News

The Power of Laser Cutting Machines for Metal: Precision and Efficiency in Modern Manufacturing

In today’s fast-paced manufacturing world, laser cutting machines for metal are at the forefront of technological innovation. Offering incredible precision, versatility, and speed, these machines are revolutionizing industries such as automotive, aerospace, and metal fabrication. With the ability to cut through a wide range of metal materials — from stainless steel to aluminum — laser cutters are crucial for creating intricate designs and parts with tight tolerances.

In this article, we explore what makes laser cutting machines for metal so efficient, how they work, and the many applications they serve in various sectors. Whether you’re in manufacturing or simply looking to understand the technology better, this guide will provide valuable insights.

1. What Is a Laser Cutting Machines for Metal?

A laser cutting machines for metal is a high-tech tool used to cut, engrave, or mark metal materials with precision. Unlike traditional cutting methods such as plasma or flame cutting, laser cutting uses a highly focused beam of light (laser) to melt, burn, or vaporize the material. The result is an extremely clean and accurate cut with minimal heat affected zones (HAZ), which means less distortion and a higher quality end product.

There are two primary types of lasers used in metal cutting:

CO2 Lasers: Known for cutting thicker materials, CO2 lasers are more commonly used for cutting mild steel, stainless steel, and aluminum. They tend to be more cost-effective for certain applications.

Fiber Lasers: Fiber lasers are becoming increasingly popular due to their higher energy efficiency and faster cutting speeds, especially when cutting thinner metals. They can cut a variety of metals and are ideal for precision cutting and intricate designs.

https://www.kflaserpro.com/

2. How Does a Laser Cutting Machines for Metal Work?

At its core, the laser cutting process is relatively simple but requires high levels of precision. Here’s a breakdown of the steps involved:

Laser Generation: The process starts with the generation of a laser beam, which is typically produced by either a fiber or CO2 laser source.

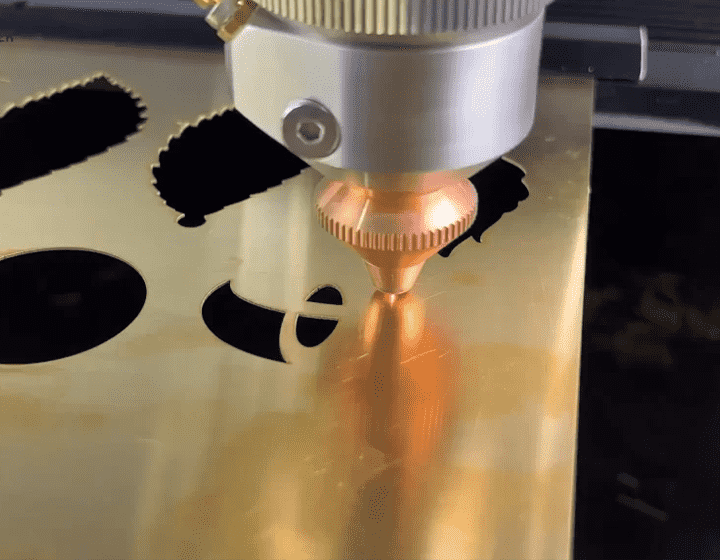

Beam Focusing: The laser is then directed through a series of mirrors or fibers to a cutting head, which focuses the beam onto the material to be cut.

Material Interaction: When the laser beam strikes the metal, the intense heat causes the metal to melt, vaporize, or burn away, depending on the material and the settings of the machine.

Assist Gas: To blow away the molten metal and prevent contamination, an assist gas (typically oxygen, nitrogen, or compressed air) is used, ensuring a cleaner cut and helping to maintain precision.

CNC Control: The CNC (Computer Numerical Control) system dictates the movement of the cutting head, ensuring that the laser follows the exact pattern as per the design specifications.

As a result, laser cutting can deliver smooth edges, high precision, and minimal thermal distortion.

https://www.kflaserpro.com/

3. Advantages of Laser Cutting Machines for Metal

Laser cutting technology offers several key advantages that make it the preferred choice for metal fabrication:

1. Precision and Accuracy

Laser cutting machines are known for their exceptional precision. The highly focused laser beam can cut through metal sheets with tolerances as tight as 0.1mm, making them ideal for industries that demand intricate designs, such as aerospace, electronics, and automotive.

2. Speed and Efficiency

Laser cutting machines for metal are incredibly fast, especially when cutting thinner materials. With fiber lasers, cutting speeds can reach up to 30% faster than CO2 lasers, leading to faster turnaround times for projects. This efficiency improves throughput and reduces labor costs.

3. Minimal Heat Affected Zones (HAZ)

Unlike traditional cutting methods that can distort materials due to heat buildup, laser cutting is a cold cutting process. The small heat-affected zone ensures that there’s less warping or discoloration of the material, making it ideal for precision parts.

4. Reduced Material Waste

Laser cutting is a material-efficient process, as it uses narrow kerf widths (the width of the cut) which minimizes waste. Since the laser beam only touches the material in a focused area, there’s little to no material loss, making it a more sustainable and cost-effective cutting method.

5. Versatility

Laser cutting machines for metal can handle a wide range of materials, from thin sheets of aluminum to thicker steel. Additionally, they are compatible with a variety of metals, including stainless steel, carbon steel, brass, titanium, and even copper.

6. Low Maintenance

Compared to mechanical cutting tools, laser cutting machines have fewer moving parts, reducing wear and tear and extending the lifespan of the machine. Fiber lasers, in particular, require minimal maintenance, which makes them a reliable long-term investment.

4. Applications of Laser Cutting Machines for Metal

Laser cutting machines are used in a wide range of industries, providing precise cuts for various applications. Here are some of the most common uses:

1. Automotive Industry

Laser cutters are used to create metal body panels, engine components, and chassis parts. Their precision ensures that parts fit perfectly, reducing the need for post-cutting adjustments and enhancing assembly line efficiency.

2. Aerospace

In aerospace, where precision is paramount, laser cutting machines are used to cut parts made of titanium, aluminum, and other high-performance alloys. Laser cutting allows for the creation of complex parts that are both lightweight and strong, essential for aircraft and spacecraft.

3. Electronics Manufacturing

Laser cutting is often used in the production of metal enclosures and components for electronic devices. The technology’s precision enables the creation of intricate designs and patterns, which are crucial for the functionality of modern electronics.

4. Metal Fabrication

Metal fabricators use laser cutting for everything from sheet metal fabrication to customized metal parts. Laser cutters are perfect for high-volume production runs, enabling manufacturers to quickly produce high-quality parts with complex geometries.

5. Signage and Architecture

Laser cutters are also used for creating decorative metal panels, custom signage, and architectural components. The ability to cut precise patterns and shapes from metal sheets makes laser cutting ideal for these creative applications.

5. Factors to Consider When Purchasing a Metal Laser Cutting Machines

When investing in a laser cutting machines for metal, several factors should be carefully considered to ensure that the equipment aligns with your needs:

Laser Power: Higher power lasers can cut through thicker materials more efficiently, so it’s essential to choose a machine with the appropriate power rating based on the materials you’ll be cutting.

Material Compatibility: Not all lasers are suited for all materials. Make sure the machine you select can handle the types of metal you need to work with, whether it’s stainless steel, aluminum, or other metals.

Cutting Speed and Efficiency: Speed is a critical factor, especially if you’re working with high-volume production. Fiber lasers are faster than CO2 lasers and are a great choice for cutting thinner materials.

Software and Automation: Consider the machine’s compatibility with CAD/CAM software and whether it offers automated loading/unloading systems, which can increase productivity and reduce labor costs.

Maintenance and Support: Look for a machine that is easy to maintain and comes with reliable customer support. Opt for machines with fiber lasers as they require less maintenance compared to other types.

Budget: While fiber laser machines can be a significant investment, their speed, precision, and low maintenance costs make them a great long-term solution. Ensure that the investment aligns with your production needs.

With their precision, speed, and versatility, laser cutting machines for metal are changing the landscape of modern manufacturing. From automotive components to electronic parts and aerospace applications, laser cutting technology is providing industries with the ability to meet demanding specifications while improving efficiency. Whether you are working with thick steel sheets or thin aluminum panels, there’s no denying that laser cutting is one of the most powerful tools in the metalworking industry today.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine