News

Unveiling the Power of the 3kW Fiber Laser

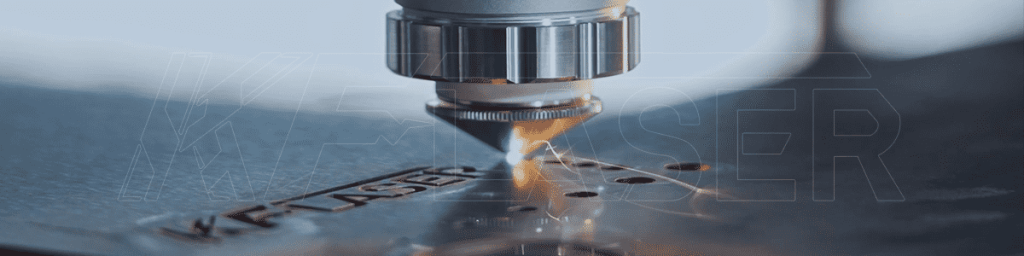

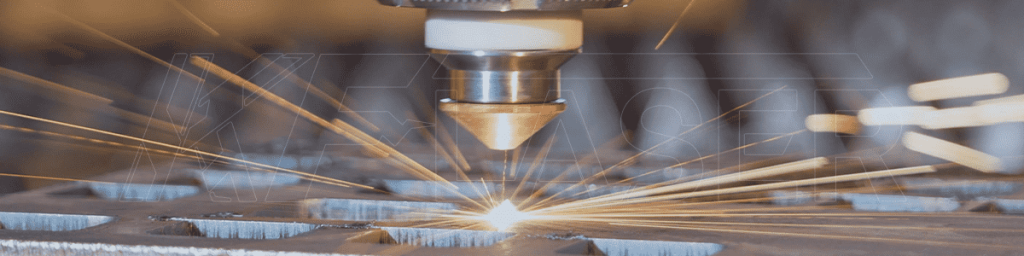

In today’s fast-evolving industrial landscape, the 3kW fiber laser stands as a game-changer in the world of precision cutting. Imagine a technology that merges speed, accuracy, and energy efficiency to provide the ultimate cutting experience—this is exactly what the 3kW fiber laser offers. As industries demand higher precision and quicker turnaround times, the 3kW fiber laser technology rises to the occasion, meeting and often exceeding these expectations.

But what makes this technology so remarkable? Why is it becoming an indispensable tool for industries across the globe? Let’s dive deeper into how this laser technology has transformed manufacturing processes, making them faster, smarter, and more cost-effective than ever before.

What Is a 3kW Fiber Laser?

A 3kW fiber laser is a type of solid-state laser that uses a fiber optic cable as the active medium for the laser beam. This technology is known for its remarkable cutting abilities, especially in metals like steel, aluminum, and brass. The “3kW” refers to the power output of the laser, making it a powerful tool for cutting through thick materials with ease.

Key Features of a 3kW Fiber Laser:

High Power Output: With a 3kW output, this laser can cut through materials up to 25mm in thickness with exceptional precision.

Energy Efficiency: Unlike CO2 lasers, fiber lasers are highly energy-efficient, converting more energy into the laser beam, which minimizes power consumption and operating costs.

Versatility: It can cut a variety of materials, including metals, plastics, and certain composites, making it a versatile tool for numerous industries.

Compact Design: Fiber lasers are more compact compared to other types, saving valuable floor space in busy production environments.

Advantages of the 3kW Fiber Laser for Cutting

1. Enhanced Precision and Accuracy

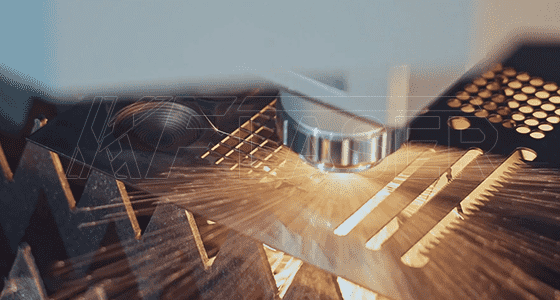

The primary advantage of a 3kW fiber laser lies in its precision. Fiber lasers produce a fine laser beam, enabling intricate and detailed cuts that would be difficult or impossible with traditional cutting methods. Whether it’s cutting complex geometries, intricate shapes, or fine details, this laser technology ensures every cut is made with pinpoint accuracy.

2. Faster Cutting Speeds

In comparison to CO2 lasers, the 3kW fiber laser operates at faster cutting speeds, especially for thinner materials. The advanced fiber optic technology allows for rapid material removal without compromising on quality. This translates into shorter production times and higher throughput for manufacturers.

3. Reduced Maintenance Costs

Fiber lasers have a much lower maintenance requirement than CO2 lasers. They don’t require frequent mirror alignments or lens cleaning. Their rugged design makes them more durable in the long run, reducing overall maintenance costs and downtime.

4. Superior Edge Quality

One of the key reasons many manufacturers prefer fiber lasers is the superior edge quality they provide. The concentrated energy of the laser beam results in clean, smooth edges without the need for secondary finishing processes.

5. Energy Efficiency

Fiber lasers are incredibly energy-efficient, consuming less power to operate than traditional laser systems. This makes them not only environmentally friendly but also more cost-effective over time, especially for high-volume cutting tasks.

Applications of the 3kW Fiber Laser

The 3kW fiber laser has found its place in various industries, revolutionizing how manufacturers approach material processing. Below are some of the key sectors that benefit from its cutting-edge technology:

1. Automotive Industry

In the automotive sector, precision cutting is critical for producing components that fit perfectly. From body panels to interior trim, the 3kW fiber laser is used to cut metal parts with high speed and accuracy. It is especially valuable for mass production, where consistency is key.

2. Aerospace Industry

The aerospace industry demands parts that meet stringent standards of quality and precision. The 3kW fiber laser excels in cutting lightweight alloys and composites, helping aerospace manufacturers create parts that are both strong and lightweight.

3. Sheet Metal Fabrication

Fiber lasers are ideal for cutting sheet metal, especially for industries that require high-speed production and a flawless finish. The 3kW fiber laser is highly effective in cutting steel, stainless steel, aluminum, and other materials commonly used in sheet metal fabrication.

4. Electronics Manufacturing

Precision cutting is also crucial in the electronics industry, particularly for components such as circuit boards and housings. The 3kW fiber laser ensures the clean cuts needed for sensitive electronic parts.

5. Medical Device Manufacturing

The medical device industry relies on lasers for cutting high-precision components for surgical instruments and other medical equipment. The 3kW fiber laser offers the precision and cleanliness needed in this highly regulated industry.

Factors to Consider When Choosing a 3kW Fiber Laser

While the 3kW fiber laser offers significant advantages, choosing the right one for your application requires careful consideration. Here are some key factors to keep in mind:

1. Material Thickness

Consider the thickness of the materials you intend to cut. The 3kW fiber laser is ideal for medium-thickness materials. For extremely thick materials, you may need a higher-powered laser.

2. Cutting Speed

If high production speed is a priority, the 3kW fiber laser is an excellent choice. However, for industries requiring ultra-fast cutting for thin materials, higher-powered lasers might offer better performance.

3. System Integration

Check how well the fiber laser integrates with your existing manufacturing system. Look for compatibility with software, automation systems, and material handling tools for a streamlined workflow.

4. Maintenance and Support

Investing in a 3kW fiber laser also means thinking about long-term support and service. Opt for suppliers that provide robust after-sales service, including training, maintenance, and troubleshooting.

The Future of Fiber Lasers in Manufacturing

The future of 3kW fiber lasers is brighter than ever, with continuous advancements in technology pushing the boundaries of what’s possible. As industries evolve, fiber lasers will only become more integrated into automated production lines, with higher powers and even greater efficiencies on the horizon.

Manufacturers can expect faster cutting times, even more accurate results, and lower costs as new innovations in fiber laser technology continue to emerge. As such, the 3kW fiber laser is not just a tool for today; it’s a stepping stone to the future of precision manufacturing.

By embracing the power of the 3kW fiber laser, industries are not only improving their manufacturing processes but also preparing for a future where efficiency and precision are paramount. This revolutionary technology is transforming the way products are made, ensuring a competitive edge for those who adopt it.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine