Noticias

¿Qué espesor tendrá un corte con láser de fibra de 1000 W?? Explorando los límites del corte por láser de fibra

Imagine a tool so precise that it can slice through metal with the elegance of a scalpel, transforming raw materials into finely crafted components in mere moments. La tecnología de corte por láser de fibra ha revolucionado la industria manufacturera, ofreciendo velocidad, exactitud, y versatilidad que los métodos tradicionales simplemente no pueden igualar. But as you consider investing in a 1000W máquina de corte por láser de fibra, a critical question arises: how thick can it really cut?

En esta guía completa, we’ll explore the capabilities of a 1000W fiber laser cutter, the factors affecting cutting thickness, and practical applications across various industries. Al final de este artículo, you’ll have a clear understanding of what to expect from a 1000W fiber laser, empowering you to make informed decisions that can enhance your production processes.

1. Understanding Fiber Laser Cutting Technology

- ¿Qué es el corte por láser de fibra??

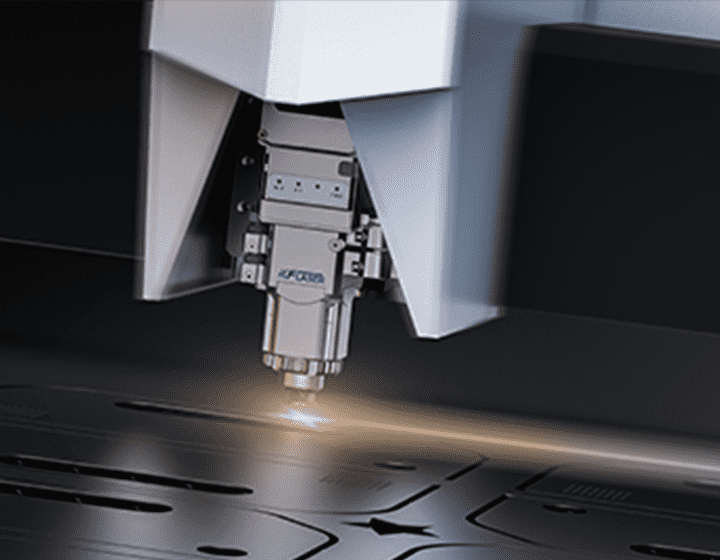

Fiber laser cutting uses a solid-state laser that transmits light through optical fibers. This technology is renowned for its efficiency, precisión, and ability to cut various materials, particularmente metales. Unlike traditional CO2 lasers, fiber lasers offer better absorption rates, especially for reflective materials, and deliver cleaner cuts with minimal heat distortion.

- Key Advantages of Fiber Lasers

Velocidad y eficiencia: Fiber lasers are significantly faster than their CO2 counterparts, especially when cutting thin materials.

Lower Operating Costs: With reduced energy consumption and minimal maintenance requirements, fiber lasers can be more cost-effective over time.

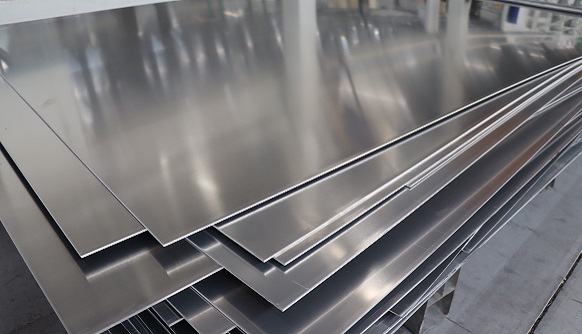

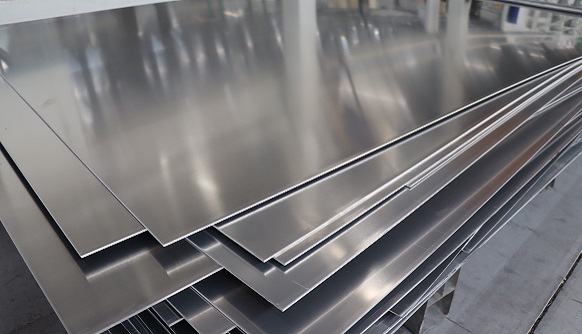

Versatilidad: Capaz de cortar una amplia gama de materiales, incluyendo acero inoxidable, aluminio, latón, y cobre, fiber lasers are ideal for diverse applications.

2. How Thick Can a 1000W Fiber Laser Cut?

- General Cutting Capabilities

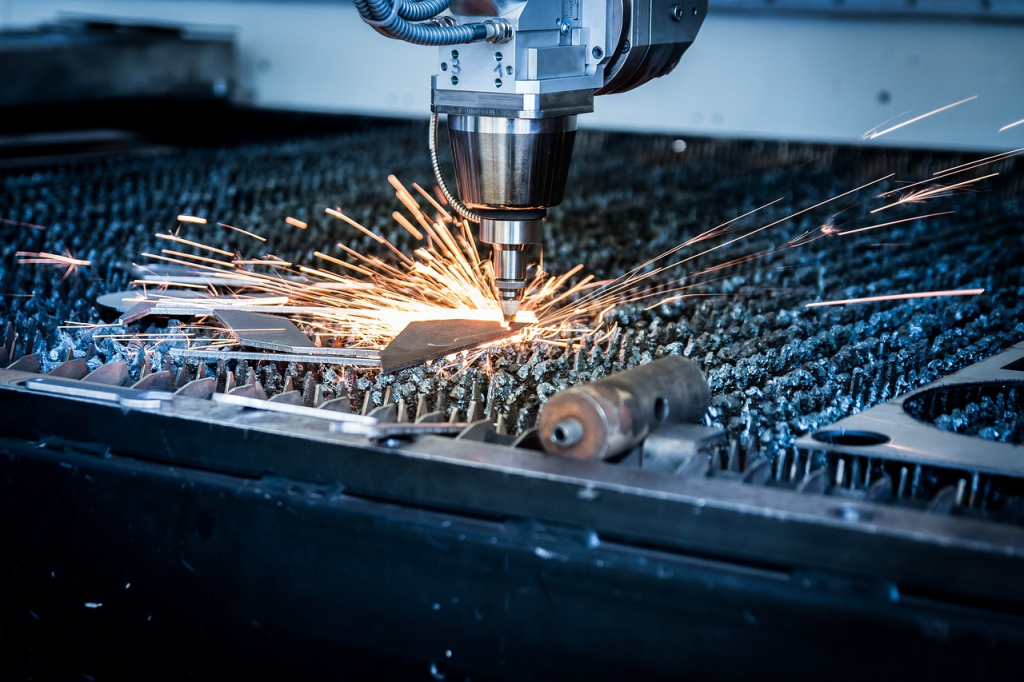

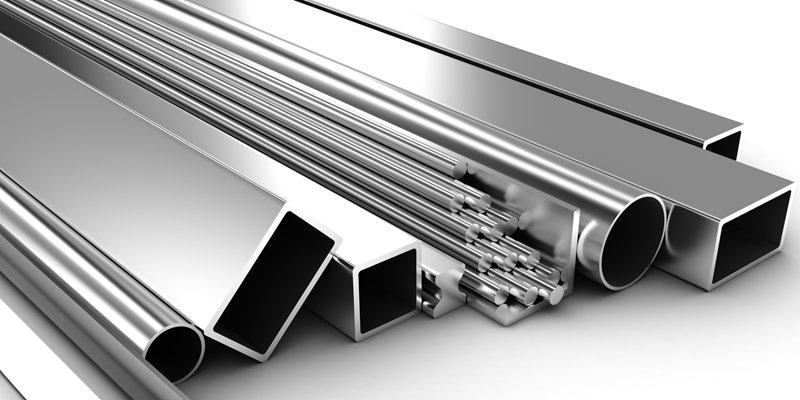

A 1000W fiber laser cutter is often capable of cutting through various metals, but the thickness it can manage effectively varies based on several factors. Generally speaking, a 1000W fiber laser can cut:

– Acero dulce: Up to approximately 10 milímetros (0.4 pulgadas)

– Acero inoxidable: Up to around 6 milímetros (0.24 pulgadas)

– Aluminio: Typically up to 5 milímetros (0.2 pulgadas)

- Factors Influencing Cutting Thickness

Several factors determine the effective cutting thickness of a fiber laser cutter, incluido:

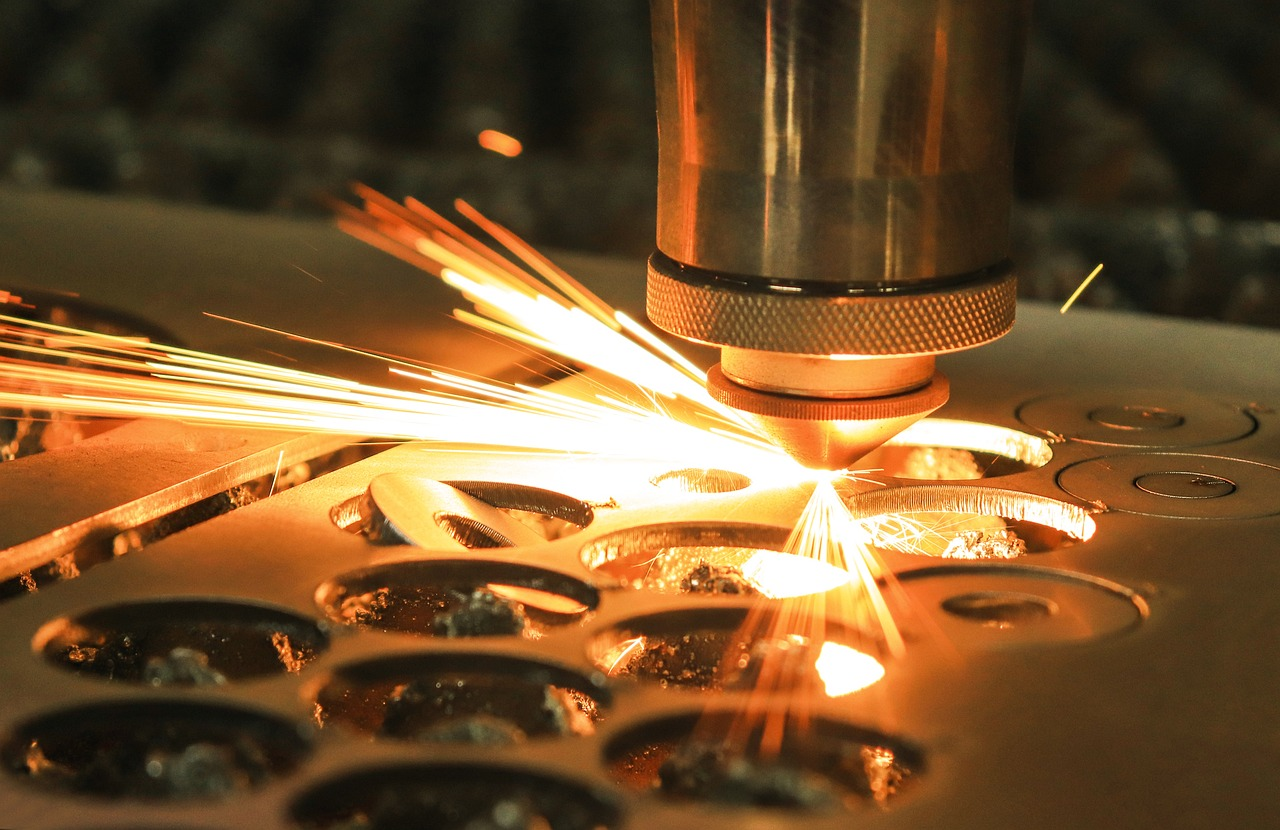

1. Tipo de material: Different materials have varying thermal properties, affecting how well they can absorb laser energy. Por ejemplo, aluminum requires more power to cut than mild steel due to its higher reflectivity.

2. Velocidad de corte: Slower cutting speeds can enhance the laser’s effectiveness in penetrating thicker materials. Sin embargo, this can impact overall productivity.

3. Focus and Lens Quality: The focal length of the lens and the quality of optical components play crucial roles in determining the beam’s intensity and focus on the workpiece.

4. Assist Gas: The type and pressure of the assist gas used during cutting can also impact performance. Por ejemplo, nitrogen is typically used for stainless steel to achieve clean cuts, while oxygen may be used for mild steel to enhance cutting speed.

- Optimal Performance Conditions

For optimal cutting performance with a 1000W fiber laser, consider the following:

– Preparación de materiales: Ensure that the material is clean and free from contaminants to maximize cutting effectiveness.

– Machine Calibration: Regular calibration of the laser system ensures that it operates at peak efficiency, optimizing cutting depth and speed.

– Experimentación: Conducting test cuts on sample materials helps determine the ideal settings for specific applications.

3. Practical Applications of 1000W Fiber Laser Cutters

- Fabricación de metal

In the metal fabrication industry, a 1000W fiber laser cutter is ideal for creating intricate parts such as brackets, marcos, and enclosures. Its ability to cut mild steel and stainless steel makes it a versatile tool for fabricators.

- Fabricación de automóviles

The automotive industry relies heavily on precision parts that require minimal post-processing. A 1000W fiber laser is capable of producing components such as body panels and chassis parts, ensuring tight tolerances that enhance vehicle safety and performance.

- Componentes aeroespaciales

The aerospace sector demands lightweight and durable materials. A 1000W fiber laser cutter can effectively handle high-performance alloys used in aircraft manufacturing, allowing for intricate designs that meet stringent safety standards.

- Electronics Production

In electronics manufacturing, La precisión es clave. A fiber laser cutter can produce detailed circuit boards and enclosures with exceptional accuracy, contributing to the reliability of electronic devices.

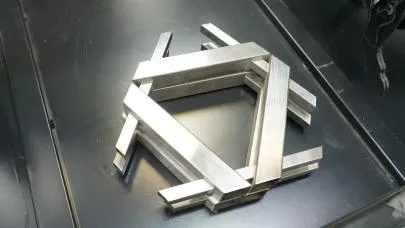

- Artistic and Decorative Uses

Artists and designers leverage fiber laser cutting technology to create custom sculptures, señalización, y elementos decorativos. The ability to cut complex patterns and intricate designs opens up new creative possibilities.

4. Tips for Maximizing Cutting Performance

- Mantenimiento regular

Maintaining your fiber laser cutter ensures consistent performance. Regular cleaning and checks on optics, espejos, and lenses help prevent issues that could impact cutting quality.

- Selección de materiales

Choosing the right material for your projects can influence cutting effectiveness. Ensure that the materials you work with fall within the recommended thickness ranges for a 1000W fiber laser cutter.

- Optimal Settings

Experiment with cutting speeds, assist gas types, and focal lengths to find the ideal settings for each specific application. Fine-tuning these parameters can significantly enhance cutting performance.

5. Tendencias futuras en la tecnología de corte por láser de fibra

A medida que avanza la tecnología, the capabilities of fiber laser cutting machines continue to improve. Innovations in beam quality, automation, and integration with smart manufacturing systems are set to enhance the efficiency and effectiveness of laser cutting processes.

- Automation and Smart Manufacturing

The integration of automation technologies with fiber lasers is streamlining production lines, allowing for faster changeovers and increased productivity. Automated systems can optimize cutting paths and monitor machine performance in real time, ensuring peak efficiency.

- Increased Power Levels

Future developments may see fiber lasers operating at higher power levels, expanding their cutting capabilities even further. This could allow 1000W lasers to handle thicker materials and broaden their applications across various industries.

6. The Role of KF LASER in Fiber Laser Cutting

En LÁSER KF, we are committed to providing cutting-edge fiber laser technology tailored to your unique production needs. Our fiber laser cutting machines are designed for optimal performance, reliability, and ease of use, ensuring that you can maximize your productivity while delivering high-quality results. Whether you are in metal fabrication, automotive manufacturing, or the arts, our solutions are engineered to help you achieve your goals.

By understanding the capabilities of a 1000W fiber laser cutter and the factors that influence cutting thickness, you can make informed decisions that enhance your operations. This knowledge empowers you to leverage fiber laser cutting technology effectively, positioning your business for success in an increasingly competitive landscape.

As you explore the possibilities of fiber laser cutting, remember that the right equipment can not only streamline your processes but also open up new avenues for innovation and creativity. Whether you are cutting metal, producing intricate designs, or manufacturing high-precision components, a fiber laser cutting machine offers the versatility and performance you need to thrive.

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora