Noticias

¿Cuál es la diferencia entre láser y láser de fibra??

En el ámbito de la fabricación moderna, precision cutting technology has become a cornerstone of productivity and innovation. Picture this: two high-powered cutting machines, each capable of transforming raw materials into intricate components with unparalleled accuracy. Yet, one harnesses the power of traditional laser technology while the other wields the advanced prowess of fiber laser technology. The question arises: what is the difference between laser and fiber laser cutting?

Understanding these differences is not merely academic; it’s essential for businesses looking to optimize their production processes, reducir costos, and improve quality. En esta guía completa, we will delve into the intricacies of laser and fiber laser technologies, exploring their mechanisms, ventajas, aplicaciones, and which might be the best fit for your needs.

1.The Basics of Laser Technology

- What is Laser Cutting?

Laser cutting is a manufacturing process that uses a focused beam of light to cut through various materials. The laser generates intense heat that melts, quemaduras, o vaporiza el material, resulting in precise cuts with minimal mechanical force. This technology has been widely adopted across multiple industries, including automotive, aeroespacial, y electrónica.

- The Mechanism of Traditional Laser Cutting

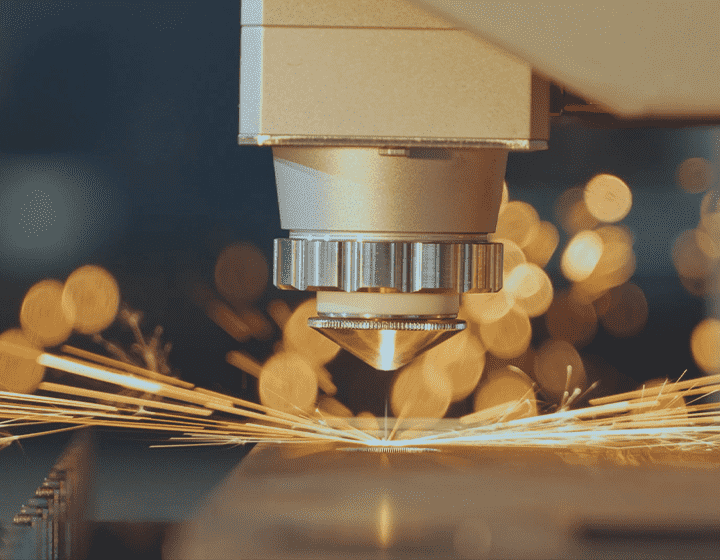

Traditional laser cutting typically employs a CO2 laser, which uses a gas mixture of carbon dioxide, nitrógeno, and helium to generate the laser beam. This beam is then directed through mirrors and lenses to focus it on the material being cut. CO2 lasers are known for their versatility and ability to cut a wide range of materials, incluyendo metales, plástica, and wood.

2. ¿Qué es el corte por láser de fibra??

- Understanding Fiber Laser Technology

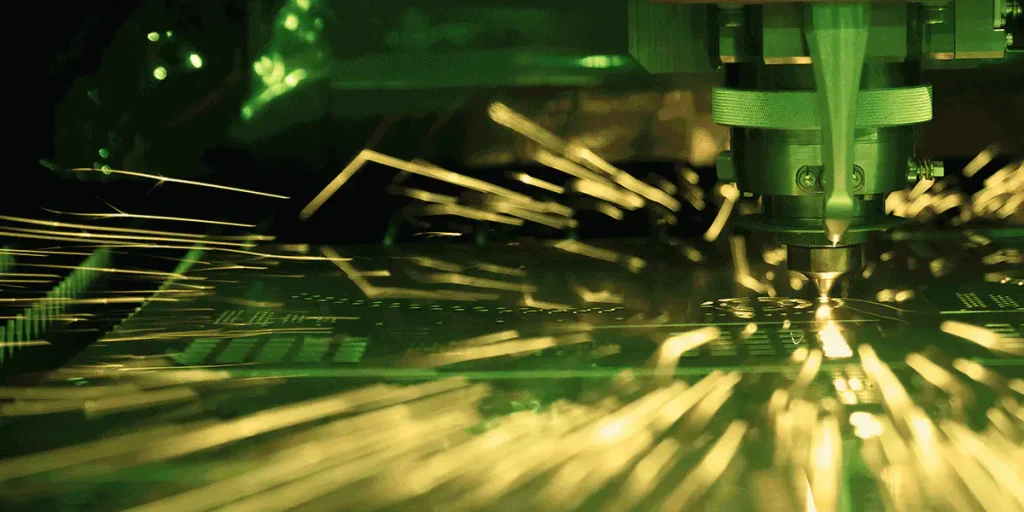

Fiber laser cutting utilizes a solid-state laser that transmits light through optical fibers. This technology is relatively newer than CO2 lasers but has gained immense popularity due to its efficiency and precision. Fiber lasers are especially effective for cutting metals, making them an invaluable tool in modern manufacturing.

- The Mechanism of Fiber Laser Cutting

In fiber laser cutting, the laser beam is generated using rare earth elements, which are amplified in a fiber medium. The light travels through the fiber and is focused on the material to be cut. This method allows for greater absorption of the laser energy by the material, leading to faster and cleaner cuts compared to traditional laser cutting methods.

3. Key Differences Between Laser and Fiber Laser Cutting

- Energy Source and Efficiency

– Traditional Laser (CO2): Utilizes a gas mixture, requiring more energy to generate a beam. It is less efficient in terms of energy consumption, particularly for metals.

– Fiber Laser: Operates on solid-state technology, offering greater efficiency and lower operational costs. Fiber lasers consume less power while delivering a higher intensity beam.

- Compatibilidad de materiales

– Traditional Laser: Effective for cutting a broad range of materials, incluidos los no metales. Sin embargo, its performance diminishes with reflective materials like aluminum and copper.

– Fiber Laser: Excels at cutting reflective materials, maintaining high efficiency and quality. It is widely used for metals, making it the preferred choice in industries requiring precision.

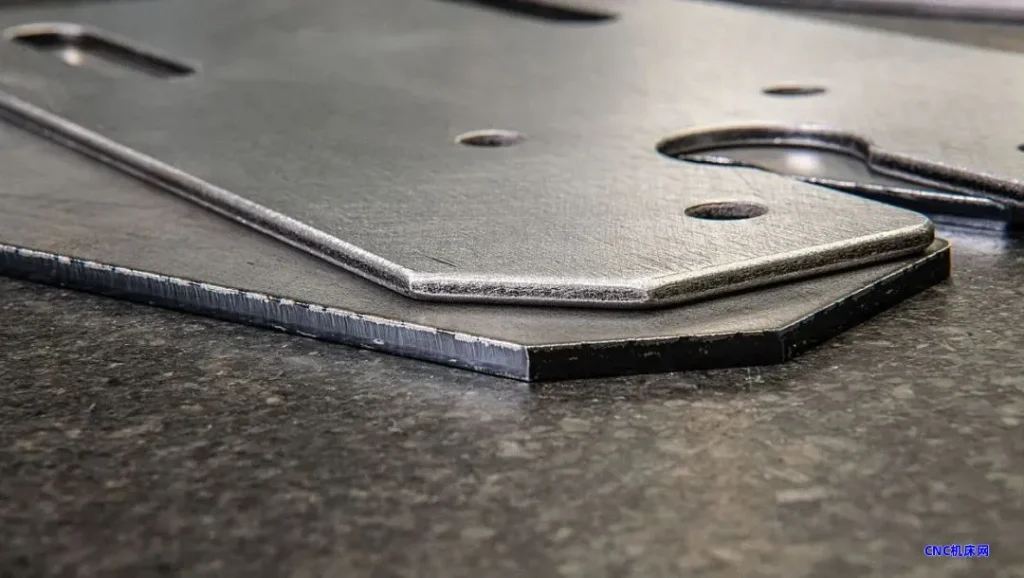

- Cutting Speed and Quality

– Traditional Laser: Generally slower in cutting metals, especially thicker sections. The quality of cuts may require additional finishing processes.

– Fiber Laser: Offers superior cutting speeds and produces clean, Bordes lisos con zonas mínimas afectadas por el calor.. Esto reduce la necesidad de postprocesamiento, saving time and costs.

- Maintenance and Durability

– Traditional Laser: Requires regular maintenance, including cleaning mirrors and lenses, which can wear out over time.

– Fiber Laser: Lower maintenance needs due to the absence of reflective optics. This results in less downtime and increased productivity.

- Consideraciones de costos

– Traditional Laser: Initial setup costs can be lower, but operational costs may accumulate due to energy consumption and maintenance requirements.

– Fiber Laser: Higher initial costs may be offset by lower operating costs and increased efficiency, leading to a better return on investment over time.

4. Applications of Laser and Fiber Laser Cutting

- Industries Utilizing Traditional Laser Cutting

1. Textiles: Cutting intricate patterns in fabrics.

2. Woodworking: Creating detailed designs in wood materials.

3. Señalización: Producing illuminated and non-illuminated signs.

- Industries Utilizing Fiber Laser Cutting

1. Automotor: Precision cutting of body panels and components.

2. Aeroespacial: Manufacturing lightweight yet strong parts.

3. Dispositivos médicos: Creating high-precision surgical instruments and implants.

- Emerging Applications

Both technologies are continuously evolving, finding new applications in fields such as electronics manufacturing, jewelry design, and decorative arts. The adaptability of fiber lasers particularly allows for innovative uses in various sectors.

5. Making the Right Choice: Laser vs. Fiber Laser

Choosing between a traditional laser and a fiber laser cutting machine depends on several factors:

- Material Requirements

Consider the types of materials you will be cutting and their thickness. Fiber lasers are particularly effective for metals, while traditional lasers may be more suitable for non-metals.

- Production Volume

Para producción de gran volumen, the speed and efficiency of fiber lasers make them a better choice, whereas traditional lasers may suffice for smaller, less complex tasks.

- Budget Constraints

Evaluate both initial and long-term costs. Fiber lasers may have a higher upfront investment, but their operational savings can lead to a better overall return.

- Specific Application Needs

Analyze the precision and quality requirements of your projects. If your work demands intricate cuts and minimal finishing, a fiber laser is likely the better option.

6. The Role of LÁSER KF in Laser Technology

At KF LASER, we recognize the importance of choosing the right cutting technology for your business. Our range of fiber laser cutting machines is designed to meet diverse manufacturing needs, providing you with the precision, eficiencia, and reliability necessary to excel in today’s competitive landscape. Our commitment to quality and customer support ensures that you will receive the guidance needed to optimize your operations.

7. Future Trends in Laser Technology

- Advancements in Fiber Laser Technology

The future of laser cutting technology looks promising. Innovations in fiber laser technology are expected to enhance cutting speeds, improve energy efficiency, and expand the range of materials that can be effectively cut.

- Automatización e Integración

As manufacturing processes become increasingly automated, integrating laser cutting machines with smart technology will optimize production flows, Reducir el desperdicio, and enhance overall efficiency.

- Sostenibilidad

The push for sustainable manufacturing practices is likely to drive advancements in laser technology, leading to lower emissions and waste. Both laser types will continue to evolve to meet these demands.

By understanding the differences between traditional laser and fiber laser cutting technologies, businesses can make informed decisions that align with their production goals and operational needs. Whether you choose the versatility of a traditional laser or the advanced capabilities of a fiber laser, investing in the right technology is crucial for success in today’s dynamic market.

Historias destacadas

-

4000Guía de la máquina de corte por láser W | Esenciales09 Dic 2025

4000Guía de la máquina de corte por láser W | Esenciales09 Dic 2025 -

Máquina cortadora de metales por láser de fibra a la venta05 Dic 2025

Máquina cortadora de metales por láser de fibra a la venta05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora