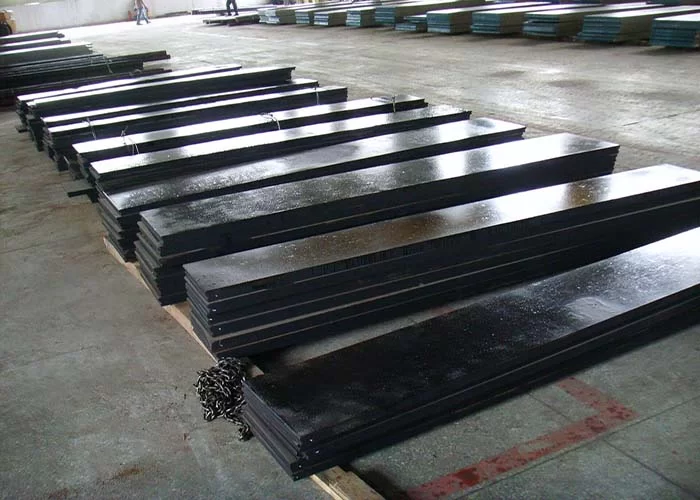

Laser cut steel sheets have become indispensable in the modern manufacturing world. The precision, speed, and versatility offered by laser cutting technology have reshaped industries, providing a superior solution for intricate cuts and high-quality finishes. As the demand for advanced manufacturing methods continues to grow, laser cutting of steel sheets stands at the forefront of this revolution.

In today’s competitive market, achieving efficiency while maintaining exceptional product quality is crucial. Laser cut steel sheets deliver on both, providing businesses with the tools to create complex shapes with minimal material waste and maximum accuracy. This article delves into the transformative benefits of laser cutting steel sheets, shedding light on how this technology continues to redefine the manufacturing landscape.

The process of laser cutting involves using a focused beam of light to melt, burn, or vaporize steel sheets with exceptional precision. This method stands out due to several distinct advantages over traditional cutting techniques, making it the go-to choice for a variety of industries.

✔Unmatched Precision and Accuracy

When it comes to laser cut steel sheets, precision is paramount. The accuracy of a laser beam ensures that each cut is sharp and flawless, with minimal deviation from the design. For industries that require exact specifications, such as aerospace and automotive, this level of precision is invaluable. The ability to achieve tight tolerances without any mechanical contact also reduces the risk of distortion, further enhancing the quality of the final product.

✔High Speed and Efficiency

Laser cutting technology is known for its speed, particularly when processing materials like steel. Compared to traditional mechanical cutting methods, laser cut steel sheets can be processed more quickly without sacrificing quality. This results in faster turnaround times and increased production efficiency. The high-speed nature of laser cutting also contributes to cost reduction, as it minimizes the time required to produce complex components.

✔Minimal Material Waste

One of the significant advantages of using laser cut steel sheets is the minimal material waste generated during the cutting process. The narrow kerf (cut width) produced by the laser reduces the amount of excess material, ensuring that businesses get the most out of their raw materials. In industries where materials are expensive, such as aerospace or medical device manufacturing, this efficiency leads to considerable cost savings.

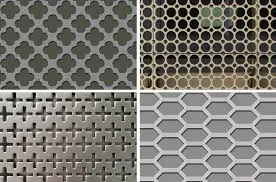

✔Capability to Cut Complex Shapes

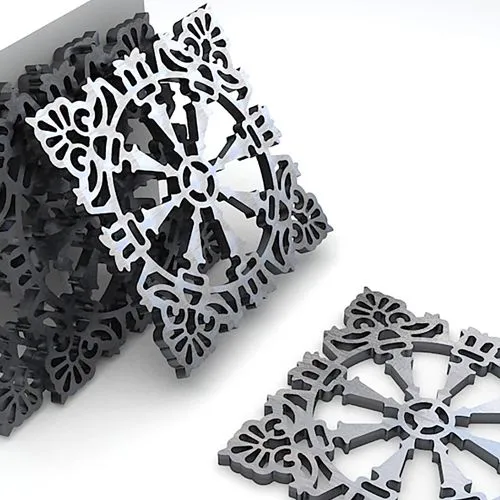

Laser cutting is unparalleled when it comes to producing complex and intricate shapes from steel sheets. Whether it’s cutting holes, curved edges, or irregular shapes, laser cutting can handle it all with ease. This capability is especially important for industries that require high customization, such as architectural design and custom fabrication. The flexibility offered by laser cut steel sheets opens up new possibilities for design and manufacturing that would be challenging to achieve with traditional methods.

✔Clean and Smooth Edges

The precision of laser cut steel sheets ensures that the edges of the cut material are smooth and clean, requiring little to no post-processing. This is a significant advantage in applications where the final finish is important, such as in decorative metalwork or components used in high-performance machinery. The reduced need for finishing processes like sanding or grinding helps speed up production and ensures a higher-quality output.

The versatility and efficiency of laser cutting technology have made it a crucial part of many industries. Here’s how laser cut steel sheets are benefiting sectors across the globe:

Automotive Industry

In the automotive sector, laser cut steel sheets are essential for producing complex body panels, structural components, and chassis parts. Laser cutting ensures that these parts meet exacting standards of precision, allowing for a faster and more cost-effective production process. As the automotive industry shifts towards more customized and lightweight designs, laser cutting remains the preferred method for steel sheet fabrication.

Aerospace Industry

For the aerospace industry, laser cut steel sheets are used to create parts that require both strength and precision. Components such as brackets, panels, and structural elements benefit from the accuracy and efficiency provided by laser cutting. Given the demanding nature of aerospace manufacturing, the ability to cut steel sheets with high precision ensures the safety and reliability of critical components.

Architecture and Construction

The architecture and construction industries have also embraced laser cut steel sheets for creating intricate designs and structures. From custom decorative metal panels to structural reinforcements, laser cutting allows architects to achieve creative and functional designs with ease. The ability to work with various thicknesses of steel ensures that these industries can use laser cut steel sheets for both aesthetic and structural applications.

Electronics Manufacturing

In the electronics industry, laser cutting technology is used to create precise enclosures, brackets, and heat sinks. These components, often made from steel sheets, require high accuracy and clean cuts to meet strict specifications. Laser cut steel sheets are the ideal solution for producing these small, complex parts in large quantities without compromising on quality.

Energy Sector

The energy sector, particularly in the production of wind turbines, power plants, and other large-scale machinery, relies heavily on laser cut steel sheets. The precision and speed of laser cutting make it the perfect solution for manufacturing parts that must withstand extreme conditions while maintaining strict tolerances. By utilizing laser cut steel sheets, companies can ensure the durability and functionality of their equipment.

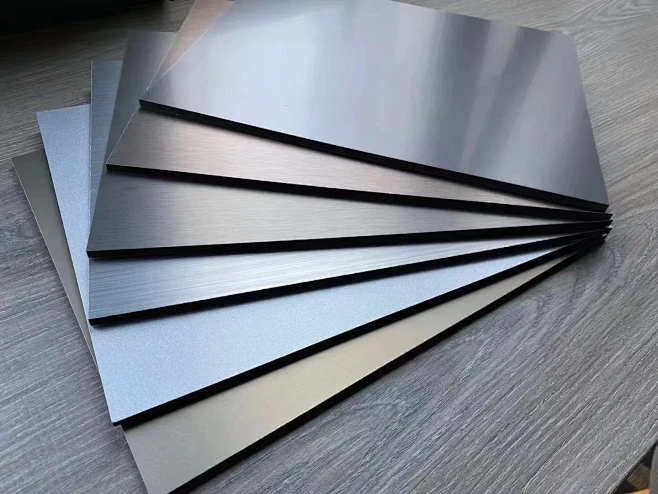

Selecting the right type of steel is crucial for achieving the desired results with laser cutting. Some factors to consider include the thickness of the material, the type of steel, and the complexity of the design.

◆Mild Steel

Mild steel is commonly used for laser cutting because it is cost-effective and easy to work with. It is ideal for a variety of applications, including general fabrication and structural components. Mild steel is often used for laser cut steel sheets in industries such as construction and automotive manufacturing.

◆Stainless Steel

Stainless steel is prized for its corrosion resistance and strength, making it an excellent choice for laser cutting in industries like aerospace, medical device manufacturing, and food processing. Laser cut steel sheets made from stainless steel offer both durability and a smooth finish, making them suitable for high-performance applications.

◆Aluminum

While not as strong as steel, aluminum is lightweight and highly resistant to corrosion. It is often used for laser cutting in industries that require lightweight materials, such as aerospace and electronics. Aluminum laser cut steel sheets are ideal for producing parts that need to be both durable and lightweight.

◆Tool Steel

Tool steel is known for its hardness and ability to withstand wear and tear. It is used for making cutting tools and dies, and laser cut steel sheets made from tool steel are often used in manufacturing processes that require precise, durable tools.

As laser cutting technology continues to advance, the possibilities for laser cut steel sheets will only expand. Innovations in laser types, such as fiber lasers, promise even faster cutting speeds and greater energy efficiency. Additionally, the integration of AI and machine learning in laser cutting machines will help optimize the cutting process, ensuring higher efficiency, precision, and reduced material waste.

The ongoing development of laser cut steel sheets technology ensures that industries across the globe can continue to take advantage of its benefits, from increased productivity to more complex and customized designs.

With the advent of laser cut steel sheets, manufacturers are able to achieve precision, efficiency, and versatility previously thought unattainable. Whether it’s for automotive, aerospace, or general fabrication, laser cutting technology continues to redefine the possibilities of steel sheet fabrication.