News

Best CNC Fiber Laser Cutters

The best CNC fiber laser cutting machine slices through armored plating like warm butter, carves titanium heart valves with 0.005mm tolerance, and transforms raw metal coils into electric vehicle chassis overnight. Choose wrong, and you’ll hemorrhage $500/hour in botched cuts, scrapped materials, and production downtime. This isn’t another spec sheet regurgitation – it’s your tactical field manual for navigating the photon warfare landscape.

The Power Matrix

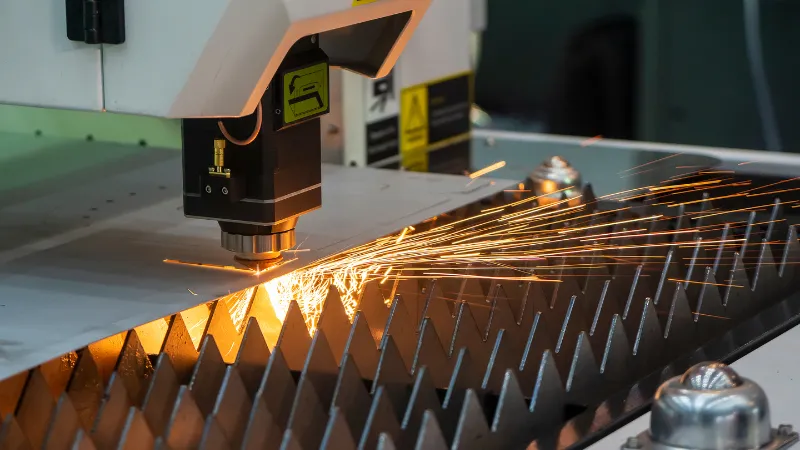

Cutting Capability Spectrum

Thin-Sheet Dominance (<6mm):

- Speed Threshold: 100m/min at 1kW

- Gas Protocol: Nitrogen purity ≥99.95%

- Precision Benchmark: ±0.03mm positional accuracy

Mid-Range Mastery (6-20mm):

- Beam Delivery: 30μm fiber core diameter

- Pierce Time: <0.8 seconds for 15mm carbon steel

- Assist Gas: Oxygen at 15bar for exothermic boost

Heavy-Plate Siege (>20mm):

- Power Requirement: 12kW+ with adaptive beam shaping

- Nozzle Tech: 3-stage tapered design

- Cooling System: 24°C chiller temperature stability

Power vs. Material Throat Chart

Laser Power | Carbon Steel | Stainless | Aluminum |

3kW | 0-15mm | 0-10mm | 0-8mm |

6kW | 0-25mm | 0-18mm | 0-15mm |

12kW | 0-40mm | 0-30mm | 0-25mm |

Precision Warfare Systems

Motion Control Arsenal

- Linear Drive Tech: 3G acceleration, 0.001mm repeatability

- Collision Avoidance: 360° LiDAR scanning at 100Hz

- Thermal Compensation: 0.01mm/°C distortion correction

Accuracy Standards by Industry

Sector | Kerf Tolerance | Surface RA | Perf Speed |

Aerospace | ±0.02mm | <0.8μm | 800 holes/min |

Medical | ±0.01mm | <0.5μm | 1200 holes/min |

Automotive | ±0.05mm | <1.2μm | 600 holes/min |

Covert Performance Killers

Hidden Spec Decoder

- Beam Parameter Product (BPP):

- <2.5 mm-mrad for micro-cutting

- 0 mm-mrad for thick plates

2. Modulation Depth:

- 500ns pulse rise time for copper

- 1μs minimum for reflective alloys

3. Fiber Degradation Rate:

- <0.5% power loss per 1,000 hours

Maintenance Failure Points

Component | Critical Metric | Replacement Cost |

Cutting Head | 8,000 hour lifespan | $18,000 |

Focus Lens | 300 hour coating life | $2,500 |

Fiber Cable | 50,000 bend cycles | $9,800 |

Automation Battlefield

Unmanned Production Tactics

- Pallet Systems: 120-second material swap

- Nozzle Changers: 7-second automatic swap

- Scrap Ejection: 90kg/min conveyor removal

Downtime Reduction Matrix

Feature | Setup Time | Impact |

Auto Focus | 0 seconds | 98% reduction |

Material Sensor | 12 seconds | 83% reduction |

AI Nesting | 18 seconds | 79% reduction |

Cost of Ownership Warfare

5-Year Financial Recon

- Energy Consumption: 0.8 kW/h per operating hour at 6kW

- Gas Expenditure: $18/hour for nitrogen cutting

- Consumable Drain: $43/day for lenses/nozzles

ROI Projection Comparison

Machine Tier | Initial Cost | 5-Year Operating Cost | Breakeven Point |

Entry (3kW) | $150,000 | $310,000 | 14 months |

Mid (6kW) | $280,000 | $520,000 | 18 months |

Industrial (12kW) | $520,000 | $890,000 | 22 months |

Photon Delivery Architecture

Beam Path Engineering

- Fiber Coupling Efficiency: >98% transmission rate

- Collimation Optics: 150mm focal length standard

- Process Monitoring: 20,000 Hz plasma detection

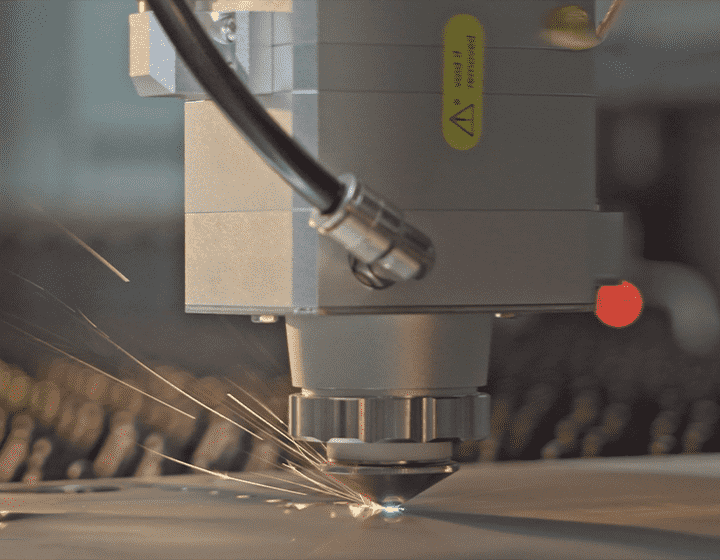

Cutting Head Specifications

Parameter | Standard | High-Performance |

Focus Range | 0-200mm | 0-300mm |

Nozzle Change | Manual | 4-second auto |

Cooling | Air-cooled | Liquid-cooled |

Software Command Center

Digital Twin Integration

- Nesting Efficiency: 92% material utilization

- Predictive Maintenance: 98% failure anticipation

- Cloud Analytics: Real-time global benchmarking

Cutting Parameter Database

Material | Thickness | Power | Speed | Gas |

Mild Steel | 10mm | 4kW | 2.4m/min | O₂ |

Aluminum | 8mm | 3.5kW | 3.1m/min | N₂ |

Brass | 5mm | 2.2kW | 4.8m/min | Air |

Factory Floor Integration

Installation Combat Rules

- Power Requirements: 60kVA ±5% voltage stability

- Floor Load: 1,500kg/m² minimum

- Exhaust Flow: 6,000m³/hour extraction

Environmental Red Lines

Factor | Tolerance | Failure Consequence |

Ambient Temp | 15-30°C | Beam drift |

Humidity | <70% | Lens condensation |

Dust Level | ISO Class 6 | Optical contamination |

Future Photon Frontiers

2028 Technology Forecast

- Multi-Beam Systems: Simultaneous cutting at 4 points

- Quantum Cooling: Zero-wait chiller recovery

- Self-Healing Optics: Ceramic lens regeneration

Emerging Material Threats

- Carbon-fiber composites requiring 1070nm wavelength

- Refractory metals needing 400W/mm² intensity

- Functionally graded materials demanding real-time parameter shifting

“Modern fiber lasers don’t cut metal – they vaporize molecular bonds with picosecond precision,” observes Dr. Aris Thorne, photonics engineer. “But that power becomes useless without military-grade motion systems.”

Tactical Acquisition Protocol

Supplier Vetting Checklist

- Factory Certification: ISO 9017:2025 compliance

- Component Traceability: Semiconductor-level lot tracking

- Uptime Guarantee: 95% operational SLA

Acceptance Test Parameters

Test | Standard | Rejection Threshold |

Positional Accuracy | ISO 10791-7 | >0.015mm deviation |

Beam Circularity | DIN 32567 | <92% roundness |

Pierce Consistency | ASTM E2906 | >0.1s variance |

Implementation Timeline

Phase | Duration | Critical Path |

Site Prep | 10 Days | Power/air/gas infrastructure |

Installation | 5 Days | Foundation leveling <0.02mm/m |

Calibration | 3 Days | Beam alignment ±2μm |

Validation | 2 Days | Test cuts on 5 materials |

Final Photon Command: “The true best CNC fiber laser cutting machine reveals itself not in showroom demos, but in year three of relentless production – where maintenance costs and cutting consistency separate warriors from casualties.”

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine