Noticias

La guía completa de cortadores de tubos láser

In a world where precision, eficiencia, and innovation reign supreme, laser tube cutters stand as the heroes of modern fabrication. Imagine a technology so advanced that it can slice through metals like butter while crafting intricate designs with millimeter-level accuracy. Laser tube cutting machines have transformed manufacturing processes across industries, offering unparalleled speed, flexibilidad, y precisión. En esta guía, we delve deep into the mechanics, aplicaciones, and advantages of laser tube cutting technology—the ultimate game-changer in metal fabrication.

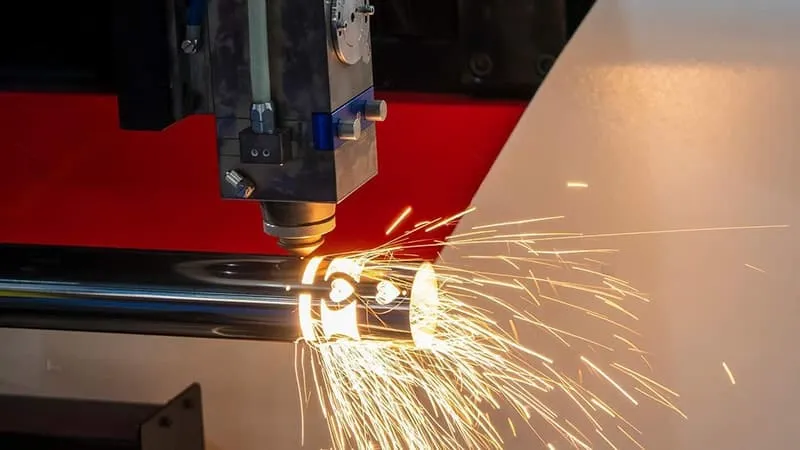

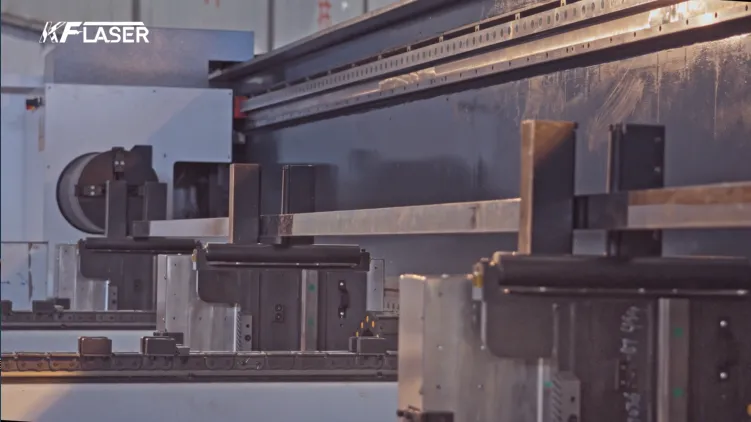

1.What Is a Laser Tube Cutter?

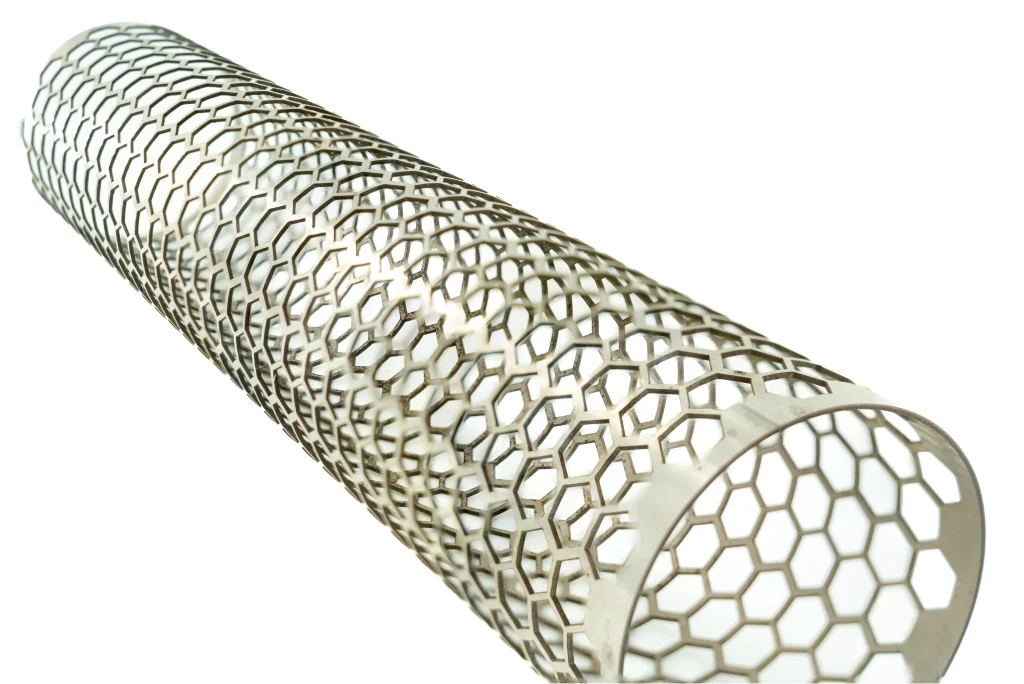

A laser tube cutter is a specialized machine that utilizes a high-powered laser to cut, drill, and shape metal tubes and pipes. With the power of laser technology, these machines deliver precise cuts on a wide range of materials, incluyendo acero inoxidable, aluminio, titanio, latón, and even reflective metals like copper. A diferencia de los métodos de corte tradicionales, laser tube cutters offer a non-contact process, ensuring cleaner edges, desperdicio mínimo, and faster production times.

The keyword “cortador de tubos láser” not only highlights the machine’s core purpose but also underscores its versatility. From automotive components to architectural structures, these machines cater to a myriad of industrial needs.

☟ The video below can help you understand the cutting process of the laser tube cutting machine.

2.Why Are Laser Tube Cutters Revolutionary?

1. Precision Beyond Compare

Laser tube cutters achieve accuracy down to 0.01 milímetros. This level of precision is critical in industries where even a minor error can lead to significant losses.

2. Speed That Saves Time

Con velocidades de corte de hasta 500 inches per minute, laser tube cutters drastically reduce production times. Whether it’s mass production or a single prototype, these machines excel in delivering results quickly.

3. Flexibility Across Designs

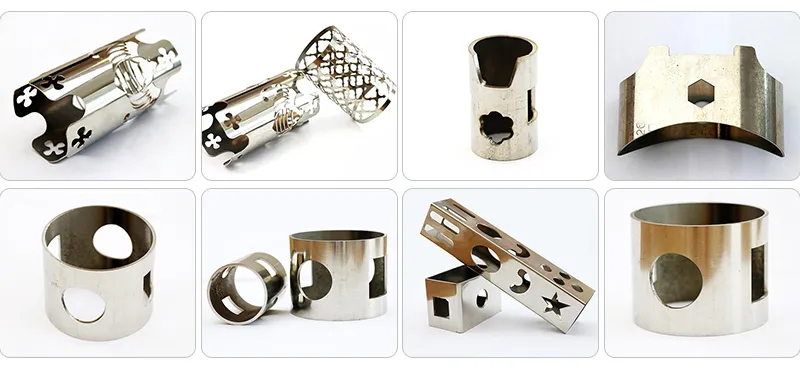

The ability to cut complex shapes, slots, and patterns makes laser tube cutters indispensable for modern design and engineering projects.

4. Respetuoso con el medio ambiente

Laser tube cutting generates minimal waste compared to traditional methods. The process also requires less energy, especially with fiber laser technology, making it a sustainable choice for manufacturers.

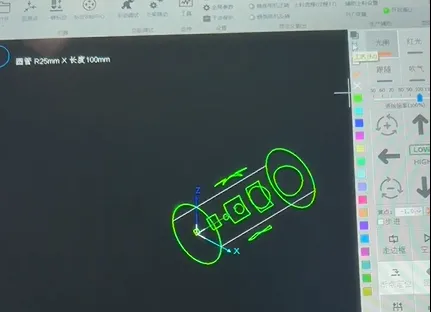

5. Automatización e Integración

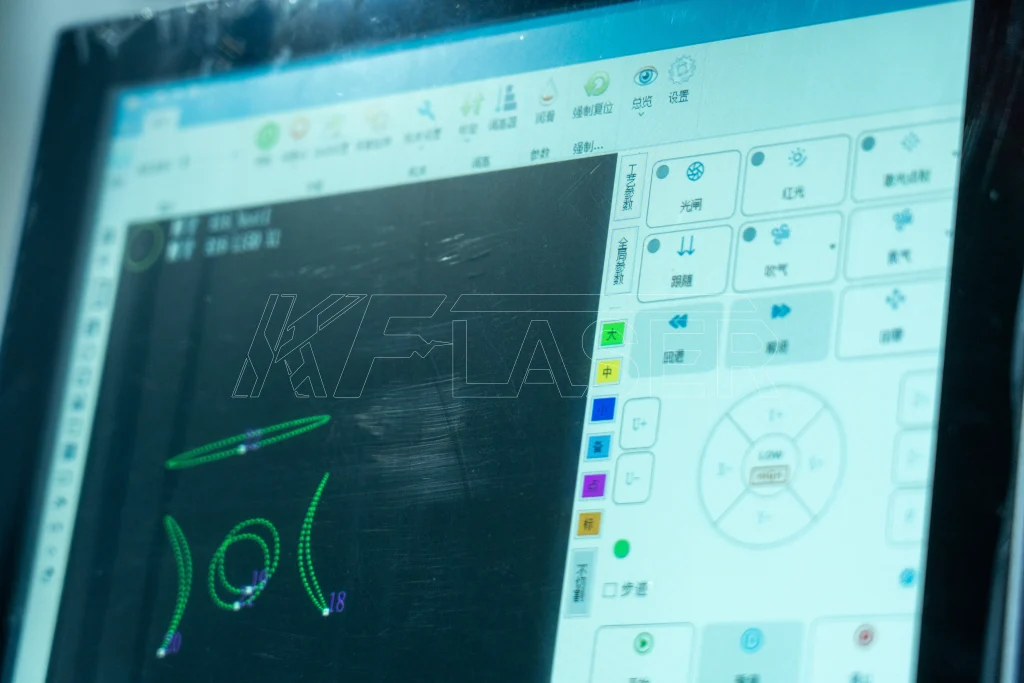

Modern laser tube cutters come equipped with CNC (Control numérico por computadora) systems and automation features, enabling seamless integration into smart manufacturing workflows.

3.How Does a Laser Tube Cutter Work?

The process of laser tube cutting involves several carefully orchestrated steps:

1. Configuración de materiales:

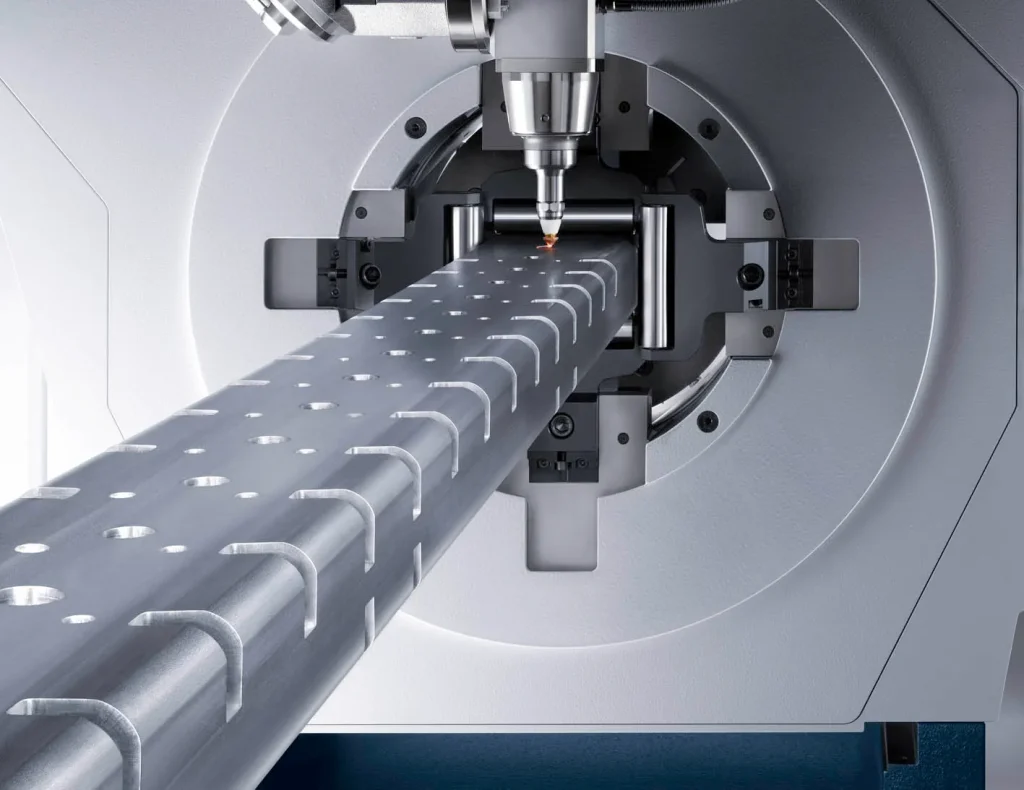

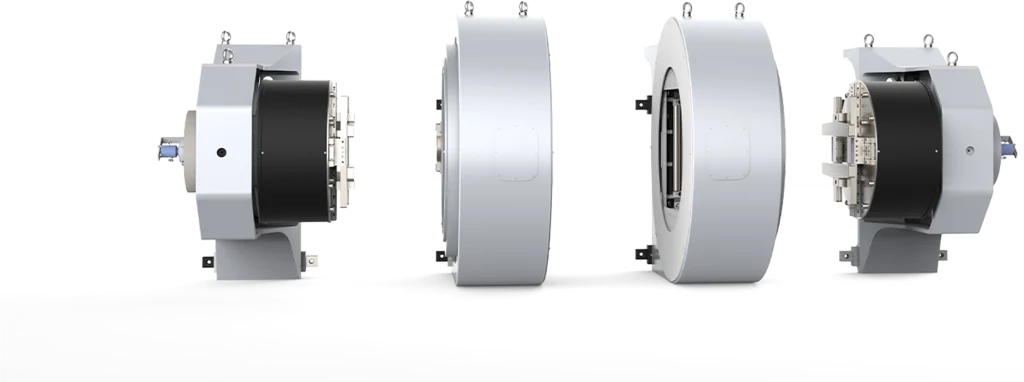

The metal tube is securely mounted onto the machine using clamps or chucks.

2. Laser Calibration:

The machine’s laser head is calibrated to focus on the tube’s surface, adjusting parameters such as power, velocidad, and wavelength based on the material type.

3. Proceso de corte:

The laser beam melts or vaporizes the material along the desired path. Assist gases like nitrogen or oxygen blow away molten material for a clean cut.

4. CNC Guidance:

The machine’s CNC system precisely controls the laser’s movement, ensuring accuracy across intricate designs.

5. Post-Cutting:

The finished parts are deburred and inspected to ensure they meet design specifications.

4.Types of Laser Tube Cutting Machines

Laser tube cutters can be categorized based on the type of laser technology they use. Each type has its own advantages, catering to different applications:

1. Cortadoras láser de fibra

Fiber laser cutters are the pinnacle of efficiency and precision. They use fiber-optic cables to amplify the laser beam, offering exceptional cutting quality for both thin and thick metals.

– Wavelength: 1.06 μm

– Ventajas: High energy efficiency (>40%), bajo mantenimiento, and the ability to cut reflective materials like brass and copper.

– Aplicaciones: Automotive parts, componentes aeroespaciales, and intricate decorative pieces.

2.Cortadoras láser de CO2

CO2 lasers rely on a gas mixture to generate the laser beam. While they are effective for cutting non-metals, they are less efficient than fiber lasers for metal applications.

– Wavelength: 10.6 μm

– Ventajas: Lower initial cost and versatility across materials like wood, acrílico, and leather.

– Aplicaciones: Señalización, furniture, and light metal fabrication.

3.Hybrid Laser Systems

Some machines combine fiber and CO2 laser technologies, offering flexibility across a wider range of materials and thicknesses. These systems are ideal for manufacturers handling diverse projects.

5.Key Parameters for Optimized Laser Tube Cutting

To achieve the best results, operators must carefully manage several parameters:

1. Potencia del láser:

Determines the machine’s ability to cut through various material thicknesses. Higher power is needed for thicker tubes.

2. Velocidad de corte:

Faster speeds improve productivity but may compromise edge quality on thicker materials.

3. Assist Gas Pressure:

Gases like nitrogen and oxygen enhance cutting precision and prevent oxidation.

4. Focus Spot Size:

A smaller focus spot ensures finer cuts, crucial for intricate designs.

5. Espesor del material:

Fiber lasers excel at cutting both thin and thick materials, whereas CO2 lasers are better suited for moderate thicknesses.

6.Applications of Laser Tube Cutters

The versatility of laser tube cutters makes them indispensable across various industries:

1. Industria automotriz

Laser tube cutters are used to fabricate exhaust systems, roll cages, y componentes estructurales. Their precision ensures safety and durability in automotive designs.

2.Aerospace Engineering

Lightweight and high-strength parts, such as frames and brackets, are efficiently produced using laser tube cutting technology.

3.Construcción y Arquitectura

From decorative railings to structural beams, laser tube cutters enable architects and engineers to realize complex designs with ease.

4. Dispositivos médicos

Surgical instruments, prótesis, and equipment frames benefit from the precision and cleanliness of laser tube cutting.

5. Fabricación de muebles

The flexibility to cut unique shapes and patterns allows designers to create innovative furniture pieces.

7.Advantages of Using Laser Tube Cutters

1. Rentabilidad

While the initial investment may be high, the long-term savings in material, energy, and labor costs make laser tube cutters a wise choice.

2. Desechos reducidos

The precise nature of laser cutting minimizes material wastage, contributing to both cost savings and environmental sustainability.

3. Scalability

Whether you need a single prototype or mass production, laser tube cutters can easily scale to meet demand.

4. Enhanced Design Freedom

The ability to cut complex geometries opens up new possibilities in product design and engineering.

8.What to Consider When Choosing a Laser Tube Cutter

Investing in a laser tube cutter requires careful consideration of several factors:

1. **Compatibilidad de materiales:** Ensure the machine can handle the materials you work with most frequently.

2. **Tube Dimensions:** Check the maximum tube length and diameter the machine can accommodate.

3. **Requisitos de energía:** Match the machine’s power output to your production needs.

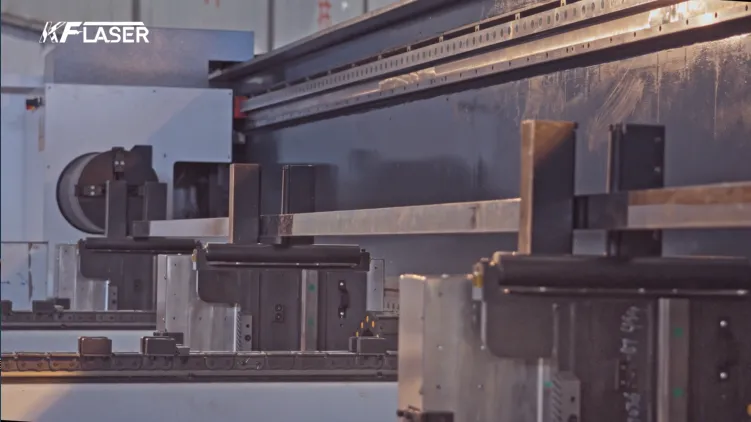

4. **Características de automatización:** Look for features like automatic loading and unloading to enhance productivity.

5. **Presupuesto:** Factor in both the initial investment and ongoing maintenance costs.

9.Future of Laser Tube Cutting Technology

A medida que las industrias continúan evolucionando, laser tube cutting technology is set to become even more advanced. Innovations such as AI-driven CNC systems, 3D cutting capabilities, and enhanced automation will further improve efficiency and precision. Companies like LÁSER KF están liderando la carga, developing cutting-edge solutions that cater to the dynamic needs of modern manufacturing.

The potential applications for laser tube cutters are virtually limitless, making them a cornerstone of the future fabrication landscape. By investing in this technology, businesses can not only stay competitive but also drive innovation in their respective fields.

BORN FOR THE FUTURE

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora