Noticias

The Power Behind Precision – High Power Fiber Laser Cutting Machines

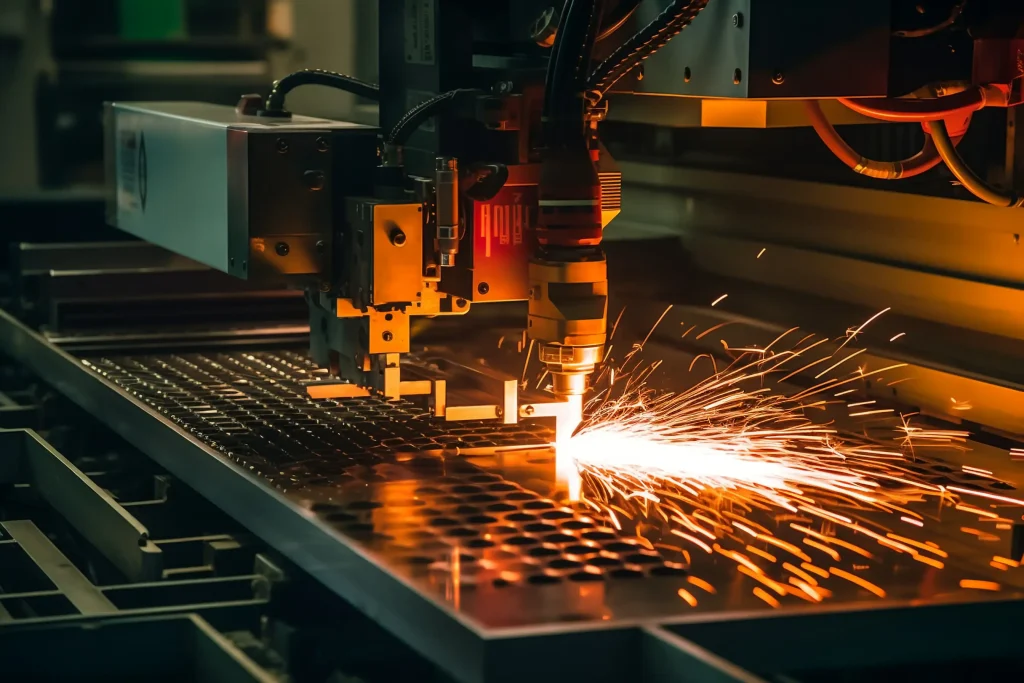

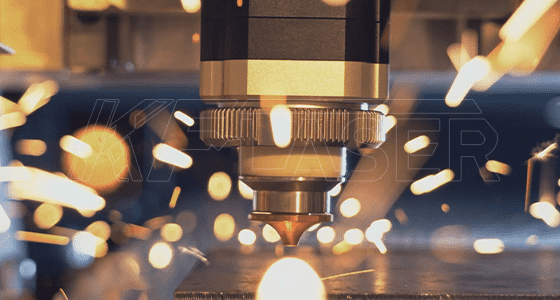

In today’s world of advanced manufacturing, precisión, velocidad, and cost-efficiency are paramount. Enter the high power fiber laser cutting machine – a technological marvel that has revolutionized how industries cut, forma, and process metals and other materials. Whether you’re in aerospace, automotor, or general manufacturing, understanding the capabilities of these machines can drastically enhance your operations. This article dives deep into the significance, ventajas, and cost-efficiency of high power fiber laser cutting machines, helping you make informed decisions for your business needs.

What is a High Power Fiber Laser Cutting Machine?

A high power fiber laser cutting machine uses fiber optic technology to deliver intense laser beams, capable of cutting through thick materials with unmatched precision. Unlike traditional CO2 lasers, fiber lasers are more efficient, require less maintenance, and provide better beam quality. El “high power” aspect refers to the machine’s ability to operate with increased wattage, often ranging from 1 kW to 15 kW or more, allowing it to cut through thicker materials with ease.

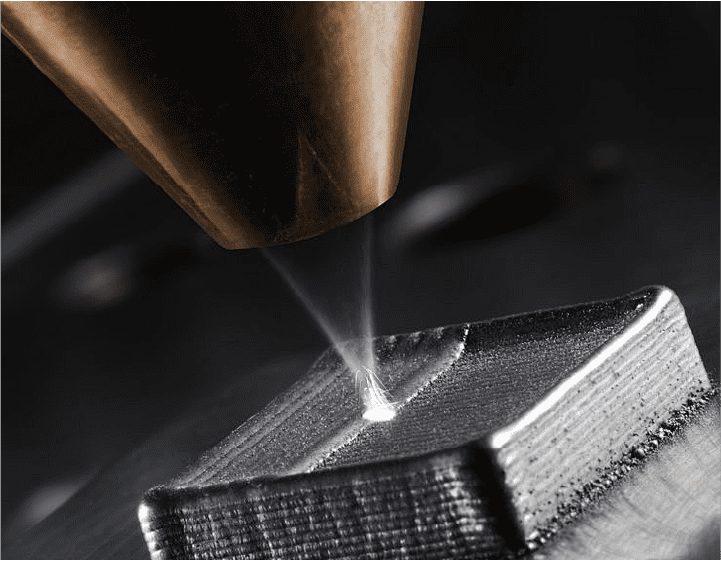

How High Power Fiber Laser Cutting Machines Work

High power fiber lasers utilize a solid-state laser source, where the light is generated by an optical fiber doped with rare-earth elements like ytterbium. The laser light is then amplified and directed through fiber optics, creating a high-energy beam that can focus on a very small point. This concentrated heat energy melts or vaporizes the material, providing an efficient and precise cutting method. What sets high power fiber lasers apart is their ability to cut through metals as thick as 30 mm or more, which is ideal for industries requiring high precision and speed.

Advantages of High Power Fiber Laser Cutting Machines

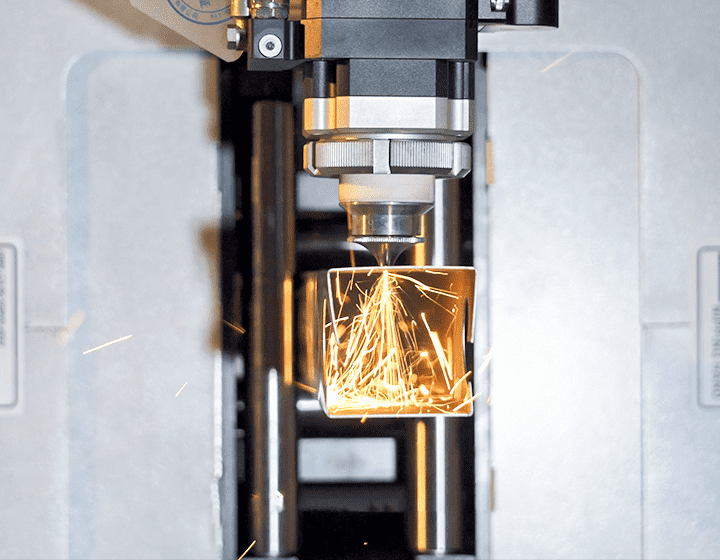

1. Precisión y calidad

The ability to focus the laser beam on a small spot ensures exceptional cutting accuracy. Whether it’s intricate designs or heavy-duty cuts, a high power fiber laser cutting machine offers consistent and flawless results with minimal burr formation.

2. Faster Processing Times

The power of the fiber laser cuts through materials at a much faster rate compared to traditional methods, boosting production efficiency. The high wattage capacity also means these machines can handle a wide range of thicknesses, from thin sheets to thick plates, reducing operational delays.

3. Eficiencia energética

Compared to older technologies like CO2 lasers, fiber lasers consume less power while delivering higher output. This energy efficiency can translate into significant savings over time, making fiber lasers a cost-effective investment for companies focused on sustainability and profit.

4. Bajo mantenimiento

High power fiber laser cutting machines require minimal maintenance due to the simplicity and robustness of the fiber-optic components. There are no mirrors to align or lenses to clean, reducing downtime and operational costs.

5. Versatilidad

These machines can cut a variety of metals, incluyendo acero inoxidable, aluminio, titanio, and mild steel, making them a versatile choice for a wide range of industries. The adaptability of high power fiber lasers ensures their suitability for cutting not just metal but other materials like plastics, madera, and ceramics.

How High Power Fiber Lasers Are Changing the Industry

The impact of high power fiber laser cutting machines can be felt across several industries:

Aeroespacial: The need for high precision and the ability to cut through thick materials quickly makes fiber lasers a game-changer in aerospace manufacturing, where every part must meet stringent specifications.

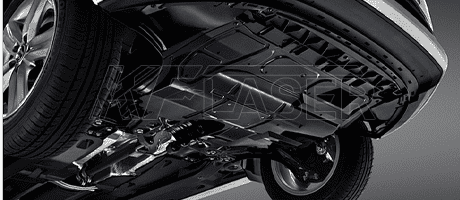

Automotor: With the growing demand for lightweight and durable vehicles, high power fiber lasers allow manufacturers to cut and weld parts with high accuracy and minimal waste, speeding up production cycles.

Heavy Equipment: The construction and heavy machinery sectors benefit from high power fiber lasers’ ability to handle tough materials with precision, reducing the need for post-processing.

Dispositivos médicos: Fiber laser cutting machines are essential in the production of high-precision medical equipment, where intricate designs and precision are critical.

Factors Affecting the Cost of High Power Fiber Laser Cutting Machines

When considering a high power fiber laser cutting machine, the cost can vary greatly depending on several factors:

1. Power Output

The higher the power output, the more expensive the machine. Machines with power levels ranging from 1 kW to 6 kW are often considered entry-level, while machines with power levels above 6 kW can cost significantly more due to their ability to cut through thicker materials.

2. Tipo de material y espesor

Machines capable of cutting specific materials (like stainless steel or titanium) or materials of different thicknesses can impact the cost. Machines with advanced capabilities for thicker or more difficult materials typically come with higher price tags.

3. Brand and Features

While this article does not focus on specific brands, it’s important to note that the reputation of the manufacturer, along with additional features such as automated loading and unloading, higher beam quality, or advanced software capabilities, can significantly affect pricing.

4. Maintenance and Service Contracts

Some manufacturers offer service contracts that cover regular maintenance, software updates, and emergency repairs. These additional services can increase the overall cost of ownership but ensure long-term reliability and performance.

Calculating the ROI of High Power Fiber Laser Cutting Machines

The return on investment (retorno de la inversión) for a high power fiber laser cutting machine should not be measured solely by the initial purchase price. Consider the following factors to understand the long-term value:

Operational Efficiency: Reduced cutting times and fewer errors can lead to higher output and less waste, directly impacting profitability.

Energy Savings: Lower energy consumption over time means the machine will pay for itself much quicker than traditional CO2 lasers.

Costos de mano de obra reducidos: Automation features and minimal need for manual intervention can reduce the labor force required for cutting tasks.

Less Material Waste: Precision cutting minimizes waste, helping reduce material costs and maximize material use.

How to Choose the Right High Power Fiber Laser Cutting Machine

When selecting a high power fiber laser cutting machine, consider the following:

Your Material Requirements: Ensure the machine can handle the types of materials you need to cut.

Espesor de corte: Match the machine’s power output to the thickness of the materials you work with regularly.

Machine Size and Footprint: Consider the space available in your facility to accommodate the machine.

Características de automatización: If your production line demands high-volume, automated systems, look for machines with integrated automation.

Total Cost of Ownership: Beyond the initial price, consider maintenance, energy usage, and software upgrades.

By understanding the benefits, cost considerations, and technological advancements of high power fiber laser cutting machines, you can make an informed decision that enhances your operations, boosts productivity, and delivers greater precision in your work.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora