News

Best Software for Laser Cutting: Top Solutions for Precision and Efficiency

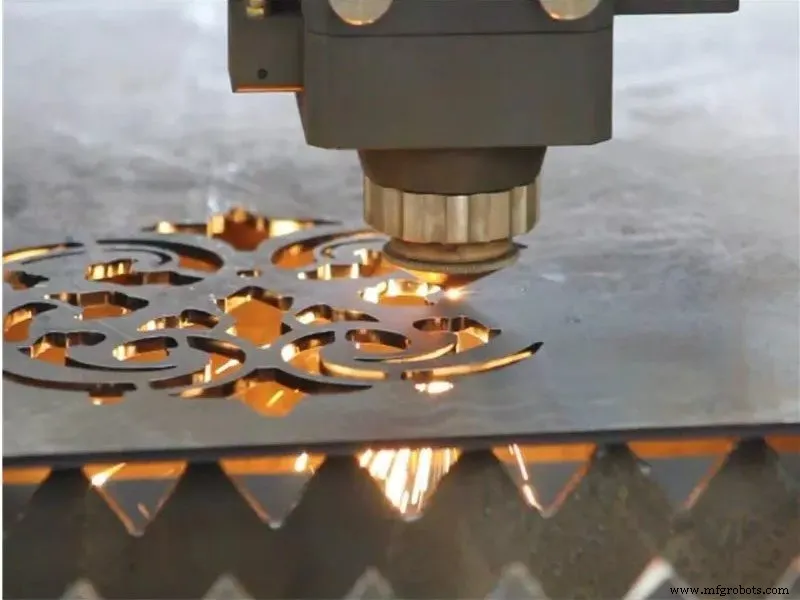

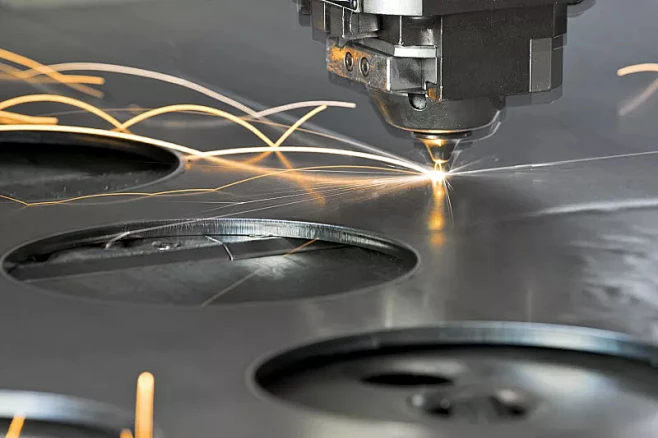

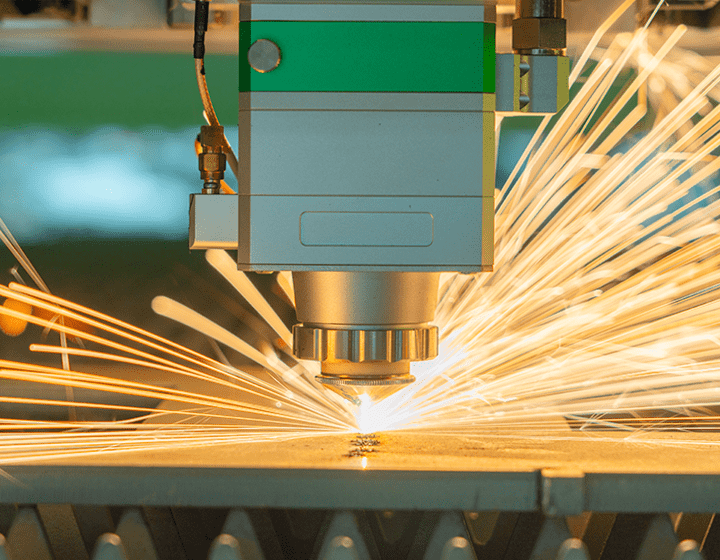

In the world of laser cutting, choosing the right software is crucial to achieving high precision, efficiency, and seamless operation. Whether you are working with metal, wood, or acrylic, the software that controls your laser cutting machine plays a vital role in determining the quality of your cuts, the speed of production, and overall workflow efficiency. In this article, we will explore the best software for laser cutting, highlighting key features, benefits, and factors to consider when selecting the right solution for your needs.

Why is Choosing the Best Laser Cutting Software Important?

Laser cutting software is the bridge between your design files and the laser cutting machine. It converts the digital design into a format that the machine can read, controlling every aspect of the cutting process, including speed, power, path, and material handling. The right software can:

- Optimize cutting paths for faster production.

- Reduce waste and improve material usage.

- Provide real-timemonitoring for improved quality control.

- Enhance user experience with easy-to-understand interfaces.

- Allow for quick modifications and design adjustments.

With so many options available, it’s essential to choose software that aligns with your laser cutting machine’s capabilities and your business’s production needs.

Top 5 Best Software for Laser Cutting

Here are some of the best software options for laser cutting, each offering unique features tailored to different types of businesses and laser cutting applications:

1. LightBurn

Best for: Small to medium-sized businesses, hobbyists, and makers.

LightBurn is one of the most popular choices for laser cutting and engraving due to its versatility and user-friendly interface. It supports a wide range of laser machines and offers advanced features, such as vector editing, image tracing, and multiple layer management.

Key Features:

- Supports many laser cutters, including GRBL, Ruida, and Trocen controllers.

- Advanced tools for vector editing and image tracing.

- Real-time preview of cuts to optimize the cutting process.

- Advanced material management for better workflow.

- Built-in camera support for enhanced precision.

Why Choose LightBurn:

- Easy to use, even for beginners.

- Powerful editing tools, eliminating the need for additional CAD software.

- Cost-effective for small businesses or hobbyists.

2. AutoCAD with Laser Cutting Plugins

Best for: Professional designers and engineering teams.

AutoCAD is a widely used CAD software, and with the addition of laser cutting plugins (like the AutoCAD DXF plugin), it can seamlessly integrate into laser cutting workflows. This software is ideal for industries where precise and complex designs are required.

Key Features:

- Full support for 2D and 3D design.

- Customizable templates and libraries for laser cutting.

- Compatibility with DXF and DWG file formats.

- Integration with other engineering tools and software.

Why Choose AutoCAD:

- Industry-standard software for design and drafting.

- Ability to create detailed, complex designs.

- Flexible integration with other engineering software.

3. Fusion 360 (with CAM for Laser Cutting)

Best for: Engineers and designers who need both CAD and CAM capabilities.

Fusion 360 from Autodesk is a powerful cloud-based CAD/CAM solution. While it’s primarily known for its 3D modeling capabilities, Fusion 360 also supports laser cutting workflows, offering advanced features for both design and manufacturing.

Key Features:

- Cloud-based design and collaboration tools.

- CAM tools for laser cutting operations.

- Parametric design capabilities for precise engineering.

- Integrated tools for 3D modeling, simulation, and manufacturing.

Why Choose Fusion 360:

- Ideal for businesses needing both design and CAM functionality.

- Powerful simulation tools for testing designs before cutting.

- Cloud-based collaboration, allowing teams to work remotely.

4. RDWorks

Best for: Users with Ruida-controlled laser machines.

RDWorks is a popular software solution for laser cutting machines that use Ruida controllers. It’s widely used in many industries and offers a simple interface with powerful features, perfect for users who require straightforward operation without complex setup.

Key Features:

- Full support for Ruida laser controllers.

- Simple, intuitive interface with easy-to-navigate tools.

- Auto-generation of cutting paths and tool paths.

- Extensive support for various file formats (DXF, BMP, etc.).

Why Choose RDWorks:

- Ideal for users with Ruida controllers.

- Simple interface with quick setup.

- Reliable, consistent performance for everyday laser cutting tasks.

5. Inkscape (with Laser Cutting Plugin)

Best for: Hobbyists and makers looking for a free option.

Inkscape is a free, open-source vector graphics software that can be used for laser cutting when paired with a laser cutting plugin. It’s an excellent choice for those who want to get started with laser cutting without investing in expensive software.

Key Features:

- Free, open-source, and highly customizable.

- Supports SVG file format for laser cutting.

- Wide range of vector editing tools.

- Extensive library of plugins for enhanced functionality.

Why Choose Inkscape:

- Completely free to use.

- Perfect for small-scale projects and hobbyists.

- Easy to learn and user-friendly interface.

Factors to Consider When Choosing Laser Cutting Software

When selecting the best software for laser cutting, consider the following factors to ensure you get the most suitable solution for your needs:

1. Compatibility with Your Laser Cutter

Ensure that the software supports your specific laser cutting machine and its controller type. Some software may only work with certain models or brands, so compatibility is crucial for smooth operation.

2. Ease of Use

Look for software with an intuitive interface that reduces the learning curve. A simple, easy-to-navigate program will help your team get up and running quickly, reducing downtime.

3. Advanced Features

Depending on your needs, advanced features like image tracing, vector editing, 3D modeling, or automatic nesting can significantly enhance productivity. Consider the features that will benefit your specific applications.

4. Cost

While some software solutions come with a hefty price tag, others offer more affordable options or even free versions. Evaluate your budget and the value each software provides to your business.

5. Support and Updates

Ensure that the software provider offers adequate support and regular updates to address bugs, compatibility issues, and new feature releases. A responsive support team is essential for resolving issues quickly.

Conclusion

Selecting the best software for laser cutting is a critical decision for improving your production quality, efficiency, and workflow. Whether you are a hobbyist looking for an easy-to-use solution or a professional in need of advanced features, the options listed above provide a range of tools that can suit various business needs.

Investing in the right software can help you maximize the potential of your laser cutting machine, ensuring precise cuts, optimal material usage, and enhanced productivity. Choose a software solution that aligns with your needs, budget, and machine compatibility for the best results.

This guide is designed to help you make an informed decision when selecting laser cutting software, ensuring you get the right fit for your business and projects.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine