Noticias

Máquina de cortar láser: Beneficios y aplicaciones en la fabricación de metales

The laser cutting sheet metal machine represents a revolutionary advancement in metal fabrication, providing unprecedented precision, velocidad, y versatilidad. Industries involved in manufacturing and fabricating metal products have recognized laser cutting as a game-changing technology, offering significant advantages over traditional cutting methods. Whether you’re involved in aerospace, automotor, or even small-scale sheet metal projects, understanding how these machines work and their key benefits can help enhance your production process.

Laser cutting technology is based on using a high-powered laser beam directed onto a metal surface to cut or engrave it. The energy from the laser beam melts or vaporizes the metal along a predefined path, providing a level of control that is difficult to achieve with conventional cutting tools. The result is a highly precise and clean cut with minimal material waste and a reduced need for secondary finishing processes.

1.How Does a Máquina de cortar láser Work?

At the heart of a laser cutting sheet metal machine is the laser itself, which is focused onto the material using mirrors and lenses. The laser beam melts or burns through the metal, and a high-pressure gas (often oxygen or nitrogen) is blown onto the cut to remove molten metal, preventing oxidation and ensuring a clean cut.

Modern laser cutting machines are typically equipped with a computer numerical control (CNC) sistema, which allows the machine to follow intricate paths with extreme precision. CNC systems also enable quick changes in design, making it easy to switch from one job to the next without much downtime.

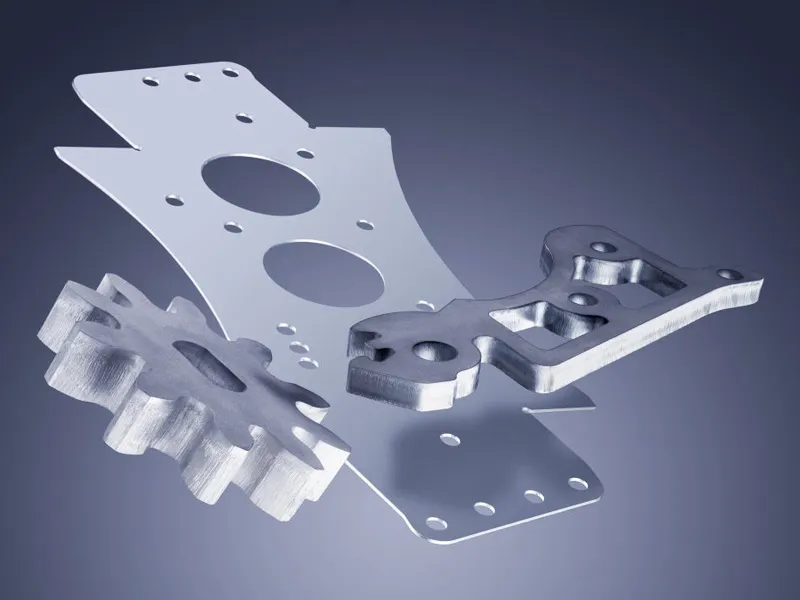

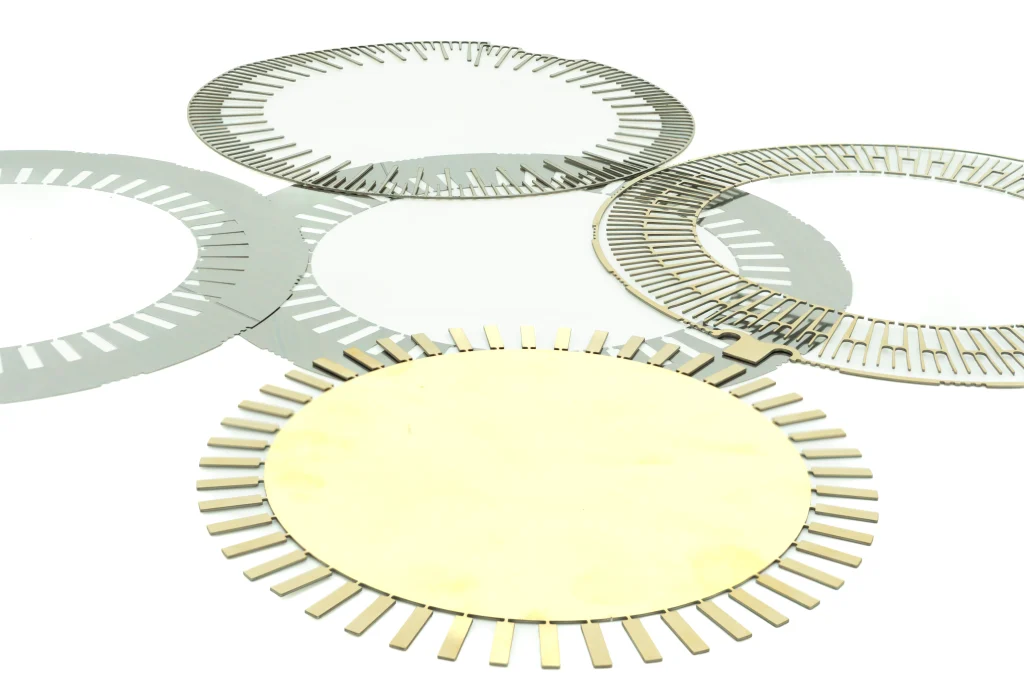

Laser cutting can handle a variety of materials, but it is especially well-suited for sheet metal. The ability to create highly intricate patterns with fine details and the capability to cut through different thicknesses of metal makes laser cutting an invaluable tool in many industries.

2.Key Benefits of Laser Cutting Sheet Metal Machines

Precisión y exactitud

Laser cutting machines for sheet metal are known for their extraordinary precision. The fine laser beam can cut intricate details with micron-level accuracy, which is essential for industries where precision is paramount. This high degree of accuracy ensures that parts fit together perfectly without the need for further adjustments, reducing material waste and production time.

Velocidad y eficiencia

One of the standout features of a laser cutting sheet metal machine is its speed. El corte por láser es significativamente más rápido que los métodos de corte tradicionales., such as mechanical cutting or plasma cutting. The high efficiency of these machines not only speeds up production but also leads to reduced operational costs, making it a great option for industries with tight deadlines and large-scale production needs.

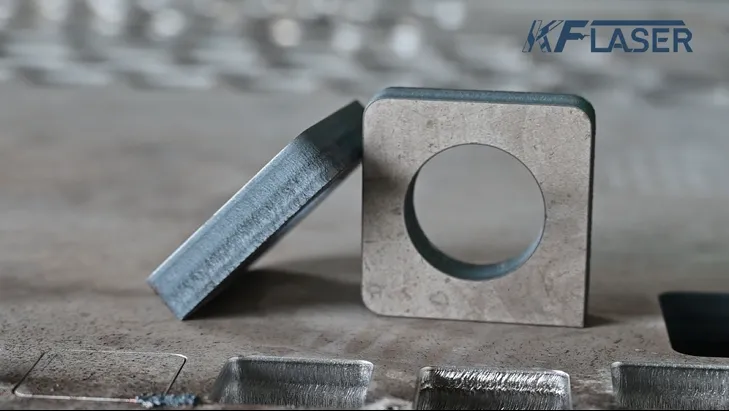

Clean and Smooth Cuts

El corte por láser produce limpieza, smooth edges with minimal burrs, reducing the need for post-processing. This feature is especially important in industries like aerospace, where tight tolerances and high-quality finishes are required. The minimized heat-affected zone (Cría) means there is less distortion or warping of the material, ensuring that the final product is of the highest quality.

Reduced Waste and Material Utilization

Laser cutting machines are highly efficient when it comes to material usage. The narrow kerf (width of the cut) means less material is wasted, which is crucial when working with expensive metals. The reduced need for additional processes like deburring and finishing also saves both time and money. In industries where material costs are high, this efficiency can lead to substantial savings.

Versatility in Cutting Different Metals

Laser cutting machines for sheet metal can cut a wide variety of metals, including mild steel, acero inoxidable, aluminio, and non-ferrous materials. This versatility makes them highly adaptable for a range of industries, from automotive manufacturing to custom metal artwork and everything in between. With the right settings, these machines can cut metals of varying thicknesses, from thin sheets to heavy-duty plates.

3.Applications of Laser Cutting Sheet Metal Machines

Laser cutting sheet metal machines are widely used in several industries, thanks to their efficiency, precisión, and adaptability. Below are just a few of the key sectors that rely on this technology:

Industria automotriz

En la fabricación de automóviles, laser cutting is used to create a variety of components, including body panels, paréntesis, y piezas estructurales. The precision of laser cutting ensures that these components fit together with the utmost accuracy, contributing to the safety and performance of vehicles.

Aerospace Manufacturing

Aerospace companies use laser cutting machines for sheet metal to produce parts for aircraft, spacecraft, and other complex systems. The high precision required in aerospace applications makes laser cutting the ideal solution for creating lightweight, durable components with tight tolerances.

Arquitectura y Construcción

Laser cutting has found applications in architecture and construction, where it is used to create decorative elements, metal facades, and structural steel components. The ability to create intricate designs without compromising strength is a key advantage for architects and builders.

Sheet Metal Fabrication

Laser cutting sheet metal machines are essential in the sheet metal fabrication industry, where they are used to produce everything from HVAC ducts to kitchen appliances. The speed and precision of laser cutting make it the preferred choice for fabricating parts from thin metal sheets.

4.Why Choose a Laser Cutting Sheet Metal Machine?

✔Higher Productivity

Laser cutting machines are automated and require minimal manual intervention. This leads to faster production cycles, increased throughput, and reduced labor costs. With laser cutting, manufacturers can achieve higher productivity without compromising quality.

✔Flexibility in Design

Laser cutting machines offer unparalleled flexibility when it comes to design changes. Since the machine follows a digital design path, it is easy to modify or adjust designs as needed. This flexibility allows manufacturers to quickly adapt to changes in client requirements or industry trends.

✔Minimal Post-Processing

Because laser cutting produces such clean and precise cuts, there is less need for post-processing. Other cutting methods may leave rough edges or require extensive deburring and grinding to smooth out imperfections. With laser cutting, most components are ready to go straight from the machine, saving time and reducing costs.

✔ Less Environmental Impact

Laser cutting is more environmentally friendly compared to traditional cutting methods. The process produces fewer fumes and reduces material waste, making it a greener option for businesses looking to reduce their environmental footprint. Además, laser cutting is more energy-efficient than other methods, further lowering its impact.

5.Future Trends in Laser Cutting Sheet Metal Machines

As laser technology continues to advance, the capabilities of laser cutting machines are expanding. The integration of fiber laser technology is making the cutting process even faster and more efficient. Moreover, developments in automation and AI-driven systems are making it easier to program and operate laser cutting machines, allowing businesses to achieve even greater levels of precision and speed.

With industries constantly seeking faster, more efficient, and sustainable manufacturing processes, the future of laser cutting in sheet metal fabrication looks brighter than ever. As laser cutting technology evolves, businesses will continue to benefit from the increasing performance, affordability, and versatility of these machines, solidifying their place at the forefront of modern manufacturing.

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora