Noticias

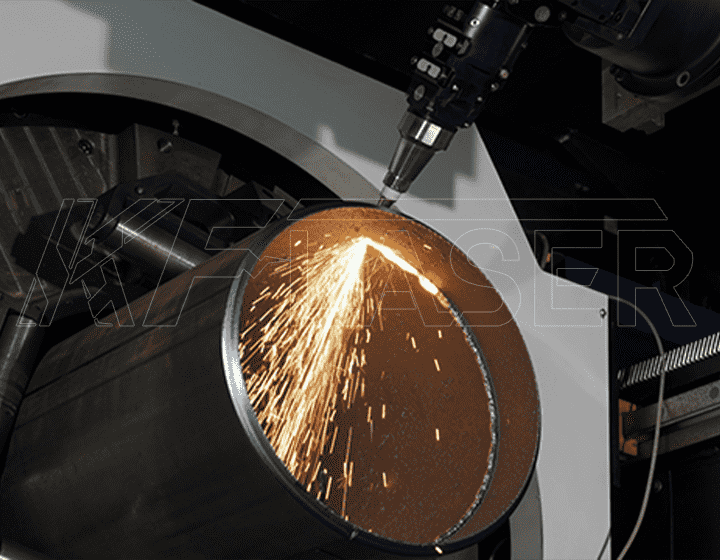

La máquina de corte por láser industrial: Precisión, Eficiencia, e innovación en su esencia

★ Las máquinas de corte por láser industriales han revolucionado la industria manufacturera. Su precisión, eficiencia, y la versatilidad han transformado la forma en que se diseñan los productos, fabricado, y ensamblado. De la industria aeroespacial a la automoción, desde la construcción hasta los bienes de consumo, Estas máquinas se han convertido en herramientas indispensables., permitiendo a los fabricantes satisfacer las demandas modernas de calidad y velocidad. Pero, ¿qué hace que una máquina de corte por láser industrial sea tan vital?, y ¿cómo pueden las empresas aprovechar sus capacidades para alcanzar la excelencia en la producción??

En este artículo, Exploraremos todo lo relacionado con las máquinas de corte por láser industriales, desde sus principios de funcionamiento hasta sus aplicaciones clave., Los factores a considerar al comprar uno., y el futuro de la tecnología de corte por láser. Si es un fabricante experimentado o alguien que explora este campo por primera vez, Esta guía proporcionará información valiosa sobre esta tecnología transformadora..

1.¿Qué es una máquina de corte por láser industrial??

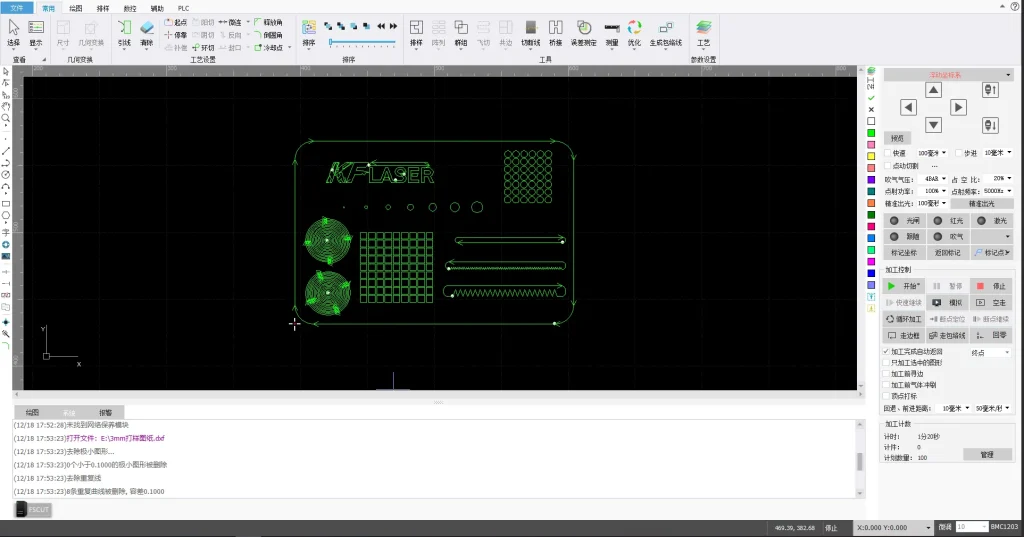

En su núcleo, Una máquina de corte por láser industrial es una herramienta controlada por computadora que utiliza un rayo láser concentrado para cortar., grabar, o grabar materiales con extrema precisión. Estas máquinas dependen del control numérico por computadora. (CNC) tecnología, que traduce las instrucciones de diseño en movimientos precisos del rayo láser, asegurando cortes y formas precisos en todo momento.

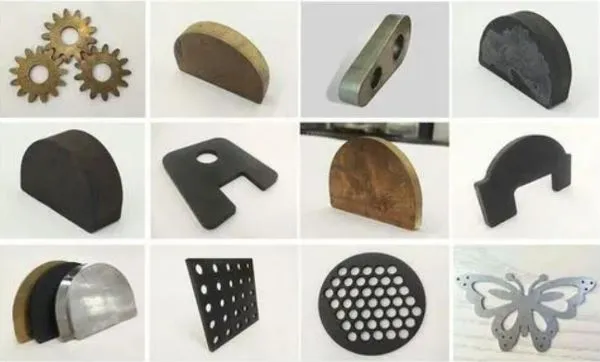

Las máquinas de corte por láser industriales no se limitan a un solo tipo de material. Pueden trabajar en metales., plástica, madera, vaso, e incluso materiales compuestos, convirtiéndolos en herramientas versátiles para diversas industrias. Pero lo que los distingue es su precisión incomparable., velocidad, y capacidad para manejar diseños complejos que las herramientas de corte tradicionales luchan por lograr.

2.¿Cómo funciona una máquina de corte por láser industrial??

El funcionamiento de una máquina de corte por láser industrial se basa en los siguientes pasos:

1. Creación de diseño:

un archivo de diseño, normalmente en formatos como DXF o DWG, se crea usando CAD (Diseño asistido por computadora) software. Este archivo contiene las instrucciones específicas para la forma y dimensiones del corte..

2. Conversión de datos:

Luego, el diseño se convierte a un formato legible por máquina utilizando CAM. (Fabricación asistida por computadora) software, que genera el código CNC para guiar el movimiento del láser.

3. Preparación de materiales:

El material elegido se coloca de forma segura en la plataforma de corte de la máquina para garantizar la estabilidad durante el proceso de corte..

4. Generación láser:

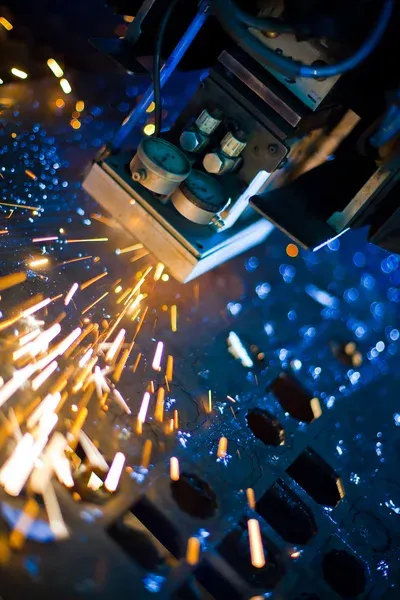

La fuente láser genera un haz de luz de alta potencia., que se enfoca a través de lentes o cables de fibra óptica para crear un punto de calor concentrado capaz de fundir, incendio, o vaporizar el material.

5. Proceso de corte:

El cabezal láser controlado por CNC se mueve a través del material siguiendo la ruta programada, realizar cortes precisos basados en el archivo de diseño.

6. Ayudar al uso de gas:

Gases como el oxígeno., nitrógeno, o aire comprimido se utilizan a menudo para eliminar el material fundido y mejorar la eficiencia y calidad del corte..

7. Inspección de calidad:

Una vez completado el proceso de corte, Las piezas terminadas se inspeccionan para garantizar que cumplan con las especificaciones requeridas..

3.Tipos de máquinas de corte por láser industriales

Existen varios tipos de máquinas de corte por láser industriales., cada uno diseñado para aplicaciones y materiales específicos. Los tres tipos más comunes son:

1. Máquinas de corte por láser de CO2

Los láseres de CO2 se encuentran entre las primeras y más utilizadas tecnologías de corte por láser.. Usan una mezcla de gases. (principalmente dióxido de carbono) para producir un rayo láser. Estas máquinas son ideales para cortar materiales no metálicos como la madera., acrílico, y plasticos, así como metales finos.

Ventajas:

– Rentable para materiales no metálicos

– Excelente calidad de borde en metales más gruesos

– Adecuado para grabado y grabado.

Limitaciones:

– Capacidad limitada para cortar materiales altamente reflectantes como aluminio y cobre.

– Mayores requisitos de mantenimiento debido a espejos y ópticas.

2. Máquinas de corte por láser de fibra

Los láseres de fibra utilizan una fuente láser de estado sólido y fibras ópticas para amplificar el rayo láser.. Estas máquinas destacan por su eficiencia y son especialmente efectivas para cortar metales., incluyendo acero inoxidable, aluminio, y latón.

Ventajas:

– Velocidades de corte más rápidas, especialmente para metales finos

– Bajo mantenimiento con menos piezas móviles

– Capaz de cortar materiales reflectantes.

Limitaciones:

– Inversión inicial más alta

– Menos eficaz para materiales no metálicos.

3. Máquinas de corte por láser de cristal

Láseres de cristal, como Nd:YAG y Nd:Yvo, utilizar cristales como medio láser. Son adecuados para el corte de alta precisión de metales y cerámicas, pero se utilizan con menos frecuencia debido a sus mayores costos operativos..

Ventajas:

– Alta potencia para cortar materiales más gruesos

– Adecuado para bien, trabajo detallado

Limitaciones:

– Mantenimiento costoso debido a la corta vida útil de los cristales.

– No es tan eficiente energéticamente como los láseres de fibra

4.Aplicaciones de las máquinas de corte por láser industriales

Las máquinas de corte por láser industriales se utilizan en una amplia gama de industrias debido a su versatilidad y precisión.. Estas son algunas de las aplicaciones clave.:

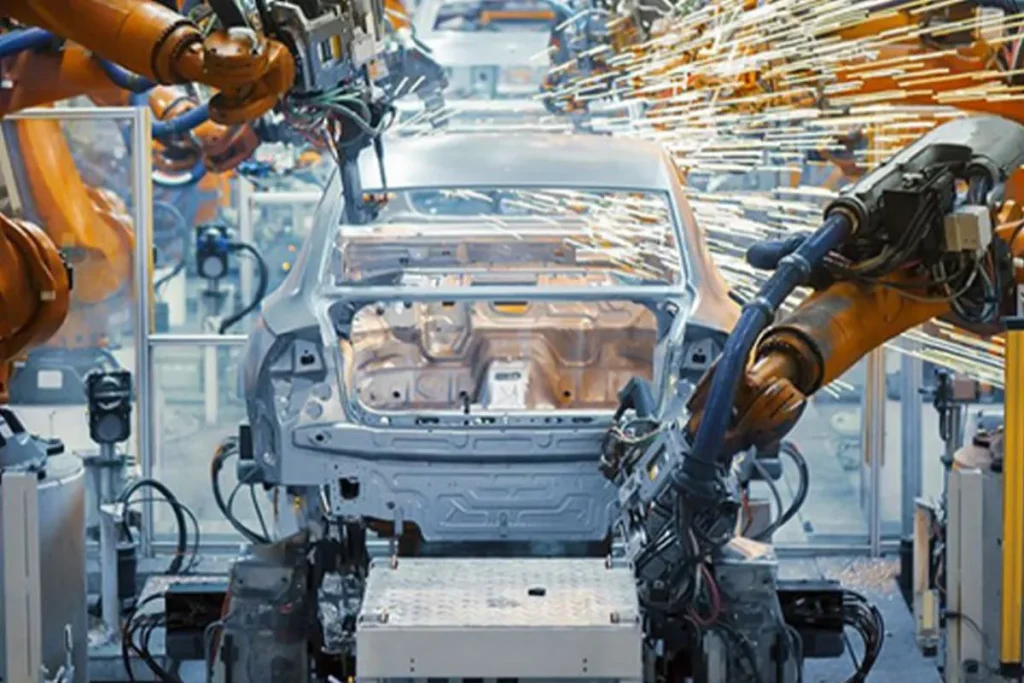

1. Industria automotriz

– Cortar y dar forma a los paneles de la carrocería.

– Fabricación de componentes de motor.

– Fabricación de piezas personalizadas para vehículos.

2. Industria aeroespacial

– Cortar materiales ligeros como titanio y composites

– Fabricación de componentes de precisión para aviones.

– Grabado de números de serie y marcas de identificación.

3. Construcción y Arquitectura

– Creación de intrincados diseños metálicos para elementos arquitectónicos.

– Fabricación de estructuras de acero para edificios.

– Fabricación de paneles decorativos y barandillas.

4. Industria Electrónica

– Corte y grabado de placas de circuito

– Fabricación de disipadores de calor y conectores.

– Corte de precisión para la fabricación de semiconductores

5. Fabricación de dispositivos médicos

– Producir instrumentos quirúrgicos con diseños complejos.

– Fabricación de implantes y prótesis.

– Grabado de marcas de identificación en herramientas médicas.

6. Fabricación de joyas

– Elaboración de diseños complejos en metales preciosos.

– Grabado de patrones y mensajes personalizados.

– Creando piezas ligeras pero duraderas

7. Sector de energías renovables

– Fabricación de componentes para aerogeneradores y paneles solares.

– Cortar formas precisas para sistemas de almacenamiento de energía

– Fabricación de piezas para pilas de combustible de hidrógeno.

5.Ventajas de las máquinas de corte por láser industriales

1. Alta precisión y exactitud

Las máquinas de corte por láser industriales pueden alcanzar tolerancias tan estrictas como ±0,01 mm, asegurando el más alto nivel de precisión para diseños complejos.

2. Velocidad y eficiencia

El corte por láser es significativamente más rápido que los métodos tradicionales, especialmente para materiales delgados. Esto reduce el tiempo de producción y aumenta la eficiencia general..

3. Versatilidad

Estas máquinas pueden cortar una amplia variedad de materiales., desde metales y plásticos hasta vidrio y madera, haciéndolos ideales para diversas industrias.

4. Desperdicio mínimo de material

El rayo láser enfocado crea cortes estrechos, Maximizar la utilización del material y minimizar el desperdicio..

5. Proceso sin contacto

El proceso de corte por láser no entra en contacto físico con el material., reduciendo el desgaste de las herramientas y eliminando el riesgo de distorsión del material.

6. Postprocesamiento reducido

Los bordes cortados con láser son limpios y lisos., a menudo eliminando la necesidad de procesos de acabado adicionales como rectificado o desbarbado.

6.Factores a considerar al elegir una máquina de corte por láser industrial

1. Tipo de material: Determine los materiales que cortará con más frecuencia y elija el tipo de láser correspondiente..

2. Espesor de corte: Asegúrese de que la máquina tenga la potencia necesaria para cortar los materiales más gruesos con los que trabaja..

3. Requisitos de precisión: Para diseños complejos, opte por una máquina con alta precisión y calidad de haz.

4. Velocidad de corte: Considere el volumen de producción y seleccione una máquina con la velocidad adecuada para satisfacer sus necesidades..

5. Costos de mantenimiento y operación: Evaluar el costo total de propiedad, incluyendo mantenimiento y consumibles como gases auxiliares.

6. Compatibilidad de software: Asegúrese de que el software de la máquina se integre perfectamente con sus sistemas de diseño y fabricación existentes..

7. Opciones de automatización: Para producción de gran volumen, Busque máquinas con capacidades de corte y manipulación de materiales automatizadas..

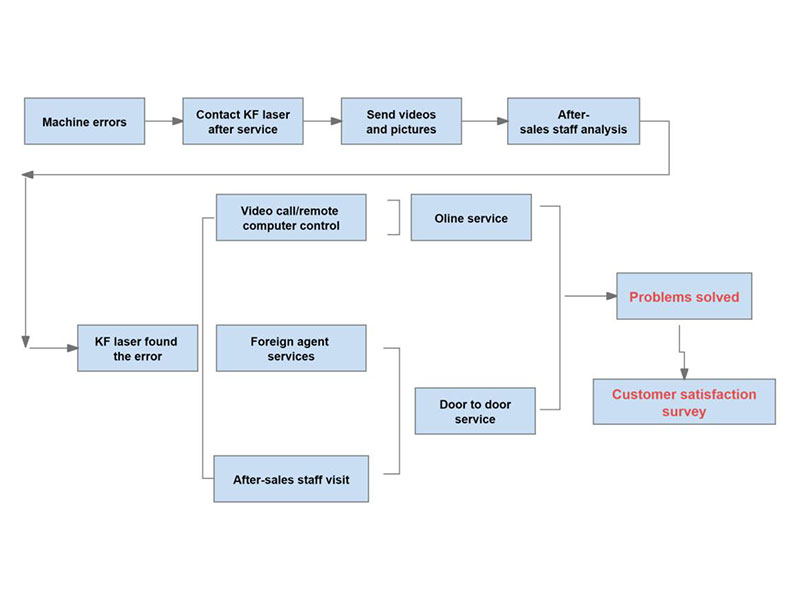

8. Soporte técnico y garantía: Elija un proveedor como KF LASER que ofrezca soporte técnico sólido y una garantía integral.

La mejor opción para máquinas de corte por láser industriales.

Para más información, por favor visite el sitio web de la página de inicio

Entra ahora7.El futuro de las máquinas de corte por láser industriales

El futuro de las máquinas de corte por láser industriales es prometedor, con avances centrados en la automatización, Integración de IA, y mayor eficiencia energética. Las tendencias emergentes incluyen:

1. Máquinas más inteligentes:

Sistemas impulsados por IA capaces de optimizar las rutas de corte, predecir las necesidades de mantenimiento, y minimizando el tiempo de inactividad.

2. Soluciones ecológicas:

Desarrollo de láseres con menor consumo energético y componentes reciclables para reducir la huella ambiental.

3. 3D cortando láser:

Ampliación de capacidades de corte tridimensional para geometrías más complejas en aplicaciones automotrices y aeroespaciales..

4. Máquinas híbridas:

Combinando el corte por láser con otras tecnologías como la fabricación aditiva para ofrecer soluciones multifuncionales.

5. Mayor accesibilidad:

A medida que los costos disminuyen, Más pequeñas y medianas empresas adoptarán la tecnología de corte por láser., impulsando la innovación en todas las industrias.

**Conclusión**

Sin duda, las máquinas de corte por láser industriales han remodelado el panorama manufacturero., ofreciendo una precisión inigualable, velocidad, y versatilidad. Entendiendo sus capacidades y manteniéndose informado sobre los últimos avances., Las empresas pueden aprovechar todo el potencial de esta tecnología transformadora para seguir siendo competitivas en un mercado en constante evolución..

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora