Noticias

Máquina de cortar láser de alta potencia: Eficiencia y precisión en la industria moderna

When it comes to precision and speed in industrial cutting, high power laser cutting machines stand at the forefront of technological advancements. These machines use powerful lasers to cut through various materials, from metals to plastics, with unmatched precision and minimal thermal distortion. Whether you are in manufacturing, aeroespacial, automotor, or construction, the high power laser cutting machine is essential for streamlining your processes and improving overall productivity.

But what exactly sets these machines apart from their conventional counterparts? Why has their popularity soared in industries worldwide? This article will delve deep into the world of high power laser cutting, breaking down its benefits, key features, and applications, all while providing insights into how it can transform your business operations.

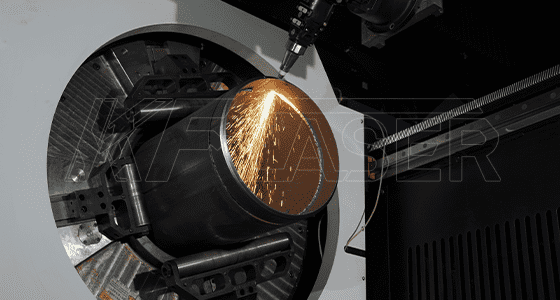

How High Power Laser Cutting Machines Work

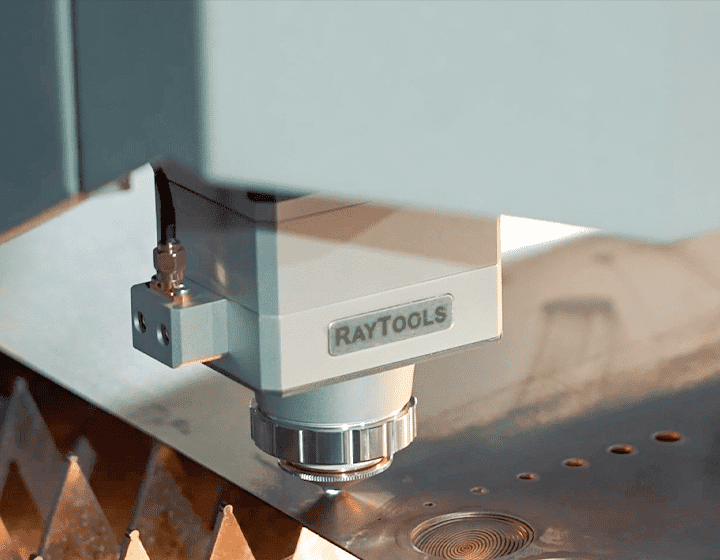

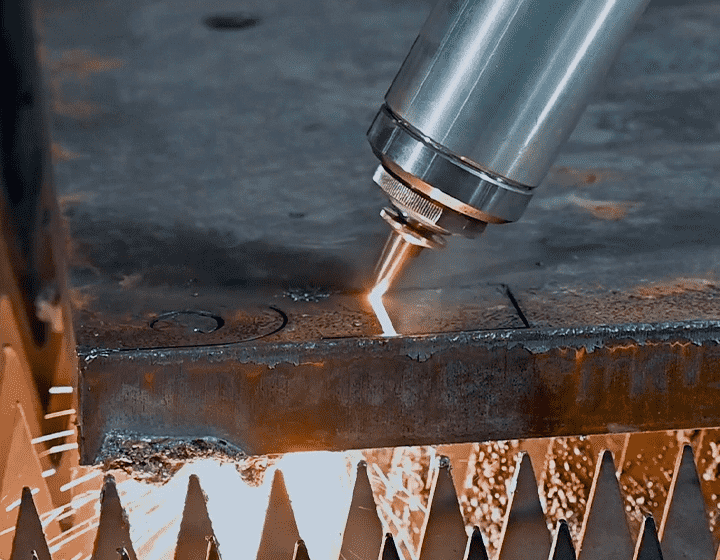

At the core of a high power laser cutting machine is its ability to direct a concentrated beam of light at a material, usually focused by a series of lenses and mirrors. The intense heat from the laser melts, quemaduras, o vaporiza el material, creando un corte limpio. A typical high power laser cutting machine can operate with a laser power ranging from several kilowatts (kW) to even hundreds of kW for industrial applications.

These machines are equipped with sophisticated computer numerical control (CNC) systems that allow for fine-tuned adjustments and high accuracy. This ensures that each cut is consistent and precise, even on intricate designs or complex materials.

The primary advantages of high power laser cutting machines incluir:

- Exceptional precision, down to microns.

- High-speed operation that minimizes processing time.

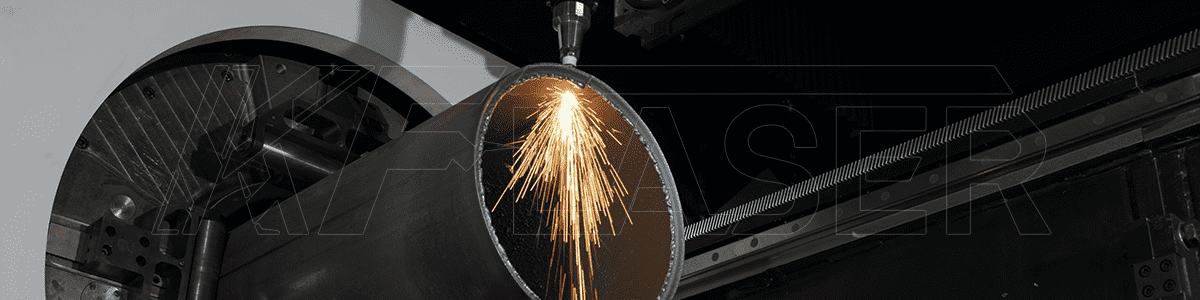

- Ability to cut a wide range of materials, incluyendo metales, composites, and even certain types of glass.

- Clean edges and minimal thermal effects, reducing the need for post-processing.

Applications of High Power Laser Cutting Machines

The applications of high power laser cutting machines are vast and varied, spanning across numerous industries:

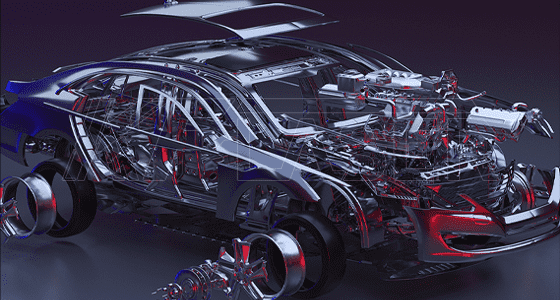

1. Industria automotriz

En el sector del automóvil, high power laser cutting machines are used to cut and shape a wide range of materials, from body panels to engine parts. The ability to cut complex geometries and intricate designs is particularly valuable for producing lightweight, high-performance vehicles.

2. Industria aeroespacial

Aerospace manufacturing requires precision components made from advanced materials like titanium and aluminum alloys. Laser cutting is ideal for these applications, as it allows for the creation of components with exceptional accuracy, even in materials that are difficult to work with using traditional methods.

3. Fabricación de productos electrónicos

In electronics, precision is paramount, especially when working with delicate circuit boards or metal enclosures. High power laser cutting is used to create fine cuts and patterns without compromising the integrity of the materials, ensuring high-quality products in this fast-paced industry.

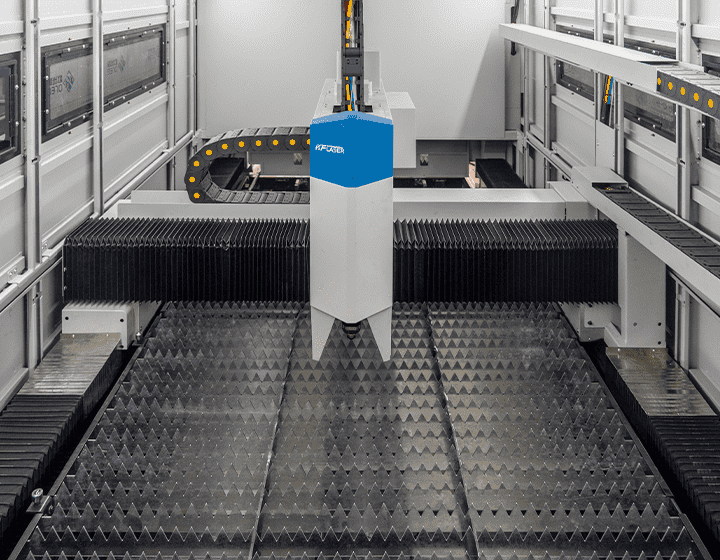

4. Metal Fabrication and Construction

For construction and metal fabrication, laser cutting machines offer high-speed solutions for cutting large sheets of metal or custom pieces for construction projects. This includes creating steel structures, marcos, and architectural designs with intricate cuts that are often required for modern building designs.

Considerations When Choosing a High Power Laser Cutting Machine

While high power laser cutting machines offer many benefits, it is essential to carefully consider your specific needs before making an investment. Some factors to keep in mind include:

1. Laser Power and Material Thickness

The laser power directly affects the machine’s ability to cut through various material thicknesses. Por ejemplo, higher wattage lasers are required for cutting through thick metal sheets or dense materials. It is crucial to choose a machine with sufficient power for your material needs.

2. Velocidad de corte y eficiencia

Consider how much speed you need for your cutting tasks. While higher power lasers are generally faster, the efficiency of the machine can vary depending on the material type and thickness. Balancing speed with precision is key for many industries.

3. Automation and CNC Systems

Modern laser cutting machines are often equipped with advanced CNC systems that automate the cutting process. Look for machines that offer easy integration with existing workflows, as well as customizable features to meet your specific requirements.

4. Mantenimiento y soporte

High power laser cutting machines require regular maintenance to ensure peak performance. Check whether the manufacturer provides comprehensive support, including training, spare parts, and servicing, to minimize downtime and maximize the lifespan of the machine.

Future Trends in High Power Laser Cutting Technology

As the demand for more efficient, preciso, and sustainable manufacturing methods continues to grow, the future of high power laser cutting machines looks promising. Future advancements are likely to focus on further increasing cutting speeds, reducing energy consumption, and improving automation. Además, innovations in fiber laser technology and hybrid systems are paving the way for even more versatile and powerful machines.

A medida que las industrias continúan evolucionando, high power laser cutting will play an increasingly pivotal role in shaping the future of manufacturing, engineering, and production processes across the globe.

By understanding the capabilities and applications of high power laser cutting machines, businesses can make informed decisions on investing in the technology. With their unmatched precision, versatilidad, y velocidad, these machines have the potential to revolutionize manufacturing processes, bringing significant improvements in both quality and cost-efficiency.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora