News

4KW Fiber Laser Cutter: The Ultimate Guide to Precision Cutting in 2025

A 4kw fiber laser cutter isn’t just a tool—it’s a revolution in metal fabrication. In an industry where milliseconds and millimeters define success, this machine stands at the crossroads of power and precision, redefining what’s possible for manufacturers, fabricators, and artisans alike. Whether you’re cutting thick steel plates for industrial machinery or intricate aluminum components for aerospace, the 4kw fiber laser cutter delivers results that were once reserved for high-end industrial setups, now accessible to small and medium enterprises (SMEs) and large factories alike. But what makes this technology so transformative? Why has it become the go-to choice for professionals seeking to balance speed, quality, and operational costs? This guide dives deep into the world of 4kw fiber laser cutters, unpacking their mechanics, advantages, applications, and critical considerations for anyone looking to invest in or optimize their cutting processes.

The Evolution of Laser Cutting: Why 4KW Fiber Lasers Are Dominating the Market

Laser cutting technology has come a long way since its inception in the 1960s. From CO2 lasers that revolutionized wood and plastic cutting to Nd:YAG lasers for metalworking, each iteration brought incremental improvements. But the rise of fiber laser technology in the early 2000s marked a paradigm shift—and the 4kw fiber laser cutter is its most impactful manifestation yet.

Fiber lasers differ from their predecessors in one key aspect: they use optical fibers doped with rare-earth elements (like erbium or ytterbium) to amplify light, rather than gas or crystal mediums. This design eliminates many of the inefficiencies of older lasers. For instance, CO2 lasers lose up to 30% of their energy through mirrors and tubes, while fiber lasers boast an energy efficiency rate of 25-30%—meaning more power is directed toward the material, not wasted as heat. This efficiency translates directly to cost savings: a 4kw fiber laser cutter consumes up to 70% less electricity than a comparable CO2 laser, making it a sustainable choice for businesses aiming to reduce their carbon footprint and utility bills.

But why 4kw specifically? Power matters in laser cutting, but it’s not just about raw force. The 4kw range strikes a sweet spot between versatility and practicality. It can handle materials from 0.5mm thin sheets to 25mm thick steel with ease, making it suitable for diverse applications—from automotive parts and construction beams to decorative metal art and electronics enclosures. Higher-powered lasers (6kw or 10kw) exist, but they often require specialized infrastructure (like reinforced flooring and advanced cooling systems) and are overkill for most SMEs. Lower-powered options (1-2kw) struggle with thicker materials, limiting their industrial utility. The 4kw fiber laser cutter, in contrast, adapts to both high-volume production runs and custom, low-batch projects, making it the workhorse of modern fabrication shops.

How a 4KW Fiber Laser Cutter Works: Breaking Down the Science

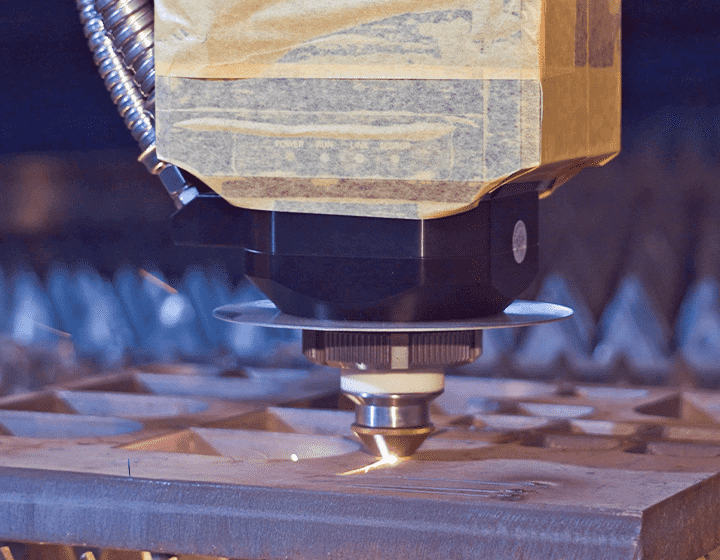

To truly appreciate the capabilities of a 4kw fiber laser cutter, it helps to understand its inner workings. At its core, the machine converts electrical energy into a focused beam of light that melts, burns, or vaporizes material with pinpoint accuracy. Here’s a step-by-step breakdown of the process:

- Pump Diodes Generate photons: The system starts with high-power pump diodes, which emit light at specific wavelengths (typically around 915nm or 976nm). These diodes act like “energy injectors,” supplying the initial light needed to kickstart the laser generation process.

- Optical Fiber Amplifies the Beam: The light from the pump diodes travels through a doped optical fiber—usually made of silica glass mixed with ytterbium ions. As the photons pass through the fiber, they collide with the ytterbium ions, exciting them to a higher energy state. When these ions relax back to their ground state, they emit photons of the same wavelength, phase, and direction as the original light—a process called stimulated emission. This chain reaction amplifies the beam exponentially, resulting in a high-intensity laser.

- Beam Delivery System Focuses the Light: The amplified laser beam exits the fiber and travels through a beam delivery system, which includes mirrors and a focusing lens. This system narrows the beam to a tiny spot (often as small as 0.1mm in diameter) at the material’s surface. The smaller the spot size, the higher the energy density—meaning the laser can cut through thicker materials or create finer details.

- Material Interaction: Melting, Vaporization, or Ablation: When the focused beam hits the material, its energy is absorbed, raising the temperature to extreme levels (thousands of degrees Celsius). For metals like steel or aluminum, the laser melts the material, and a high-pressure assist gas (usually oxygen, nitrogen, or air) blows away the molten debris, leaving a clean cut. For non-metals or thin materials, the laser may vaporize the material directly or cause ablation (removal of material layer by layer).

- CNC Control Ensures Precision: The entire process is controlled by a computer numerical control (CNC) system, which interprets design files (like CAD or DXF) and guides the laser head along the cutting path with sub-micrometer accuracy. Modern 4kw fiber laser cutters can achieve positioning accuracies of ±0.03mm and repeatability of ±0.01mm—critical for applications where parts must fit together with zero tolerance.

Key Considerations When Investing in a 4KW Fiber Laser Cutter

While a 4kw fiber laser cutter offers numerous benefits, it’s not a one-size-fits-all solution. To ensure you make the right investment, consider these critical factors:

1. Material Thickness and Type

First, assess your typical cutting needs. What’s the thickest material you regularly work with? A 4kw laser can handle up to 25mm mild steel, 15mm stainless steel, and 10mm aluminum under optimal conditions. If you frequently cut materials thicker than this (e.g., 30mm steel), you may need a higher-powered laser (6kw or more). Conversely, if you only cut thin sheets (up to 5mm), a 3kw model might be more cost-effective.

2. Work Area Size

4kw fiber laser cutters come with various bed sizes, ranging from 1.5m x 3m (common for SMEs) to 3m x 6m (for large-scale production). Choose a bed size that matches your largest sheets to minimize material waste and reduce the need for multiple setups. If you handle mixed batch sizes, look for machines with automatic sheet loading/unloading systems to save time on material handling.

3. Cooling Requirements

High-power lasers generate significant heat, so a robust cooling system is essential. Most 4kw fiber lasers use closed-loop water chillers, which maintain a stable temperature to prevent overheating and ensure consistent cutting performance. Consider the chiller’s cooling capacity (measured in kW) and whether it’s air-cooled or water-cooled—air-cooled units are easier to install but less efficient for large machines.

4. Software and Ease of Use

The best laser cutter is only as good as its software. Look for intuitive CNC control systems that support common design file formats (DXF, DWG, AI) and offer features like nesting optimization (to minimize material waste), real-time cutting simulation, and remote monitoring. Training is also a factor: ensure the manufacturer provides comprehensive training for your operators, or partner with a supplier that offers ongoing technical support.

5. Budget and Total Cost of Ownership (TCO)

The upfront cost of a 4kw fiber laser cutter ranges from 80,000to80,000to250,000, depending on bed size, automation features, and brand. But TCO includes more than just the purchase price—factor in:

- Installation costs: Electrical upgrades (most 4kw lasers require 3-phase power), floor reinforcement, and ventilation systems.

- Consumables: Focusing lenses, protective windows, assist gases (oxygen, nitrogen), and fume extraction filters.

- Maintenance: Regular service (typically annual) and unexpected repairs.

- Training: Operator and technician training to maximize productivity and minimize downtime.

Many manufacturers offer financing options or lease-to-own programs, which can help spread the cost over time.

Advantages of a 4KW Fiber Laser Cutter: Why It Outperforms Traditional Cutting Methods

The 4kw fiber laser cutter isn’t just another tool in the fabrication shop—it’s a upgrade that touches every aspect of production, from speed and quality to cost and sustainability. Let’s explore its key advantages over traditional methods like plasma cutting, waterjet cutting, and mechanical sawing:

1. Unmatched Speed and Productivity

Speed is where fiber lasers truly shine. A 4kw fiber laser cutter can cut 10mm mild steel at speeds up to 30 meters per minute—three times faster than a plasma cutter and five times faster than a waterjet system. For high-volume production, this translates to shorter lead times, higher throughput, and the ability to take on more orders without expanding labor or equipment. Even for thick materials (e.g., 20mm steel), the 4kw laser maintains impressive speeds, often outpacing mechanical methods by 200-300%.

2. Superior Cut Quality and Precision

Traditional cutting methods often leave rough edges, burrs, or heat-affected zones (HAZs)—areas where the material’s properties are altered by excessive heat. A 4kw fiber laser cutter minimizes these issues thanks to its focused beam and controlled heat input. The result is a smooth, burr-free edge with a HAZ as narrow as 0.05mm, reducing the need for post-processing (like grinding or sanding). This precision is a game-changer for industries like automotive and aerospace, where part tolerances are measured in microns.

3. Versatility Across Materials

While 4kw fiber lasers are primarily used for metals, they excel with a wide range of materials, including:

- Ferrous metals: Mild steel, stainless steel, carbon steel.

- Non-ferrous metals: Aluminum, copper, brass, titanium.

- Alloys: Nickel alloys, Hastelloy, Inconel (used in high-temperature applications).

- Thin non-metals: Polycarbonate, acrylic, and certain composites (with specialized settings).

This versatility eliminates the need for multiple machines, saving floor space and simplifying workflow. A single 4kw fiber laser cutter can handle everything from thin-sheet metal signage to thick structural beams, making it ideal for job shops with diverse client needs.

4. Lower Operational Costs

At first glance, a 4kw fiber laser cutter may seem like a significant investment, but its long-term cost savings are undeniable. Here’s why:

- Energy Efficiency: As mentioned earlier, fiber lasers use up to 70% less electricity than CO2 lasers and 50% less than plasma cutters. For a machine running 8 hours a day, this can save thousands of dollars annually in utility bills.

- Reduced Consumables: Unlike plasma cutters, which require electrodes and nozzles, or waterjets, which need abrasive garnet, fiber lasers have minimal consumables. The main wear items are the focusing lens and protective window, which typically last 6-12 months and cost a few hundred dollars to replace.

- Lower Labor Costs: The CNC-controlled automation reduces the need for skilled operators. One technician can oversee multiple machines, and the elimination of post-processing steps (like deburring) cuts down on manual labor.

5. Environmental Benefits

Sustainability is no longer a buzzword—it’s a business imperative. 4kw fiber laser cutters align with green manufacturing goals in several ways:

- Reduced Waste: The precision cutting minimizes material waste, as the narrow kerf (the width of the cut) leaves more usable material on the sheet.

- No Toxic Emissions: Unlike plasma cutting, which can release harmful fumes, or waterjets, which generate silt waste, fiber laser cutting produces minimal emissions (easily captured by fume extraction systems).

- Energy Efficiency: Lower electricity usage reduces the carbon footprint, making it easier for businesses to meet environmental regulations and ESG targets.

Applications of 4KW Fiber Laser Cutters: Where They Excel

The 4kw fiber laser cutter’s blend of power, precision, and versatility has made it indispensable across industries. Here are some of the most impactful applications:

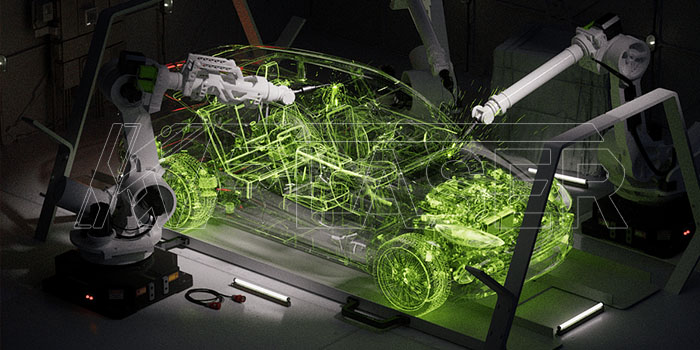

Automotive Manufacturing

From chassis components and engine parts to body panels and exhaust systems, the automotive industry relies on 4kw fiber lasers for high-speed, high-precision cutting. The ability to handle both thin aluminum sheets (for lightweighting) and thick steel brackets (for structural strength) makes these machines a staple in automotive plants. Additionally, their speed supports just-in-time (JIT) production models, reducing inventory costs and improving efficiency.

Aerospace and Defense

Aerospace applications demand materials like titanium, Inconel, and carbon fiber composites—all of which are challenging to cut with traditional methods. 4kw fiber lasers tackle these materials with ease, creating intricate parts like turbine blades, fuel lines, and satellite components. The minimal HAZ is critical here, as heat-affected zones can weaken materials in high-stress environments.

Construction and Architecture

In construction, 4kw fiber lasers cut structural steel beams, rebar, and decorative metal elements (like facades and railings). For architects, they enable complex designs that were once impossible or prohibitively expensive—think curved steel panels for modern skyscrapers or custom metal artwork for public spaces. The speed of these machines also helps meet tight construction deadlines, even for large-scale projects.

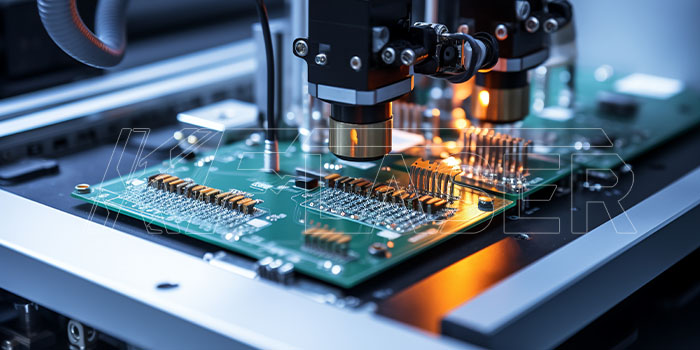

Electronics and Precision Engineering

The electronics industry requires tiny, precise parts like heat sinks, sensor housings, and circuit board enclosures. 4kw fiber lasers cut these components with micron-level accuracy, ensuring proper fit and function. Their ability to work with thin copper and aluminum sheets (used in heat dissipation) makes them ideal for devices like smartphones, laptops, and medical equipment.

Art and Custom Fabrication

Beyond industrial applications, 4kw fiber lasers are empowering artists and custom fabricators to push creative boundaries. From metal sculptures and signage to custom furniture and jewelry, the precision and speed of these machines allow for intricate designs that would take weeks to create by hand. Small businesses and artisans now have access to the same technology as large factories, democratizing metal fabrication.

Key Considerations When Investing in a 4KW Fiber Laser Cutter

While a 4kw fiber laser cutter offers numerous benefits, it’s not a one-size-fits-all solution. To ensure you make the right investment, consider these critical factors:

1. Material Thickness and Type

First, assess your typical cutting needs. What’s the thickest material you regularly work with? A 4kw laser can handle up to 25mm mild steel, 15mm stainless steel, and 10mm aluminum under optimal conditions. If you frequently cut materials thicker than this (e.g., 30mm steel), you may need a higher-powered laser (6kw or more). Conversely, if you only cut thin sheets (up to 5mm), a 3kw model might be more cost-effective.

2. Work Area Size

4kw fiber laser cutters come with various bed sizes, ranging from 1.5m x 3m (common for SMEs) to 3m x 6m (for large-scale production). Choose a bed size that matches your largest sheets to minimize material waste and reduce the need for multiple setups. If you handle mixed batch sizes, look for machines with automatic sheet loading/unloading systems to save time on material handling.

3. Cooling Requirements

High-power lasers generate significant heat, so a robust cooling system is essential. Most 4kw fiber lasers use closed-loop water chillers, which maintain a stable temperature to prevent overheating and ensure consistent cutting performance. Consider the chiller’s cooling capacity (measured in kW) and whether it’s air-cooled or water-cooled—air-cooled units are easier to install but less efficient for large machines.

4. Software and Ease of Use

The best laser cutter is only as good as its software. Look for intuitive CNC control systems that support common design file formats (DXF, DWG, AI) and offer features like nesting optimization (to minimize material waste), real-time cutting simulation, and remote monitoring. Training is also a factor: ensure the manufacturer provides comprehensive training for your operators, or partner with a supplier that offers ongoing technical support.

5. Budget and Total Cost of Ownership (TCO)

The upfront cost of a 4kw fiber laser cutter ranges from 80,000to80,000to250,000, depending on bed size, automation features, and brand. But TCO includes more than just the purchase price—factor in:

- Installation costs: Electrical upgrades (most 4kw lasers require 3-phase power), floor reinforcement, and ventilation systems.

- Consumables: Focusing lenses, protective windows, assist gases (oxygen, nitrogen), and fume extraction filters.

- Maintenance: Regular service (typically annual) and unexpected repairs.

- Training: Operator and technician training to maximize productivity and minimize downtime.

Many manufacturers offer financing options or lease-to-own programs, which can help spread the cost over time.

Maximizing Performance: Tips for Optimizing Your 4KW Fiber Laser Cutter

Once you’ve invested in a 4kw fiber laser cutter, proper operation and maintenance are key to unlocking its full potential. Here are actionable tips to optimize performance:

1. Choose the Right Assist Gas

The assist gas plays a critical role in cutting quality and speed. For most metals:

- Oxygen: Ideal for mild steel, as it reacts with the metal to produce additional heat (exothermic reaction), increasing cutting speed. However, it can leave a thin oxide layer on the edge, which may require post-processing.

- Nitrogen: Used for stainless steel, aluminum, and other non-ferrous metals to prevent oxidation. It produces clean, bright edges but is more expensive than oxygen.

- Air: A cost-effective option for low-carbon steel and non-critical applications, but may result in slightly rougher edges.

Experiment with gas pressure and flow rates—too little pressure can cause dross (molten metal residue) on the bottom of the cut, while too much can distort thin materials.

2. Maintain Optimal Lens Condition

The focusing lens is the heart of the beam delivery system, and even minor damage (like scratches or dirt) can degrade cutting quality. Clean the lens daily with a lint-free cloth and lens cleaner, and replace it immediately if you notice cracks or pitting. A damaged lens not only reduces precision but can also cause heat to build up in the laser head, leading to costly repairs.

3. Calibrate the Machine Regularly

Over time, vibrations, temperature changes, and normal wear can misalign the beam delivery system or shift the bed position. Schedule monthly calibration checks to ensure the laser is focused correctly and the cutting path matches the design files. Most CNC systems have built-in calibration tools, but for critical applications, consider hiring a professional service technician annually.

4. Optimize Cutting Parameters

Every material and thickness requires specific parameters, including laser power, cutting speed, frequency, and pulse width. Start with the manufacturer’s recommended settings, but don’t be afraid to experiment. For example, increasing the frequency for thin aluminum can reduce spatter, while lowering the speed for thick steel can improve edge quality. Keep a log of successful parameter combinations to build a “recipe book” for future jobs.

5. Invest in Fume Extraction

Laser cutting produces metal fumes, which can be harmful to operators and damaging to the machine. Install a high-quality fume extraction system with a HEPA filter to capture particles and ensure a safe working environment. Proper ventilation also prevents fumes from coating the lens and mirrors, reducing maintenance needs.

The Future of 4KW Fiber Laser Cutting: What’s Next?

As technology advances, 4kw fiber laser cutters are poised to become even more powerful, efficient, and accessible. Here are some trends to watch:

1. Increased Automation

The next generation of 4kw fiber lasers will integrate advanced automation features, such as AI-powered nesting (to maximize material utilization), robotic loading/unloading arms, and real-time defect detection (using cameras and machine learning). These upgrades will reduce reliance on manual labor, further lowering costs and improving consistency.

2. Higher Power Density

Manufacturers are developing fiber lasers with higher beam quality (measured by M² factor), allowing for even smaller spot sizes and higher energy density. This will enable 4kw lasers to cut thicker materials (approaching 30mm steel) and create finer details, blurring the line between 4kw and higher-powered models.

3. Integration with Industry 4.0

Industry 4.0 (the fourth industrial revolution) focuses on smart manufacturing, where machines communicate with each other and with central systems in real time. Future 4kw fiber lasers will connect to cloud-based platforms, allowing

Mastering Metal: Why 4kW Fiber Lasers Are Reshaping Industrial Cutting (And How to Choose Wisely)

The relentless hum of fabrication shops is getting a powerful upgrade. Forget struggling with plasma limitations or slower lasers on demanding jobs. The 4kW fiber laser cutter isn’t just another tool; it’s a strategic leap in precision, speed, and capability for serious metalworkers. Forget generic specs – let’s cut straight to what really matters for your bottom line.

The Operator’s Dilemma: When Your Current Setup Hits Its Wall

You know the frustration. That rush order for 1/2″ stainless plates piles up because your 2kW machine crawls, needing multiple passes and chewing through consumables. Plasma leaves bevelled edges needing costly secondary finishing. Oxy-fuel? Slow and imprecise. Downtime for nozzle changes or lens cleaning eats into profits. The bottleneck is real, and the market demands faster turnaround and tighter tolerances. This is where the 4kW fiber laser steps in – not as a luxury, but as the new competitive baseline.

Why 4kW? The Sweet Spot Unlocked

Think of 4kW as the industrial workhorse sweet spot. It bridges the gap between lower-power machines (great for thin sheet) and ultra-high-power beasts (expensive overkill for many). Here’s what this powerhouse actually delivers on the shop floor:

- Conquering Thickness with Authority:Suddenly, 16mm (5/8″) mild steel, 12mm (1/2″) stainless steel, and 10mm aluminum become efficient, single-pass realities. No more outsourcing thick plates or suffering glacial speeds. This directly expands your service offerings and wins bigger contracts.

- Blistering Speed, Even on Thinner Gauges:Don’t think it’s just for thick stuff. On 3mm mild steel, a 4kW can be 2-3x faster than a 2kW laser. Imagine doubling your throughput on popular gauge materials overnight. That’s raw productivity translating to profit.

- Sharper Edges, Less Hassle:Higher power often means less dross and a cleaner cut edge, especially on thicker materials. This reduces post-processing time significantly – less grinding, smoother edges ready for welding or assembly. Superior cut quality enhances your reputation.

- Unmatched Versatility:From intricate designs on delicate 22-gauge brass to powering through structural A36 plate, the 4kW handles a dizzying array of jobs without constant machine changeovers. It’s the ultimate “one machine for (almost) all” solution in medium-to-heavy fabrication.

- ROI You Can Actually Calculate:While the initial investment is higher than lower kW machines, the dramatic gains in cutting speed, reduced labor for secondary operations, and ability to tackle high-margin thick-metal jobs mean payback periods are often surprisingly aggressive. Factor in minimal consumables compared to plasma.

Real-World Applications: Where 4kW Shines (Literally)

This isn’t theoretical. Walk into any shop leveraging a 4kW effectively, and you’ll see:

- Heavy Equipment & Agriculture:Robust brackets, thick chassis parts, wear plates, harvester components cut swiftly and accurately.

- Construction & Infrastructure:Structural beams (up to limitations), flanges, thick brackets, custom architectural elements with complex profiles.

- Transportation & Trailers:Axle components, reinforced suspension parts, heavy-duty trailer frames and fittings.

- Energy & Mining:Durable housings, machinery parts, thick support structures built to last.

- Job Shops Thriving:Handling diverse client demands efficiently, from thin decorative pieces to hefty industrial parts without skipping a beat.

Choosing Your 4kW Champion: Beyond the Brochure Hype

Buying a laser is a major commitment. Don’t just look at the price tag and power rating. Dig deeper:

- The Heart: The Fiber Source:Not all 4kW sources are equal. IPG, Raycus, Max, JPT? Research reliability, power stability over time (critical for edge quality), and service support. Demand real-world cut samples at your required thicknesses.

- Motion & Mechanics:Precision bearings, robust linear guides, and a rigid gantry structure are non-negotiable for consistent accuracy, especially at speed on thick material. A flimsy frame paired with 4kW is a recipe for vibration and poor cuts.

- Control System & Software:An intuitive, powerful controller (like CypCut, PA, Siemens) is your daily interface. Look for features like efficient nesting (nesting software integration is key), collision avoidance, comprehensive process databases, and ease of use for operators. Can it handle complex DXF files flawlessly?

- Cooling & Chiller:4kW generates serious heat. A high-capacity, reliable chiller is critical to prevent power dips and protect your investment. Don’t underspec this!

- Table & Exhaust:A sturdy table supporting the high acceleration and heavy sheets is essential. Powerful fume extraction keeps the optics clean and the work environment safe. Consider downdraft vs. crossflow based on your typical sheet sizes and materials.

- Service & Support:What’s the local service network like? Response time? Parts availability? This is often the make-or-break factor long-term. Talk to existing customers.

4kW vs. The Competition: Cutting Through the Noise

- 3kW:A significant jump in thick-metal capability and speed. If you regularly cut above 10mm mild steel, 4kW is a game-changer.

- 6kW+:For many shops, 6kW offers diminishing returns on investment unless cutting very thick material (20mm+ consistently). The 4kW provides most of the heavy-duty capability at a more accessible price point with lower operating costs (power consumption, chiller load).

- Plasma:Laser wins hands-down on precision, edge quality, speed (on thinner/thick!), and operating costs (no gases!). Plasma might still edge out on extremely thick sections (>25mm) cost-effectively, but with significant quality trade-offs.

- Waterjet:Laser is exponentially faster for metals and doesn’t require abrasive. Waterjet wins for non-metals or metals where zero heat-affected zone (HAZ) is critical. Laser operating costs are generally lower.

The Future-Proof Investment

Choosing a 4kW fiber laser isn’t just buying a machine; it’s upgrading your entire fabrication capability. It empowers you to:

- Win More Bids:Quote competitively on thicker, more complex jobs previously outsourced.

- Boost Profit Margins:Slash cutting times and secondary processing costs.

- Increase Capacity:Handle higher volumes with the same footprint.

- Enhance Quality:Deliver superior cut edges that impress customers.

- Stay Competitive:Keep pace with industry standards moving towards higher power efficiency.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine