News

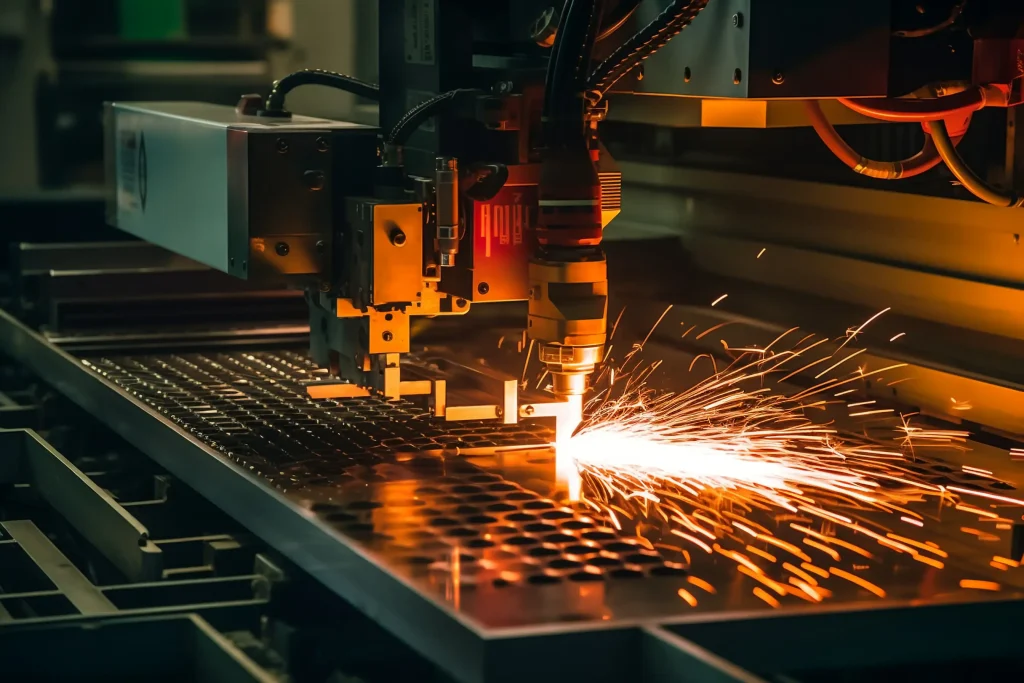

Best Steel for Laser Cutting Guide

The best steel for laser cutting transforms stubborn metal sheets into aerospace components with micron precision, carves architectural masterpieces overnight, and turns prototyping chaos into production-line perfection. One miscalculation in material selection, however, can trigger catastrophic warping, ragged edges, or financial hemorrhage from wasted resources. Forget generic charts – this is your tactical metallurgical playbook.

The Steel Selection Battlefield

Metallurgical Combat Zones

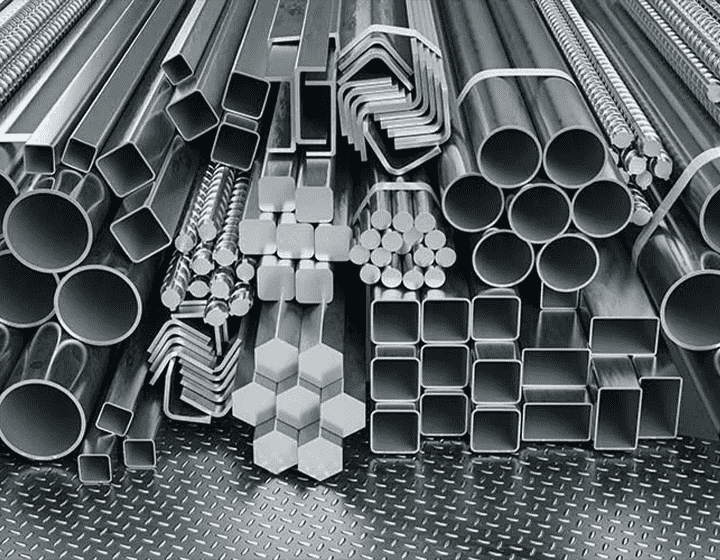

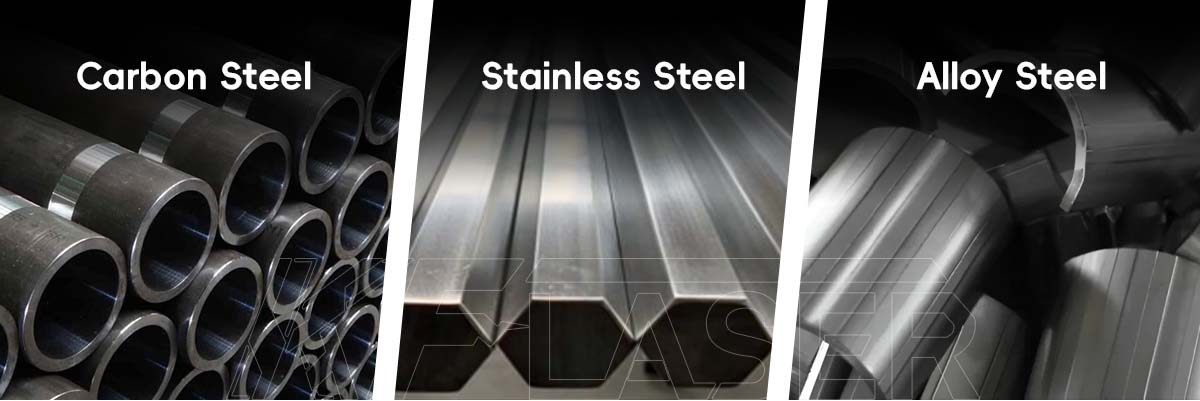

- Carbon Steel Frontline(Low/Medium Carbon):

- Advantage: Cost-efficient cutting at 6-12m/min (1mm)

- Threat: Oxide dross buildup beyond 15mm thickness

- Critical Spec: 0.3% max carbon content for clean edges

2. Stainless Steel Theater(304/316):

- Beam Engagement: Requires nitrogen assist gas

- Speed Trap: 40% slower than carbon steel

- Victory Condition: RA<1.5µm surface finish

3. Alloy Steel Recon(4140/Tool Steel):

- Covert Ops: Pre-heating to 200°C prevents cracking

- Lethal Threshold: >0.5% chromium demands power adjustment

Thickness vs. Power Matrix

Material | 1kW Max Thickness | 4kW Max Thickness |

Mild Steel | 8mm | 25mm |

304 Stainless | 6mm | 20mm |

Aluminum | 5mm | 15mm |

Surface Finish Warfare

Defect Elimination Protocol

- Dross Adhesion: Increase gas pressure by 0.8 bar per mm thickness

- Heat Affected Zone (HAZ): Limit to 0.1mm via pulse modulation

- Micro-cracking: Maintain 300°C interpass temperature

Edge Quality Standards

Application | Permissible RA | Kerf Tolerance |

Medical Devices | <0.8µm | ±0.03mm |

Automotive | <1.2µm | ±0.05mm |

Structural | <2.5µm | ±0.1mm |

Cost-Benefit Reconnaissance

Economic Impact Analysis

- Material Waste Reduction: Optimized nesting saves 18-22% stock

- Secondary Processing: Proper steel choice eliminates $27/hr grinding

- Energy Consumption: Low-carbon steels cut at 1.8kW vs 3.5kW for alloys

Total Operational Cost (Per Ton)

Steel Grade | Cutting Cost | Scrap Loss | Post-Processing |

A36 Carbon | $145 | $48 | $62 |

304 Stainless | $310 | $92 | $185 |

Corten Weathering | $280 | $115 | $210 |

Covert Threats: Hidden Metallurgical Saboteurs

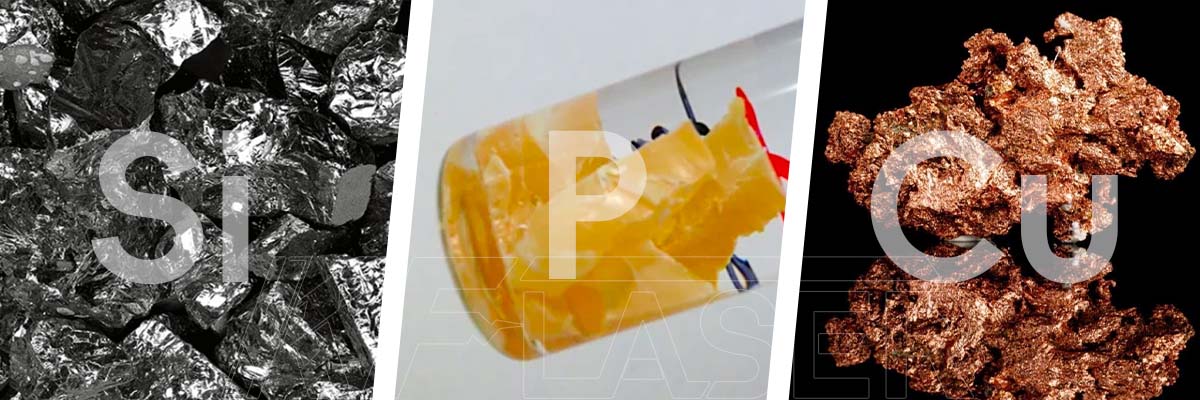

Elemental Combatants

- Silicon (Si): >0.25% causes refractory slag

- Phosphorus (P): >0.04% induces micro-fractures

- Copper (Cu): >0.35% creates beam reflection hazards

Compositional Red Lines

Element | Safe Range | Danger Threshold |

C | 0.01-0.25% | >0.3% |

Mn | 0.3-1.5% | >1.8% |

S | <0.03% | >0.05% |

Industry 4.0 Material Intelligence

Smart Selection Algorithms

- Digital Twin Simulation: Predict cut quality before processing

- Cloud-Based Grade Libraries: 25,000+ material profiles

- AI-Assist Parameter Generation: 0.8 second setup times

Sensor-Driven Cutting Adjustments

- Beam Monitoring: 20,000 Hz focal point tracking

- Thermal Imaging: ±2°C HAZ control

- Spectral Analysis: Real-time alloy verification

Global Sourcing Intelligence

Supply Chain Tactics

- Mill Cert Verification: Cross-check 7 critical parameters

- Batch Testing Protocol: 3-sample destructive testing

- Geopolitical Risk Zones: Avoid sanctioned region materials

Quality Control Checklist

- Flatness tolerance: <1.5mm/m²

- Internal stress levels: <15 MPa residual

- Surface oxidation: Max 3µm depth

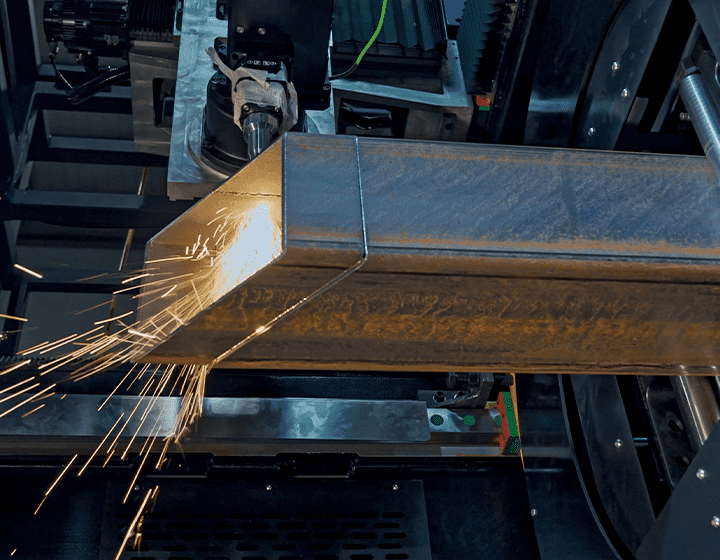

The Thickness Deception

Calibration Countermeasures

- 5-3mm Range: 99% focus position, nitrogen assist

- 4-12mm Range: -1.5mm focus, oxygen enhancement

- 15-25mm Range: -3mm focus, 30° nozzle tilt

Speed vs. Thickness Curve

Thickness (mm) | Carbon Steel | Stainless Steel |

1 | 12m/min | 8m/min |

5 | 3.2m/min | 1.8m/min |

12 | 0.9m/min | 0.5m/min |

Post-Cutting Combat

Stress Relief Maneuvers

- Vibration Aging: 97% stress reduction in 18 minutes

- Cryogenic Treatment: -196°C stabilization cycle

- Laser Peening: 200% fatigue life extension

Distortion Correction Limits

Thickness | Allowable Warp | Correction Cost Factor |

<3mm | 0.8mm/m | 1.0x base cutting |

5-8mm | 1.2mm/m | 1.7x base cutting |

>10mm | 2.0mm/m | 3.2x base cutting |

Future Steel Frontiers

Emerging Alloy Classes

- Nano-structured Steels: 40% faster cutting speeds

- Functionally Graded Materials: Zone-specific composition

- Metamaterial Hybrids: Beam-steering cutting properties

2028 Technical Projections

- AI-driven autonomous material selection

- Quantum-annealed zero-distortion steels

- Photonic material fingerprinting

“Selecting the best steel for laser cutting resembles bomb disposal,” cautions Dr. Elena Rostova, metallurgical engineer. “One misjudged element can detonate your entire project budget.”

Tactical Procurement Strategy

Supplier Negotiation Framework

- Payment Terms: 30% with order, 60% after certification

- Material Certification: EN 10204 3.1 mill reports required

- Rejection Rights: 0.5% composition deviation triggers return

Logistics Parameters

- Maximum coil camber: 3mm per meter

- Packaging: VCI film + desiccant protection

- Traceability: QR code per sheet

Field Deployment Timeline

Phase | Duration | Critical Actions |

Material Sourcing | 15 Days | Supplier vetting, test sampling |

Machine Calibration | 3 Days | Focus alignment, gas optimization |

Test Cutting | 2 Days | Parameter validation, quality sign-off |

Full Production | 1 Day | First article approval |

Final Metallurgical Command: “The true best steel for laser cutting reveals itself only when technical specifications align with operational reality. Victory belongs to those who master both metallurgy and physics.”

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine