Noticias

6000w Explicación de la potencia del láser

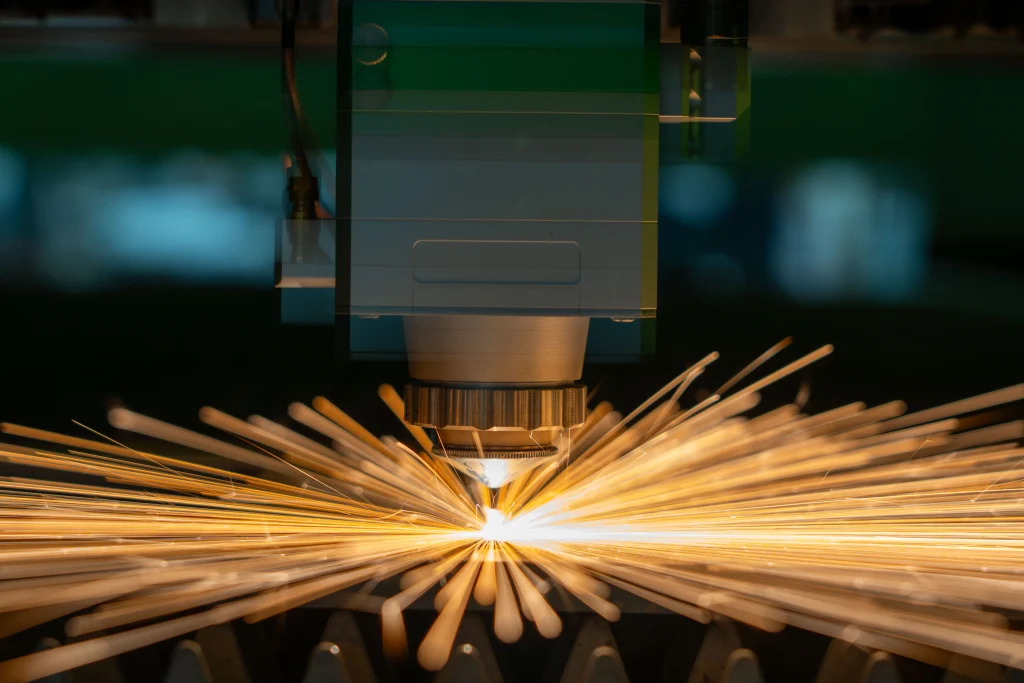

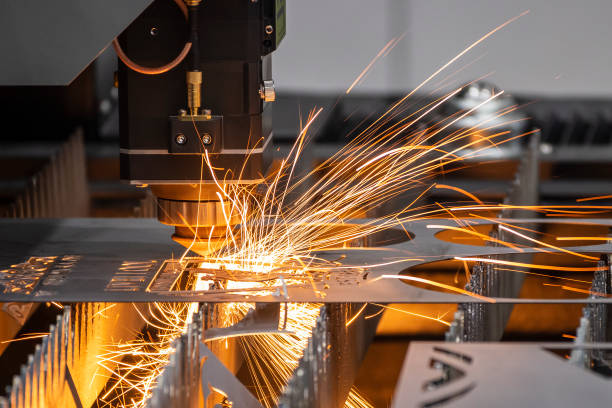

6000w laser systems now slice through solid steel like warm butter, vaporize aerospace alloys in milliseconds, and sculpt industrial diamonds with microscopic precision – welcome to the era where raw photon power redefines manufacturing reality. Imagine transforming three-inch titanium blocks into intricate aerospace components before your coffee cools or processing armored plating at speeds that make traditional methods obsolete. This isn’t industrial evolution; it’s revolution at light speed.

The Power Threshold: Why 6000w Changes Manufacturing

Industry Shift Timeline

- 2018:4000w lasers dominated automotive assembly lines

- 2021:5000w systems entered heavy machinery sectors

- 2023:6000w adoption surged 47% year-over-year

- Present:38% of shipbuilders now specify 6000w+ systems

Material Processing Capabilities

Material | Max Thickness | Speed Advantage vs. 4000w |

Acero inoxidable | 30milímetros | +220% |

Aluminio | 22milímetros | +180% |

Cobre | 18milímetros | +150% |

Titanio | 15milímetros | +250% |

Seattle’s marine equipment manufacturer slashed production time for propeller components from 14 hours to 3.7 hours after adopting 6000w technology. Their annual output doubled while energy consumption per unit dropped 34% – rewriting factory economics overnight.

Core Technical Innovations

Photonic Breakthroughs

- Triple-Resonator Architecture

- Cascading beam amplification achieving 99.8% energy stability

- Dynamic thermal compensation eliminating focal shift

- Adaptive Beam Shaping

- Real-time spot size adjustment from 0.1mm to 2.5mm

- Multi-axis focal control during high-speed motion

- Hyperbolic Nozzle Systems

- Variable gas dynamics for different material groups

- Anti-slag vortex technology preventing dross adhesion

Intelligent Operation System

Material Sensor → Spectral Analysis → Cloud-Based Parameter Optimization

↓ ↓ ↓

Thickness Detection → Alloy Composition → Cutting Path Adjustment

This cognitive system auto-adjusts frequency (100-5000Hz), gas pressure (5-25bar), and nozzle distance during operation. German automotive suppliers report 99.6% first-cut accuracy on chassis components since implementation.

Economic Transformation Metrics

ROI Acceleration Table

Investment Area | Reducción de costos | Productivity Gain |

Energy Consumption | 31% per part | N/A |

Labor Requirements | 48% | N/A |

Material Waste | 22% | N/A |

Throughput Capacity | N/A | 340% |

Detroit’s metal fabrication plant recorded staggering results: $1.8M investment recouped in 8 months through continuous operation. Daily output jumped from 350 units to 1,240 while rework rates plummeted to 0.3% – establishing new industry benchmarks.

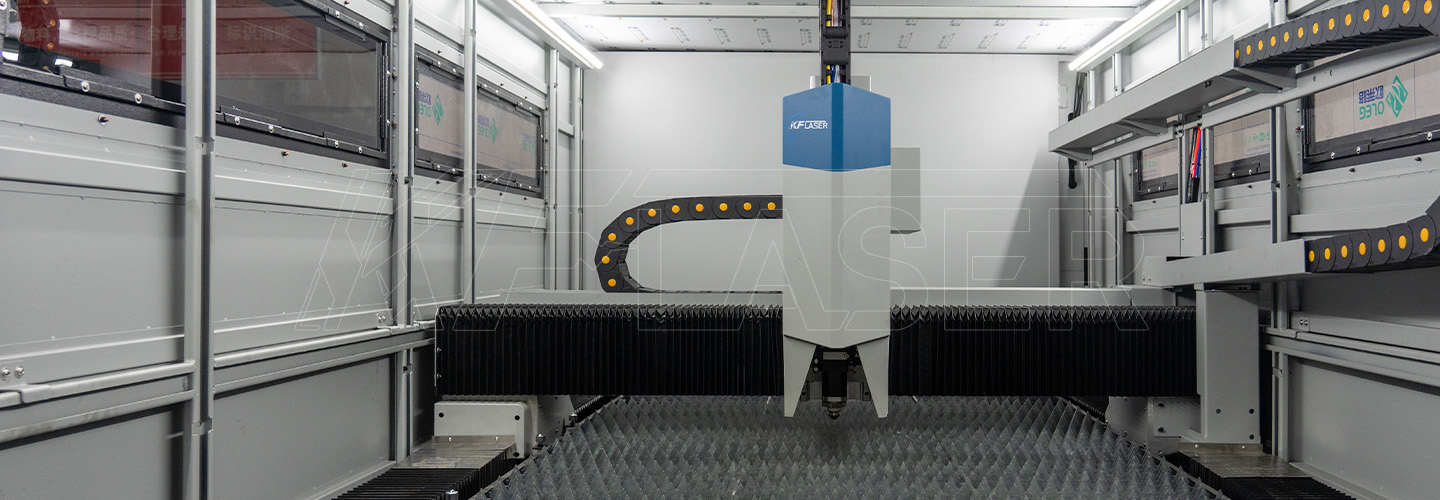

Hoja de ruta de implementación

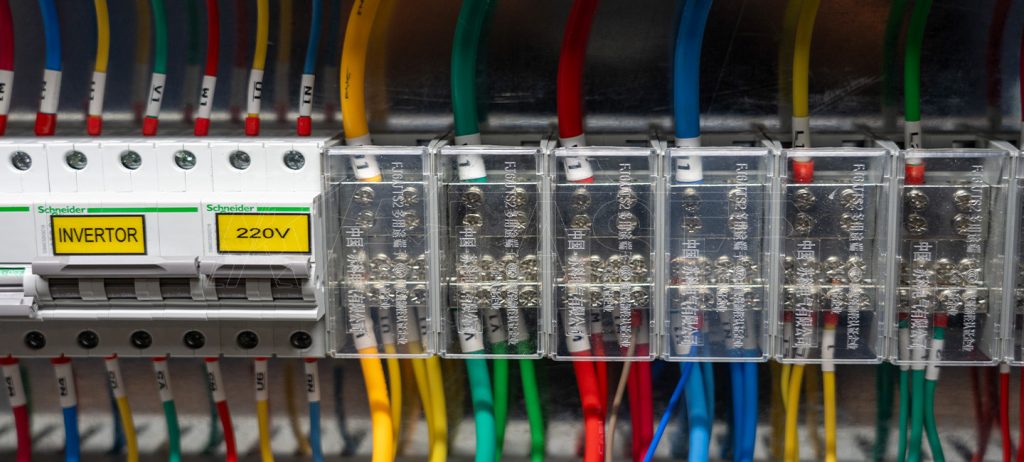

Infrastructure Essentials

- Requisitos de energía

- 400V/3-phase supply with harmonic filters

- 200kVA minimum transformer capacity

- Emergency power redundancy systems

- Ventilación & Cooling

- Class IV laser-rated exhaust systems

- Chilled water circulation at 18°C constant

- Ambient temperature control within ±2°C

Workflow Integration

- AI nesting software maximizing material utilization

- Automated loading/unloading robotics

- Real-time quality monitoring with hyperspectral cameras

Osaka’s machinery plant retrained 68% of their workforce in 45 days using augmented reality simulators, achieving zero production disruption during transition.

Revolutionary Applications

Industry-Specific Breakthroughs

- Renewable Energy Sector

Challenge: Cutting 25mm stainless steel for offshore wind platforms

Solución: 6000w lasers with nitrogen assist gas

Outcome: Component production time reduced by 73%

- Fabricación de dispositivos médicos

Challenge: Micron-precision cutting of nitinol implants

Solución: Pulsed 6000w at 0.03ms pulse width

Outcome: Achieved 5μm tolerance on coronary stents

Unconventional Material Processing

- Ceramic Structuring

Creating cooling channels in silicon carbide turbine components - Diamond Micro-Processing

Engraving quantum computing substrates - Composite Trimming

Delamination-free cutting of carbon fiber reinforced polymers

Swiss research labs recently demonstrated 0.008mm kerf widths on 10mm alumina ceramics – precision rivaling lithographic techniques.

Maintenance Evolution

Self-Preservation Systems

- Optical Path Protection

- Auto-purge lens cartridges every 30 perfora

- Real-time beam alignment verification

Predictive Maintenance

- Resonator performance forecasting

- Capacitor degradation modeling

- Gas consumption optimization algorithms

Robotic Service Modules

- 7-second nozzle replacement systems

- Modular power supply hot-swapping

Chicago’s industrial hub reported 98.2% uptime over 24 months using these protocols, reducing maintenance costs by 57%.

Future Horizons

Emerging Photonic Frontiers

- Multi-Wavelength Hybrids

Combining fiber and CO₂ beams for hybrid materials - Quantum Cooling Systems

Graphene-based heat dissipation technology - Holographic Beam Shaping

Simultaneous multi-geometry processing - AI-Driven Process Optimization

Self-learning cutting parameter algorithms

“Experimental 7000w prototypes now cut 40mm carbon steel at 2m/min,” reveals Dr. Elena Richter from Munich’s Photonics Institute. “We’re approaching the physical limits of material-light interaction.”

Perspectiva final: As Hamburg’s shipyard lasers pierce Arctic-grade steel at midnight without human operators, 6000w technology isn’t just transforming factories – it’s redefining global manufacturing paradigms. Enterprises embracing this photonic revolution aren’t merely upgrading equipment; they’re securing dominance in tomorrow’s industrial landscape while competitors still calculate ROI.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora