News

Fiber Laser Metal Cutting: The Future of Precision and Efficiency in Manufacturing

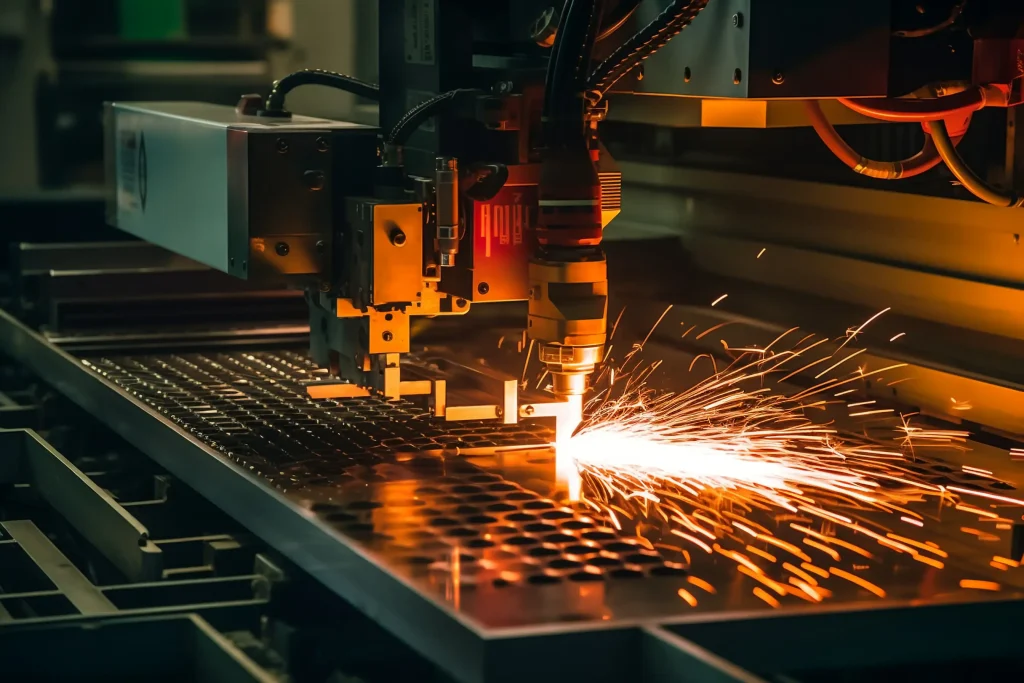

In today’s rapidly evolving manufacturing landscape, fiber laser metal cutting has become an essential tool for businesses seeking precision, efficiency, and cost savings. Whether you’re cutting stainless steel, aluminum, or copper, fiber lasers offer a level of speed and accuracy that traditional cutting methods simply can’t match. But what exactly is fiber laser metal cutting, and why should you invest in this cutting-edge technology? Let’s dive into the world of fiber laser cutting machines and discover how they’re transforming industries around the globe.

☺ You can share this article to:

Ⅰ. What Is Fiber Laser Metal Cutting?

◆ The Basics of Fiber Laser Cutting Technology

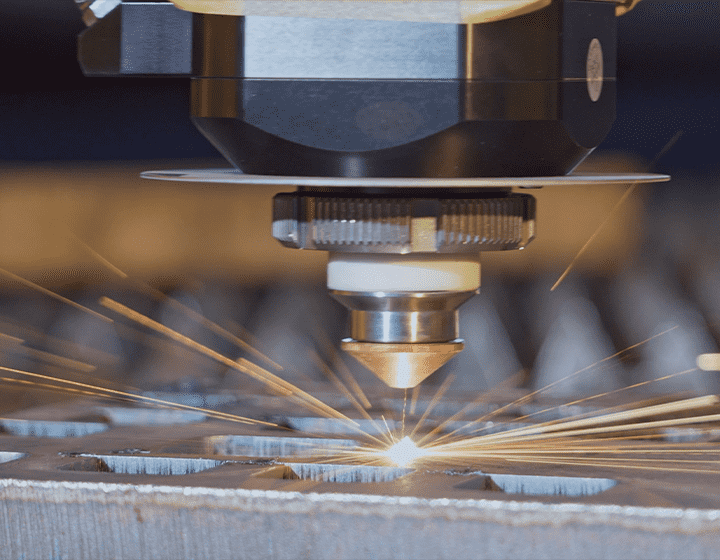

Fiber laser metal cutting refers to the process of using a fiber-optic laser beam to cut through various types of metal. The laser is generated by a solid-state fiber laser and transmitted through a fiber-optic cable to the cutting head. The concentrated laser beam focuses intense heat onto the material, causing it to melt, burn, or vaporize, depending on the material’s properties and thickness.

Unlike traditional CO2 lasers, fiber lasers have a smaller beam diameter and higher efficiency, making them ideal for high-precision cutting tasks. Fiber laser metal cutting machines are highly versatile, enabling manufacturers to achieve precise cuts in both thin and thick metal sheets.

◆ How Does Fiber Laser Cutting Compare to Other Cutting Methods?

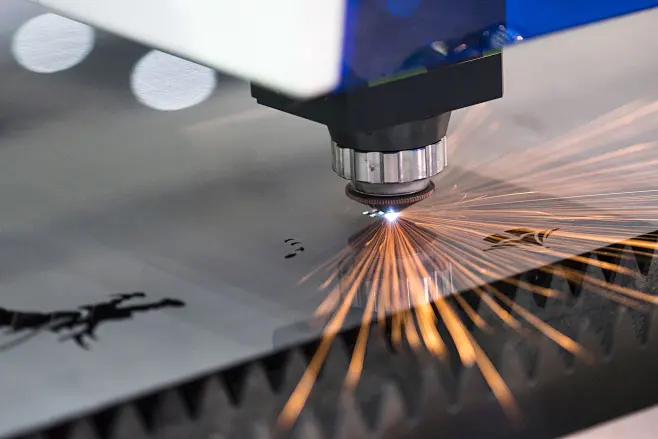

Fiber laser cutting has emerged as one of the most powerful and accurate methods of cutting metals, particularly when compared to older technologies like plasma or mechanical cutting. Here are some of the key advantages of fiber lasers over other methods:

▶ Speed: Fiber lasers can cut through metal at much faster speeds compared to traditional methods, dramatically reducing production times.

▶ Precision: The laser beam is incredibly focused, allowing for finer details and clean cuts with minimal kerf width.

▶ Cost Efficiency: Despite the initial investment in the equipment, fiber lasers often lead to lower operational costs in the long term due to their reduced energy consumption and minimal wear and tear.

Ⅱ. Advantages of Fiber Laser Metal Cutting Machines

◆ Unmatched Cutting Speed

One of the primary reasons manufacturers are turning to fiber laser metal cutting is the speed at which it can process materials. Fiber lasers are known for their high cutting speeds, even when working with thicker materials. The technology allows for continuous cutting without needing to pause or make adjustments, increasing the overall productivity of a business.

◆ High Precision and Quality

Precision is a critical factor when cutting metals, and fiber lasers excel in this area. The focused laser beam ensures that each cut is made with extreme accuracy, producing high-quality edges without burrs or distortions. This is especially important in industries like aerospace, automotive manufacturing, and medical device production, where tight tolerances are required.

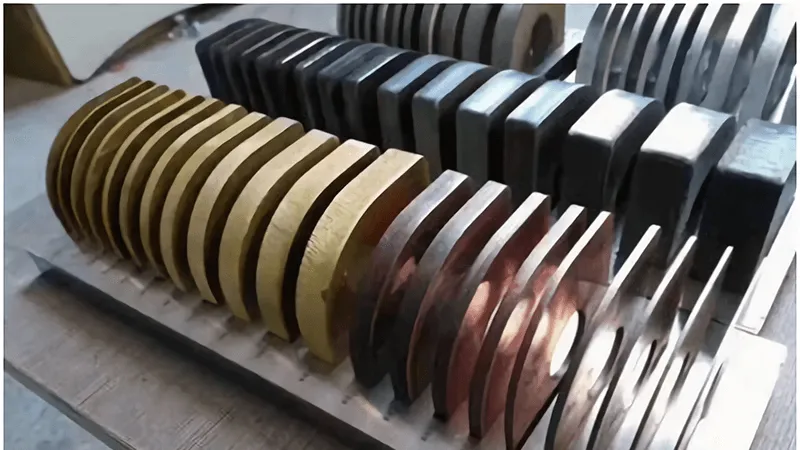

◆ Versatility in Material Types

Fiber lasers are compatible with a wide variety of materials, including stainless steel, aluminum, titanium, and brass. This makes them an ideal solution for industries that need to work with different metals on a daily basis. The ability to cut both thin and thick metals with ease makes fiber lasers a versatile tool in the manufacturing sector.

◆ Lower Operating Costs

Although fiber laser cutting machines can require a significant initial investment, their lower operating costs make them an excellent choice in the long term. Fiber lasers consume less electricity compared to CO2 lasers, which reduces overall energy consumption. Additionally, fiber laser systems typically require less maintenance, which leads to lower downtime and service costs.

Ⅲ. Key Features to Consider When Buying a Fiber Laser Metal Cutting Machine

◆ Power Rating and Material Thickness

The power rating of a fiber laser cutting machine directly impacts the types of materials and thicknesses it can handle. Machines with higher power ratings (e.g., 3000W or 4000W) are suitable for cutting thicker materials, while lower-power machines (e.g., 1000W) are more appropriate for cutting thinner metals. It’s important to select the right machine based on the typical material thickness you plan to cut.

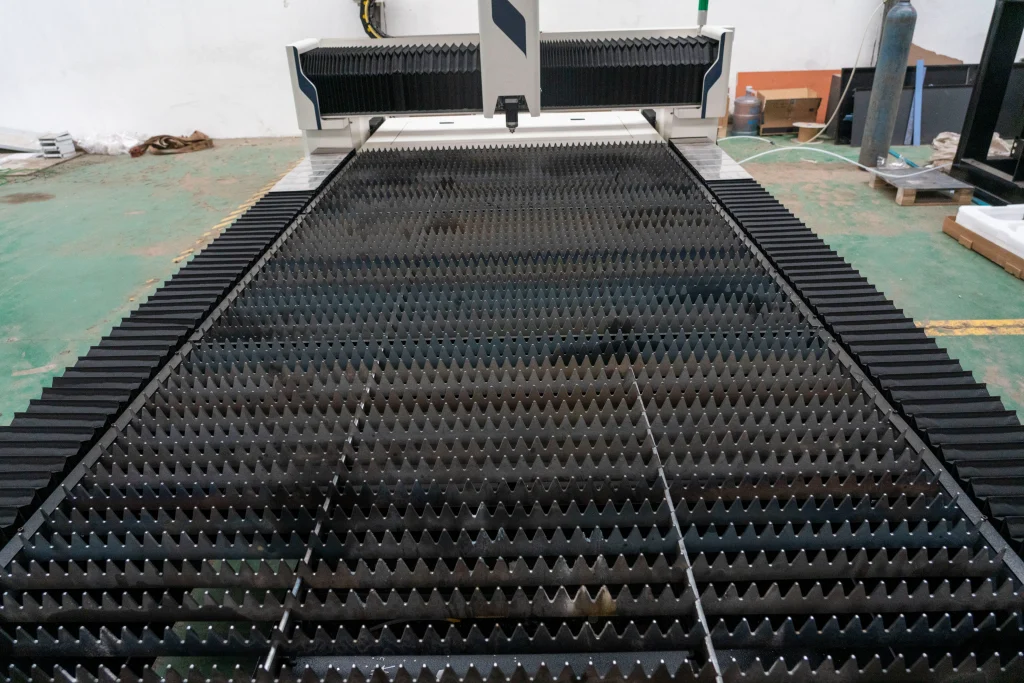

◆ Cutting Area and Size

The cutting area of a fiber laser machine will determine the maximum size of the material it can process. Larger machines are capable of handling bigger sheets, but they come at a higher price. Evaluate your production needs and space limitations before deciding on the size and cutting bed capacity of the machine.

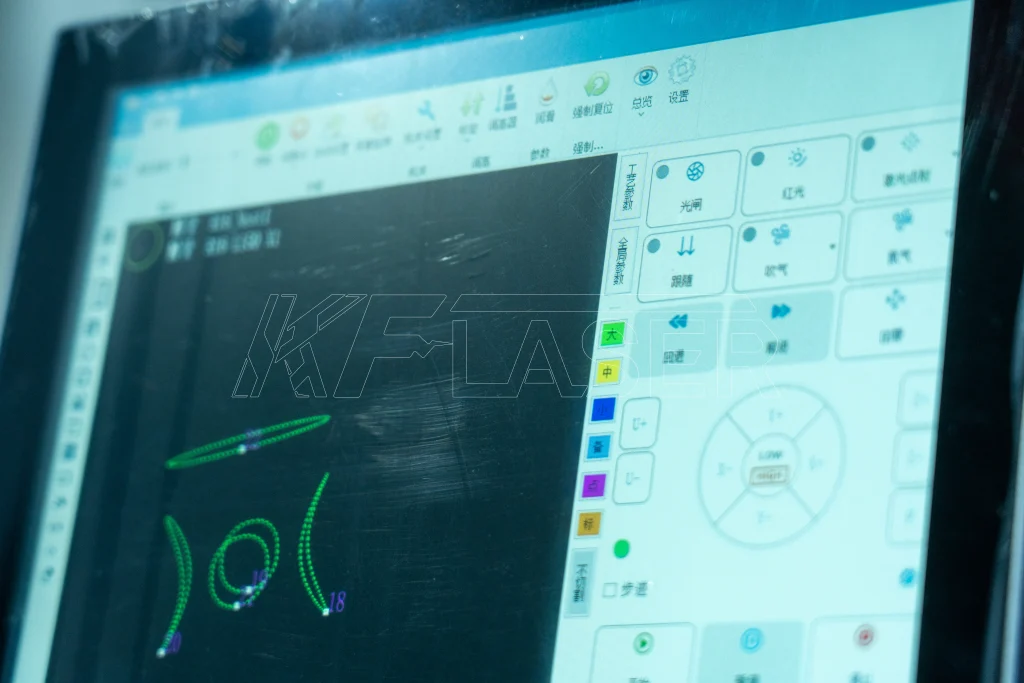

◆ Automation and Software Integration

Advanced fiber laser metal cutting machines come with automated features such as automatic focus adjustment, material handling, and cutting path optimization. These features can reduce human error and improve production efficiency. Look for machines that are equipped with user-friendly software to optimize the cutting process and ensure maximum precision.

◆ Maintenance and Support

Regular maintenance is essential to ensure the longevity and efficiency of your fiber laser cutting machine. When purchasing, check for the level of technical support and warranty options offered by the manufacturer. A strong support network will ensure that you can quickly resolve any issues that may arise during operation.

Ⅳ. Price Range of Fiber Laser Metal Cutting Machines

The price of fiber laser cutting machines can vary significantly based on factors such as machine size, cutting power, and features. Here’s an approximate breakdown of what to expect:

| type | Price Range | power | Features |

| Entry-Level Machines | $10,000 to $50,000 | around 1000W to 2000W | It can cut thinner metals at high speed and high precision, but cannot handle thicker materials or mass production. |

| Mid-Range Machines | $50,000 to $150,000 | 3000W to 4000W | Equipped with additional features such as advanced automation and software integration to increase productivity. |

| High-End Machines | $150,000 and Above | high power | With high power ratings, large cutting areas and advanced software, it can handle complex projects on an industrial scale. |

◆ Entry-Level Machines: $10,000 to $50,000

Entry-level fiber laser machines are typically more affordable and suitable for small to medium-sized businesses. These machines may have lower power ratings (around 1000W to 2000W) and smaller cutting areas. While they offer excellent precision and speed for thinner metals, they may not be able to handle thicker materials or high-volume production.

◆ Mid-Range Machines: $50,000 to $150,000

Mid-range fiber laser cutting machines are ideal for businesses that need to cut a variety of materials and thicker metals. With power ratings in the 3000W to 4000W range, these machines provide a good balance between price and capability. They’re also equipped with additional features like advanced automation and software integration for greater productivity.

◆ High-End Machines: $150,000 and Above

High-end fiber laser metal cutting machines can exceed $150,000. These machines are typically used by large manufacturers in industries like aerospace, automotive, and heavy machinery. They come with high power ratings, larger cutting areas, and state-of-the-art software that can handle complex projects at an industrial scale.

Ⅴ. How to Choose the Best Fiber Laser Metal Cutting Machine for Your Needs

◆ Understand Your Cutting Requirements

Before purchasing a fiber laser cutting machine, assess your specific cutting requirements. What types of materials do you most often work with? What thicknesses do you typically cut? Understanding your needs will help you select the machine with the right power and capabilities.

◆ Compare Prices and Features

Don’t just choose the cheapest option. Compare the prices and features of different machines to find the best value. Factor in the cost of maintenance, energy consumption, and post-purchase support when calculating the total cost of ownership.

◆ Consider Future Expansion

Choose a machine that can grow with your business. If you plan to expand your cutting capabilities in the future, it may be worth investing in a more powerful machine that can handle a wider variety of materials and larger workloads.

Your best choice for ultimate metalworking solutions.

By investing in a fiber laser metal cutting machine, you can significantly improve your production efficiency, reduce operational costs, and increase the quality of your final products. With the right machine, your business will be equipped to meet the demands of modern manufacturing.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine