Noticias

La revolución del cortador láser de 4KW: Cortar metal como la tecnología del mañana hoy

What if you could carve through 25mm stainless steel as effortlessly as a hot knife through butter? What if your workshop’s production speed tripled while energy bills plummeted? What if precision engineering no longer required compromising on power? These aren’t hypothetical questions—they’re the daily reality for manufacturers wielding a 4kw laser cutter for sale. In an era where industries from automotive to aerospace demand parts with micron-level accuracy, the 4KW laser cutter isn’t just a tool; it’s a time machine, compressing weeks of work into days, and a profit engine, turning raw materials into revenue with ruthless efficiency.

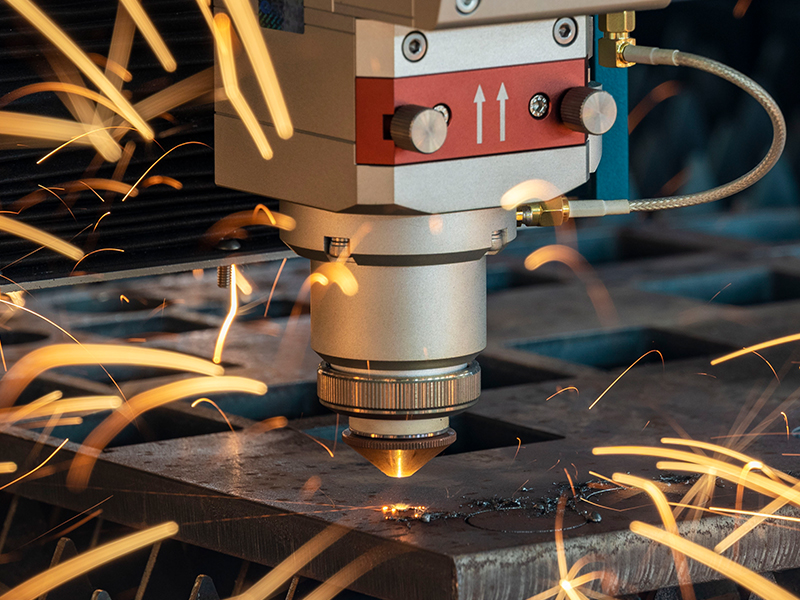

The Science Behind 4KW Laser Cutter: Why Power Matters

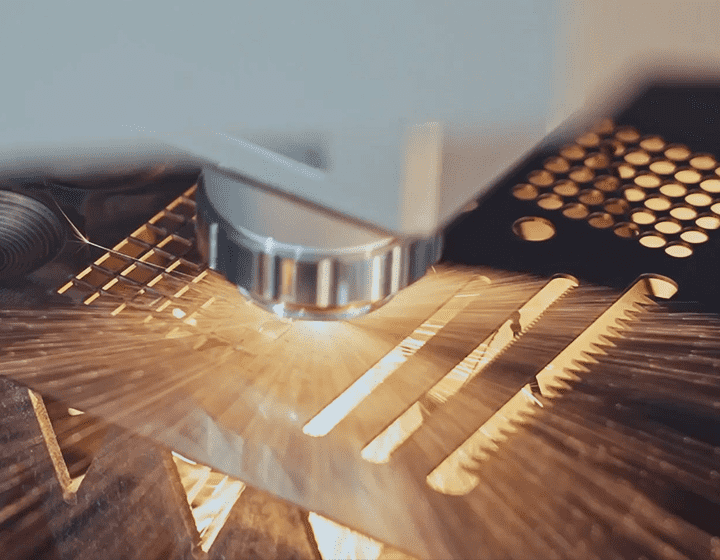

En su núcleo, a 4kw laser cutter for sale harnesses the physics of light amplification by stimulated emission of radiation (LASER). The 4KW designation refers to the laser’s power output—4 kilowatts of concentrated energy focused into a beam thinner than a human hair. This intensity isn’t arbitrary: it’s the sweet spot where cutting speed, material versatility, and energy efficiency converge.

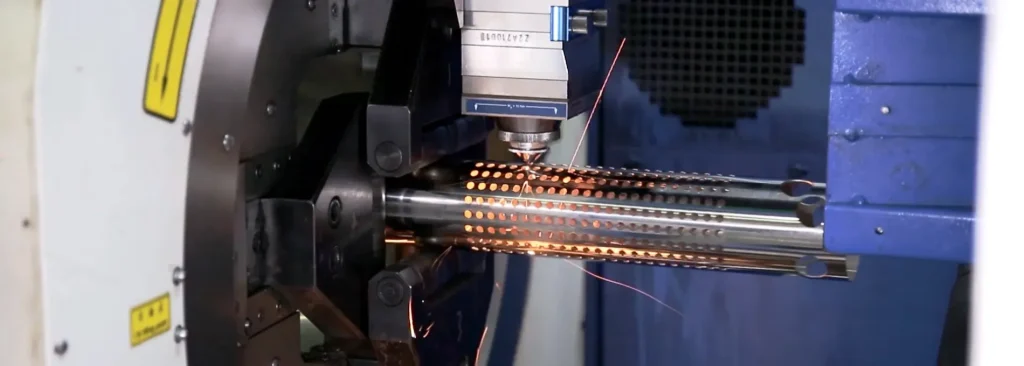

- Dominio del material: A 4KW laser cutter can slice through carbon steel up to 20mm thick, aluminum up to 15mm, and stainless steel up to 12mm, making it the workhorse of metal fabrication shops. Unlike plasma cutters, which rely on ionized gas and leave rough edges, laser cutting vaporizes material with minimal heat-affected zones (Cría), ensuring parts require little to no post-processing.

- Speed vs. Precisión: At full power, a 4KW laser cutter can cut 1mm steel at speeds exceeding 10 meters per minute—fast enough to produce 500 bracket parts in an hour. Yet even at these velocities, the beam maintains a tolerance of ±0.03mm, precise enough to etch circuit boards or cut turbine blades for jet engines.

- Eficiencia energética: Modern 4KW lasers use fiber optic technology, converting up to 30% of electrical input into usable laser energy—three times more efficient than CO2 lasers of the same power. This translates to lower electricity costs: a 4KW fiber laser typically consumes 15-20 kWh per hour, compared to 40-50 kWh for older CO2 models.

Why Invest in a 4KW Laser Cutter in 2025?

The global laser cutting machine market is projected to grow at a 7.2% CAGR through 2030, driven by demand for automation and precision manufacturing. But why specifically a 4KW model?

- Return on Investment (ROI): A mid-range 4kw laser cutting machine for sale costs between 80,000−80,000−150,000, but many manufacturers report recouping costs within 12-18 meses. Por ejemplo, a shop processing 500kg of steel weekly can save 15,000−15,000−20,000 annually on labor and material waste compared to mechanical cutting methods.

- Industry Adaptability: From architectural metalwork (think intricate facade panels) to heavy machinery parts (gear teeth with mirror-finish edges), the 4KW laser handles diverse tasks without reconfiguration. This versatility is critical in today’s market, where small-batch custom orders are as common as mass production runs.

- Sostenibilidad: With stricter environmental regulations, the 4KW laser’s low HAZ reduces material waste by up to 30% compared to plasma cutting. Además, fiber lasers contain no toxic gases (unlike CO2 lasers, which use helium and nitrogen), aligning with green manufacturing initiatives.

Key Features to Evaluate When Buying a 4KW Laser Cutter

Not all 4kw laser cutters for sale are created equal. To avoid overpaying for unnecessary features or undershooting your needs, focus on these critical specifications:

Feature | What to Look For |

Fuente láser | Fiber laser (preferred for metal cutting) with a minimum 100,000-hour lifespan. |

Bed Size | 3000mm x 1500mm is standard for industrial use; larger beds (4000mm+) suit heavy plates. |

Velocidad de corte | 8-12 m/min for 1mm steel; slower speeds for thicker materials indicate inefficient optics. |

Sistema de enfriamiento | Water-cooled (enfriador) with temperature control to prevent overheating during extended runs. |

Compatibilidad de software | Supports industry-standard CAD formats (DXF, DWG) and includes nesting optimization to minimize material waste. |

Automation Options | Pneumatic material clamping, pallet changers, and dust extraction systems reduce manual labor. |

Common Myths About 4KW Laser Cutters Debunked

Mito 1: “4KW is overkill for small shops.”

Realidad: Even small manufacturers processing 100kg of metal monthly benefit from a 4KW laser’s speed. The machine’s ability to handle both thin and thick materials eliminates the need for multiple tools, saving floor space and maintenance costs.

Mito 2: “Laser cutting is too expensive to maintain.”

Realidad: Fiber lasers have minimal moving parts; annual maintenance costs average 2,000−2,000−3,000, far less than the 10,000+requiredforplasmacutterupkeep.Consumableslikenozzlesandlensescost10,000+requiredforplasmacutterupkeep.Consumableslikenozzlesandlensescost500-$800 yearly.

Mito 3: “Only trained engineers can operate them.”

Realidad: Modern 4kw laser cutting machines for sale come with intuitive touchscreen interfaces. A technician can learn basic operation in 2-3 días, with advanced features (like parametric programming) mastered within a month.

How to Compare Prices: Avoid Hidden Costs

When evaluating a 4kw laser cutter for sale, the sticker price is just the starting point. Consider these hidden expenses:

- Installation: Rigging, electrical upgrades (4KW machines require 3-phase power), and ventilation systems can add 5,000−5,000−10,000.

- Capacitación: Manufacturer-provided training typically costs 1,500−1,500−3,000 per operator.

- Garantía: Look for 2-year coverage on the laser source and 1-year on mechanical parts; extended warranties add 10-15% to the total cost but reduce long-term risk.

Reputable suppliers offer transparent pricing, including these extras in quotes. Avoid “too-good-to-be-true” deals—they often exclude critical components like dust collectors or software licenses.

The Future of 4KW Laser Cutter: What’s Next?

A medida que avanza la tecnología, the 4kw laser cutter for sale is evolving. Innovations like adaptive beam technology (which adjusts laser power in real-time based on material thickness) and AI-driven predictive maintenance (sensors that alert operators to wear before breakdowns occur) are already hitting the market. By 2027, experts predict 4KW lasers will integrate with collaborative robots (cobots) for fully automated loading/unloading, turning standalone machines into 24/7 production cells.

Final Thoughts: Is a 4KW Laser Cutter Right for You?

If your business involves cutting metal thicker than 6mm, requires precision beyond ±0.1mm, or aims to scale production without adding shifts, a 4kw laser cutter for sale isn’t a luxury—it’s a necessity. To make the right choice:

- Audit Your Needs: Calculate your average material thickness, daily cutting volume, and most common part geometries.

- Request Demos: Ask suppliers to cut your actual materials in a live demo; compare edge quality, velocidad, and waste.

- Check References: Talk to existing owners in your industry about uptime, customer support, and ROI timelines.

In the end, a 4KW laser cutter isn’t just an investment in equipment—it’s an investment in your business’s ability to outpace competitors, meet tight deadlines, and deliver parts that make clients say, “How did you do that?” In a world where precision and speed rule, the answer is simple: with a 4kw laser cutting machine for sale.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora