Noticias

¿De qué grosor cortará un láser de fibra de 40.000 W?? Revelando el poder de la tecnología de corte por láser de fibra

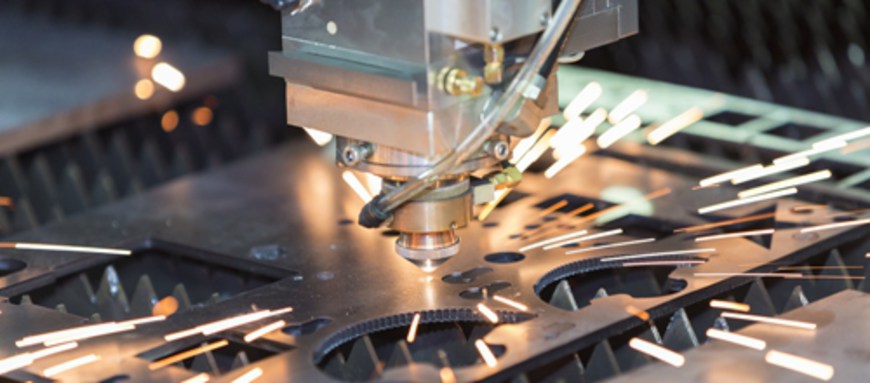

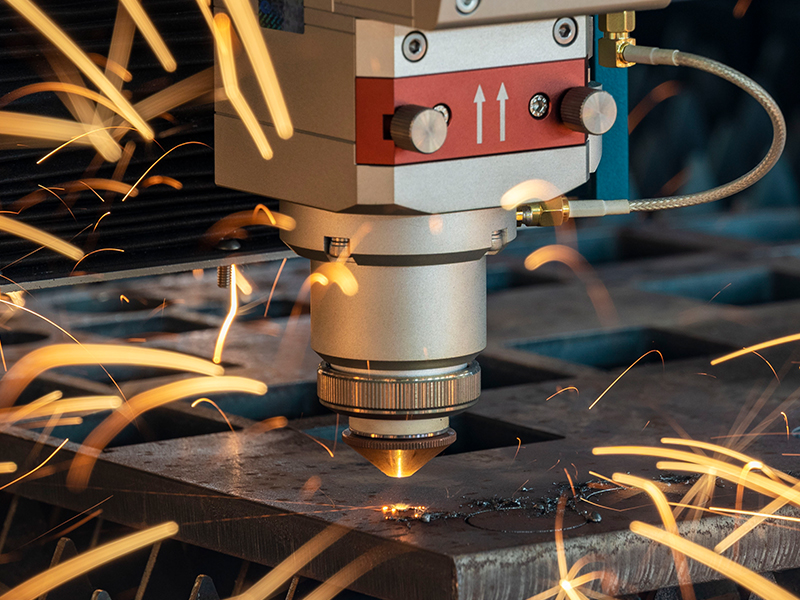

Imagínese empuñar una herramienta tan poderosa que puede cortar gruesas placas de acero como mantequilla., transformando materias primas en diseños complejos con asombrosa velocidad y precisión. Este no es un sueño futurista.; es la realidad que ofrece una máquina de corte por láser de fibra de 40.000W. Mientras las industrias se esfuerzan por lograr eficiencia y calidad, comprender las capacidades de una cortadora láser tan robusta se vuelve crucial. ¿Qué espesor puede cortar un láser de fibra de 40.000W?? Profundicemos en este tema y descubramos el increíble potencial de la tecnología de corte por láser de fibra..

1.Comprensión Corte láser de fibra

- ¿Qué es el corte por láser de fibra??

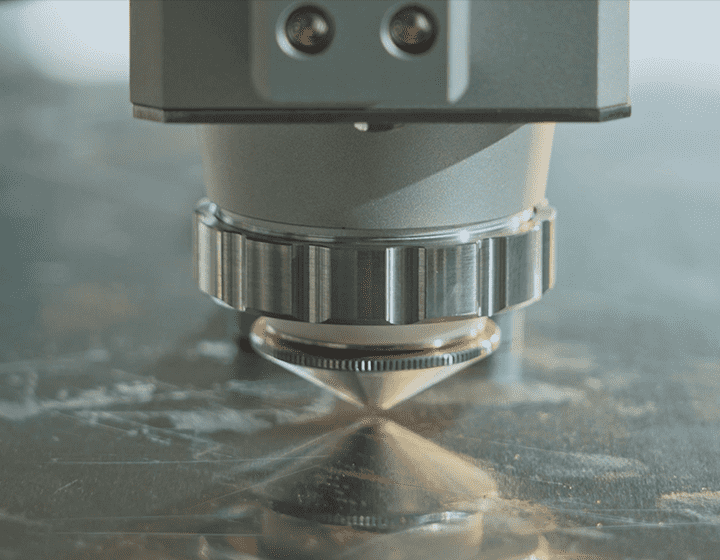

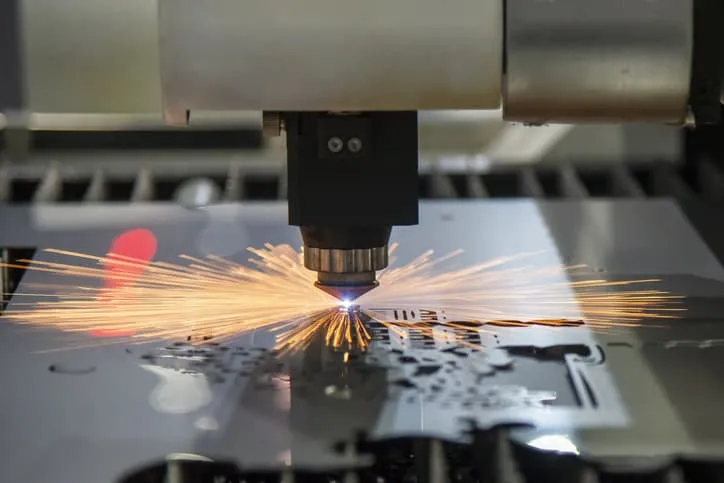

Corte por láser de fibra Utiliza un láser de estado sólido que genera un haz de luz a través de fibras ópticas.. Esta tecnología ha revolucionado el proceso de corte en diversas industrias debido a su alta eficiencia., precisión, y capacidad para manejar diversos materiales. El láser de fibra de 40.000W supone un importante avance, permitiendo una penetración profunda y un corte de alta velocidad, convirtiéndolo en un punto de inflexión para los fabricantes.

- Ventajas de la tecnología de corte por láser de fibra

– Precisión: Los láseres de fibra ofrecen una precisión notable, logrando tolerancias estrechas en los cortes.

– Velocidad: La alta potencia permite un corte rápido., aumentar la productividad general.

– Versatilidad: Capaz de cortar diversos materiales., incluyendo metales, plástica, y más.

– Bajos costos operativos: Los láseres de fibra son energéticamente eficientes, reducir los gastos operativos a largo plazo.

2. Capacidades de corte de un láser de fibra de 40.000 W

- Grosor general de corte

Un láser de fibra de 40.000 W es una de las herramientas de corte por láser más potentes disponibles en la actualidad.. Puede cortar eficazmente varios metales., con los siguientes espesores generales de corte:

– Acero dulce: Arriba a 50 milímetros (aproximadamente 2 pulgadas)

– Acero inoxidable: Arriba a 40 milímetros (aproximadamente 1.57 pulgadas)

– Aluminio: Arriba a 30 milímetros (aproximadamente 1.18 pulgadas)

– Cobre y Latón: Arriba a 20 milímetros (aproximadamente 0.79 pulgadas)

- Factores que afectan el espesor de corte

Si bien las cifras anteriores proporcionan una guía general, Varios factores pueden influir en el espesor de corte real que se puede lograr con un láser de fibra de 40.000 W.:

Tipo de material: Diferentes materiales reaccionan de manera diferente al corte por láser. Por ejemplo, El acero inoxidable absorbe la energía láser de forma diferente que el aluminio o el latón., afectando el espesor de corte.

Velocidad de corte: La velocidad a la que el láser se mueve a través del material puede afectar su capacidad para penetrar secciones gruesas.. Las velocidades más lentas pueden mejorar la profundidad pero pueden afectar la productividad.

Calidad de enfoque y haz: La calidad del rayo láser y qué tan bien se enfoca en el material afecta significativamente el rendimiento de corte.. Un haz bien enfocado puede cortar más profundamente y de forma más limpia.

Tipo de gas auxiliar: La elección del gas auxiliar, como oxígeno o nitrógeno, puede alterar el proceso de corte. El oxígeno puede mejorar la velocidad de corte del acero dulce, pero puede causar oxidación., mientras que el nitrógeno puede proporcionar cortes más limpios en acero inoxidable.

- Optimización del rendimiento

Para conseguir los mejores resultados con un láser de fibra de 40.000W, considere los siguientes consejos de optimización:

– Preparación de materiales: Asegúrese de que el material esté limpio y libre de contaminantes para maximizar la absorción y la efectividad del corte..

– Mantenimiento regular: Mantener la máquina en buen estado garantiza un rendimiento y una longevidad constantes.

– Experimentación: Realizar cortes de prueba en materiales de muestra puede ayudar a ajustar la configuración para aplicaciones específicas.

3. Practical Applications of 40,000W Fiber Lasers

- Heavy Metal Fabrication

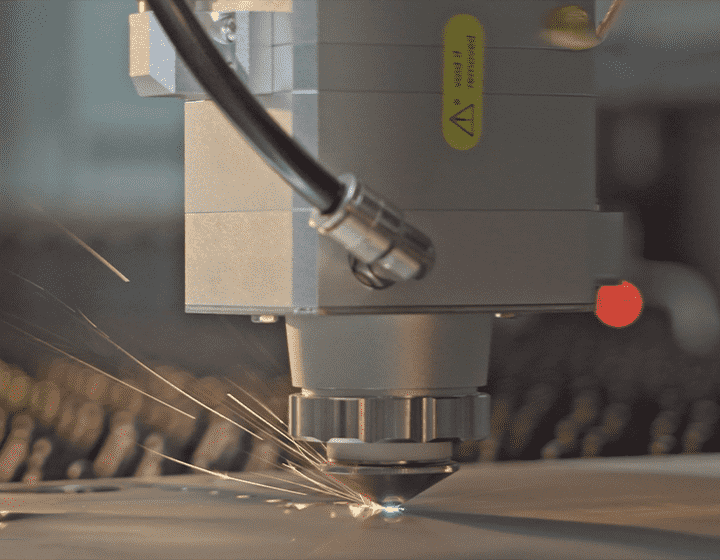

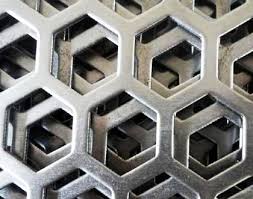

In industries where thick materials are standard, such as heavy machinery and structural components, a 40,000W fiber laser cutter shines. It can quickly and accurately cut large sections of steel, allowing for rapid production times and high-quality results.

- Shipbuilding

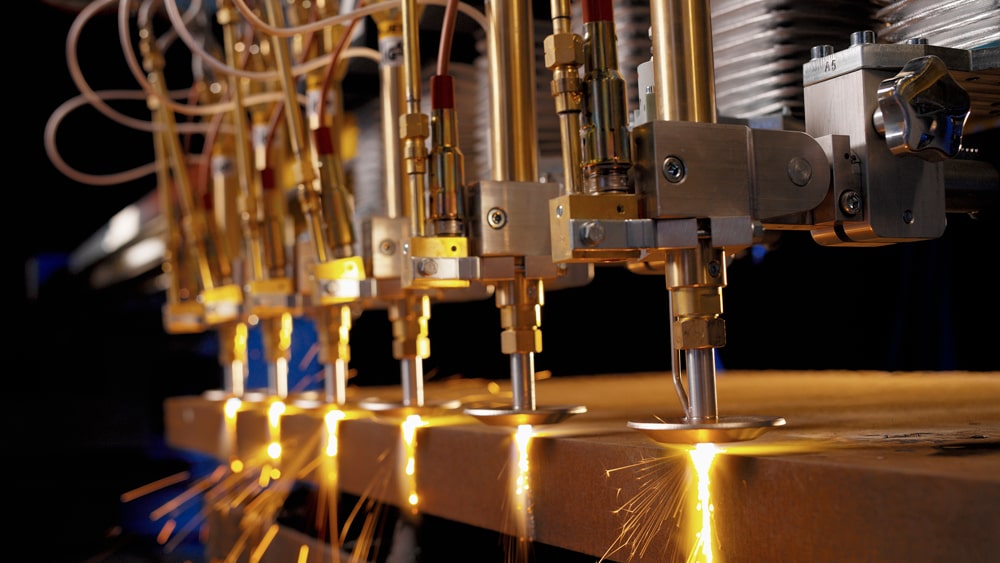

The shipbuilding industry requires robust materials that can withstand harsh marine environments. Fiber lasers are used to cut thick steel plates for ship hulls and structural components, ensuring precise fits and reducing the need for extensive finishing processes.

- Aerospace Manufacturing

The aerospace sector relies on lightweight yet strong materials. A 40,000W fiber laser can cut intricate shapes and forms in high-performance alloys, crucial para fabricar componentes que cumplan estrictos estándares de seguridad.

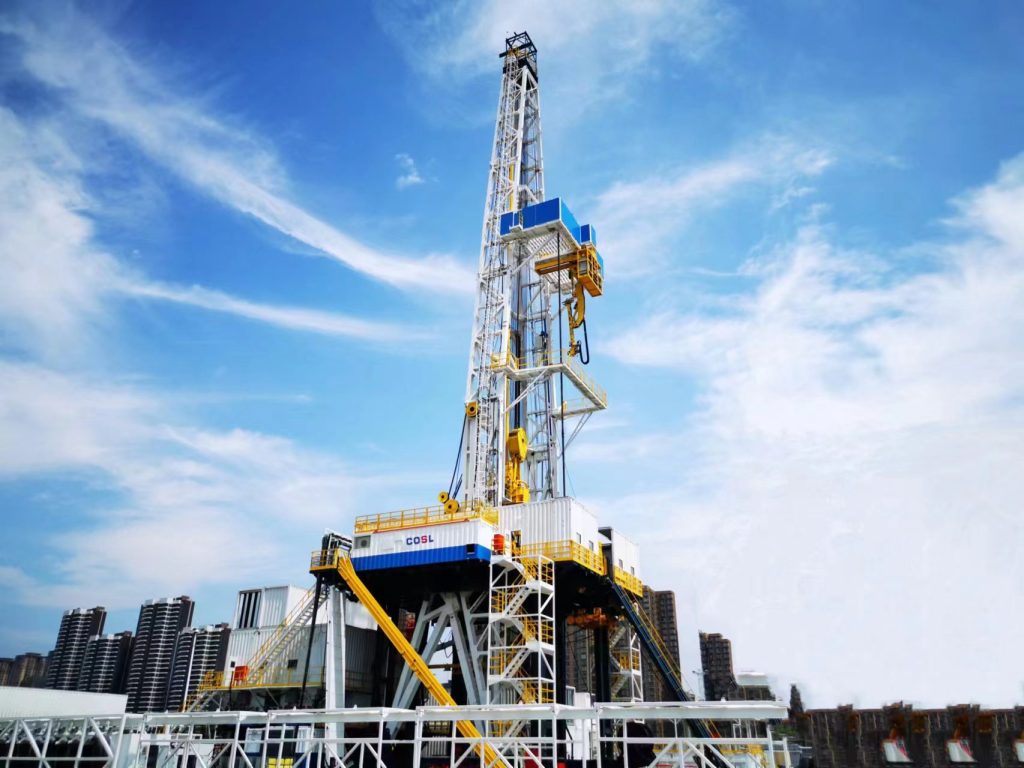

- Sector energético

En la industria energética, particularmente en petróleo y gas, la necesidad de equipos duraderos es primordial. La tecnología de corte por láser de fibra permite la creación de piezas complejas para plataformas de perforación, tuberías, y otros componentes críticos.

- Industria automotriz

Para fabricantes de automóviles, La precisión es clave. Un láser de fibra de 40.000 W puede cortar de manera eficiente componentes complejos, Garantizar tolerancias estrictas que mejoren la seguridad y el rendimiento del vehículo..

4. Ventajas de utilizar una cortadora láser de fibra de 40.000 W

- Profundidad de corte mejorada

La principal ventaja de un láser de fibra de 40.000 W es su capacidad para cortar materiales más gruesos con facilidad.. Esta capacidad abre nuevas oportunidades para los fabricantes que trabajan con aplicaciones exigentes que requieren una eliminación sustancial de material..

- Mayor productividad

La velocidad a la que puede funcionar un láser de fibra de 40.000 W mejora drásticamente las tasas de producción. Un corte más rápido se traduce en plazos de entrega más cortos, Permitir a las empresas satisfacer las demandas de los clientes de manera más eficiente..

- Calidad de borde superior

Un láser de fibra de alta potencia produce limpieza, Bordes lisos con zonas mínimas afectadas por el calor., reducir la necesidad de posprocesamiento y mejorar la calidad general del producto.

- Rentabilidad

Si bien la inversión inicial en una cortadora láser de fibra de 40.000 W puede ser sustancial, los ahorros a largo plazo en costos operativos, reducción del desperdicio de material, y una mayor eficiencia de la producción puede conducir a un retorno de la inversión favorable.

5. Consideraciones al invertir en una cortadora láser de fibra de 40.000 W

- Compatibilidad de materiales

Evalúe los tipos de materiales que planea cortar y asegúrese de que un láser de fibra de 40 000 W satisfaga sus necesidades específicas. Comprender las propiedades del material ayudará a optimizar el rendimiento de corte.

- Presupuesto y costos a largo plazo

Evalúe no solo los costos iniciales de adquirir una cortadora láser de fibra, sino también los costos continuos relacionados con el mantenimiento., consumo de energía, y consumibles. Un análisis de costes exhaustivo guiará su toma de decisiones.

- Requisitos de espacio

Una cortadora láser de fibra de 40.000 W puede requerir mucho espacio y ventilación adecuada. Asegúrese de que sus instalaciones puedan albergar la máquina y de que tenga la infraestructura adecuada para respaldar su funcionamiento..

- Soporte del fabricante

Elija un fabricante que ofrezca soporte y capacitación sólidos para sus máquinas de corte por láser de fibra.. En LÁSER KF, Brindamos asistencia integral para ayudarlo a maximizar el rendimiento de su máquina..

6. Tendencias futuras en la tecnología de corte por láser de fibra

- Integración de automatización

A medida que las industrias evolucionan, La integración de la automatización con las máquinas de corte por láser de fibra es cada vez más común.. Este desarrollo mejora la productividad al optimizar los flujos de trabajo y reducir los costos laborales..

- Mayores capacidades de energía

La demanda de mayores capacidades de corte continúa creciendo. Los avances futuros pueden conducir a láseres de fibra aún más potentes, permitiendo mayores espesores y velocidades de corte mejoradas.

- Fabricación inteligente

El cambio hacia la industria 4.0 impulsará la incorporación de tecnología IoT en máquinas de corte por láser de fibra. El monitoreo en tiempo real y el mantenimiento predictivo mejorarán la eficiencia y reducirán el tiempo de inactividad..

7.Conclusión: Liberando el poder del corte por láser de fibra

A medida que las industrias exigen tecnologías de corte más eficientes y precisas, La cortadora láser de fibra de 40.000 W se destaca como una solución formidable.. Su capacidad para cortar materiales gruesos., combinado con velocidad y calidad excepcional, lo posiciona como una herramienta vital en la fabricación moderna. Comprender las capacidades y aplicaciones de esta poderosa tecnología permitirá a las empresas mejorar sus procesos de producción., reducir costos, y mantener una ventaja competitiva.

Aprovechando las ventajas del corte por láser de fibra, Las empresas pueden desbloquear nuevas oportunidades de innovación y crecimiento., allanando el camino hacia un futuro donde la precisión y la eficiencia van de la mano. Si considera invertir en una cortadora láser de fibra, Recuerde que la elección correcta puede redefinir lo que es posible en sus operaciones.. Ya sea que esté cortando metal para maquinaria pesada, componentes aeroespaciales, o diseños intrincados, Una máquina cortadora por láser de fibra de 40.000 W es una inversión que promete ofrecer un rendimiento y un valor inigualables..

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora