Notícias

Placa de aço para corte a laser: Um processo revolucionário para precisão e eficiência

Introduction: Unveiling the Power of Placa de aço para corte a laser

No mundo da fabricação em ritmo acelerado de hoje, alcançar precisão e velocidade are no longer optional—they are necessities. When it comes to cutting steel plates, corte a laser stands out as the most efficient and accurate method available. Whether for the automotive industry, construção, or manufacturing of intricate parts, laser cutting steel plates offers unmatched quality, precisão, and the ability to handle complex shapes.

But why has laser cutting become the go-to solution for steel plate processing? Neste artigo, we will delve into the Processo de corte a laser, suas vantagens, key considerations, and how this technology is reshaping manufacturing in diverse industries.

1. What is Laser Cutting Steel Plate?

◆ The Technology Behind Laser Cutting

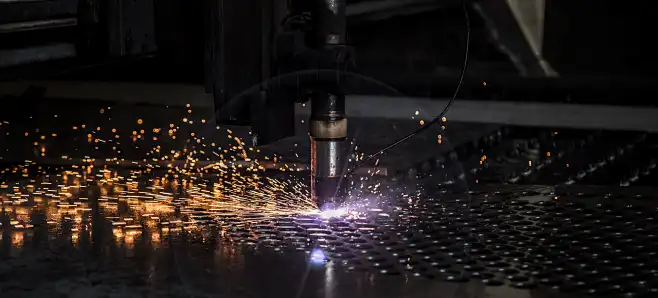

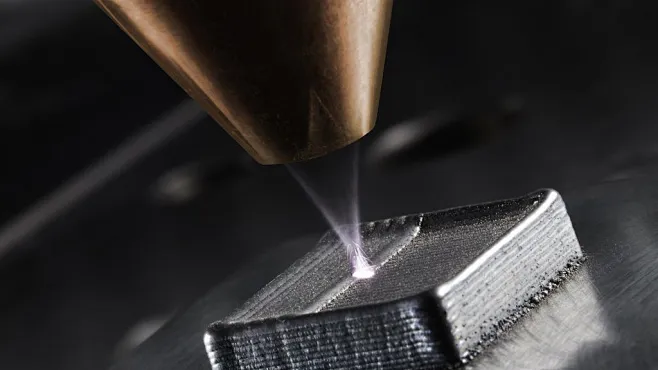

Laser cutting steel plate uses a focused laser beam to cut through steel with high precision. The laser, often a laser de fibra ou CO2 laser, generates a beam of light that is focused onto the material’s surface, which melts, queimaduras, or vaporizes the steel, depending on the material’s properties and the laser settings. The result is a limpar, corte preciso with minimal waste.

◆ How Does Laser Cutting Work?

In a typical laser cutting system, um CNC (controle numérico de computador) directs the laser beam to specific locations on the steel plate. The machine’s control system ensures that the laser cuts along the pre-programmed path, making it ideal for geometrias complexas e designs intrincados. The heat from the laser causes the steel to melt or vaporize at the point of contact, leaving a sharp and smooth edge.

★ The video below can help you understand the working principle of Laser Cutting Steel Plate more intuitively.

2. Advantages of Laser Cutting Steel Plates

◆ High Precision and Accuracy

When it comes to cutting steel, A precisão é crítica. Laser cutting allows for extremely cortes precisos, even for complex shapes, with tolerances as tight as 0.1milímetros. This high level of precision ensures that parts fit together perfectly, eliminating the need for extensive post-processing.

◆ Speed and Efficiency

Laser cutting is one of the fastest cutting methods available. Unlike traditional cutting techniques, the laser beam can quickly cut through steel plates, dramatically reducing production times. This efficiency allows manufacturers to meet high-demand production schedules while maintaining high-quality standards.

◆ Minimal Material Waste

Due to the narrow width of the laser beam, material wastage is minimized. The cuts are so precise that there is little to no scrap material left behind. This not only saves on material costs but also makes laser cutting more environmentally friendly compared to traditional methods that produce more offcuts.

◆ Versatility in Steel Plate Thickness

Laser cutting is versatile in that it can be used on a wide range of steel plate thicknesses. De thin sheets para thicker plates, lasers can cut through materials that range from 0.5mm to several inches thick, allowing businesses to work with a variety of steel products for different applications.

3. Applications of Laser Cutting Steel Plates

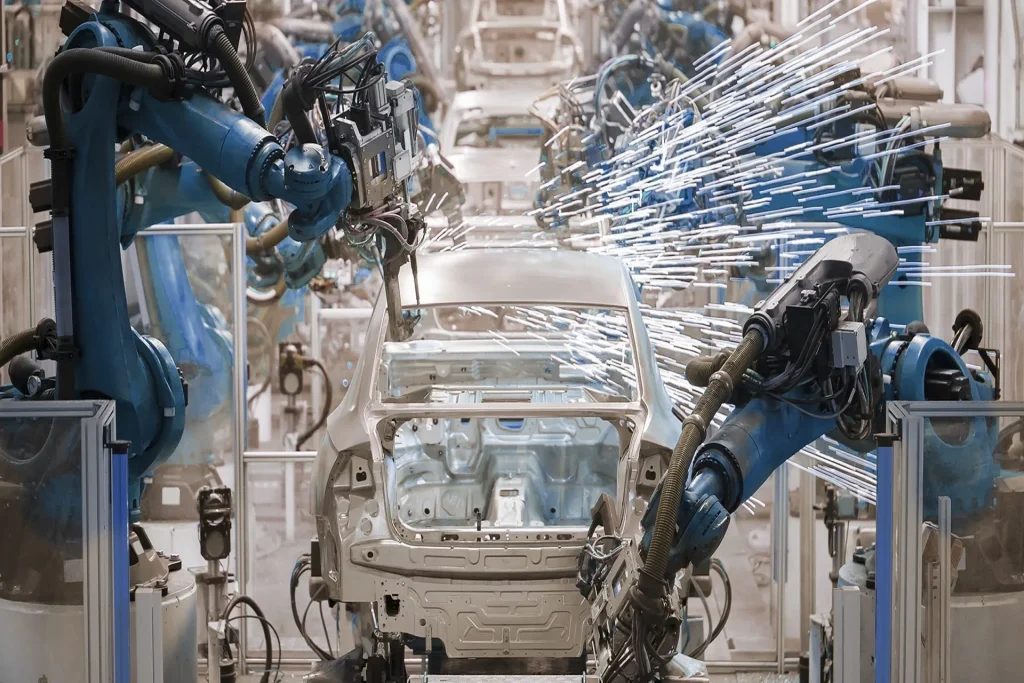

◆ Automotive Industry

Laser cutting plays a crucial role in the automotive industry, where precision and speed are paramount. Components such as colchetes, body parts, e frame structures are often produced using laser cutting, ensuring that each part fits together perfectly in the final assembly.

◆ Aerospace Manufacturing

Em aeroespacial, where weight and strength are critical, laser-cut steel plates are used to produce high-strength, lightweight components for aircraft. Laser cutting offers the precision needed to produce parts with minimal material waste while maintaining the strength required for the aerospace industry.

◆ Construction and Metal Fabrication

Laser cutting steel plates is widely used in fabricação de metal e construção for applications such as componentes estruturais, metal frames, e custom steel parts. The ability to cut steel with high precision allows manufacturers to create intricate designs and complex parts that would be difficult to achieve using traditional methods.

◆ Sheet Metal Industry

In sheet metal processing, laser cutting allows manufacturers to produce complex metal parts e painéis for industries ranging from eletrônica para appliances. The clean cuts and minimal distortion make laser cutting a superior method for producing high-quality parts.

◆ Artistic and Decorative Applications

Laser cutting isn’t just for industrial use—it’s also widely used in decorative e artistic applications. Designers use laser-cut steel plates to create custom designs, wall art, e decorative panels, taking advantage of the machine’s ability to handle detailed and intricate cuts.

4. Key Factors to Consider When Choosing a Laser Cutting Machine for Steel Plates

◆ Laser Power

O power of the laser is one of the most important factors when selecting a machine. For steel plates, laser power typically ranges from 500W to 6000W. Higher-power lasers are ideal for cutting thicker plates, while lower-power machines are sufficient for thinner materials.

◆ Cutting Speed

Máquinas de corte a laser são conhecidas por seus velocidade, but this varies depending on the material’s thickness, type, and the power of the laser. It’s important to choose a machine that balances velocidade de corte with precisão to meet production requirements.

◆ Material Handling Capacity

Steel plates come in various sizes, so it’s essential to choose a machine that can handle the size of the plates you work with. Make sure the cutting bed size matches your production needs.

◆ Automation Features

Many modern laser cutting machines come with automated features como material loading and unloading, part nesting, e cutting path optimization. These features can increase productivity, reduce human error, and ensure faster turnaround times.

5. The Future of Laser Cutting Steel Plates

As laser cutting technology continues to evolve, we can expect even more advanced machines that offer greater precision, velocidades de corte mais rápidas, e lower operating costs. Innovations such as Otimização baseada em IA, real-time process monitoring, e maior eficiência energética are expected to push the capabilities of laser cutting even further.

With the growing demand for precision, the role of laser cutting steel plates will continue to expand, enabling industries to meet increasingly complex production requirements. Whether for industrial applications, automotive manufacturing, ou artistic designs, laser cutting offers the ideal solution for high-quality, efficient steel plate cutting.

Incorporating laser cutting technology into your operations can greatly enhance your production capabilities, reduzir o desperdício, e melhorar a eficiência geral. Whether you are producing automotive parts, aerospace components, ou custom metal designs, laser cutting steel plates ensures that you meet the highest standards of quality and precision. By understanding the benefits and considerations of laser cutting, you can make an informed decision on integrating this powerful technology into your business.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa