Laser cutting metal sheets is a technology that has rapidly gained momentum in the manufacturing world, transforming industries by offering unparalleled precision, speed, and versatility. Whether it’s aerospace, automotive, or architectural design, laser cutting has become the go-to solution for achieving intricate designs, high-quality finishes, and minimal material waste. The process uses focused laser beams to cut metal with such accuracy that it has redefined the limits of what can be achieved in metalworking.

In a world where efficiency and quality are paramount, laser cutting offers a clear advantage. Laser cutting metal sheets allows manufacturers to produce complex shapes and cuts with precision that traditional methods simply cannot match. As this technology evolves, industries across the globe are adopting it as a cornerstone for their manufacturing processes.

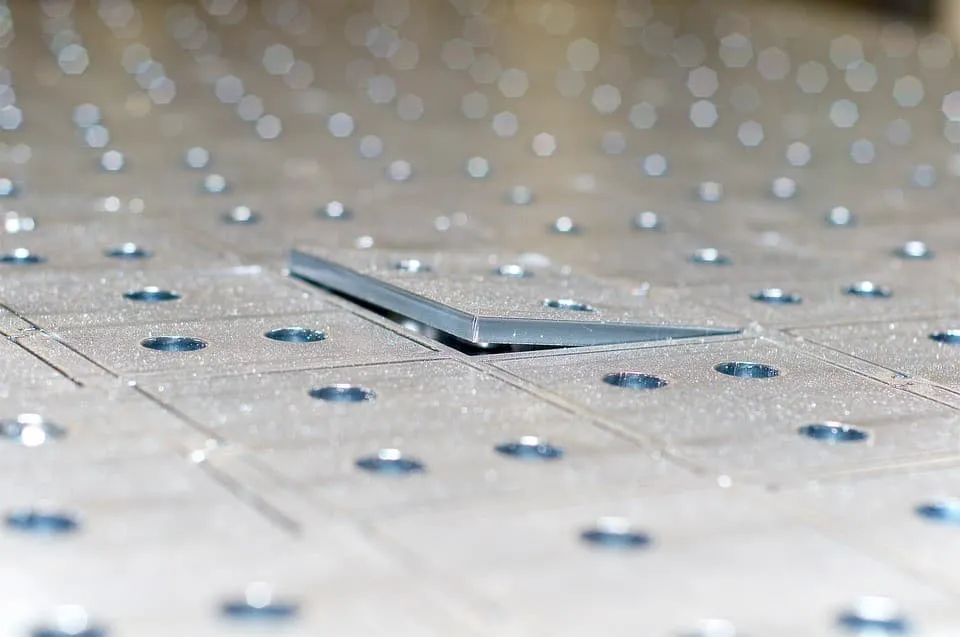

Laser cutting involves focusing a laser beam onto the material, causing it to melt, burn, or vaporize depending on the thickness and type of metal. The result is a cut with clean edges and minimal material wastage. This method is preferred over traditional cutting methods for several key reasons.

✔Exceptional Precision and Accuracy

One of the primary reasons laser cutting metal sheets is so popular is its ability to produce extremely accurate cuts. With tolerances as tight as 0.1 mm, laser cutting ensures that the final product meets the most exacting standards. This precision is crucial in industries where even the smallest error can lead to product failure, such as in aerospace and medical device manufacturing.

Laser cutting allows designers and manufacturers to work with highly intricate patterns and shapes that would be difficult, if not impossible, to achieve with conventional cutting methods. As such, laser cutting metal sheets is ideal for industries requiring high-precision components, such as the electronics and automotive sectors.

✔Speed and Efficiency

Compared to traditional methods, laser cutting metal sheets is faster and more efficient. The cutting process is automated, reducing human error and accelerating production times. Laser machines can operate continuously, offering high throughput without compromising on quality.

The high speed of laser cutting is especially beneficial in industries where production time is critical, such as in automotive manufacturing or custom fabrication. Faster turnaround times mean companies can meet tight deadlines and reduce lead times, all while maintaining exceptional quality standards.

✔Minimal Material Waste

In the manufacturing world, material costs are a significant expense. One of the standout benefits of laser cutting metal sheets is its ability to minimize material wastage. Unlike traditional cutting methods, where excess material is often lost, laser cutting uses a narrow beam that reduces kerf width. This leads to more efficient use of raw materials, saving money and reducing environmental impact.

For industries that work with expensive metals, such as titanium or stainless steel, the reduction of waste can significantly improve overall cost-effectiveness. By optimizing material use, manufacturers can produce more components with less material, increasing profitability while lowering environmental footprints.

✔Clean Cuts with Smooth Edges

The precision of laser cutting also ensures that the edges of laser cut metal sheets are smooth and clean, requiring little to no post-processing. This is especially important in applications where a polished finish is required, such as in decorative metalwork or components used in high-performance machinery. Traditional cutting methods often leave jagged or rough edges, necessitating additional finishing processes like grinding or sanding.

The ability to produce clean, smooth edges directly from the laser cutting process helps save time and costs, as well as reduces the need for further labor and equipment.

The versatility and benefits of laser cutting metal sheets make it an ideal solution for a wide range of industries. Some of the sectors that are taking full advantage of this technology include:

Automotive Industry

In the automotive industry, laser cutting metal sheets plays a critical role in the production of vehicle body panels, structural components, and exhaust systems. The precision and speed of laser cutting allow manufacturers to produce high-quality, lightweight parts that meet the rigorous demands of the automotive sector. Moreover, the ability to produce complex designs without compromising on strength or functionality is a significant advantage for car manufacturers seeking to create innovative and efficient vehicles.

Aerospace Industry

The aerospace industry relies heavily on laser cutting metal sheets for producing parts that require both high precision and strength. Components such as wing brackets, fuselage panels, and engine parts are often made using laser cutting, as the technology can produce the tight tolerances needed for these critical components. Laser cutting also allows aerospace manufacturers to reduce weight and increase the overall efficiency of their designs.

Architecture and Construction

In the architecture and construction industries, laser cutting metal sheets is used to create intricate facades, structural reinforcements, and decorative elements. Architects and designers use laser cutting to transform raw metal sheets into works of art, combining form with function. This ability to work with metal in highly customized ways has revolutionized the architectural industry, allowing for innovative designs and construction techniques.

Medical Industry

Medical device manufacturers benefit from laser cutting metal sheets for producing precision components such as surgical tools, implants, and diagnostic devices. The cleanliness and accuracy of laser cuts ensure that these components meet stringent safety and quality standards. In the medical field, even the smallest error can have significant consequences, making laser cutting an essential technology for producing safe and reliable products.

Electronics Manufacturing

In the electronics sector, laser cutting metal sheets is used to fabricate metal enclosures, heat sinks, and connectors that require a high level of precision. The clean cuts and fast turnaround times offered by laser cutting are crucial in the production of electronic devices, where time and accuracy are of the essence.

As industries continue to evolve, the demand for precision and efficiency in manufacturing will only increase. Laser cutting technology has proven time and again that it is capable of delivering these qualities, making it a vital tool for the future of manufacturing. The constant development of new laser types, such as fiber lasers, promises even faster speeds, greater energy efficiency, and improved quality.

Moreover, the integration of artificial intelligence (AI) and machine learning into laser cutting processes will further optimize production times and material usage. As a result, laser cutting metal sheets will continue to play a pivotal role in industries across the globe, from automotive to aerospace, electronics, and beyond.

In conclusion, laser cutting metal sheets offers unparalleled advantages in terms of precision, speed, material efficiency, and cost-effectiveness. As the technology continues to evolve, it will remain at the forefront of the metalworking industry, driving innovation and shaping the future of manufacturing.

By leveraging laser cutting metal sheets, businesses can stay ahead of the competition, increase operational efficiency, and produce high-quality products that meet the demands of today’s fast-paced, innovation-driven world.