News

Laser Cutting Machine Sheet: The Key to Precision and Efficiency in Modern Manufacturing

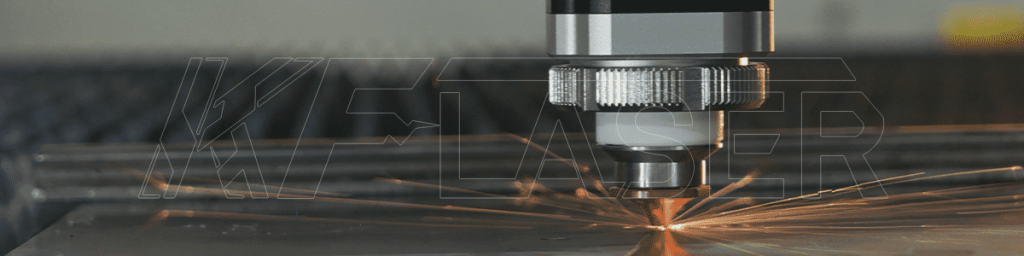

Laser cutting technology has revolutionized industries worldwide, offering unmatched precision and efficiency in the processing of sheet metal. As manufacturers continue to look for ways to enhance their production processes, laser cutting machines stand out as an indispensable tool. In this article, we will explore how laser cutting machines are used in sheet metal fabrication, the benefits they offer, and why they are becoming increasingly essential in modern manufacturing environments.

Understanding Laser Cutting for Sheet Metal

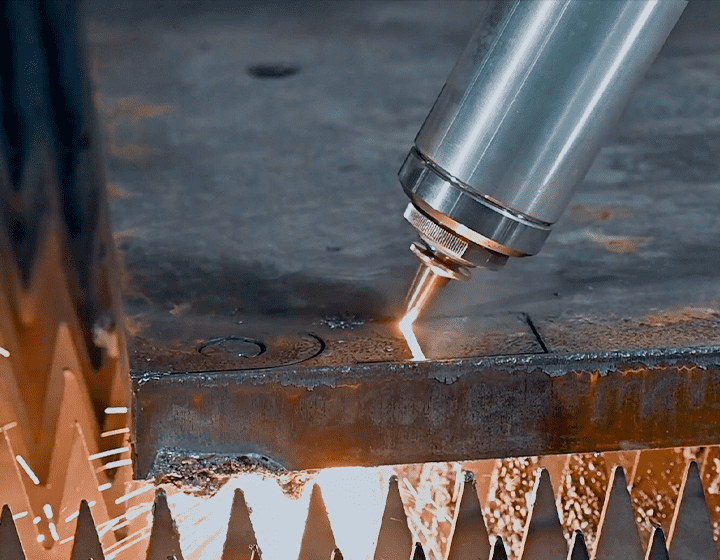

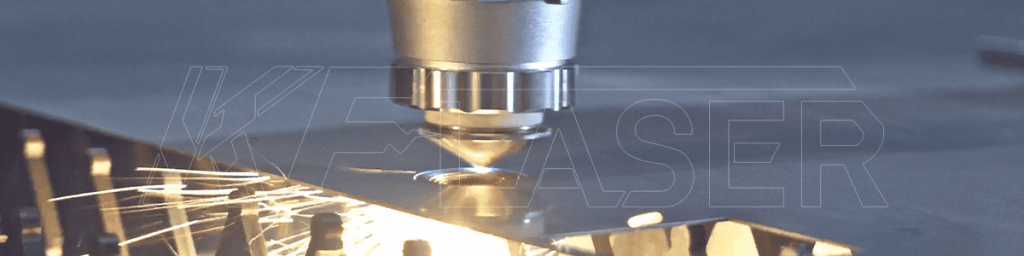

Laser cutting is a process that uses a high-powered laser beam to cut through materials, particularly metals such as steel, aluminum, and titanium. The precision of laser cutting is remarkable, making it an ideal method for creating complex shapes and intricate designs in sheet metal.

Unlike traditional cutting methods that rely on mechanical force, laser cutting works by focusing a high-energy laser beam onto the material, which melts, burns, or vaporizes the material in the path of the beam. The result is a clean, precise cut that requires minimal post-processing. This level of precision ensures that even the most delicate and detailed designs can be fabricated with ease.

Key Advantages of Using Laser Cutting Machines for Sheet Metal

1. High Precision and Accuracy

One of the standout benefits of laser cutting machines is their ability to deliver precise and accurate cuts. The technology used in these machines allows for a level of detail that would be impossible to achieve with traditional cutting methods. Whether you are working with thick or thin sheet metal, laser cutting can ensure that the edges are smooth and well-defined.

2. Minimal Material Waste

Laser cutting machines are designed to use as little material as possible, which results in minimal waste. This is particularly beneficial in industries where material costs can be a significant expense. The machine’s ability to cut shapes with minimal kerf (the width of the cut) ensures that manufacturers can make the most out of their raw materials.

3. Speed and Efficiency

Laser cutting machines are incredibly fast, allowing manufacturers to increase their throughput and meet tight production deadlines. The high-speed operation of these machines ensures that large quantities of sheet metal can be processed in a relatively short amount of time. This is particularly useful in industries like automotive and aerospace manufacturing, where high volumes of parts need to be produced quickly.

4. Versatility in Material Types

Laser cutting technology is not limited to just one type of material. It can effectively cut a wide range of materials, including various metals, plastics, and even wood. This versatility makes laser cutting machines ideal for companies that need to work with multiple materials in their production process.

The Components of a Laser Cutting Machine

Laser cutting machines typically consist of several key components that work together to perform the cutting process efficiently.

1. The Laser Source

The laser source generates the laser beam, which is directed at the material to be cut. The source can vary in power depending on the thickness and type of material being processed. Common types of laser sources include CO2 lasers, fiber lasers, and Nd:YAG lasers.

2. Beam Delivery System

Once the laser beam is generated, it is delivered to the cutting head through a series of mirrors and optical fibers. The beam delivery system ensures that the laser is accurately focused onto the material’s surface for a precise cut.

3. The Cutting Head

The cutting head is where the laser beam is focused onto the sheet metal. It also contains sensors that monitor the distance between the cutting head and the material, ensuring that the laser maintains optimal focus during the cutting process.

4. The CNC Controller

Most modern laser cutting machines are controlled by a computer numerical control (CNC) system. This system allows operators to input specific cutting parameters and adjust settings such as speed, power, and focus. The CNC controller ensures that the laser cutting machine operates efficiently and accurately, making it easier for manufacturers to produce consistent, high-quality results.

Common Applications of Laser Cutting in Sheet Metal Fabrication

Laser cutting machines are widely used across various industries for sheet metal fabrication. Some of the most common applications include:

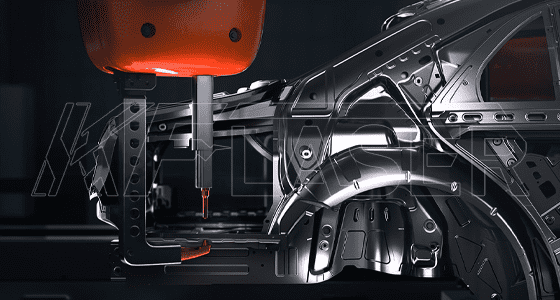

1. Automotive Industry

In the automotive sector, laser cutting is used for manufacturing various components, including body panels, chassis, and exhaust systems. The precision and speed of laser cutting make it ideal for producing high-volume parts with complex shapes.

2. Aerospace Manufacturing

Aerospace companies rely heavily on laser cutting machines to produce intricate components for aircraft, such as wing parts, engine components, and structural elements. The ability to work with materials like titanium and aluminum, combined with the precision of the laser, makes it a perfect fit for the aerospace industry.

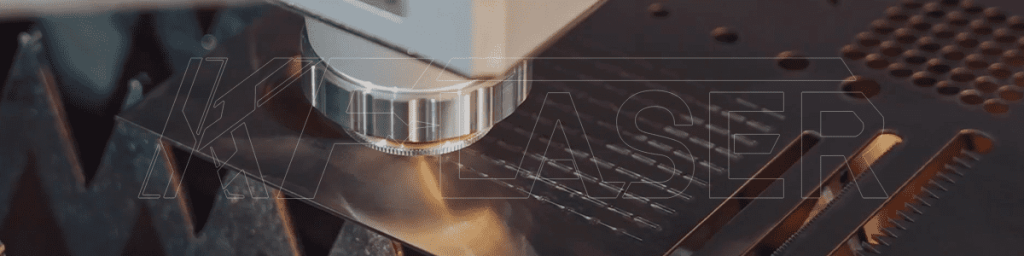

3. Sheet Metal Enclosures

Laser cutting is also commonly used for creating sheet metal enclosures for electronics and electrical equipment. The ability to cut precise holes and shapes in thin sheet metal allows manufacturers to create custom enclosures that are both functional and aesthetically pleasing.

4. Architectural Applications

Laser cutting machines are increasingly being used in the architectural industry to create decorative elements for buildings. From intricate metalwork to custom-designed panels, laser cutting allows architects to bring their designs to life with incredible detail and precision.

How to Choose the Right Laser Cutting Machine for Your Needs

Choosing the right laser cutting machine for your needs depends on several factors, including the type of materials you will be working with, the thickness of the material, and the complexity of the cuts required. Here are a few key considerations:

1. Power Requirements

Laser cutting machines come in different power ratings, which determine the maximum thickness of material the machine can cut. Higher-power machines are ideal for cutting thicker materials, while lower-power machines are better suited for thinner sheets.

2. Type of Laser

The type of laser used in the machine can also impact the quality of the cuts. CO2 lasers are commonly used for cutting non-metal materials, while fiber lasers are ideal for metals due to their higher efficiency.

3. Precision and Tolerances

If your project requires high precision and tight tolerances, it’s essential to choose a laser cutting machine that offers high accuracy. Look for machines with advanced CNC controllers and high-quality optics.

4. Automation and Integration

Consider whether the laser cutting machine can be integrated with other automation systems, such as robotic arms or conveyors, to streamline your production process. Automation can significantly increase the efficiency of your operations and reduce labor costs.

Conclusion

Laser cutting machines have revolutionized the way sheet metal is processed, offering manufacturers unparalleled precision, speed, and versatility. By understanding the technology behind laser cutting, the benefits it offers, and the various applications in different industries, businesses can make more informed decisions about incorporating laser cutting into their manufacturing processes. As the demand for more intricate and precise metal components grows, laser cutting will continue to be a crucial tool for manufacturers worldwide.

By investing in the right laser cutting machine, you can improve the quality of your products, reduce material waste, and increase overall efficiency. Whether you’re working in the automotive, aerospace, or architectural industry, laser cutting is a valuable asset that can enhance your production capabilities and set your business apart in an increasingly competitive market.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine