Noticias

La versatilidad de las máquinas de corte por láser de fibra: ¿Para qué se utilizan??

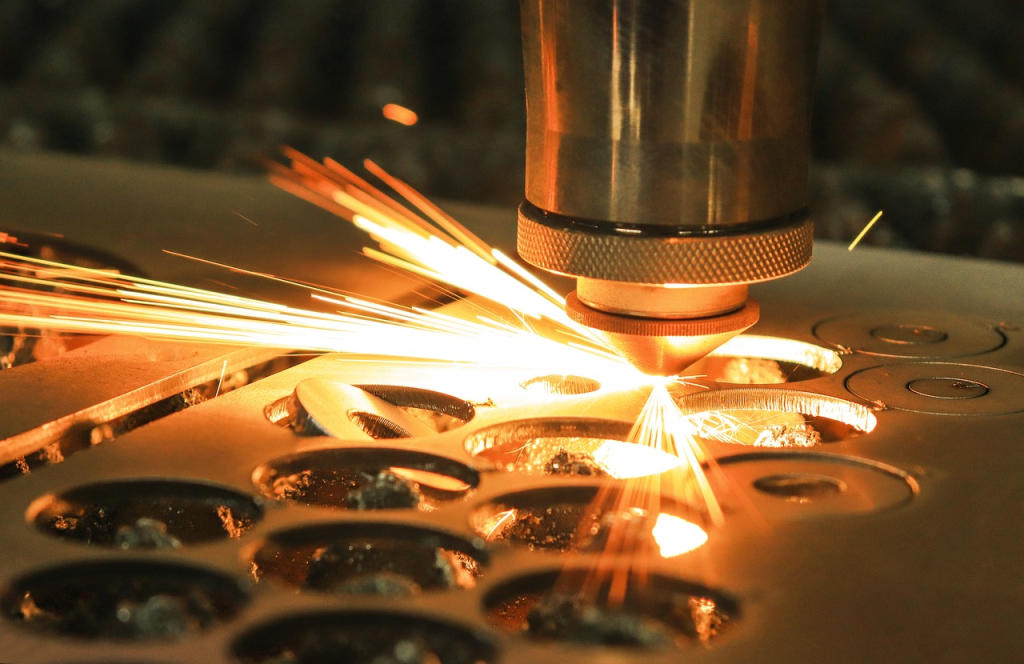

En el mundo de la fabricación moderna, where precision and efficiency reign supreme, the cortador láser de fibra has emerged as a transformative tool. Imagine a device that can slice through metal with the finesse of a chef’s knife cutting through ripe fruit, delivering flawless edges and intricate designs. This is not just a dream; it’s the reality brought forth by fiber laser cutting technology. As industries seek ways to optimize production while maintaining quality, understanding the applications of a fiber laser cutting machine becomes crucial.

1.¿Qué es un Máquina cortadora láser de fibra?

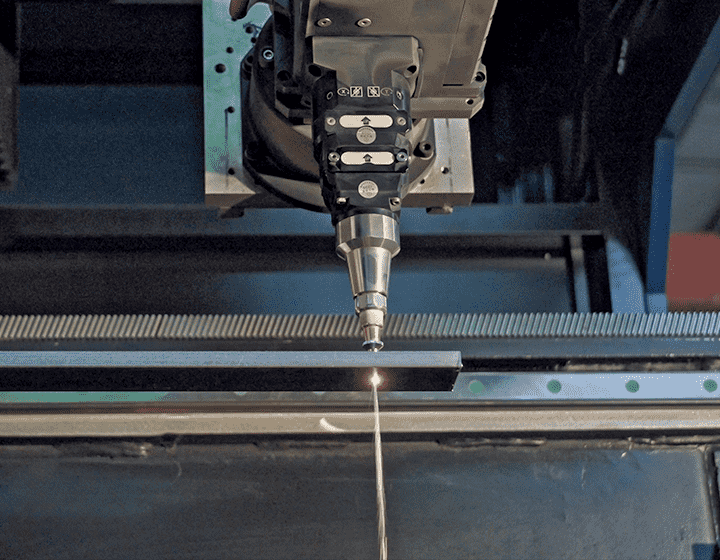

A fiber laser cutting machine utilizes a solid-state laser, transmitting light through optical fibers to create an intensely focused beam. This beam is capable of melting, incendio, or vaporizing materials with exceptional accuracy. A diferencia de los métodos de corte tradicionales, fiber laser technology operates without direct contact, significantly reducing wear and tear on the equipment and allowing for higher cutting speeds.

- The Technology Behind Fiber Lasers

Fiber lasers work on the principle of stimulating a gain medium, usually composed of rare earth elements, to produce a high-intensity beam. This technology allows for better absorption of the laser light into the material being cut, resulting in cleaner cuts and less heat distortion. The versatility of fiber lasers means they can be used across a wide range of industries, making them a favored choice for manufacturers worldwide.

2.Applications of Fiber Laser Cutting Machines

- Fabricación de metal

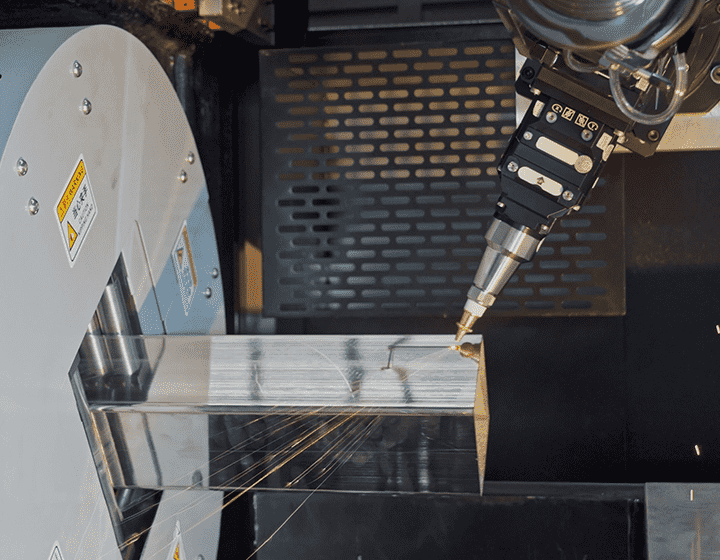

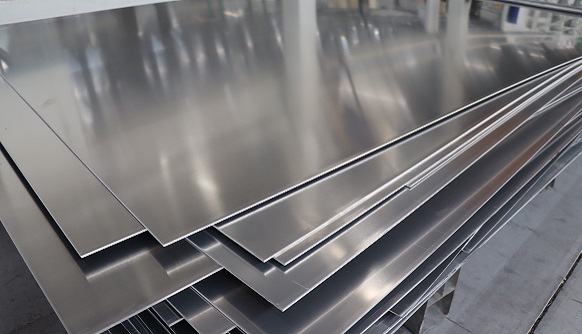

One of the primary uses of a fiber laser cutter is in metal fabrication. This includes cutting sheet metal, plates, and tubes made from materials such as:

– Acero inoxidable: Widely used for its corrosion resistance and strength, stainless steel is often cut for components in automotive, aeroespacial, and kitchenware industries.

– Aluminio: Lightweight and versatile, aluminum is popular in various applications, from consumer goods to structural components.

– Cobre y Latón: These metals are increasingly cut with fiber lasers due to their reflective properties, which can pose challenges for other laser types.

- Ejemplo: Componentes automotrices

En la industria automotriz, fiber laser cutting machines are essential for producing intricate parts like body panels and brackets. The precision of fiber lasers ensures that parts fit together perfectly, reducing assembly time and improving overall vehicle safety.

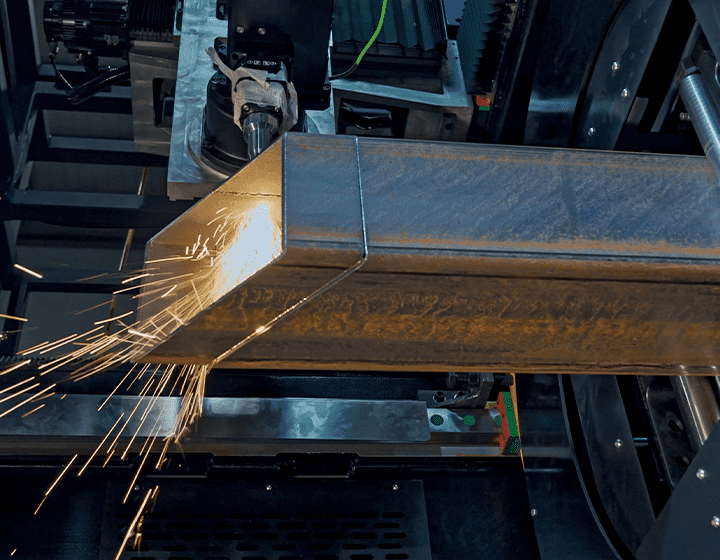

- Aerospace Manufacturing

The aerospace sector demands the highest levels of precision and quality. A fiber laser cutting machine is used to create lightweight and durable components from high-performance alloys. The ability to cut complex shapes and maintain tight tolerances makes fiber lasers an invaluable asset in aerospace manufacturing.

- Medical Device Production

In the medical field, precision is non-negotiable. Fiber laser cutters are employed to manufacture surgical instruments, implantes, and other devices that require exceptional accuracy and smooth finishes. The cleanliness of the cut edges also helps meet stringent hygiene standards.

- Jewelry Design

The art of jewelry making has been revolutionized by the use of fiber lasers. Designers can create intricate patterns and detailed engravings that would be impossible to achieve with traditional methods. The speed and precision of fiber lasers allow for rapid prototyping and production, catering to the fast-paced demands of the fashion industry.

- Decorative Applications

From artistic sculptures to custom signage, fiber laser cutting machines enable the creation of decorative metal pieces with stunning detail. Artists and fabricators utilize this technology to bring their creative visions to life, making it possible to craft complex designs that stand out in any environment.

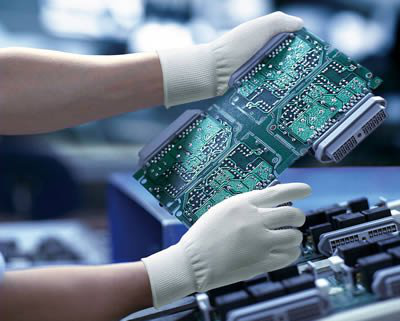

- Fabricación de productos electrónicos

The electronics industry relies heavily on fiber laser cutting for producing components like circuit boards, disipadores de calor, and enclosures. The precision of fiber lasers ensures that intricate designs can be cut without damaging the delicate materials used in electronic devices.

3.Advantages of Using Fiber Laser Cutting Machines

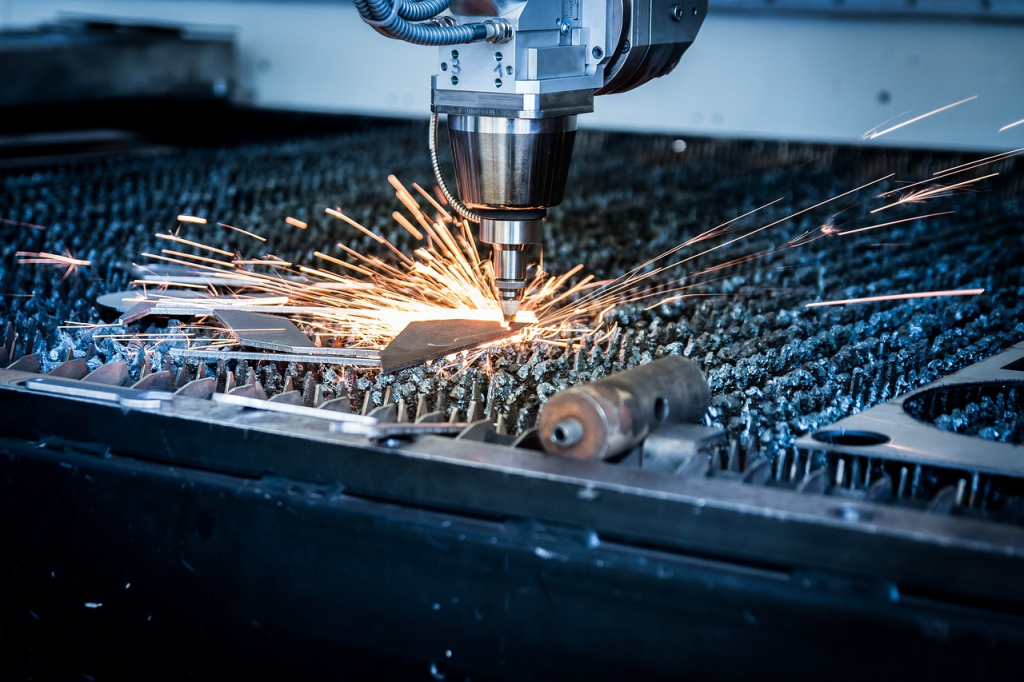

- Velocidad y eficiencia

Fiber laser cutting machines are known for their speed. The focused beam allows for rapid cutting, which increases overall productivity. This efficiency is particularly beneficial for high-volume production runs where time is critical.

- Bajos costos operativos

Compared to other cutting technologies, fiber lasers are generally more cost-effective in terms of energy consumption and maintenance. Their solid-state design eliminates the need for frequent adjustments, and they require less power to operate than CO2 lasers, leading to lower utility bills.

- Minimal Heat Affected Zone (Cría)

The precision of fiber laser cutting leads to a smaller heat affected zone compared to traditional cutting methods. This results in less distortion and discoloration of the metal, ensuring high-quality cuts that often require little to no post-processing.

- Versatilidad en todos los materiales

Fiber lasers can cut a wide range of materials, incluyendo metales, plástica, e incluso cerámica. This versatility makes them suitable for various applications across multiple industries, enhancing their value to manufacturers.

4. Choosing the Right Fiber Laser Cutting Machine

When considering a fiber laser cutting machine, several factors should guide your decision-making process:

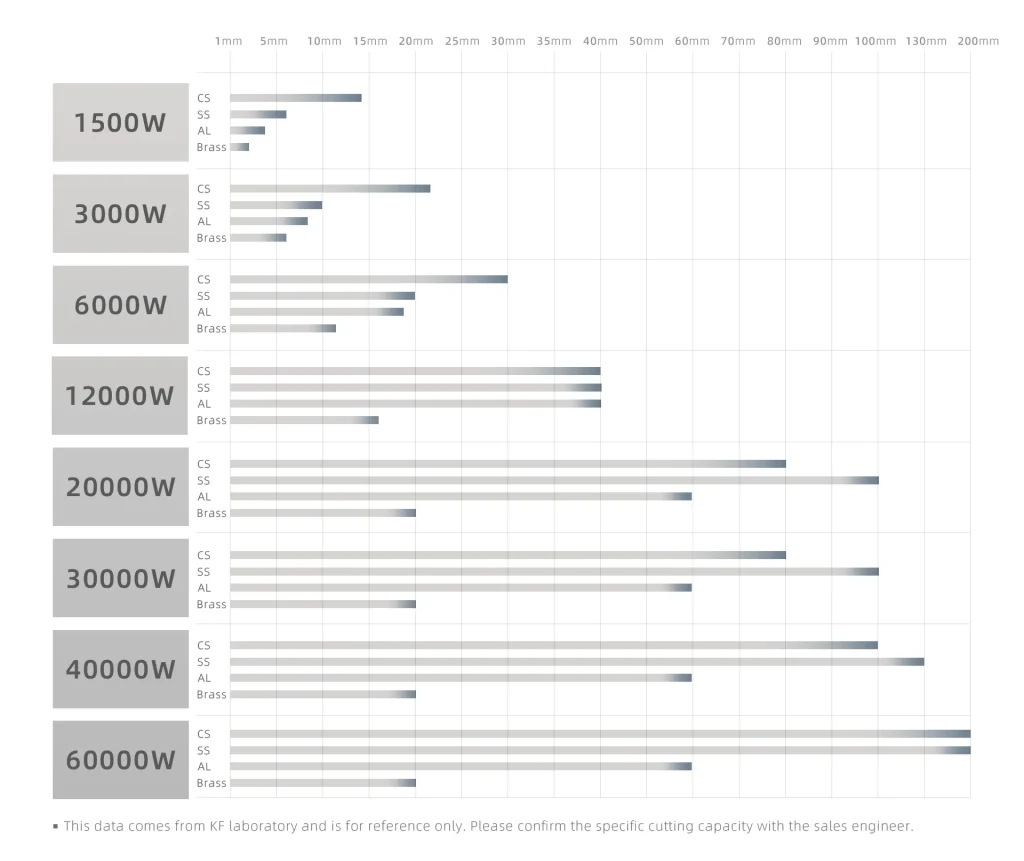

- Material Requirements

Assess the types of materials you will be cutting and their thicknesses. Different machines have varying power levels and capabilities, so it’s crucial to match the machine to your material specifications.

- Cutting Speed and Quality

Evaluate the cutting speed and quality of the machine. Faster cutting speeds can significantly enhance productivity, but ensure that speed does not compromise the quality of the cuts.

- Machine Size and Configuration

Consider the size of the machine and whether it fits within your workspace. Also, think about the configuration of the machine—whether it’s a flatbed for sheet cutting or a tube cutter for cylindrical materials.

- Budget and Total Cost of Ownership

While fiber laser machines can have a higher initial investment, analyze the total cost of ownership, incluyendo mantenimiento, consumo de energía, and potential savings in production time.

- After-Sales Support

Partnering with a reliable manufacturer is essential. Ensure that they offer robust after-sales support, including installation, capacitación, and ongoing maintenance services. En LÁSER KF, we pride ourselves on providing comprehensive customer support to help you maximize your machine’s performance.

5.Conclusión: The Future of Fiber Laser Cutting Machines

A medida que las industrias continúan evolucionando, the role of fiber laser cutting machines is set to expand. The technology behind fiber lasers is continually advancing, promising even greater efficiency, velocidad, y versatilidad. For manufacturers, investing in a fiber laser cutting machine not only enhances production capabilities but also positions them to meet the demands of an increasingly competitive marketplace.

Understanding the applications, beneficios, and considerations surrounding fiber laser cutting will empower you to make informed decisions that elevate your manufacturing processes. With the right fiber laser cutter, you can unlock new levels of precision and creativity, ensuring your business thrives in the modern industrial landscape.

By embracing this cutting-edge technology, you’ll not only streamline your operations but also deliver exceptional value to your clients and stakeholders. Entonces, whether you are in metal fabrication, aeroespacial, medical devices, or any other industry, the time to consider a fiber laser cutting machine is now.

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora