▼ In today’s manufacturing landscape, the use of sheet metal for laser cutting has become an essential component in achieving high precision, speed, and material efficiency. With industries ranging from automotive to aerospace, the need for exacting cuts and shapes is more critical than ever. Laser cutting technology, especially when paired with high-quality sheet metal, has revolutionized the way companies produce intricate parts and components.

By using sheet metal for laser cutting, businesses can minimize waste, enhance productivity, and ensure that each part meets the exact specifications required. Unlike traditional cutting methods, laser cutting uses a focused laser beam to cut through materials with minimal physical contact, offering a cleaner, more accurate alternative.

Sheet metal is the material of choice for laser cutting due to several inherent properties that make it ideal for this process. The key benefits of using sheet metal for laser cutting include:

★ Precision and Accuracy

One of the most significant advantages of using sheet metal for laser cutting is the high level of precision and accuracy that laser machines can achieve. The focused laser beam ensures that cuts are sharp and exact, which is especially important when manufacturing parts that need to fit together with other components. The minimal heat-affected zone (HAZ) further ensures that the material remains free from warping or distortion, making it a top choice for industries where tolerances are tight.

★ Speed and Efficiency

Laser cutting is known for its speed, especially when compared to traditional mechanical cutting methods. The sheet metal for laser cutting process can cut through various thicknesses of metal at high speeds without compromising on quality. This increased efficiency not only speeds up the production process but also reduces operational costs, ultimately benefiting manufacturers’ bottom lines.

★ Minimal Material Waste

Unlike traditional cutting techniques, which often result in significant material wastage, laser cutting is highly efficient in terms of material usage. By cutting with minimal kerf (the width of the cut), laser machines can help manufacturers maximize the use of each sheet of metal. This efficiency leads to cost savings, especially when working with expensive metals like stainless steel or titanium.

★ Ability to Cut Complex Shapes

Laser cutting technology excels at producing complex shapes and intricate designs with a high degree of accuracy. Sheet metal for laser cutting allows manufacturers to achieve patterns that would be difficult, if not impossible, to replicate using traditional cutting methods. The flexibility of the laser cutting process means that designs can be altered or customized quickly and easily without the need for new tooling or setups.

★ Low Maintenance and Longer Tool Life

Laser cutting machines require less maintenance than traditional cutting machines, which often have moving parts that wear out over time. The laser head itself does not make contact with the material, meaning there’s less wear and tear on the machine, extending its lifespan and reducing maintenance costs.

The advantages of using sheet metal for laser cutting have made it a vital component in many industries. Here are some of the primary applications where laser cutting plays a crucial role:

Automotive Industry

In the automotive sector, precision and speed are paramount. Laser cutting enables manufacturers to produce complex, high-quality parts such as body panels, structural components, and brackets quickly and accurately. By using sheet metal for laser cutting, automakers can improve their production efficiency and meet the stringent quality standards required in the industry.

Aerospace Industry

The aerospace industry demands the highest levels of precision and material integrity. Laser cutting allows for the production of parts like engine components, brackets, and structural elements from materials such as aluminum, titanium, and stainless steel. The ability to cut complex geometries and handle various thicknesses of sheet metal makes laser cutting essential for this industry.

Electronics Manufacturing

For the electronics industry, laser cutting is used to create enclosures, heat sinks, and other components with intricate designs. By utilizing sheet metal for laser cutting, manufacturers can produce these parts with a high degree of accuracy and without the need for additional finishing processes. This ensures that the components meet the tight tolerances required for electronic devices.

Medical Device Manufacturing

In the medical field, precision is a non-negotiable factor. Sheet metal for laser cutting is used to create surgical tools, medical devices, and implants with extreme precision. The technology allows for the creation of small, complex parts with minimal risk of contamination or material defects, which is essential for ensuring patient safety.

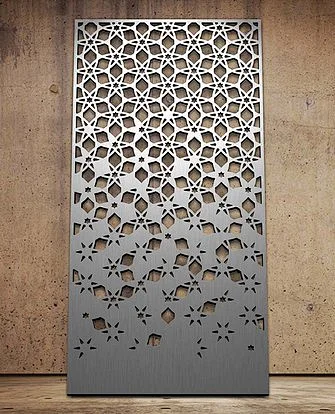

Architectural Design

Laser cutting has also found applications in architectural design, where sheet metal for laser cutting is used to create intricate facades, decorative panels, and custom installations. The ability to achieve highly detailed cuts in metal sheets allows architects and designers to push the boundaries of creative expression while maintaining structural integrity.

Not all types of sheet metal are suitable for laser cutting, and selecting the right material is critical for achieving the desired results. The most common metals used in laser cutting include:

✔Stainless Steel

Stainless steel is one of the most popular materials used for laser cutting due to its strength, corrosion resistance, and ability to withstand high temperatures. It is commonly used in industries such as aerospace, automotive, and medical device manufacturing.

✔Aluminum

Aluminum is a lightweight, corrosion-resistant material that is often used in industries where weight reduction is crucial, such as aerospace and automotive. Laser cutting can handle aluminum with ease, producing clean cuts without the need for extensive post-processing.

✔Mild Steel

Mild steel is a versatile and cost-effective material used in a variety of industries, including construction and fabrication. Laser cutting can quickly and accurately process mild steel, providing manufacturers with high-quality cuts at an affordable price.

✔Titanium

Titanium, known for its high strength-to-weight ratio and corrosion resistance, is often used in specialized industries such as aerospace and medical device manufacturing. Laser cutting is particularly effective in cutting titanium, providing clean, precise cuts that are crucial for applications requiring exceptional material properties.

The field of sheet metal for laser cutting is continually evolving, with ongoing advancements in laser technology, automation, and material science. The introduction of fiber lasers has already improved cutting speed and material efficiency, and further developments in AI-driven optimization and machine learning are expected to increase efficiency and precision even further.

As industries continue to push the boundaries of what is possible in manufacturing, the role of sheet metal for laser cutting will only become more significant. With the ongoing improvements in laser technology, manufacturers can look forward to even greater possibilities in terms of speed, accuracy, and material savings.

The sheet metal for laser cutting process has become a cornerstone of modern manufacturing. Its precision, efficiency, and versatility have transformed industries across the globe, making it a must-have technology for any manufacturer looking to stay competitive in today’s fast-paced market.