News

Fiber Laser Cutting Machine for Metal: Revolutionizing Metal Fabrication

▶ The fiber laser cutting machine for metal is at the forefront of innovation in the manufacturing industry, dramatically improving the precision and efficiency of metal cutting. This cutting-edge technology has gained widespread recognition due to its ability to handle a wide range of metals with exceptional accuracy and minimal waste. Industries such as aerospace, automotive, and construction now rely on fiber laser cutting for its speed, precision, and versatility.

Ⅰ.What Is a Fiber Laser Cutting Machine for Metal?

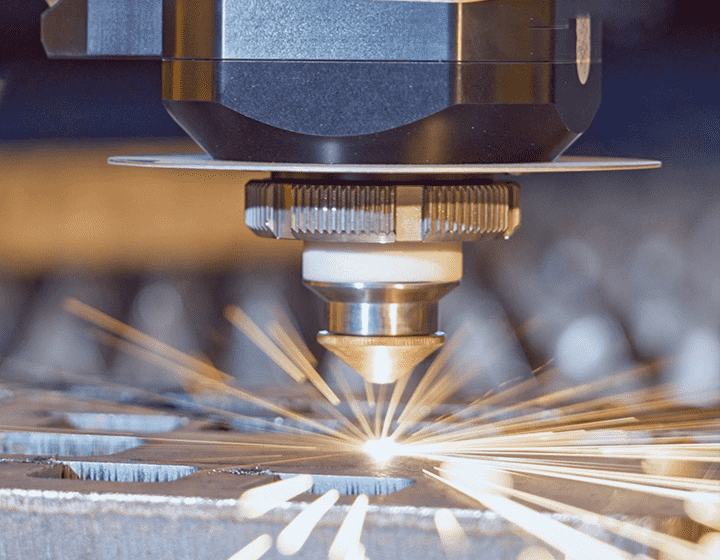

A fiber laser cutting machine for metal uses a high-powered laser beam that is focused on the metal surface to melt, burn, or vaporize the material along a designated cutting path.

The fiber laser, which is generated from a fiber optic cable, is known for its high power density, which allows for a cleaner and more precise cut compared to traditional cutting methods. The use of fiber optics also makes these lasers more energy-efficient, offering a more cost-effective solution for metal fabrication.

This machine offers a combination of superior cutting quality, speed, and low operational costs, making it ideal for high-volume metal fabrication. The integration of CNC (Computer Numerical Control) ensures that the machine can cut complex shapes with micron-level accuracy, enabling manufacturers to meet even the most demanding specifications.

Ⅱ.Why Choose a Fiber Laser Cutting Machine for Metal?

Precision and Accuracy

Fiber laser cutting machines are known for their remarkable precision. They can make cuts with incredible accuracy, typically in the range of 0.1mm or finer, ensuring that even the most intricate designs are cut exactly to specification. This high degree of accuracy is essential in industries like aerospace and automotive manufacturing, where tight tolerances and high-quality cuts are required.

High-Speed Cutting

One of the major advantages of a fiber laser cutting machine for metal is its speed. These machines can cut through metal sheets much faster than traditional cutting methods, allowing for quicker production times and improved productivity. This increased cutting speed reduces the overall lead time for manufacturing processes, making it an ideal solution for industries with high-demand production schedules.

Energy Efficiency

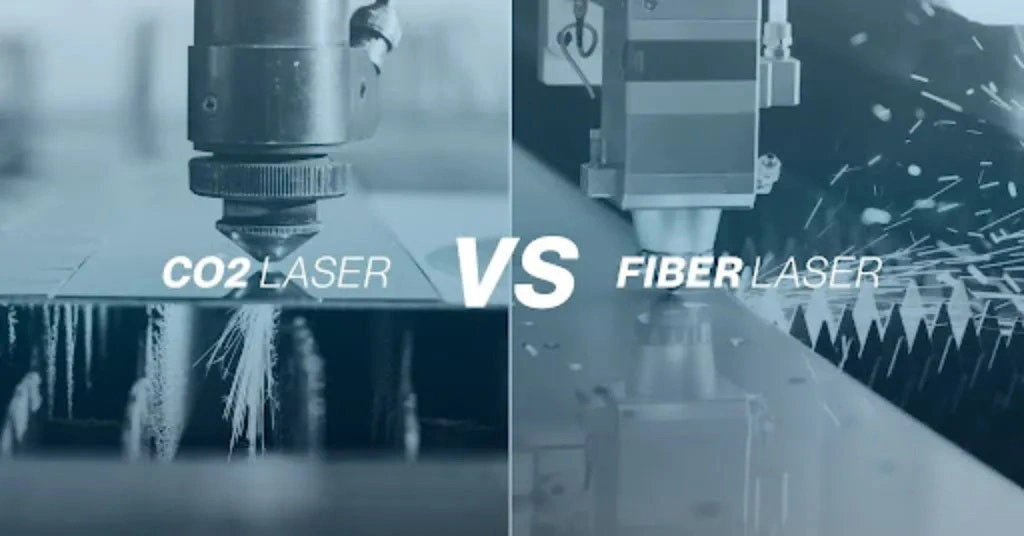

Compared to CO2 laser cutting machines, fiber laser cutters are more energy-efficient. This is due to the higher efficiency of the fiber laser source and the reduced need for cooling systems. As energy costs continue to rise, manufacturers are looking for ways to reduce their energy consumption, and fiber laser cutting machines provide an excellent solution for achieving these savings.

Low Operational Costs

While the initial investment in a fiber laser cutting machine for metal may be higher than traditional cutting machines, the long-term savings are significant. The cost of operation is lower due to reduced energy consumption, minimal maintenance, and lower material wastage. Fiber lasers also require less downtime for adjustments and repairs, contributing to a more efficient manufacturing process.

Versatility and Material Compatibility

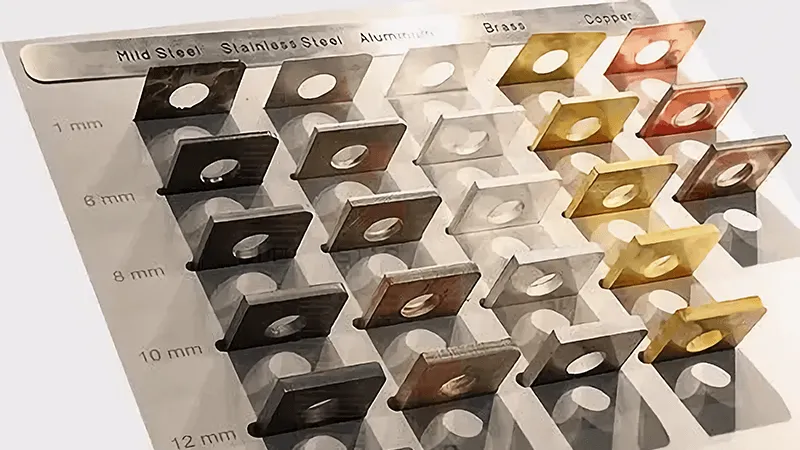

Fiber laser cutting machines for metal can handle a wide range of materials, from mild steel and stainless steel to aluminum, copper, and brass. The ability to work with different metal types and thicknesses makes fiber lasers a versatile tool for various industries. Whether cutting thin sheets or thick plates, these machines maintain consistent performance and high-quality cuts.

Minimal Heat Affected Zone (HAZ)

The heat-affected zone (HAZ) is the area around the cut that is affected by the heat generated during the cutting process. With fiber laser cutting, the HAZ is minimized, which reduces the chances of material deformation. This is especially crucial when working with thin materials or materials that are sensitive to heat, such as titanium or aluminum alloys.

Ⅲ.Applications of Fiber Laser Cutting Machines for Metal

The versatility of fiber laser cutting machines for metal makes them an indispensable tool in various industries. Some of the key applications include:

●Aerospace Manufacturing

Aerospace components require high precision and minimal tolerance, making fiber laser cutting an ideal choice. From turbine blades to structural components, fiber laser cutting ensures that each part meets the stringent standards required for the aerospace industry. The ability to cut intricate designs quickly and accurately is crucial for meeting deadlines and maintaining high-quality standards in this field.

●Automotive Industry

The automotive industry uses fiber laser cutting to produce a wide variety of components, from body panels to chassis and exhaust systems. Fiber lasers can quickly cut through thick and thin metals with high precision, ensuring that every component fits perfectly during assembly. Additionally, the high-speed capabilities of fiber laser cutting machines make them ideal for mass production, ensuring that manufacturers can meet large-scale demands without sacrificing quality.

●Metal Fabrication and Sheet Metal Industry

In the general metal fabrication and sheet metal industries, fiber laser cutting is widely used to create products such as brackets, frames, and custom metal parts. The ability to cut complex shapes with high accuracy allows fabricators to meet the diverse needs of their customers, whether for small-scale custom projects or large-scale manufacturing runs.

●Energy and Power Industry

The energy and power industry relies on fiber laser cutting to produce components for power plants, wind turbines, and solar panels. These components often require precise cuts for optimal performance, and fiber lasers provide the high accuracy needed for these applications.

●Medical Equipment Manufacturing

In the medical equipment industry, the precision of fiber laser cutting is crucial for creating surgical tools, medical device components, and implants. The ability to cut through thin, delicate materials with minimal heat buildup makes fiber lasers ideal for manufacturing medical devices that require tight tolerances and a high level of quality control.

Ⅳ.Future Trends in Fiber Laser Cutting Technology

The field of fiber laser cutting is continuously evolving, with innovations aimed at further improving efficiency, precision, and versatility. Some of the emerging trends include:

✔Automation and AI Integration

As industries continue to seek ways to improve efficiency, fiber laser cutting machines are increasingly being integrated with automation and AI technologies. These advancements allow for better control over the cutting process, optimizing parameters in real time and minimizing human error.

✔Increased Power for Cutting Thick Metals

With advancements in laser technology, fiber lasers are becoming more powerful, allowing manufacturers to cut through thicker metals more efficiently. This is particularly beneficial for industries like construction and heavy equipment manufacturing, where thicker metal sheets are often required.

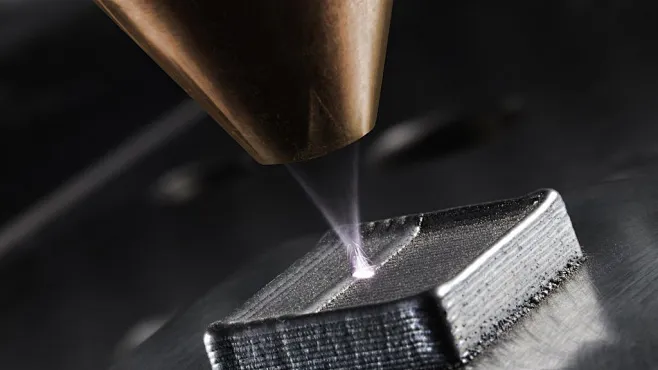

✔Fiber Laser Marking and Engraving

In addition to cutting, fiber lasers are also being used for marking and engraving metal parts. This allows manufacturers to add product identification, logos, and barcodes to metal components with exceptional detail and permanence.

Ⅴ.Why Choose Fiber Laser Cutting for Your Metal Needs?

Fiber laser cutting machines provide a range of advantages for businesses involved in metal fabrication. From high precision and energy efficiency to versatility in handling various metals, these machines represent a significant improvement over traditional cutting methods. Whether you’re cutting small-scale components or large industrial parts, a fiber laser cutting machine for metal is an essential tool for modern manufacturing.

As industries continue to demand faster, more precise, and cost-effective production methods, fiber laser cutting technology will play an even more significant role in shaping the future of metal fabrication.

Why Choose Fiber Laser Cutting for Your Metal Needs?

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine