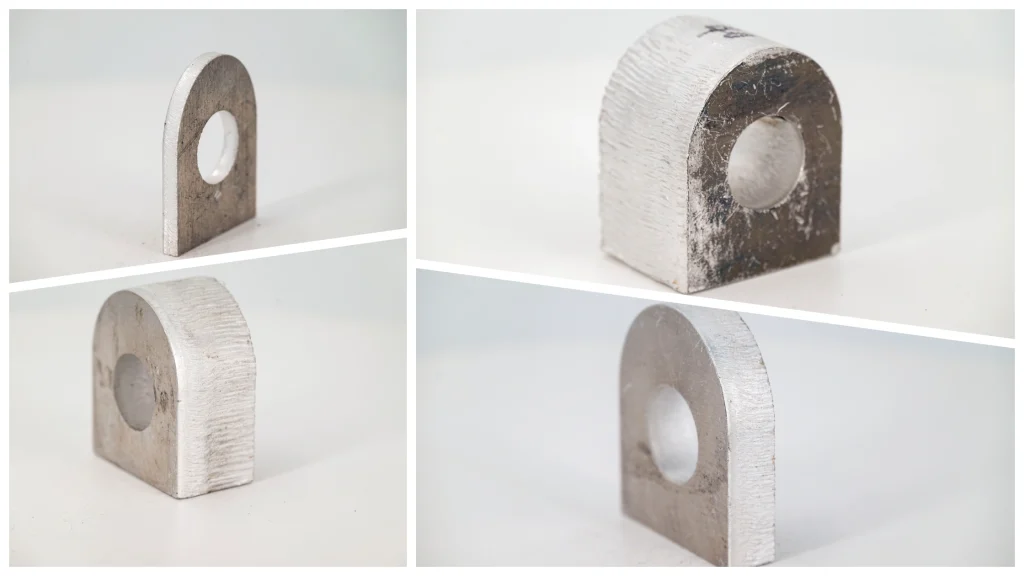

The precision of a laser cutting machine for aluminum is unmatched. Traditional cutting methods often leave rough edges, requiring additional processing to smooth them out. Laser cutting, por otro lado, uses a finely focused beam to cut through the material, leaving a smooth, polished edge. This reduces the need for secondary operations like grinding or finishing, cutting down on production time and costs.

◆ Speed and Efficiency

Laser cutting is incredibly fast. A laser cutting machine can work continuously without pausing for tool changes, unlike traditional methods that require constant tool swaps for different materials or thicknesses. This efficiency significantly boosts productivity and reduces manufacturing costs, making it a favorite among companies that need to scale operations quickly.

◆ Ability to Cut Thin and Thick Aluminum

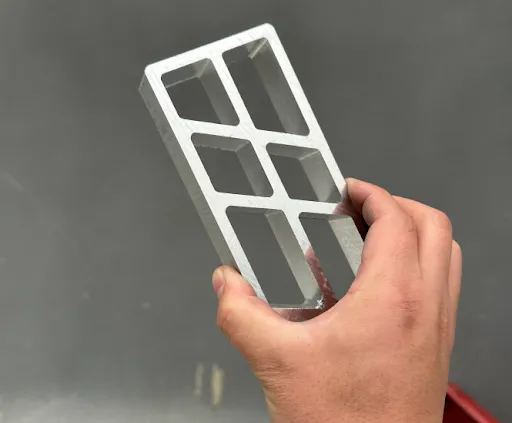

Whether you’re working with thin aluminum sheets or thicker plates, laser cutting machines for aluminum offer versatility. Machines with higher power ratings are capable of cutting through thicker materials, while lower-power machines can handle more delicate sheets with ease. This flexibility allows businesses to use the same technology for a wide range of projects.

2. Key Advantages of Using Laser Cutting Machines for Aluminum

◆ Superior Edge Quality

Laser cutting offers some of the cleanest edges in the industry. This is especially critical in industries like electronics and aerospace, where even the slightest imperfections can compromise the integrity of a part. With laser cutting machines for aluminum, companies can achieve extremely fine, burr-free edges that require little to no additional finishing work.

◆ Cost Savings Over Time

While the initial investment in a laser cutting machine may be higher than traditional methods, the long-term cost savings are substantial. With reduced material wastage, lower energy consumption, and the elimination of post-processing steps, laser cutting proves to be cost-effective in the long run.

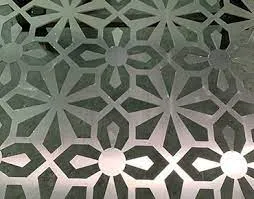

◆ Enhanced Flexibility and Customization

Laser cutting technology offers remarkable customization options. The ability to program and control the machine precisely means you can produce complex shapes with ease. From intricate designs to simple cuts, laser cutting machines for aluminum allow manufacturers to customize their products to meet specific requirements.

3. What to Look for When Buying a Laser Cutting Machine for Aluminum

◆ Power and Cutting Thickness

The power of a laser cutting machine for aluminum plays a crucial role in determining what thicknesses the machine can handle. Machines with power ratings of 1kW to 6kW are common in the industry. Higher power allows for cutting thicker aluminum sheets, while lower-power machines are more suited to cutting thinner materials. It’s important to assess your cutting needs to choose the right machine power for your application.

◆ Speed and Cutting Precision

Cutting speed is another important factor to consider. Faster machines may improve productivity, but they must not compromise on precision. High-end laser cutting machines are equipped with advanced technologies that balance both speed and precision, ensuring quality results in every cut.

◆ Laser Technology and Beam Quality

Laser cutting machines utilize different types of lasers, including CO2 and fiber lasers. Fiber lasers are particularly well-suited for cutting aluminum due to their high efficiency and ability to generate a smaller, more focused beam. A machine equipped with a fiber laser will deliver superior performance in cutting aluminum.

◆ Maintenance and Support

Like any sophisticated piece of machinery, laser cutting machines for aluminum require regular maintenance to function at peak efficiency. When purchasing a machine, it’s important to consider the manufacturer’s customer service and the availability of support services. Routine checks and part replacements can help avoid downtime and keep operations running smoothly.

4. Price Range for Laser Cutting Machines for Aluminum

| type | Price Range | fuerza | Características |

| Máquinas de nivel de entrada | $10,000 a $50,000 | around 1kW to 2kW | It can effectively cut thin aluminum plates, but is not suitable for cutting thicker materials. |

| Máquinas de rango medio | $50,000 a $150,000 | in the 3kW to 4kW range | Capable of handling a wide range of aluminum thicknesses, it is ideal for businesses that need to cut both thin and thick materials. |

| High-End Machines | $150,000 and Above | 5kW or more | Equipped with the most advanced features and software. Capable of high volume production and high precision cutting of very thick aluminum materials, but with higher upfront costs. |

◆ Entry-Level Machines: $10,000 a $50,000

Entry-level laser cutting machines typically feature lower power ratings (around 1kW to 2kW) and are suitable for businesses with relatively small-scale production needs. These machines are effective for cutting thin aluminum sheets but may not perform as well with thicker materials. They’re a good starting point for smaller workshops or businesses that don’t need to cut large volumes.

◆ Mid-Range Machines: $50,000 a $150,000

Mid-range laser cutting machines, which typically feature power ratings in the 3kW to 4kW range, are capable of handling a wider variety of aluminum thicknesses. These machines are ideal for businesses that need to cut both thin and thick materials, offering the best balance between price and functionality.

◆ High-End Machines: $150,000 and Above

High-end laser cutting machines come equipped with advanced features, such as automated material handling, high-power lasers (5kW or more), and state-of-the-art software. These machines are capable of high-volume production, cutting extremely thick aluminum materials with high precision. The upfront cost is higher, but they are ideal for large-scale operations and high-precision cutting.

5. The Future of Laser Cutting Machines for Aluminum

A medida que la tecnología continúa evolucionando, laser cutting machines for aluminum will become even more advanced. Innovations in beam quality, velocidad, and automation are already changing the game, allowing for faster, more efficient cutting processes. Además, with growing demand for environmentally-friendly manufacturing practices, future machines will likely be even more energy-efficient, providing additional cost savings while reducing environmental impact.

Laser cutting is undoubtedly one of the most important technologies in modern manufacturing. When it comes to cutting aluminum, fiber laser machines stand out as the top choice for their precision, eficiencia, and cost-effectiveness. Whether you’re a small business or a large manufacturer, investing in a laser cutting machine for aluminum can improve your production process, reducir costos, and lead to higher-quality products.

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora