News

Tube Cutting Laser Machine: Precision and Efficiency for Modern Fabrication

A tube cutting laser machine is a revolutionary tool in the metalworking industry, transforming the way manufacturers approach tube cutting. This high-tech solution brings precision, speed, and flexibility to metal fabrication, enabling industries such as automotive, aerospace, and construction to produce high-quality components with remarkable efficiency. In a world where precision and cost-effectiveness are paramount, laser tube cutting offers an innovative solution that is reshaping manufacturing practices.

1.What is a Tube Cutting Laser Machine?

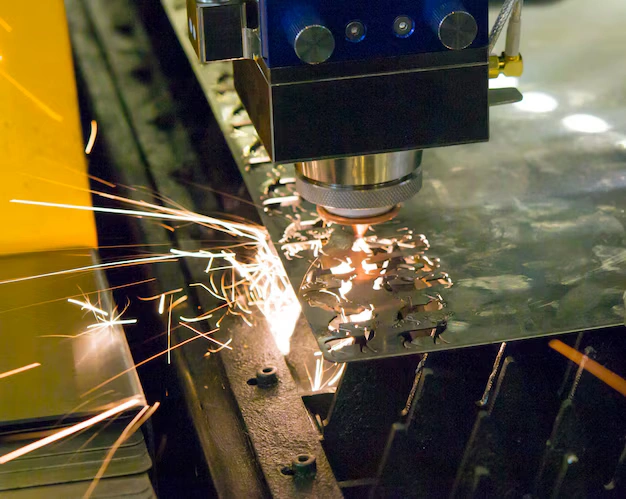

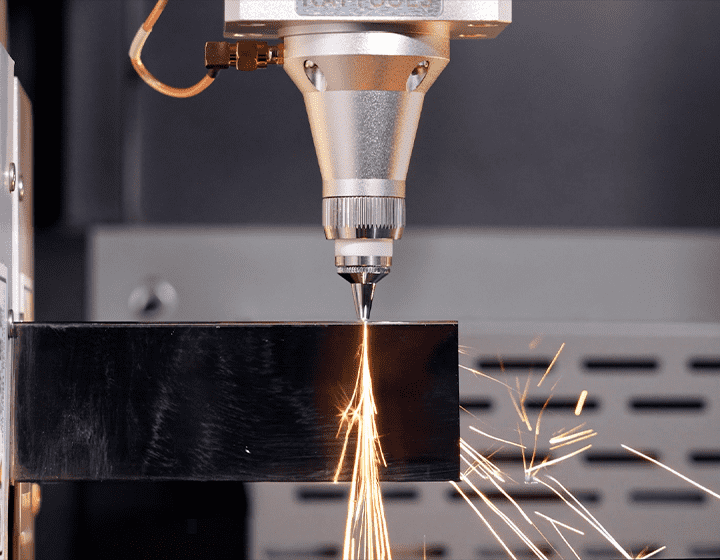

A tube cutting laser machine uses a focused laser beam to cut through tubes of various materials, including metals such as steel, aluminum, and copper. This laser technology is driven by a fiber-optic laser, offering exceptional power and precision. The machine’s ability to make highly accurate cuts with minimal material waste makes it an ideal choice for a wide range of industries.

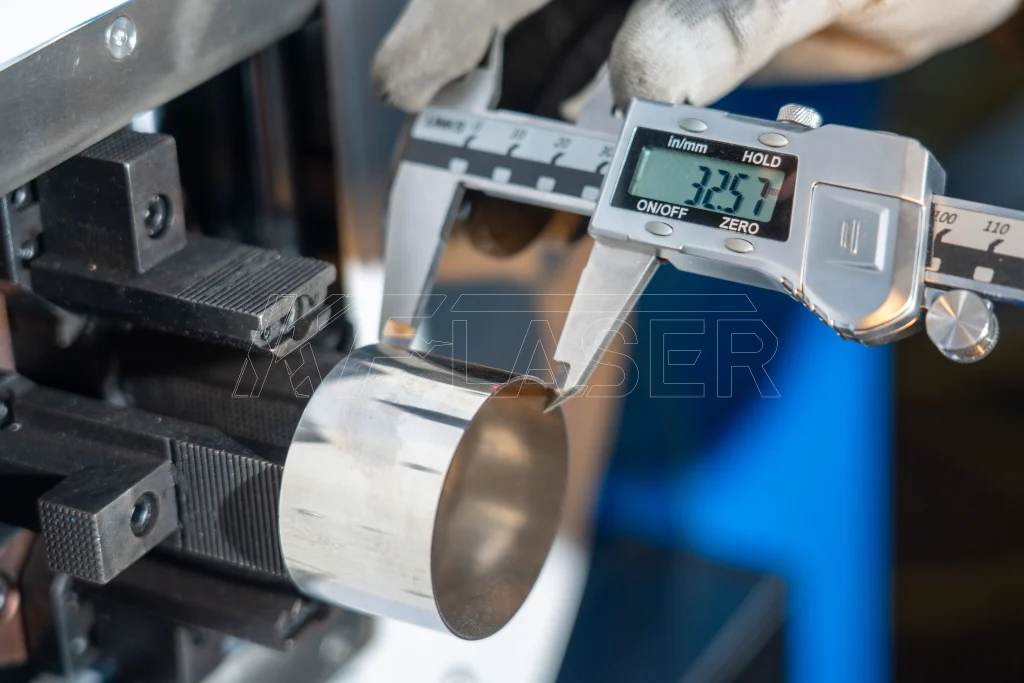

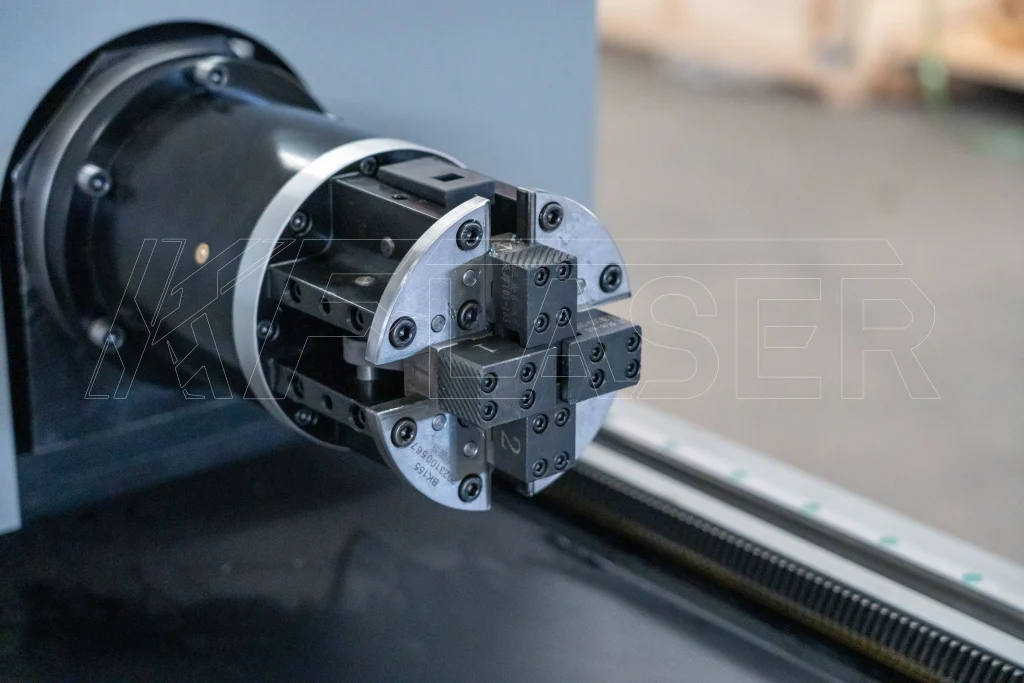

Laser tube cutting machines are often integrated with computer numerical control (CNC) systems, which means they can automatically cut complex shapes with high levels of accuracy. This system allows operators to program cutting paths, providing a reliable and automated solution for cutting different types and sizes of tubes.

2.Why Choose a Tube Cutting Laser Machine?

✔High Precision Cutting

One of the most significant advantages of a tube cutting laser machine is its ability to deliver highly accurate cuts. The laser focuses intense heat on the tube material, allowing for precise control over the cutting process. The accuracy of the cut is crucial in industries where even slight deviations can lead to defects and increased production costs. This precision ensures that the parts fit together correctly, reducing the need for costly rework and improving overall production efficiency.

✔Efficiency and Speed

Laser tube cutting machines offer an unparalleled cutting speed compared to traditional methods. Whether cutting through thin or thick tubes, the laser can slice through materials quickly, minimizing downtime and reducing production times. In high-volume manufacturing environments, where time is critical, the speed of a tube cutting laser machine can make a significant difference in overall productivity.

✔Minimal Material Waste

A key benefit of tube cutting lasers is their ability to minimize material waste. Traditional cutting methods often generate excess material that needs to be discarded or reworked, leading to higher costs and more waste. Laser cutting, on the other hand, offers exceptional accuracy, ensuring that the cut tube matches the required specifications. This minimizes waste, which not only reduces material costs but also promotes a more environmentally friendly manufacturing process.

✔Versatility in Material Types and Thicknesses

Tube cutting laser machines can handle a wide range of materials, including various metals like stainless steel, carbon steel, and aluminum. Additionally, they can cut through tubes of varying thicknesses, making them versatile enough for different industries and applications. Whether for thin-walled tubes or thicker pipe materials, these machines provide consistent and reliable cutting quality.

✔Reduced Heat-Affected Zone (HAZ)

Unlike traditional cutting methods that often generate large heat-affected zones, laser cutting produces a minimal HAZ. This results in cleaner cuts with less thermal distortion, preserving the integrity of the material. In applications where precision and material strength are essential, such as in the aerospace or medical industries, the reduced HAZ is a crucial benefit.

3.Applications of Tube Cutting Laser Machines

The versatility of tube cutting laser machines makes them suitable for a wide variety of industries. Here are some of the key applications where these machines are proving to be indispensable:

◆Automotive Industry

In the automotive sector, tube cutting laser machines are used to create components such as exhaust pipes, structural frames, and chassis. These components require high precision to ensure proper fit and function in the final vehicle assembly. Laser cutting ensures that the parts are manufactured with the highest levels of accuracy, reducing the potential for defects that could compromise vehicle safety or performance.

◆Aerospace Manufacturing

Aerospace manufacturing requires the utmost precision when it comes to cutting tubes and pipes for components such as fuselages, wings, and engine parts. Laser tube cutting provides the accuracy needed to meet the stringent standards of the aerospace industry, ensuring that parts are cut to the exact dimensions required for optimal performance and safety.

◆Construction and Structural Steelwork

In the construction industry, laser tube cutting is used for creating intricate metal structures, beams, columns, and frames. The ability to cut tubes with precision ensures that the structural components fit together seamlessly during assembly. Laser cutting machines are especially valuable in the production of custom steel structures, where every piece must meet specific design requirements.

◆Medical Device Manufacturing

Laser tube cutting machines are also essential in the medical device industry, where they are used to cut tubes for surgical instruments, implants, and other medical devices. Given the critical nature of these components, precision is vital to ensure proper functionality and safety. Fiber laser cutting delivers the accuracy needed for such sensitive applications, making it a popular choice for medical manufacturers.

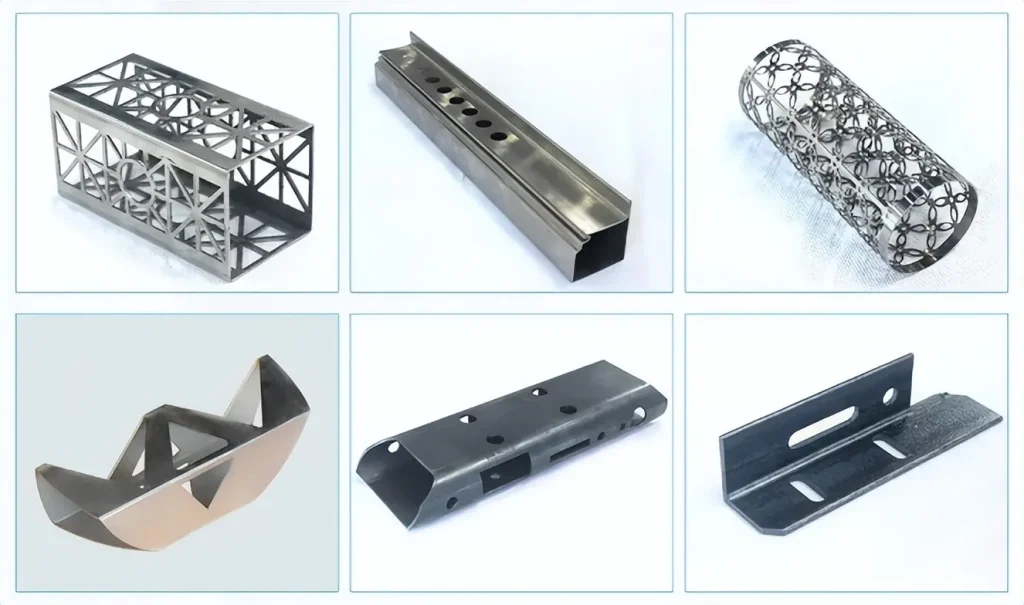

◆Furniture and Decorative Metalwork

For industries that rely on metal furniture or decorative metal products, such as railings, handrails, and frames, tube cutting laser machines provide an efficient and cost-effective solution. These machines can produce intricate designs with high precision, allowing manufacturers to create stylish and functional products that meet customer demands.

4.Advantages Over Traditional Tube Cutting Methods

▼Reduced Human Error

Traditional tube cutting methods often rely on manual labor or basic mechanical processes, which can lead to human error. With a tube cutting laser machine, the entire process is automated, reducing the risk of mistakes that could result in faulty products. The consistency and repeatability of laser cutting ensure that each part is identical to the last, improving overall quality control.

▼Improved Production Flexibility

Laser cutting machines are adaptable and can easily switch between different tube sizes and materials without the need for significant adjustments. This flexibility allows manufacturers to quickly adjust to changing production requirements, whether for small batches or large-volume runs.

▼Ability to Cut Complex Shapes

A major advantage of tube cutting lasers is their ability to cut intricate shapes and patterns. Traditional cutting methods often struggle with complex geometries, leading to a time-consuming process. With a laser, manufacturers can quickly and accurately cut tubes into intricate designs, which is particularly useful for applications requiring complex cuts or decorative elements.

▼Minimal Post-Cutting Processes

Laser cutting results in cleaner cuts with smoother edges, reducing the need for secondary processes such as grinding or deburring. This streamlines the production process, saving time and labor costs while maintaining high-quality standards.

5.The Future of Tube Cutting Laser Machines

The future of tube cutting laser technology is bright, with ongoing advancements aimed at improving cutting capabilities, speed, and efficiency. Some emerging trends include the integration of advanced software solutions for enhanced cutting path optimization, the use of AI for predictive maintenance, and the continued development of high-powered fiber lasers capable of handling even thicker materials.

As industries continue to evolve and demand faster, more efficient production processes, tube cutting laser machines will remain a key tool in achieving these goals. Their ability to deliver precise, high-quality cuts in a variety of materials and applications makes them an essential part of modern manufacturing.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine