Noticias

Máquina de corte de acero láser: Precisión, Eficiencia, y versatilidad en el corte de metal

The laser steel cutting machine has become an essential tool in modern manufacturing and fabrication. With advancements in laser technology, industries that rely on cutting steel have experienced significant improvements in both quality and efficiency. Whether you’re creating complex shapes for aerospace components, automotive parts, or industrial machinery, the precision and speed of laser cutting can elevate the quality of your products while reducing operational costs.

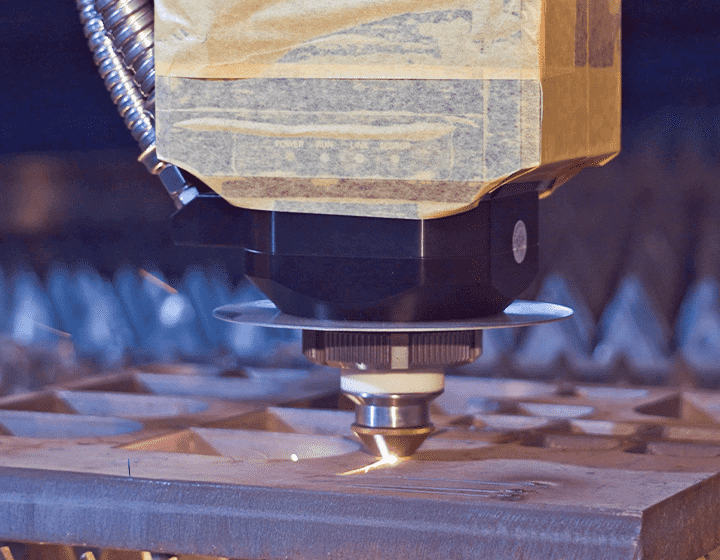

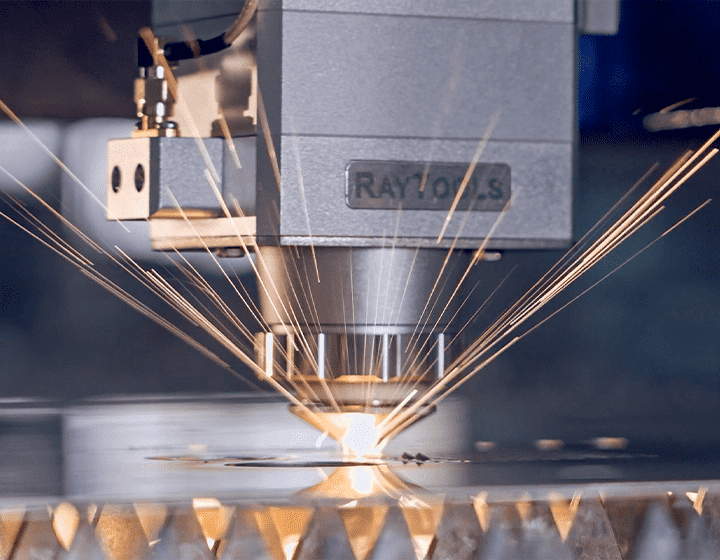

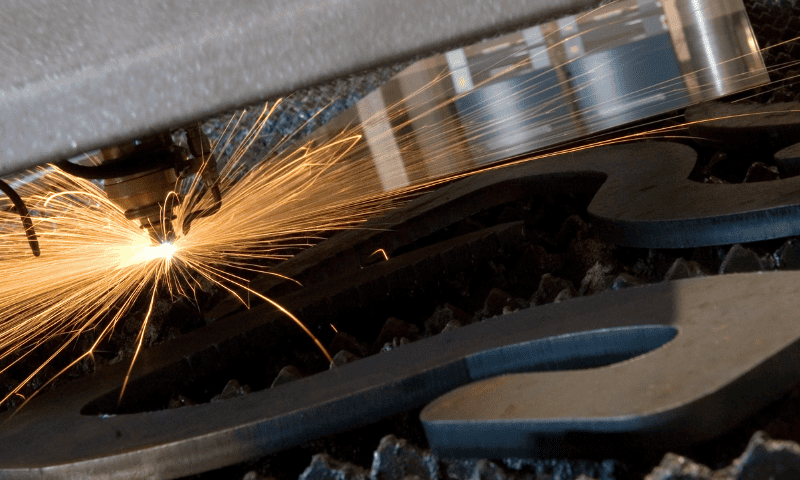

Laser cutting machines for steel use a focused laser beam to cut through materials with high precision. The process involves directing a powerful laser beam onto the steel surface, where it melts, quemaduras, o vaporiza el material. This method provides clean, precise cuts with minimal waste, making it ideal for both mass production and intricate, custom designs.

Ⅰ.How Does a Máquina de corte de acero láser Work?

Laser cutting machines for steel operate through a sophisticated setup where a high-powered laser is focused on the steel surface. The laser melts or vaporizes the material along the defined path, and the material is either blown away by a gas stream or falls away after being cut. The laser’s fine focus allows for minimal heat distortion, which is a major advantage over traditional cutting methods, such as plasma cutting or mechanical cutting.

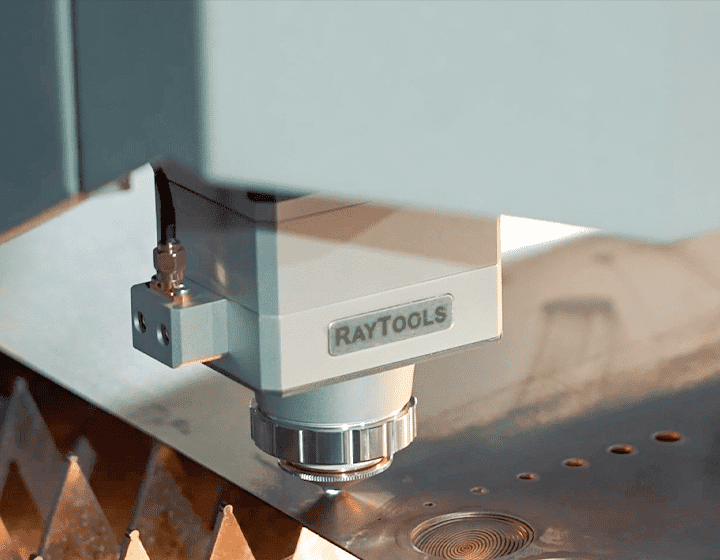

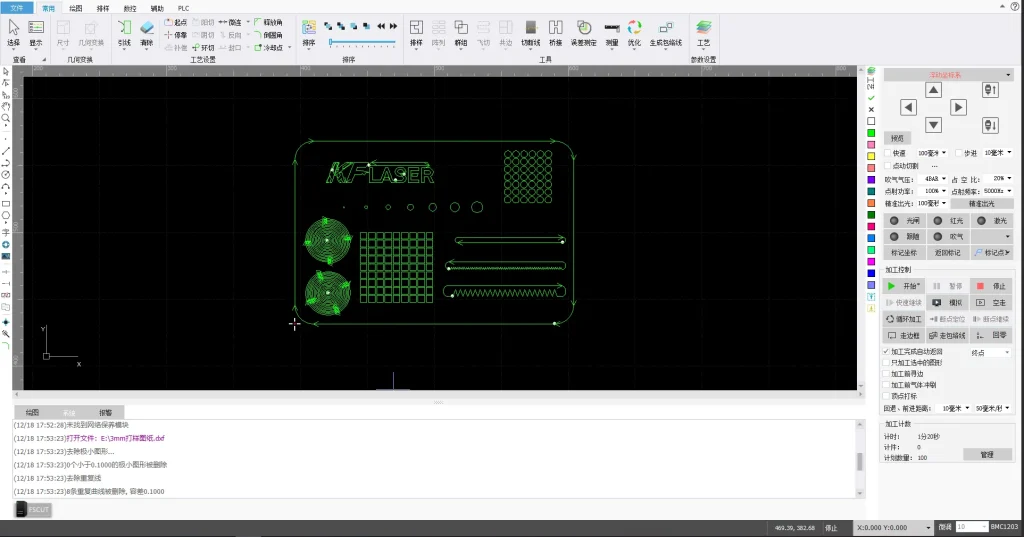

The machine is usually controlled via a computer numerical control (CNC) sistema, which ensures precise cuts based on pre-programmed designs. The combination of high-tech software and hardware allows manufacturers to cut even the most complex shapes with a high degree of accuracy and repeatability.

Ⅱ.Key Benefits of Using a Laser Steel Cutting Machine

1. Unmatched Precision and Accuracy

Laser cutting machines offer some of the most precise cutting capabilities available today. The accuracy of laser cutting is often measured in microns, allowing manufacturers to achieve tight tolerances that are impossible with traditional methods. This high level of precision is essential for industries like aerospace, where the exactness of each part is crucial.

2. Velocidad y eficiencia

Laser cutting machines for steel are known for their speed. The automated nature of these machines, combined with their ability to cut through thick steel quickly, ensures faster production times compared to other methods. This increase in speed leads to lower manufacturing costs and shorter lead times, making it an attractive choice for high-volume production environments.

3. Clean Cuts with Minimal Heat Affected Zone (Cría)

One of the standout features of laser cutting is the minimal heat affected zone (Cría). Unlike plasma or flame cutting, which can cause heat damage to the edges of the cut material, laser cutting minimizes thermal distortion. This results in a smoother edge, requiring less post-processing and improving the overall quality of the final product.

4. Versatility in Material Types and Thickness

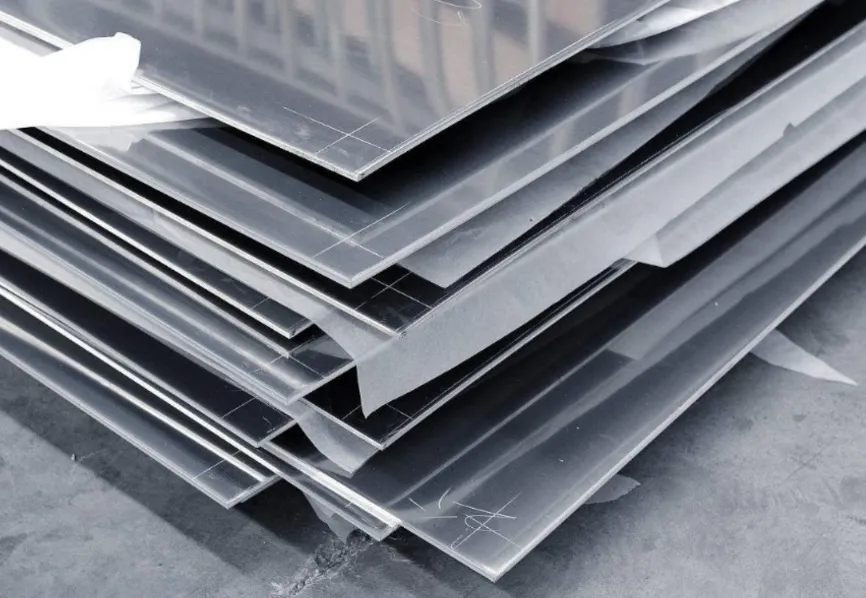

Laser cutting machines for steel can handle a wide range of material thicknesses, from thin sheets of steel to thick plates. Además, they can work with various steel alloys, providing manufacturers with the versatility to cut materials that are difficult to process with other machines. This versatility makes laser cutting a viable option for many industries, including construction, automotor, and metalworking.

5. Reduced Waste and High Material Utilization

Laser cutting offers excellent material utilization. Since the laser beam is so precise, the kerf (the width of the cut) is narrow, meaning there’s less material waste compared to traditional cutting methods. This high level of efficiency makes laser cutting a cost-effective solution for projects where material costs are a concern.

Ⅲ.Applications of Laser Steel Cutting Machines

Laser steel cutting machines are used in a wide variety of industries and applications. Here are a few sectors that benefit from this advanced technology:

Industria automotriz

Laser cutting has become integral in the automotive industry for manufacturing parts such as body panels, paréntesis, y componentes estructurales. The ability to make highly precise cuts, even on complex geometries, is essential for producing parts that meet stringent safety standards and fit within the limited tolerances of automotive designs.

Aerospace Manufacturing

In the aerospace sector, laser cutting machines are used to create critical components for aircraft, such as fuselages, wings, y piezas del motor. The precision required in aerospace manufacturing is incredibly high, and laser cutting machines meet these demands while ensuring a clean, smooth finish that minimizes the need for additional processing.

Metal Fabrication and Construction

Laser steel cutting machines are widely used in the fabrication of structural steel components. They can cut complex shapes for buildings, puentes, and industrial structures, all with high accuracy and speed. The ability to handle large steel plates makes laser cutting ideal for custom and mass production in the construction sector.

Procesamiento de chapa metálica

Laser cutting is also essential in the sheet metal processing industry, where it is used for cutting various shapes and designs for everything from home appliances to industrial equipment. The flexibility and adaptability of laser cutting machines make them perfect for industries that require a high volume of parts with precise dimensions.

Ⅳ.Why Choose a Laser Steel Cutting Machine?

Higher Production Throughput

Laser cutting machines are faster than traditional cutting methods. They require fewer machine setups and less manual intervention, increasing production efficiency. For businesses that need to produce large quantities of parts quickly, the speed and automation of laser cutting are significant advantages.

Precision and Repeatability

The precision of laser cutting technology ensures that every part is cut to the exact specifications, with minimal variation from the original design. This level of consistency is essential for industries that require high-quality products, such as electronics or medical device manufacturing.

Reduced Post-Processing Needs

Because laser cutting produces cleaner edges and minimizes heat distortion, the need for post-cutting operations like deburring, grinding, or polishing is significantly reduced. This saves both time and money by reducing labor costs and additional processing steps.

Cutting Complex and Intricate Shapes

Laser cutting machines excel at cutting complex and intricate shapes, which can be a challenge for traditional cutting methods. Whether it’s a small part with fine details or a large component with multiple features, laser cutting provides the flexibility to achieve the most intricate designs with ease.

Ⅴ.The Future of Laser Steel Cutting Machines

A medida que la tecnología continúa evolucionando, laser cutting machines are becoming even more efficient. La integración de la inteligencia artificial (AI) and machine learning in laser cutting systems will further enhance cutting speeds, exactitud, and adaptability. With innovations such as fiber lasers, laser steel cutting machines will continue to improve in both performance and cost-effectiveness, ensuring their place in the future of metalworking.

En conclusión, laser steel cutting machines are a powerful tool in the modern manufacturing landscape, offering significant benefits in terms of precision, velocidad, versatilidad, and cost-effectiveness. Whether you are cutting large steel plates or intricate designs, laser cutting technology will continue to drive efficiency and innovation in metal cutting processes.

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora