Notícias

Máquina de corte a laser peru: Por que é a escolha ideal para a fabricação de precisão

Introduction: The Growing Demand for Laser Cutting Machines in Turkey

O laser cutting machine market in Turkey has witnessed significant growth in recent years, driven by advancements in technology, a booming industrial sector, and an increasing demand for high-precision manufacturing. If you’re in search of a laser cutting machine in Turkey, you’re likely considering factors such as affordability, reliability, and the ability to handle complex cutting tasks. Turkey has emerged as a leader in providing cost-effective yet high-performance laser cutting machines tailored to diverse industries, ranging from automotive to metal fabrication.

But what makes Turkey such an attractive market for Máquinas de corte a laser? Neste artigo, we’ll explore the advantages of investing in laser cutting technology in Turkey, what to consider when purchasing a machine, and the features that make these machines stand out.

1. O que é um Máquina de corte a laser and How Does It Work?

◆ Introduction to Laser Cutting Technology

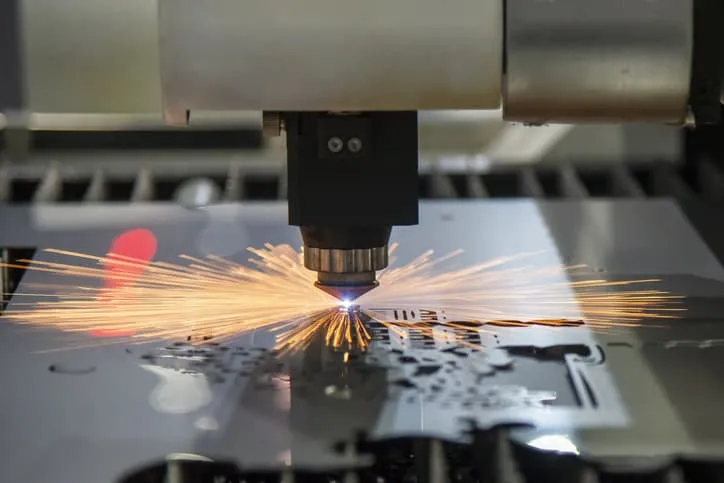

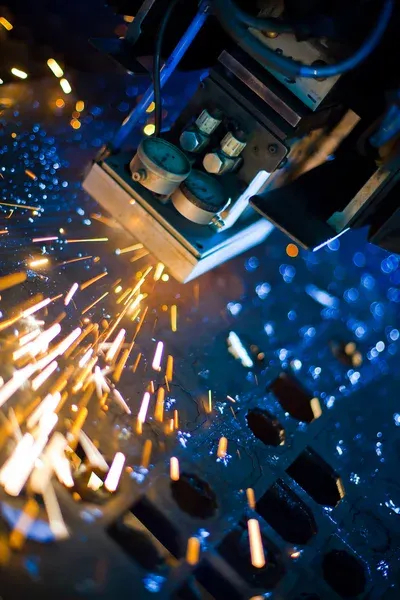

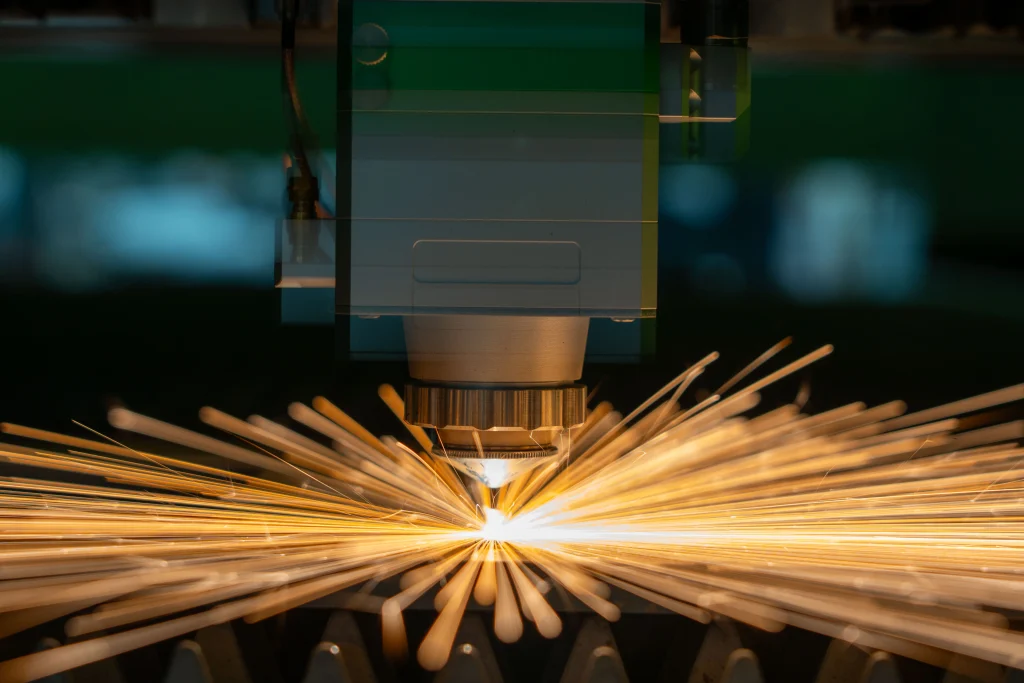

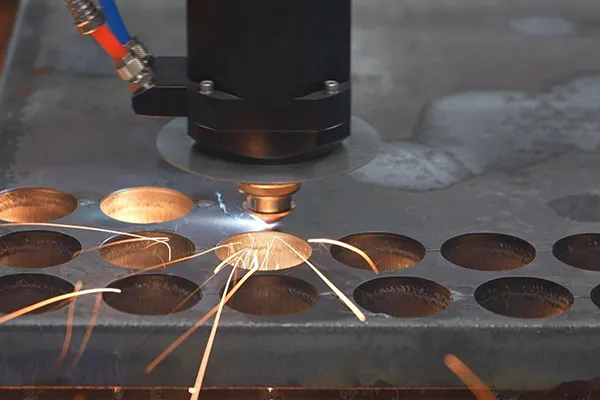

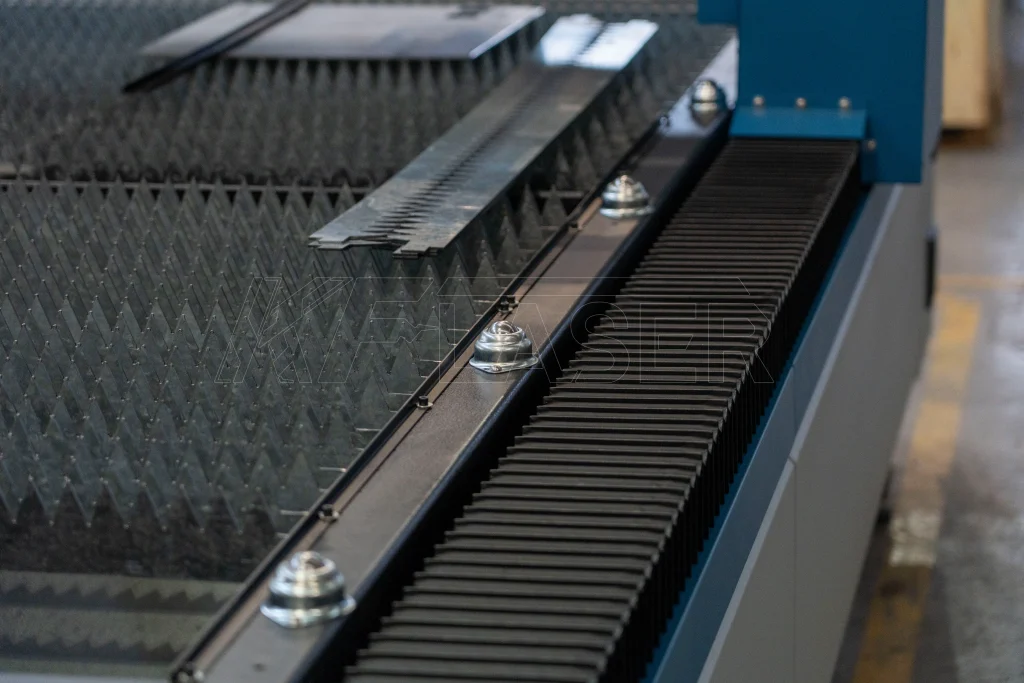

UM Máquina de corte a laser uses a focused beam of light to cut through materials such as metal, madeira, plástico, e mais. The laser’s precision allows it to cut with extreme accuracy and clean edges, making it ideal for industries that require high-quality manufacturing. Laser cutting is performed through CNC technology, where the laser path is guided by computer programming to produce precise cuts.

◆ How Does It Work?

Laser cutting machines operate by emitting a highly focused laser beam that is directed onto the surface of a material. The heat from the laser beam melts or vaporizes the material at the contact point, leaving a clean, corte preciso. The machine’s computer system controls the velocidade, poder, e movement of the laser, ensuring that each cut is performed according to the desired specifications. The versatility of these machines means they can handle everything from thin sheets of metal to thick industrial materials.

✔ The video below is of the KF Laser ST series plate and tube integrated cutting machine, which can give you a clearer understanding of the working principle of the cutting machine.

2. Why Choose Laser Cutting Machines in Turkey?

◆ Cost-Effectiveness

One of the primary reasons many businesses are turning to laser cutting machines in Turkey is their affordability. Compared to other countries, Turkey offers competitive prices for laser cutting technology, making it an attractive destination for businesses looking to optimize their operations without breaking the budget.

◆ High-Quality Manufacturing Standards

Despite the affordability, laser cutting machines in Turkey adhere to high manufacturing standards. Turkish manufacturers invest in cutting-edge technology, ensuring that the machines are durable, confiável, and capable of delivering high-precision cuts consistently.

◆ Skilled Workforce and After-Sales Support

Turkey boasts a skilled workforce experienced in advanced manufacturing techniques, which ensures that laser cutting machines are designed, tested, and maintained to high standards. Adicionalmente, many Turkish manufacturers offer excellent after-sales support, including training, maintenance services, and technical assistance, which adds tremendous value to customers purchasing laser cutting machines in Turkey.

3. Key Features to Look for in a Laser Cutting Machine

When considering a laser cutting machine in Turkey, it’s essential to look for several key features that ensure you’re making a smart investment:

◆ Power and Capacity

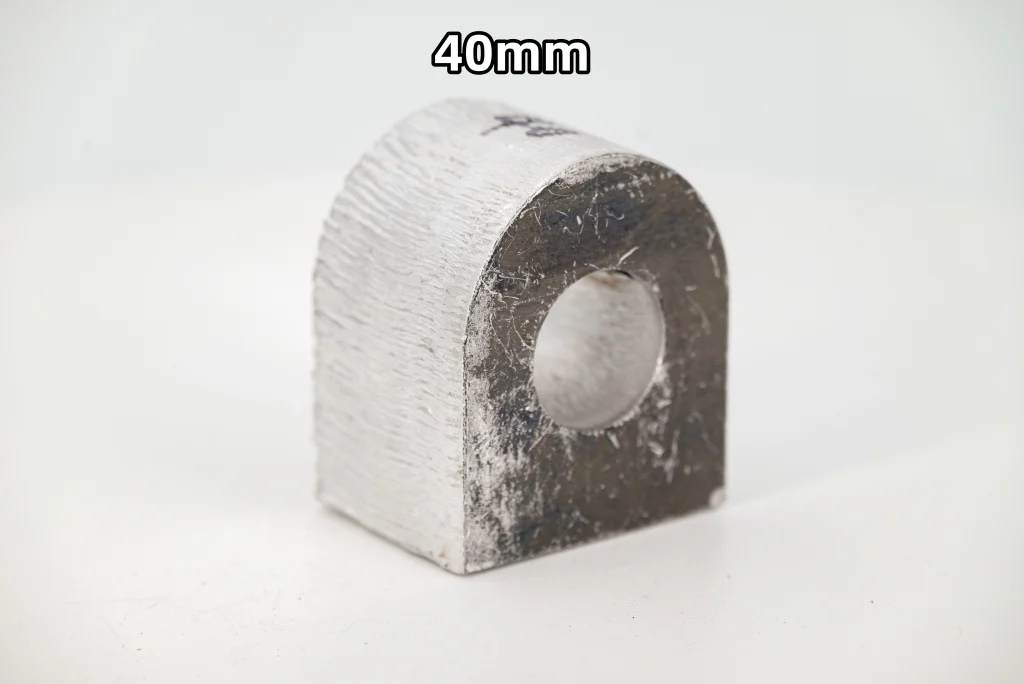

O laser power typically ranges from 500W to 6000W for different cutting capacities. Higher-power machines can cut thicker materials faster, while lower-power machines are more suited to thin materials. Choose a machine that matches your specific production needs.

◆ Precision and Speed

Look for a machine that balances precisão e velocidade. Laser cutting machines in Turkey are known for their precise cutting capabilities, ensuring minimal waste and high-quality results. High-speed cutting also ensures that production times are reduced, increasing overall efficiency.

◆ Versatility in Material Handling

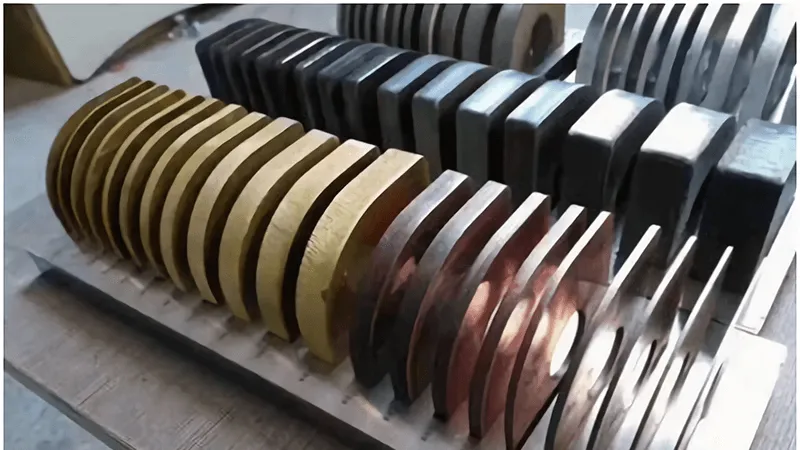

A good laser cutting machine can handle a wide range of materials, Incluindo aço inoxidável, alumínio, latão, cobre, plástico, e madeira. When purchasing, consider the material versatility of the machine to ensure it can accommodate your diverse cutting requirements.

◆ Cutting Bed Size

The size of the cutting bed determines how large a material can be processed. For larger sheets, you’ll need a machine with an appropriately sized bed to accommodate the dimensions of your materials.

4. Applications of Laser Cutting Machines in Various Industries

Laser cutting machines are widely used in the Automotivo e aeroespacial industries to create complex and precise parts. From cutting body panels to manufacturing critical components for aircraft, the accuracy and speed of laser cutting make it an indispensable tool in these high-precision industries.

◆ Metal Fabrication and Construction

In fabricação de metal, laser cutting is used for everything from creating intricate designs to cutting large sheets of metal. O construction industry also benefits from laser cutting, as it allows for the precise shaping of metal components used in buildings and infrastructure.

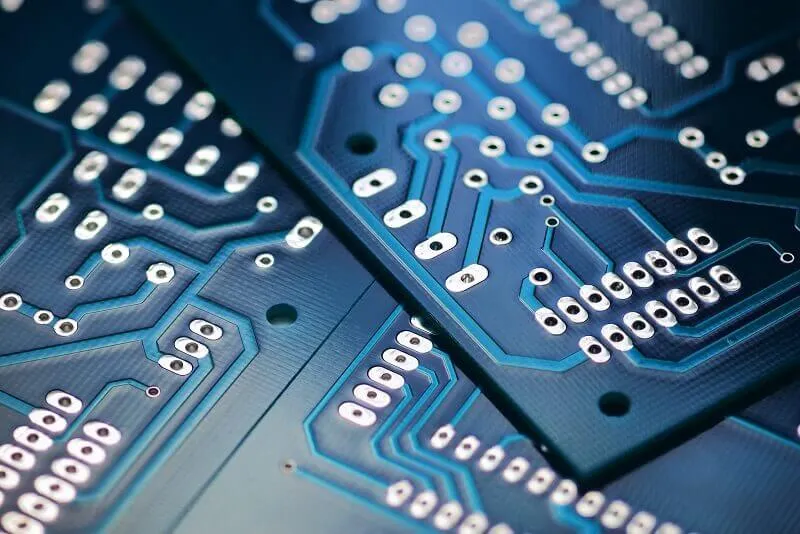

◆ Electronics

In the eletrônica indústria, laser cutting is used to make placas de circuito, gabinetes de metal, e outras partes críticas. The precision required in these components makes laser cutting the ideal choice for electronics manufacturers.

Laser cutting technology is also used to create decorative arts, sinalização personalizada, e engraved designs. The fine details achievable with laser cutting make it the perfect solution for creating unique designs on a variety of materials.

5. Choosing the Right Laser Cutting Machine for Your Business in Turkey

◆ Assess Your Business Needs

Before making a purchase, it’s essential to evaluate your business needs. Consider the materials you typically work with, the types of cuts required, and the volume of production. This assessment will guide you in selecting the most appropriate laser cutting machine for your operations.

◆ Research Local

Manufacturers and Suppliers

Ao comprar a laser cutting machine in Turkey, it’s essential to research local manufacturers and suppliers. Many Turkish companies offer a range of machines with varying features, so choosing a reputable supplier with solid customer reviews will ensure a good investment.

◆ Consider Maintenance and Support Services

Ensure that the manufacturer offers strong maintenance and support services. This can include training for your operators, regular maintenance checks, and readily available spare parts. A reliable support system can significantly enhance the longevity and performance of your laser cutting machine.

As the demand for precision manufacturing grows, laser cutting machines in Turkey are becoming an essential part of industries worldwide. Whether you’re involved in Automotivo, eletrônica, ou fabricação de metal, Turkey offers high-quality, affordable laser cutting solutions that meet the needs of modern manufacturers. By considering factors such as power, precisão, e versatilidade, you can find the right machine that suits your business and helps take your production to the next level.

Notícias principais

-

4000Guia da máquina de corte a laser W | Fundamentos09 dezembro 2025

4000Guia da máquina de corte a laser W | Fundamentos09 dezembro 2025 -

Máquina de corte de metal a laser de fibra para venda05 dezembro 2025

Máquina de corte de metal a laser de fibra para venda05 dezembro 2025 -

4000 Watt Laser | Poder de corte industrial02 dezembro 2025

4000 Watt Laser | Poder de corte industrial02 dezembro 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa