Noticias

Máquina de cortar láser para lámina de metal: Transformación de precisión en metalurgia

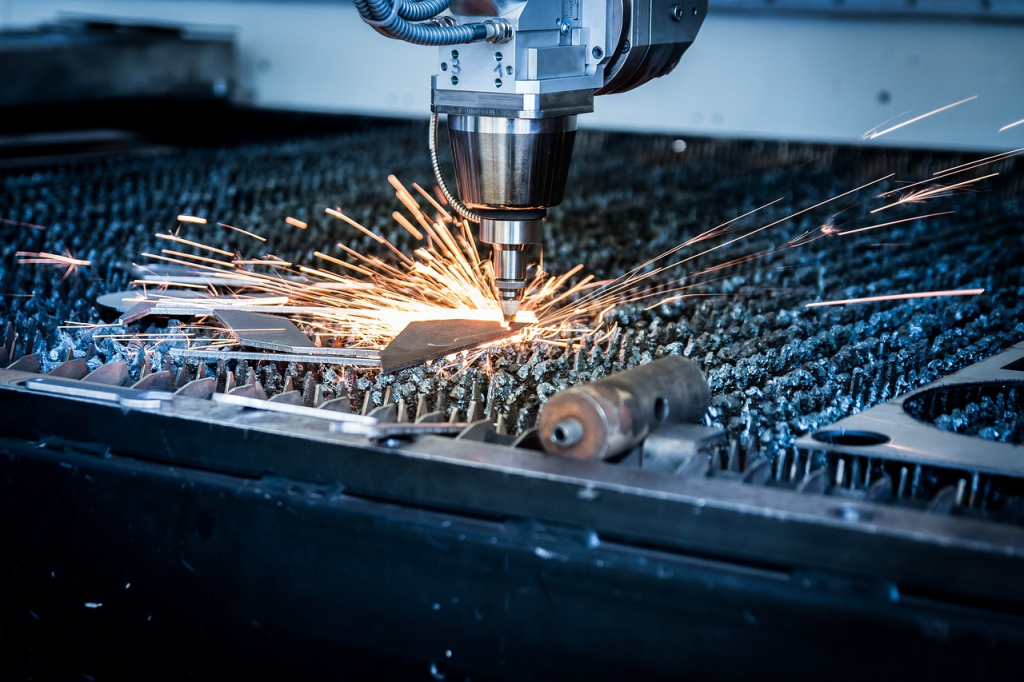

The manufacturing and fabrication industries are in a constant state of evolution, driven by the demand for higher precision, greater efficiency, and improved cost-effectiveness. In this dynamic environment, laser cutting machines for metal sheets stand at the forefront of revolutionizing how metal materials are processed. These advanced tools have dramatically changed metal cutting by offering unmatched accuracy, velocidad, y versatilidad. Whether it’s cutting steel, aluminio, or other metals, laser cutting machines are the preferred choice for professionals who need reliable, high-quality cuts.

☺ You can share this article to:

Ⅰ. Why Choose Laser Cutting Machines for Metal Sheets?

◆ Unparalleled Precision and Clean Cuts

One of the biggest advantages of using a laser cutting machine for metal sheets is the level of precision it delivers. Unlike traditional mechanical cutting methods, laser cutting involves the use of high-powered lasers that create narrow, focused beams. This allows the machine to cut metal sheets with extremely tight tolerances and clean edges. The result? Reduced need for post-processing work such as grinding or deburring, making laser cutting the go-to solution for high-precision metalworking.

◆ Speed and Efficiency

Laser cutting machines not only provide high precision but also enable faster cutting speeds compared to other methods. This means businesses can increase their production capacity and reduce turnaround times. Moreover, laser cutting is a non-contact process, meaning that there is minimal wear and tear on the cutting tool, which extends the machine’s lifespan and reduces the cost of maintenance and tool replacement.

◆ Versatility in Material Handling

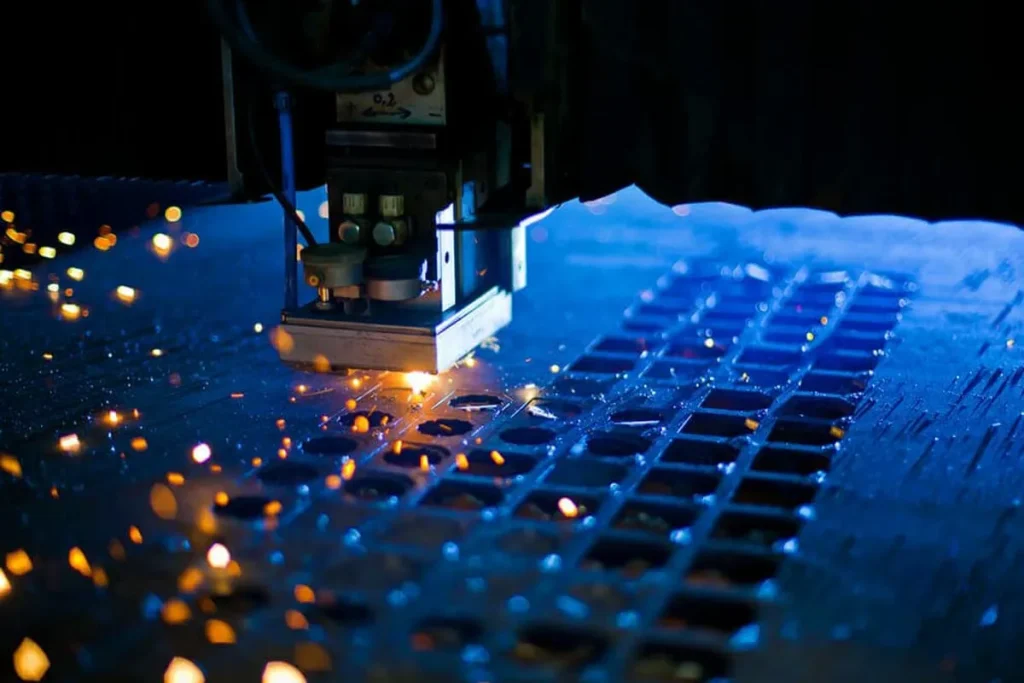

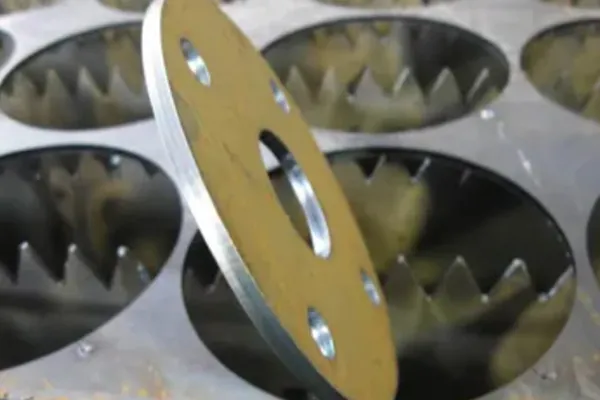

The flexibility of laser cutting machines for metal sheets extends beyond just the type of metal they can handle. These machines can easily cut through materials of varying thicknesses and complexities, whether it’s thin sheet metal for intricate designs or thicker metal plates for structural components. The ability to program the machine to make multiple cuts with high repeatability makes it an essential tool for both prototyping and large-scale manufacturing runs.

Ⅱ. Key Advantages of Laser Cutting Metal Sheets

◆ Quality and Surface Finish

One of the key reasons laser cutting is preferred in the metalworking industry is the superior surface finish it provides. The high energy of the laser results in a smooth, polished cut that minimizes the need for additional finishing steps. This high-quality finish ensures that parts meet stringent design specifications without the added cost of post-processing.

◆ Reduced Waste and Material Savings

Laser cutting technology uses a focused beam that cuts with minimal kerf (the width of the cut), allowing manufacturers to maximize the use of raw materials. This significantly reduces waste and maximizes efficiency in terms of material costs. Además, laser cutting machines are highly automated, reducing the likelihood of human error and further optimizing material usage.

◆ Cost-Effectiveness for Small and Large Runs

While the initial investment in a laser cutting machine for metal sheets can be substantial, the long-term cost savings far outweigh the expense. La precisión, velocidad, and minimal waste provided by laser cutting mean lower overall production costs. This makes laser cutting suitable not only for high-volume production but also for small batches or custom orders, offering flexibility to businesses of all sizes.

Ⅲ. Choosing the Right Laser Cutting Machine for Metal Sheets

◆ Power and Cutting Capability

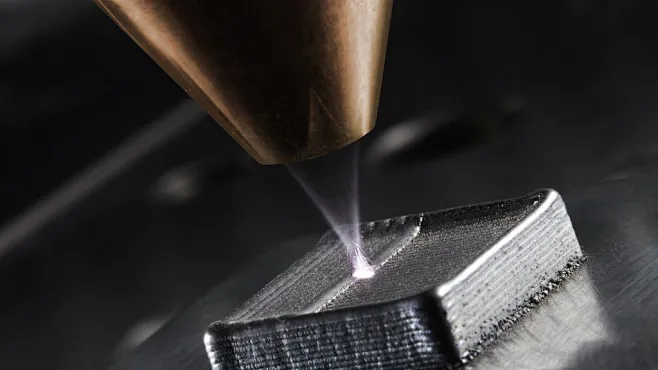

The power of the laser cutting machine plays a crucial role in determining what thicknesses and types of metal it can cut. CO2 lasers and fiber lasers are the two primary types of lasers used in metal cutting. Fiber lasers are particularly well-suited for cutting metal sheets due to their high efficiency and ability to cut thinner sheets at higher speeds. The power of the machine, typically measured in watts (kW), will determine its cutting speed and thickness capacity.

For thinner sheets (under 6mm), a laser with a power rating of 1kW to 2kW is generally sufficient. Sin embargo, for cutting thicker materials, a higher power machine, such as one with 4kW to 6kW, is more appropriate.

◆ Automation and Software Integration

Modern laser cutting machines come equipped with advanced software that automates the cutting process. These systems can interpret CAD files directly, allowing for highly complex shapes and designs to be cut with precision. Además, automated features like material loading systems and cutting head adjustments enhance productivity by reducing manual labor and improving efficiency.

◆ Maintenance and Support

A reliable laser cutting machine for metal sheets is one that requires minimal downtime and maintenance. As with any machinery, routine maintenance and servicing are necessary to keep the machine operating at peak efficiency. When selecting a machine, consider the warranty, atención al cliente, and availability of spare parts.

Ⅳ. How to Determine the Price of a Laser Cutting Machine for Metal Sheets

| Fuerza | Cutting thickness | Características |

| 1kW to 2kW | Less than 3mm thick | Unable to handle larger items or thicker metals, it provides a cost-effective solution for smaller operations. |

| 2kW to 4kW | Wider range of materials and thicknesses | More versatile, cutting a wider range of materials and thicknesses. Suitable for both large and small production runs, with automatic material handling and software integration as standard. |

| above 5kW | Up to 20mm or more | Equipped with automated systems, sophisticated controls and cutting-edge software integration. Higher priced, but offers advantages in speed, accuracy and throughput. |

◆ Entry-Level Machines: $25,000 a $50,000

Entry-level laser cutting machines are typically suitable for small shops or businesses that need to process thinner metal sheets (less than 3mm thick). These machines generally come with a power rating of 1kW to 2kW and are ideal for basic applications. They may not be able to handle larger projects or thicker metals, but they offer a cost-effective solution for smaller operations.

◆ Mid-Range Machines: $50,000 a $150,000

Mid-range machines offer a balance of price and performance, with power ratings ranging from 2kW to 4kW. These machines are more versatile and can cut a wider range of materials and thicknesses. They are suitable for companies that need a reliable solution for both small and large production runs. Features like automated material handling and better software integration come standard in these machines.

◆ High-End Machines: $150,000 and Above

For businesses with large-scale production needs, high-end laser cutting machines are a must. These machines can have power ratings above 5kW and are capable of cutting through very thick sheets of metal (up to 20mm or more). They come with advanced automation systems, precision control, and cutting-edge software integration. The price of these machines is higher, but the benefits they offer in terms of speed, exactitud, and throughput make them a valuable investment for high-volume manufacturers.

Ⅴ. The Future of Laser Cutting Machines for Metal Sheets

The evolution of laser cutting technology continues to reshape industries worldwide. Innovations in fiber laser technology, software development, and automation will further enhance the precision, eficiencia, and versatility of laser cutting machines for metal sheets. The increasing demand for environmentally-friendly production methods also means that future machines will likely be more energy-efficient, reducing operational costs while minimizing environmental impact.

Laser cutting machines for metal sheets are essential tools in modern manufacturing, ofreciendo una precisión inigualable, velocidad, and cost-effectiveness. Whether you’re working with thin sheets of steel or thick aluminum plates, a laser cutting machine can transform your production process and improve product quality. By understanding the features, capabilities, and costs associated with these machines, businesses can make an informed decision that leads to greater operational efficiency and reduced long-term costs.

▶ You can contact us through the following ways to get a quote immediately.☟

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora