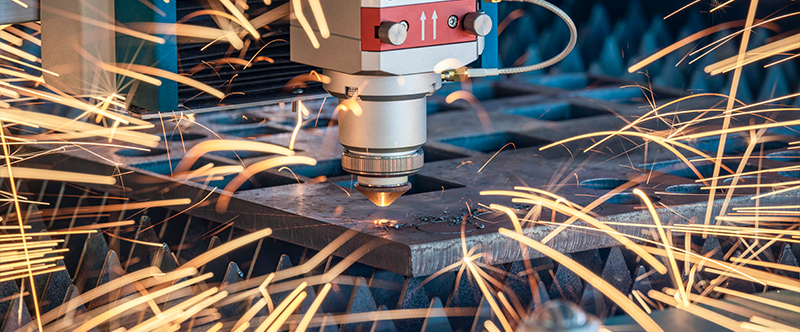

Fiber laser cutting machines have revolutionized the manufacturing landscape, offering unparalleled efficiency, precision, and versatility. These machines utilize the advanced technology of fiber optics to deliver cutting-edge solutions for metal processing. The following comprehensive guide will delve into the features, benefits, and applications of fiber laser cutting machines, while ensuring optimal SEO performance by incorporating the keyword “fiber laser cutting machine” throughout the content.

Fiber laser cutting machines are designed to provide high-speed and high-precision cutting for a wide range of materials, particularly metals. The key to their effectiveness lies in the wavelength of the laser, which allows for efficient absorption by metals, resulting in faster and cleaner cuts. Unlike traditional cutting methods, fiber laser technology offers a non-contact process, minimizing wear and tear on the machine while ensuring consistent quality.

Fiber laser cutting machines offer several advantages over other cutting technologies. These include:

– Speed and Precision: The fiber laser cutting machine is capable of cutting at high speeds, significantly reducing production time while maintaining precision.

– Versatility: It can cut various metals, including stainless steel, aluminum, copper, and brass, making it suitable for diverse applications.

– Cost-Efficiency: With minimal maintenance requirements and lower power consumption, fiber laser cutting machines offer a cost-effective solution for metal fabrication.

– High Quality: The technology ensures smooth edges and high accuracy, reducing the need for secondary processing.

When comparing fiber laser cutting machines to CO2 lasers, several distinctions emerge:

– Wavelength Efficiency: Fiber lasers operate at a wavelength that is more readily absorbed by metals, leading to faster and more efficient cutting. In contrast, CO2 lasers, with a longer wavelength, are less effective at cutting metals and are better suited for non-metal materials.

– Heat Affected Zone (HAZ): The smaller HAZ in fiber laser cutting results in less thermal distortion, ensuring higher-quality cuts.

– Operational Costs: Fiber laser cutting machines generally have lower operating costs due to reduced power consumption and minimal maintenance needs.

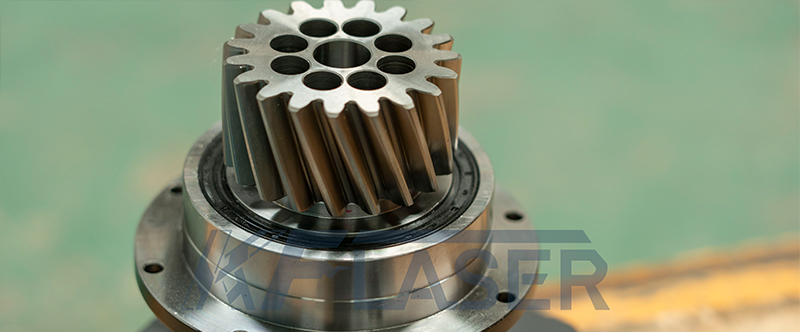

Fiber laser cutting machines are used across various industries, including automotive, aerospace, electronics, and construction. Their ability to cut a wide range of metals with precision makes them indispensable in these sectors.

– Automotive Industry: Fiber laser cutting machines are used to cut complex shapes and components with high accuracy, essential for vehicle manufacturing.

– Aerospace: The precision and reliability of fiber lasers make them ideal for cutting lightweight, high-strength materials used in aircraft construction.

– Electronics: These machines are used to cut intricate components required in electronic devices, ensuring consistency and quality.

– Construction: Fiber laser cutting machines are employed in cutting structural steel and other metals used in building frameworks and infrastructure.

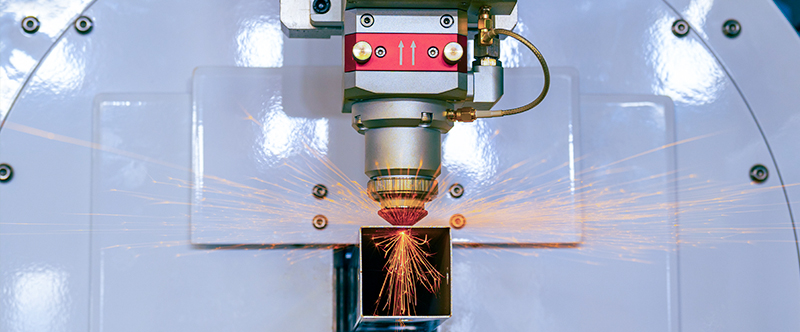

The evolution of fiber laser cutting technology has led to several innovations that enhance performance and usability:

– Advanced Motion Systems: Modern fiber laser cutting machines are equipped with advanced motion systems that ensure smooth and precise movement, contributing to higher accuracy in cuts.

– Innovative Beam Delivery: The latest fiber laser cutting machines feature innovative beam delivery systems that optimize the focus and intensity of the laser, resulting in faster cutting speeds and improved quality.

– Automation Integration: Fiber laser cutting machines can be easily integrated into automated production lines, maximizing productivity and reducing labor costs.

One of the significant advantages of fiber laser cutting machines is their low maintenance requirements. With no consumable gases and minimal wear on components, these machines are designed for long-term use. Additionally, the solid-state architecture of fiber lasers contributes to their durability, ensuring consistent performance over time.

– Routine Checks: Regular inspection of the laser’s optics and cooling system can help maintain optimal performance.

– Software Updates: Keeping the machine’s software up to date ensures that it operates with the latest features and improvements.

– Operator Training: Proper training for operators can extend the lifespan of the machine by ensuring it is used correctly and efficiently.

Fiber laser cutting machines offer an environmentally friendly alternative to traditional cutting methods. Their energy efficiency and low waste production contribute to a smaller carbon footprint. Moreover, the precision of fiber laser cutting reduces material waste, further enhancing its environmental benefits.

– Energy Efficiency: Fiber lasers consume less energy than other cutting technologies, reducing overall power consumption.

– Material Conservation: The accuracy of fiber laser cutting minimizes the amount of material wasted during the cutting process.

– Reduced Emissions: With no need for consumable gases, fiber laser cutting machines produce fewer emissions, contributing to a cleaner work environment.

Selecting the right fiber laser cutting machine depends on several factors, including the type of material being cut, the thickness of the material, and the required precision.

– Material Compatibility: Ensure the machine is compatible with the types of metals you intend to cut. Fiber lasers are particularly effective for cutting reflective metals like aluminum and copper.

– Power Requirements: Consider the power output of the laser, which affects cutting speed and thickness capabilities.

– Cutting Speed and Accuracy: Evaluate the machine’s cutting speed and accuracy to ensure it meets your production needs.

As technology continues to advance, fiber laser cutting machines are expected to evolve, offering even greater efficiency and capabilities.

– AI Integration: The integration of artificial intelligence in fiber laser cutting machines could enhance precision and automate complex cutting tasks.

– Improved Beam Quality: Future developments may focus on improving beam quality, allowing for even finer cuts and faster processing speeds.

– Sustainability Enhancements: As environmental concerns grow, future fiber laser cutting machines may incorporate more sustainable practices, such as using renewable energy sources.

Fiber laser cutting machines represent the pinnacle of modern manufacturing technology. Their speed, precision, and versatility make them an essential tool for industries ranging from automotive to aerospace. As technology continues to advance, these machines will only become more powerful and efficient, solidifying their place at the forefront of metal fabrication.

By understanding the capabilities and advantages of fiber laser cutting machines, manufacturers can make informed decisions that will enhance productivity, reduce costs, and improve overall product quality. Whether for large-scale industrial applications or intricate design work, fiber laser cutting machines are the optimal choice for any metal cutting needs.