News

Plate and Tube Laser Cutting Machine

You can share this article to:

When precision meets versatility, and when speed meets efficiency, the plate and tube laser cutting machine takes center stage in modern manufacturing. This groundbreaking equipment has revolutionized the metal processing industry, combining the capability to cut flat plates and cylindrical tubes in one streamlined operation. From automotive to aerospace, and from intricate designs to robust industrial applications, this machine is the unsung hero of efficiency, precision, and innovation.

But why is it hailed as a game-changer? Why are industries transitioning from traditional methods to this dual-function marvel? Let’s explore the depths of this cutting-edge technology and uncover its secrets, applications, and unmatched advantages that make it indispensable.

1. What is a Plate and Tube Laser Cutting Machine?

A plate and tube laser cutting machine is a dual-purpose laser cutting device capable of processing both flat sheets (plates) and tubular (pipes and tubes) materials with exceptional precision. Leveraging fiber laser technology, it provides manufacturers with the flexibility to handle various shapes, sizes, and material types, making it a sought-after solution in industries that require versatility and productivity.

This machine operates using an integrated system of high-powered lasers, CNC (Computer Numerical Control) software, and rotary axes (for tubular materials). Together, these components create a unified machine capable of delivering clean cuts, reduced material wastage, and increased operational efficiency.

2. Key Components of a Plate and Tube Laser Cutting Machine

1. Laser Source

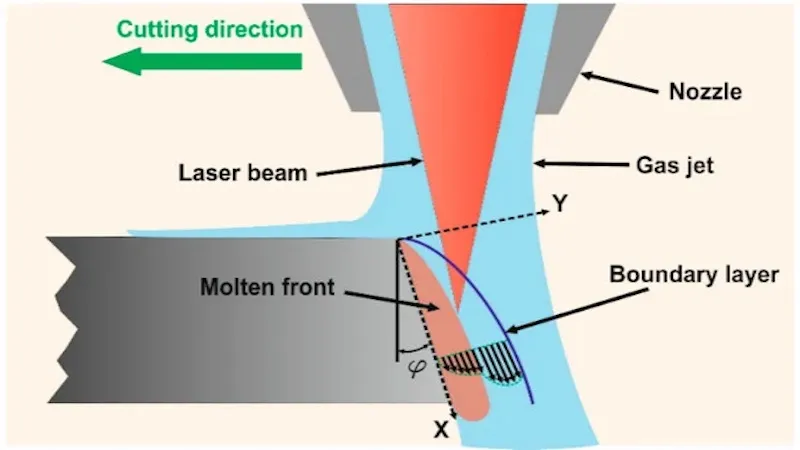

The laser source generates a concentrated laser beam that provides the energy needed to melt or vaporize the material. This determines cutting precision, speed, and the range of materials that can be processed.

2. Cutting Head

Equipped with advanced nozzles and sensors, the cutting head focuses the laser onto the material. It also includes automatic height detection, enabling precise adjustments for uneven surfaces, ensuring smooth, consistent cuts.

3. CNC Controller

At the heart of the machine is its CNC controller. This system interprets the user’s design data, converting it into machine-readable code to automate the cutting process with precision.

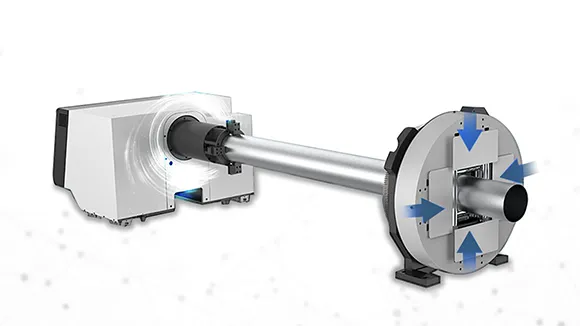

4. Rotary Axis (for Tubes)

The rotary axis enables precise positioning and cutting of tubular materials, whether cylindrical, square, or custom profiles. This allows for intricate cuts on pipes and tubes, enhancing the machine’s versatility.

5. Cooling System

The cooling system prevents overheating during operation, ensuring consistent performance and extending the lifespan of the laser source and other critical components.

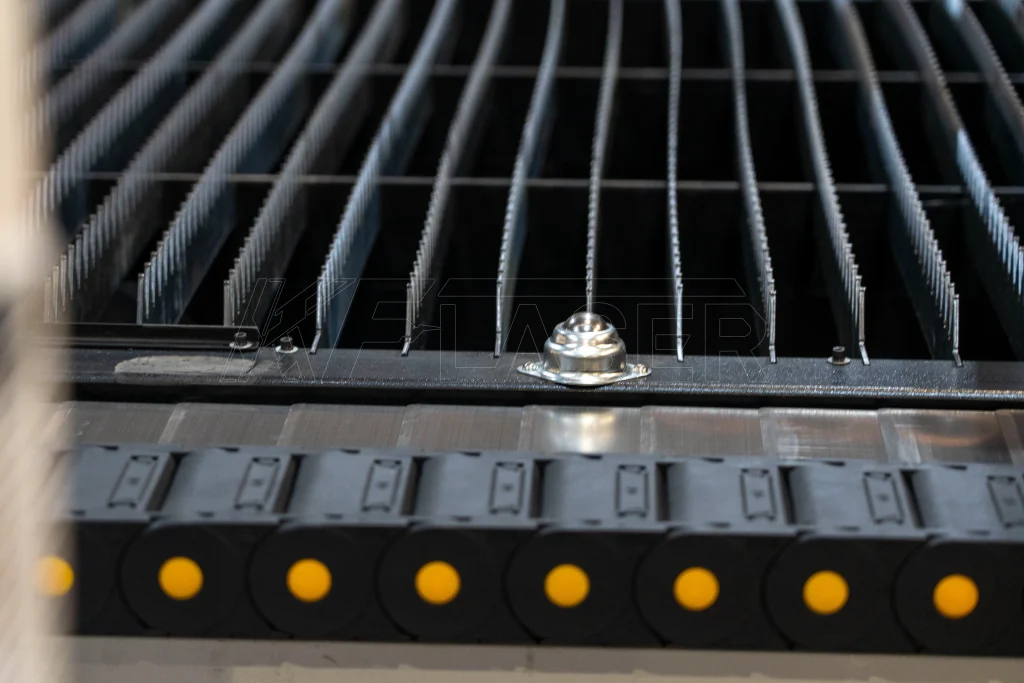

6. Worktable

The robust worktable provides a stable platform for material placement, equipped with automatic loading and unloading features to boost productivity.

3. Advantages of Using a Plate and Tube Laser Cutting Machine

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

1. Dual-Purpose Functionality

One of the standout benefits is its ability to process both sheets and tubes. This eliminates the need for multiple machines, reducing costs and saving space on the production floor.

2. High Precision and Accuracy

With a focused laser beam, the machine delivers clean cuts with tight tolerances. This level of precision ensures the creation of intricate designs and complex geometries that would be impossible with traditional methods.

3. Increased Productivity

The high-speed cutting capabilities and automation features, such as automatic material feeding, reduce downtime and boost overall output. Projects that once took hours can now be completed in minutes.

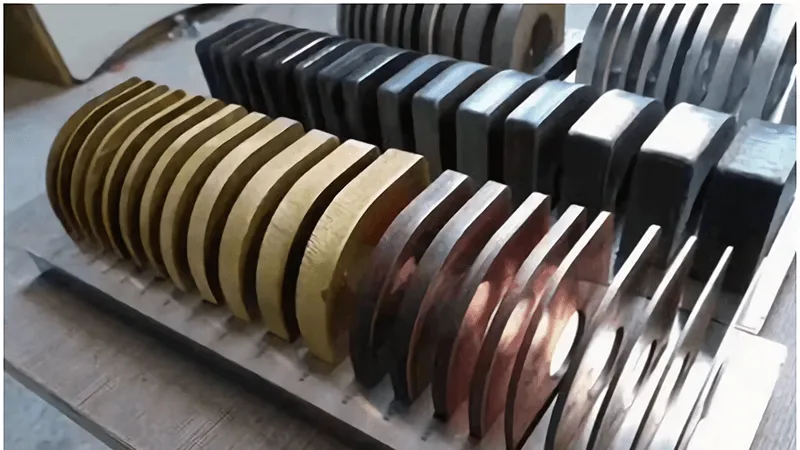

4. Versatility

The machine can handle a wide variety of materials, including carbon steel, stainless steel, aluminum, brass, and copper. Additionally, it accommodates various thicknesses, making it suitable for diverse applications.

5. Reduced Material Waste

Advanced nesting software optimizes material usage, minimizing scrap and maximizing yield. The narrow laser beam width ensures cuts are precise, reducing unnecessary material loss.

6. Environmental Benefits

Laser cutting is an environmentally friendly process, producing minimal fumes, dust, or harmful emissions compared to traditional cutting methods.

7. Cost Efficiency

By combining the functionalities of two machines into one, businesses save on both capital investment and maintenance costs, while also reducing operational expenses through improved efficiency.

4. Applications of Plate and Tube Laser Cutting Machines

1. Automotive Industry

From chassis components to exhaust systems, the machine ensures precision in automotive manufacturing, enhancing vehicle performance and safety.

2. Aerospace Industry

Its ability to handle lightweight yet durable materials makes it ideal for producing parts such as fuselages, wings, and other aircraft components.

3. Construction and Architecture

The machine is used to create structural components, decorative elements, and intricate facades for buildings and bridges.

4. Medical Equipment

Precision is paramount in the medical field. The machine produces surgical tools, implants, and other critical devices with tight tolerances and smooth finishes.

5. Electronics Industry

It cuts complex designs and components for electronic devices, ensuring accuracy and repeatability for high-tech manufacturing.

6. Furniture and Interior Design

Whether it’s creating sleek furniture frames or intricate patterns for interior decor, this machine delivers designs that are both functional and aesthetically pleasing.

7. Renewable Energy

Components for solar panels, wind turbines, and other renewable energy systems are manufactured efficiently using this technology.

5. How Does a Plate and Tube Laser Cutting Machine Work?

1.Design Input:

CAD/CAM software is used to design the cutting pattern, which is then converted into machine-readable code.

2.Material Placement:

Plates or tubes are loaded onto the worktable or rotary axis. Automatic loading systems ensure seamless operation.

3.Laser Cutting:

The machine’s laser source emits a high-intensity beam, guided by the cutting head, to process the material according to the design.

4.Post-Cut Handling:

Finished components are unloaded, with minimal or no need for additional finishing.

6. Key Features to Consider When Choosing a Plate and Tube Laser Cutting Machine

Metal cutting machinery laser systems can process a wide variety of metals, each with unique characteristics:

1. Laser Power

Higher power enables cutting of thicker materials but comes at a higher cost. Evaluate your material needs before choosing the power level.

2. Worktable Size

Ensure the table size matches your material dimensions to avoid limitations in cutting capacity.

3. Automation Features

Look for machines with automatic material feeding, nesting software, and real-time monitoring to maximize efficiency.

4. Maintenance Requirements

Opt for machines with minimal maintenance needs to reduce downtime and operational costs.

5. Brand and Support

Choose a trusted manufacturer like KF LASER that provides excellent customer support, training, and after-sales service.

7. The Future of Plate and Tube Laser Cutting Machines

As industries continue to evolve, the demand for versatile and efficient manufacturing solutions will grow. Plate and tube laser cutting machines are poised to lead this transformation, enabling the production of increasingly complex components with unmatched precision and speed.

With innovations like AI-assisted design, real-time monitoring, and IoT integration, these machines are set to redefine the manufacturing landscape. Businesses that adopt this technology will not only improve their operational efficiency but also gain a competitive edge in their respective markets.

The Future of Plate and Tube Laser Cutting Machines

At KF LASER, we specialize in delivering cutting-edge plate and tube laser cutting machines that empower businesses to achieve their goals. With unparalleled precision, versatility, and efficiency, our machines are designed to meet the demands of modern manufacturing.

For more information, feel free to contact KF LASER today and explore how our solutions can transform your production processes.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine