News

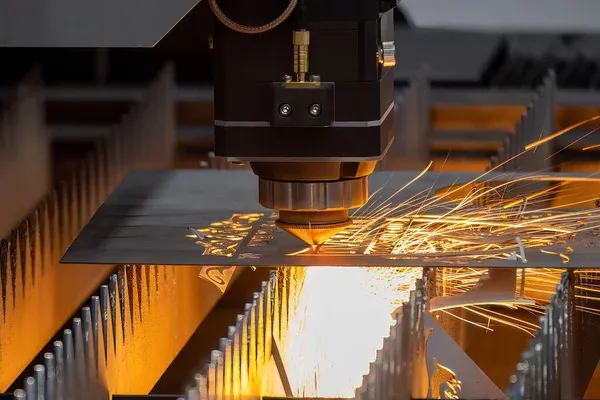

CNC Laser Cutting Machine Sheet Metal: Mastering the Science of Precision

Cutting-edge technology meets precision engineering with CNC laser cutting machines for sheet metal. Imagine a world where intricate designs, sharp edges, and complex shapes are brought to life with unparalleled accuracy and efficiency. This transformative manufacturing process is reshaping industries, from aerospace to construction, bringing speed, reliability, and creativity to the forefront of fabrication.

1.What Makes CNC Laser Cutting Machine Sheet Metal Unique?

Sheet metal laser cutting machines combine the precision of advanced lasers with the accuracy of computer numerical control (CNC) systems. This integration allows manufacturers to create intricate designs with minimal material waste. Let’s delve deeper into the qualities that make CNC laser cutting machines indispensable:

1. Unrivaled Precision:

CNC laser cutters achieve tolerances as fine as ±0.005 inches, enabling the production of intricate designs that were previously impossible with traditional methods.

2. Exceptional Speed:

Laser cutting machines process complex cuts faster than traditional tools, reducing production times significantly while maintaining precision.

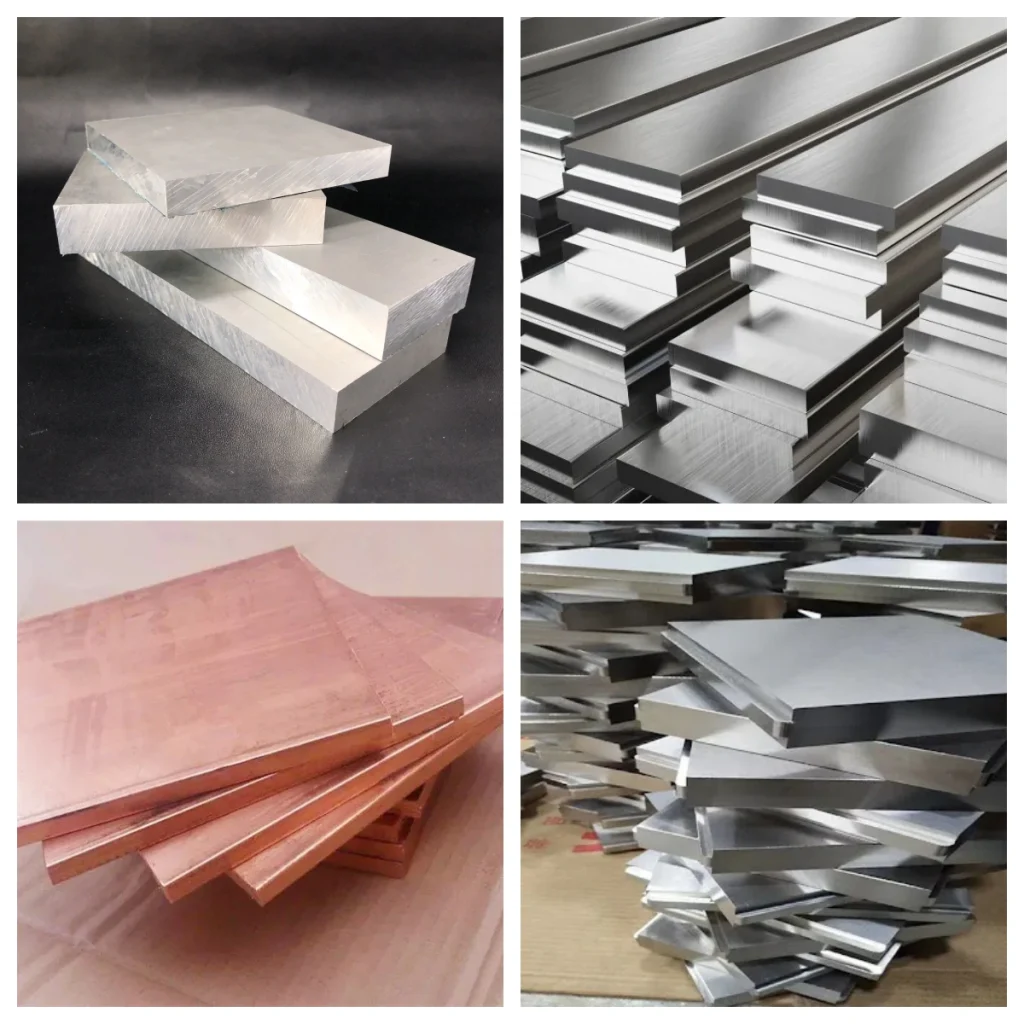

3. Versatility:

These machines can handle a variety of metals, including aluminum, stainless steel, copper, brass, and titanium, making them ideal for multiple industries.

4. Eco-Friendly Processes:

Laser cutting reduces material waste and optimizes energy usage, making it an environmentally sustainable choice for modern manufacturing.

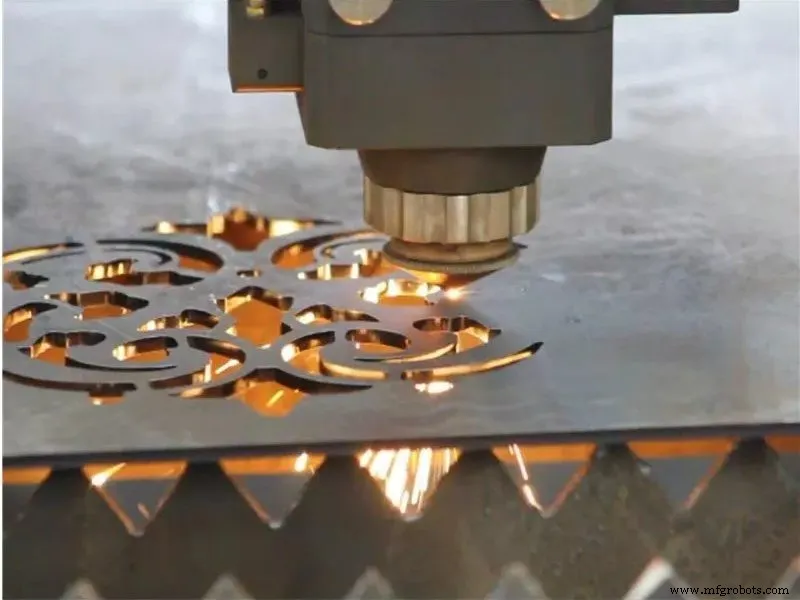

5. High Customizability:

Whether you’re working on prototypes, decorative elements, or mass production, CNC laser cutters provide the flexibility to meet any design specification.

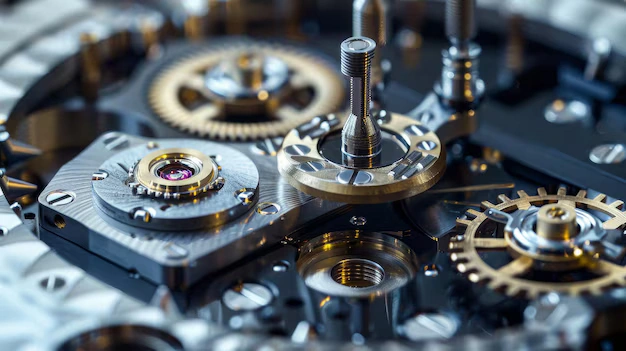

2.The Inner Workings of CNC Laser Cutting Machines

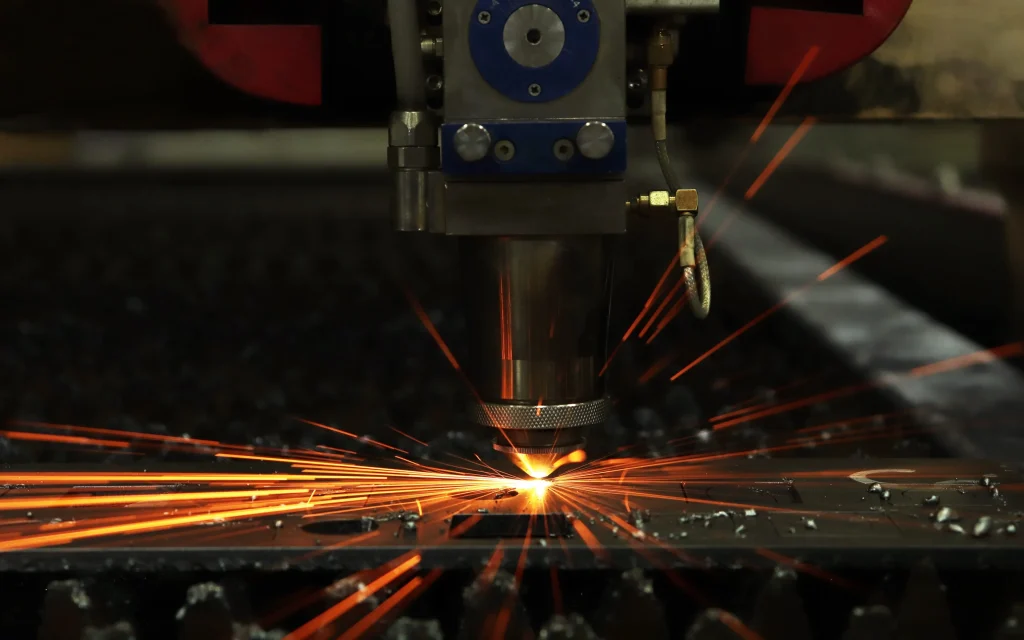

Laser cutting is a subtractive manufacturing process where a high-powered laser beam melts, vaporizes, or burns through materials. Here’s a closer look at how it all works:

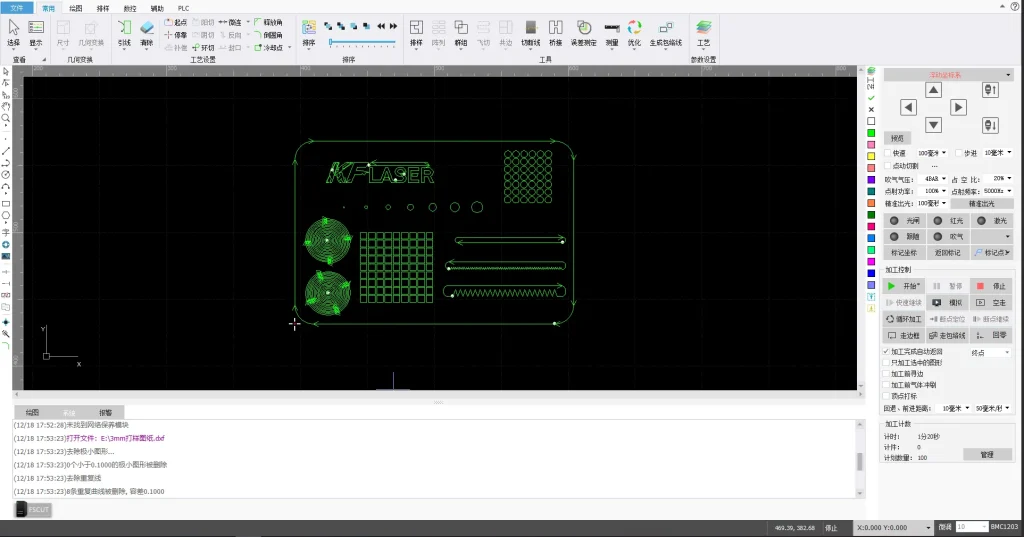

1. Design and Programming:

Engineers create a digital design using CAD (Computer-Aided Design) software. This design is then converted into CNC-readable code, ensuring the laser cutter follows exact specifications. This step allows for customization and error reduction.

2. Laser Beam Generation:

The heart of the CNC laser cutting machine lies in its laser source. Depending on the type of laser (fiber, CO2, or crystal), a focused beam of light is generated at temperatures exceeding 20,000°C. This intense heat enables the laser to cut through metals with incredible precision.

3. Material Interaction:

Once the laser beam reaches the sheet metal, it interacts with the material to either melt, burn, or vaporize it. Assist gases like nitrogen or oxygen are often used to expel molten material and enhance cutting speed.

4. Precision Movement:

The CNC system controls the movement of the laser head with extreme accuracy, following the design’s intricate patterns. This ensures uniformity and minimal material wastage.

5. Post-Processing:

After the cutting is complete, the material undergoes minimal post-processing. Clean edges and smooth surfaces mean less time spent on additional finishing processes, saving manufacturers both time and money.

3.Applications Across Industries

The versatility of CNC laser cutting machines makes them indispensable in numerous sectors. From aerospace and automotive to creative arts and medical devices, these machines have revolutionized manufacturing.

4.Why KF LASER is the Industry Leader

KF LASER sets the benchmark in CNC laser cutting technology. With cutting-edge machines and a commitment to innovation, KF LASER delivers unparalleled precision and reliability.

CNC Laser Cutting Machine Sheet Metal

Join KF Laser to get more laser cutting solutions

Learn More★ If you are interested in this article, please share it to:

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine