News

Stainless Steel Laser Cutting: A Game-Changer for Modern Metalworking

▶In the world of metal fabrication, stainless steel laser cutting has quickly become a vital tool, offering unmatched precision and efficiency. As industries continue to demand higher quality and faster production times, laser cutting technology rises to meet these needs. From automotive to aerospace, construction to medical device manufacturing, the ability to cut stainless steel with incredible accuracy opens the door to innovative design and manufacturing processes.

Laser cutting, particularly for stainless steel, represents a breakthrough in material processing. Unlike traditional cutting methods, which can introduce errors and require extensive post-processing, laser cutting offers clean, precise cuts with minimal distortion. This article will explore the benefits, applications, and future of stainless steel laser cutting, highlighting why it’s a key technology in modern manufacturing.

1.What is Stainless Steel Laser Cutting?

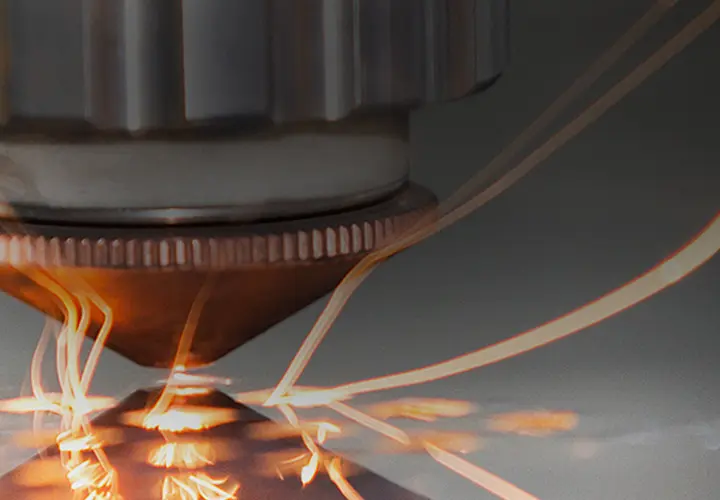

Stainless steel laser cutting involves using a high-powered laser beam to melt, burn, or vaporize sections of stainless steel. The laser is typically focused into a small spot, which provides high energy density and enables precise cuts with smooth edges. This process is guided by a computer-controlled system (CNC), ensuring that every cut is highly accurate.

Unlike mechanical cutting tools, which rely on physical contact with the material, laser cutting does not involve any contact between the tool and the material. This absence of physical contact eliminates the risks of tool wear and provides a cleaner, faster method for cutting tough materials like stainless steel.

2.Benefits of Stainless Steel Laser Cutting

✔Exceptional Precision

One of the most significant advantages of stainless steel laser cutting is the level of precision it offers. The laser is capable of making incredibly fine cuts, with minimal deviation, ensuring that even complex geometries are executed to the highest standards. This level of precision is especially critical in industries like aerospace or medical device manufacturing, where small deviations can lead to part failure or safety concerns.

✔Faster Production Times

Laser cutting is faster than traditional cutting methods, such as plasma or waterjet cutting. The efficiency of laser technology means that parts can be cut quickly, which reduces the overall production time. This is particularly beneficial in high-volume manufacturing environments, where time is money. The high cutting speed also allows manufacturers to keep up with rising demand and more complex designs.

✔Minimal Material Waste

Another significant benefit of stainless steel laser cutting is its efficiency in terms of material usage. The precision of the laser ensures that very little material is wasted during the cutting process. This results in cost savings, as less scrap material needs to be disposed of or recycled. Additionally, because the laser’s heat-affected zone is smaller compared to other methods, the overall integrity of the material is preserved.

✔Reduced Heat-Affected Zones (HAZ)

The heat-affected zone (HAZ) refers to the area of material that is impacted by the heat of the cutting process. In traditional cutting methods, the HAZ can be quite large, leading to warping, residual stresses, and other issues that require post-processing. However, stainless steel laser cutting minimizes the HAZ, resulting in cleaner cuts and reducing the need for secondary operations like welding or grinding.

✔Versatility and Flexibility

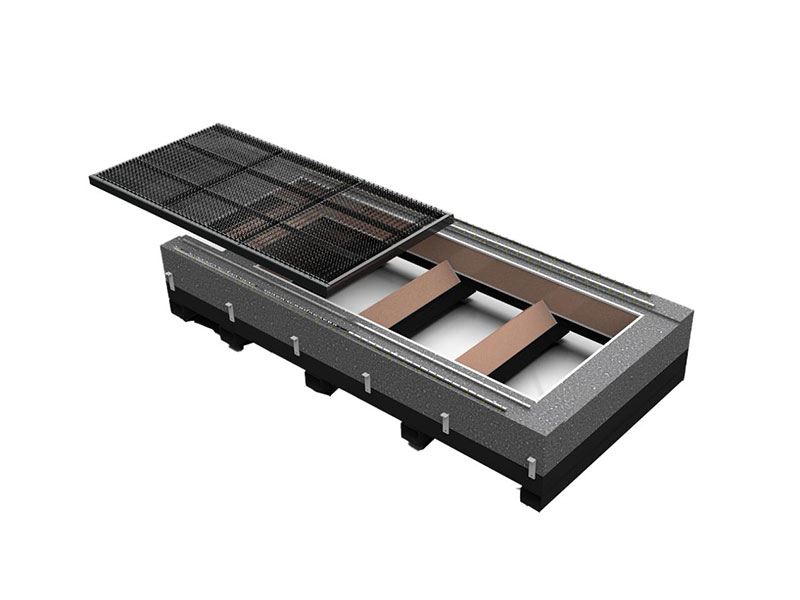

Stainless steel laser cutting is versatile enough to handle a wide range of sheet thicknesses, from thin sheets to thick plates, and can be used on various grades of stainless steel. This makes it suitable for a broad range of industries, from heavy-duty construction to the intricate demands of medical devices. Additionally, the machine’s flexibility allows manufacturers to switch between cutting different types and shapes of materials with minimal downtime.

3.Applications of Stainless Steel Laser Cutting

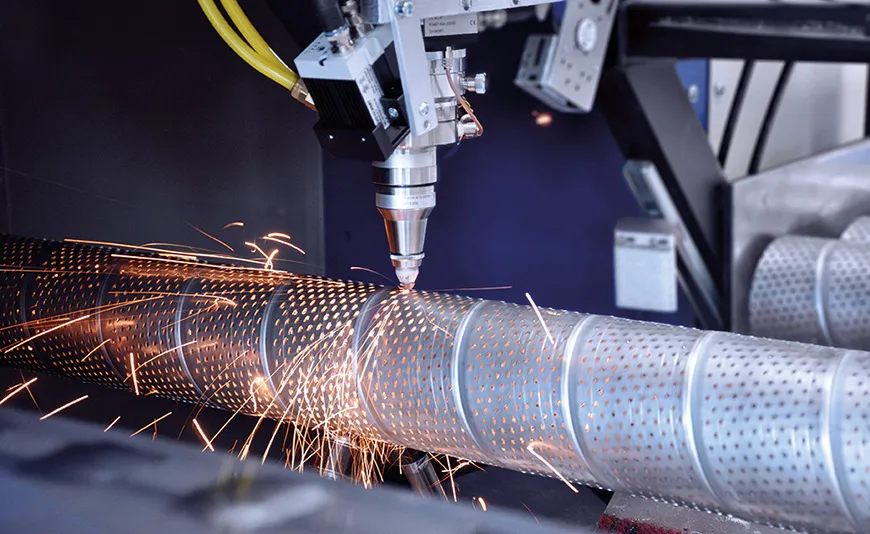

The precision and efficiency offered by stainless steel laser cutting make it a versatile tool in numerous industries. Below are some of the most common applications of this technology:

✔Automotive Industry

In the automotive industry, stainless steel laser cutting is used for a wide range of parts, including structural components, exhaust systems, and interior elements. The ability to produce accurate, high-quality cuts is essential for ensuring the performance, safety, and fitment of automotive parts. Laser cutting also allows for more complex designs and shapes that traditional cutting methods might struggle to achieve.

✔Aerospace Manufacturing

Aerospace parts often require high-strength materials like stainless steel to ensure safety and performance. Laser cutting provides the precision needed to create complex components such as turbine blades, structural frames, and support systems for aircraft. The high level of accuracy and minimal heat distortion make laser cutting ideal for aerospace manufacturing, where even slight deviations can lead to catastrophic failures.

✔Medical Device Production

The medical industry demands components that meet stringent safety and quality standards. Stainless steel laser cutting is used extensively in the production of medical devices such as surgical instruments, implants, and diagnostic equipment. The precision of laser cutting ensures that these critical components are manufactured to exact specifications, with minimal risk of defects.

✔Architectural Design and Construction

Laser-cut stainless steel is increasingly popular in architectural design due to its aesthetic appeal and functional benefits. Whether for decorative elements like gates, railings, or facades, laser cutting allows for intricate, precise patterns and designs. This process enhances the overall visual appeal of buildings while providing durable, long-lasting materials that can withstand the elements.

✔Industrial Equipment Manufacturing

In industrial manufacturing, laser cutting is used to produce components for machinery, heavy equipment, and structural frameworks. The ability to cut stainless steel with high precision is essential for ensuring that all components fit together seamlessly, improving the overall performance of the equipment. From gears to support beams, laser cutting ensures that each part is created to the required specifications.

4.The Future of Stainless Steel Laser Cutting

The future of stainless steel laser cutting looks promising, with continued advancements in laser technology pushing the boundaries of what’s possible. One trend that is becoming increasingly prominent is the development of fiber laser technology, which provides higher energy efficiency, faster cutting speeds, and the ability to cut thicker materials with greater precision.

Additionally, advancements in automation and AI-driven systems are making laser cutting even more efficient. These systems can optimize cutting paths, predict maintenance needs, and improve the overall production process. As industries continue to demand faster turnaround times and more complex designs, stainless steel laser cutting will remain a vital tool in meeting these challenges.

By embracing the power of stainless steel laser cutting, manufacturers can improve product quality, reduce production time, and minimize material waste, all while staying competitive in the fast-paced world of modern manufacturing.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine