Noticias

Mejor máquina de cortar CNC de acero inoxidable para precisión & Eficiencia

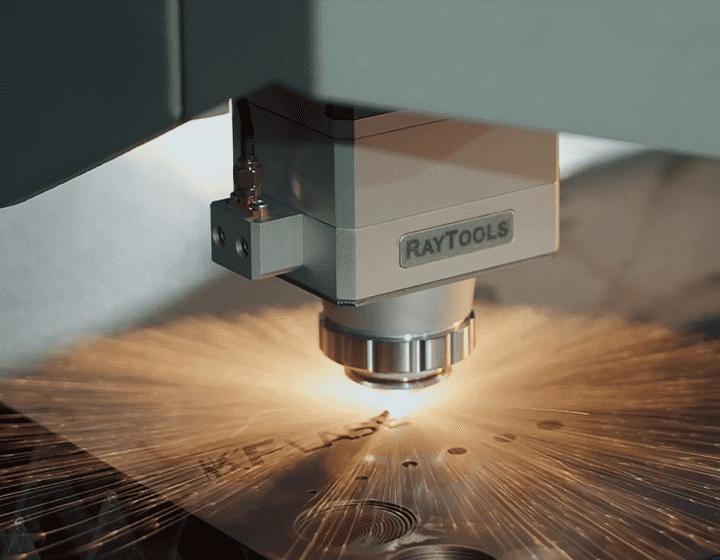

En el mundo de la fabricación moderna, la demanda de máquina de corte CNC de acero inoxidable ha aumentado dramáticamente. Ya sea que esté produciendo piezas metálicas intrincadas o componentes de servicio pesado, Tener el equipo correcto puede marcar la diferencia. CNC (Control numérico por computadora) La tecnología ha revolucionado la forma en que se cortan las piezas metálicas, permitiendo a los fabricantes lograr una precisión y eficiencia incomparables.

Esta publicación de blog explora las características clave, beneficios, y consideraciones involucradas al elegir la mejor máquina de corte CNC de acero inoxidable para su negocio. Con tantas opciones en el mercado, Es esencial comprender qué factores pueden afectar directamente la calidad y el rendimiento de sus recortes.. Al final de este artículo, Estará equipado con el conocimiento para tomar una decisión informada que elevará sus capacidades de fabricación..

Lo que hace que una máquina de corte CNC de acero inoxidable se destaque?

A máquina de corte CNC de acero inoxidable está diseñado para entregar cortes de precisión en las hojas y placas de acero inoxidable., que son conocidos por su durabilidad y resistencia a la corrosión. A diferencia de los métodos de corte tradicionales, Las máquinas CNC están automatizadas, controlado por un sistema informático, que garantiza resultados consistentes en ejecuciones de producción de alto volumen.

Características clave para buscar en una máquina de corte CNC de acero inoxidable

Alta precisión: La capacidad de la máquina para entregar cortes exactos es crucial para minimizar los desechos del material y garantizar que cada parte se ajuste perfectamente.

Compatibilidad de materiales: Estas máquinas están diseñadas específicamente para manejar la dureza y la densidad del acero inoxidable., haciéndolos un activo valioso para los fabricantes que trabajan con este material.

Automatización y eficiencia: Las máquinas CNC pueden automatizar procesos de corte complejos, Reducir la necesidad de mano de obra manual y aumentar significativamente la velocidad de producción.

Durabilidad: La naturaleza difícil de acero inoxidable significa que las máquinas de corte también deben ser duraderas. Una máquina construida con componentes robustos garantiza una vida operativa más larga y menos problemas de mantenimiento.

Ventajas de usar máquina de corte CNC de acero inoxidable

1. Precisión inigualable

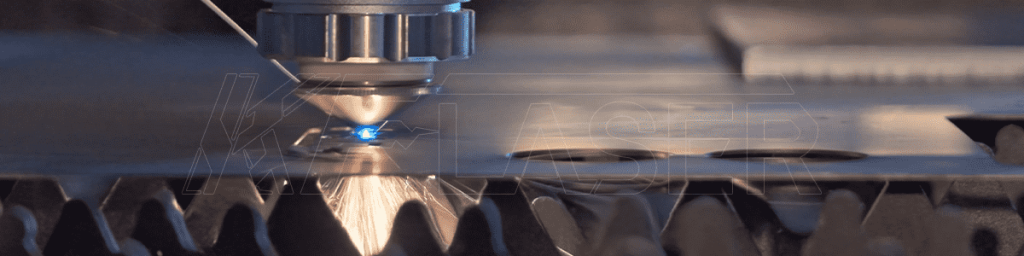

Al trabajar con acero inoxidable, La precisión es clave. El corte manual puede introducir inconsistencias, conduciendo a materiales de mala calidad y desperdicio. Con una máquina de corte CNC, Puede garantizar un nivel de precisión que sea imposible de replicar manualmente. Las máquinas CNC pueden cortar diseños complejos con tolerancias ajustadas, dando como resultado piezas que encajan sin problemas.

2. Mayor productividad

Automatizando el proceso de corte, a máquina de corte CNC de acero inoxidable mejora drásticamente la productividad. Esto permite a las empresas producir grandes lotes de piezas en una fracción del tiempo que tomaría utilizando métodos tradicionales.. La velocidad a la que funciona una máquina CNC lo hace ideal para industrias de alta demanda como Automotive, aeroespacial, y construcción.

3. Costos de mano de obra reducidos

Dado que las máquinas CNC pueden funcionar de manera autónoma, requieren menos operadores y reducen la dependencia del trabajo manual. Esto puede conducir a ahorros significativos en los costos laborales., especialmente para las empresas que necesitan mantener una gran fuerza laboral.

4. Consistencia y repetibilidad

Una de las mayores ventajas de las máquinas CNC es su capacidad para producir la misma parte repetidamente con precisión idéntica. Para industrias que requieren fabricación de alto volumen, La consistencia es primordial. Una máquina de corte CNC de acero inoxidable asegura que cada parte cumpla con las mismas especificaciones, reduciendo el riesgo de defectos.

Elegir la máquina de cortar CNC de acero inoxidable correcto

Al buscar un máquina de corte CNC de acero inoxidable, Es importante considerar varios factores para garantizar que la máquina satisfaga sus necesidades.

1. Tamaño y capacidad de la máquina

El tamaño de la máquina debe ser apropiado para la escala de sus proyectos.. Ya sea que esté cortando sábanas grandes o piezas de precisión más pequeñas, Seleccionar el tamaño correcto de la máquina puede tener un gran impacto en su flujo de trabajo y velocidad de producción.

2. Corte de velocidad y potencia

Mire la velocidad de corte y las capacidades de alimentación de la máquina. Si estás cortando hojas más gruesas de acero inoxidable, Necesitará una máquina con mayor potencia y una velocidad de corte más rápida para satisfacer las demandas de su horario de producción..

3. Compatibilidad de software

Muchas máquinas de corte CNC de acero inoxidable vienen con software avanzado que ayuda a optimizar el proceso de corte. El software permite diseños intrincados y ajustes en tiempo real.. Asegúrese de que la máquina que elija tiene un software que sea fácil de usar y compatible con sus sistemas actuales.

4. Mantenimiento y soporte

Elija una máquina con servicios de soporte de fácil acceso y necesidades de bajo mantenimiento. La disponibilidad de piezas de reemplazo y un servicio inmediato al cliente puede marcar una diferencia significativa para reducir el tiempo de inactividad.

Factores que afectan el precio de la máquina de corte CNC de acero inoxidable

El precio de un máquina de corte CNC de acero inoxidable puede variar significativamente en función de varios factores. Aquí hay un desglose de lo que afecta el costo:

1. Marca y fabricante

Mientras evitamos las marcas específicas, Es importante tener en cuenta que las máquinas de fabricantes bien establecidos generalmente vienen con etiquetas de precios más altas. Sin embargo, También pueden ofrecer una calidad de construcción superior, Mejor atención al cliente, y características más avanzadas.

2. Características y especificaciones de la máquina

Máquinas con mayor precisión, velocidades de corte más rápidas, y las funciones avanzadas de automatización costarán naturalmente más. Además, Las máquinas que pueden manejar las láminas más gruesas de acero inoxidable tienden a tener un precio más alto debido a su diseño más robusto.

3. Personalización

Algunas máquinas CNC permiten la personalización, que puede aumentar el costo general. Si su negocio requiere características de corte únicas, Es posible que deba pagar más por una máquina a medida que satisfaga sus necesidades específicas.

4. Mantenimiento y garantía

Las máquinas que vienen con garantías extendidas y planes de mantenimiento integrales pueden tener costos iniciales más altos, pero pueden ahorrarle dinero a largo plazo al reducir la probabilidad de reparaciones costosas.

Cómo obtener el mejor valor para su inversión

Invertir en un máquina de corte CNC de acero inoxidable no es una pequeña decisión. Para maximizar el valor de su inversión, Considere los siguientes consejos:

Compare múltiples modelos: Antes de tomar una decisión, Compare varios modelos que cumplan con sus requisitos. Presta atención a sus características, presupuesto, y revisiones de otros usuarios.

Considere los costos a largo plazo: Mientras que el precio inicial es importante, No olvides considerar los costos a largo plazo, incluyendo consumo de energía, mantenimiento, y posibles actualizaciones.

Busque garantía y soporte: Asegúrese de que la máquina viene con una garantía sólida y una atención al cliente confiable para evitar reparaciones costosas y tiempo de inactividad.

Evaluar el software: Dado que el software puede afectar significativamente el rendimiento y la facilidad de uso de la máquina, Elija un modelo con software que sea intuitivo y capaz de manejar la complejidad de sus proyectos.

Ya, Debe tener una comprensión más clara de qué buscar en un máquina de corte CNC de acero inoxidable. Esta tecnología avanzada ha revolucionado el corte de metales y es imprescindible para las empresas que buscan mejorar su proceso de fabricación, reducir costos, y aumentar la precisión.

Recordar, Elegir la máquina correcta es más que solo sobre el precio, se trata de encontrar el equilibrio perfecto de calidad, eficiencia, y valor a largo plazo que apoyará el crecimiento y el éxito de su empresa.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora