Notícias

O guia completo para máquinas de corte de tubos a laser de fibra: Precisão, Velocidade, e versatilidade

1. Understanding Fiber Laser Tube Cutting Machines

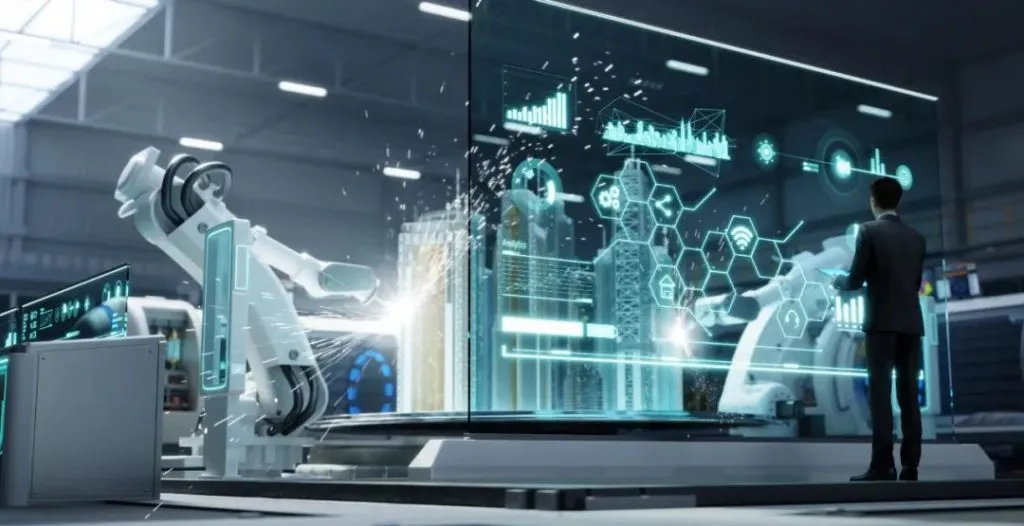

Fiber laser tube cutting machines have become a cornerstone in modern metal fabrication, oferecendo precisão e eficiência incomparáveis. These machines utilize advanced fiber laser technology to cut tubes, tubos, and various profiles with high accuracy. Whether you’re involved in the automotive, aeroespacial, or construction industry, a fiber laser tube cutting machine can significantly enhance your production capabilities. This guide will delve into how these machines work, their advantages, formulários, and important considerations when selecting one for your needs.

2. What Is a Fiber Laser Tube Cutting Machine?

A fiber laser tube cutting machine is a specialized laser cutting device designed for cutting tubes and pipes. Unlike flat sheet laser cutters, this equipment is engineered to handle the unique requirements of tube cutting, offering precision and efficiency through its use of fiber laser technology.

- How Does a Fiber Laser Tube Cutting Machine Work?

The operation of a fiber laser tube cutting machine involves several key steps:

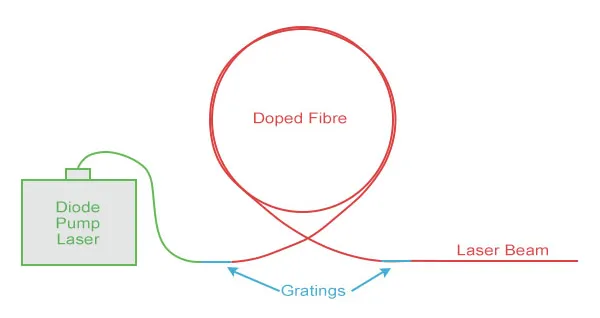

– Geração a laser: The machine generates a high-intensity laser beam using a fiber laser source. This laser is created through a process of light amplification, using diodes to channel light into fiber optics.

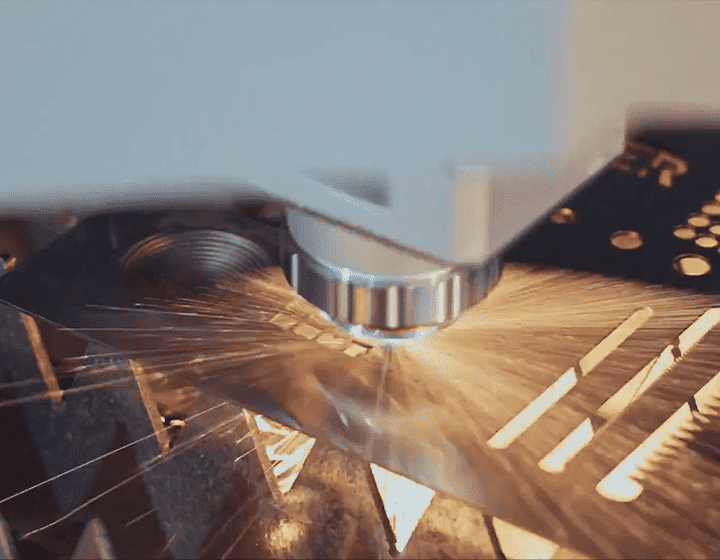

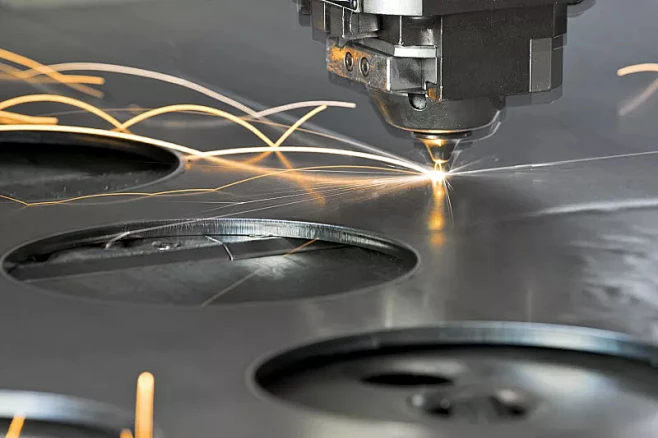

– Foco em feixe: The generated laser beam is directed through a series of mirrors or fiber-optic cables to the cutting head, where it is focused into a small spot on the surface of the tube.

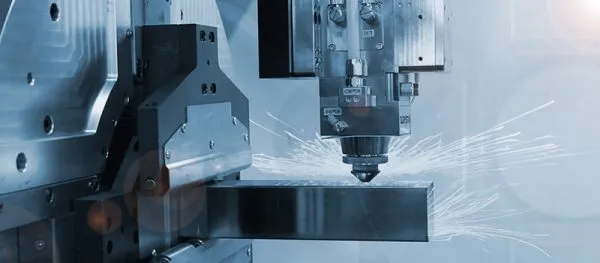

– Interação material: When the focused laser beam meets the tube surface, it heats the material to a point where it melts or vaporizes, allowing for precise cuts.

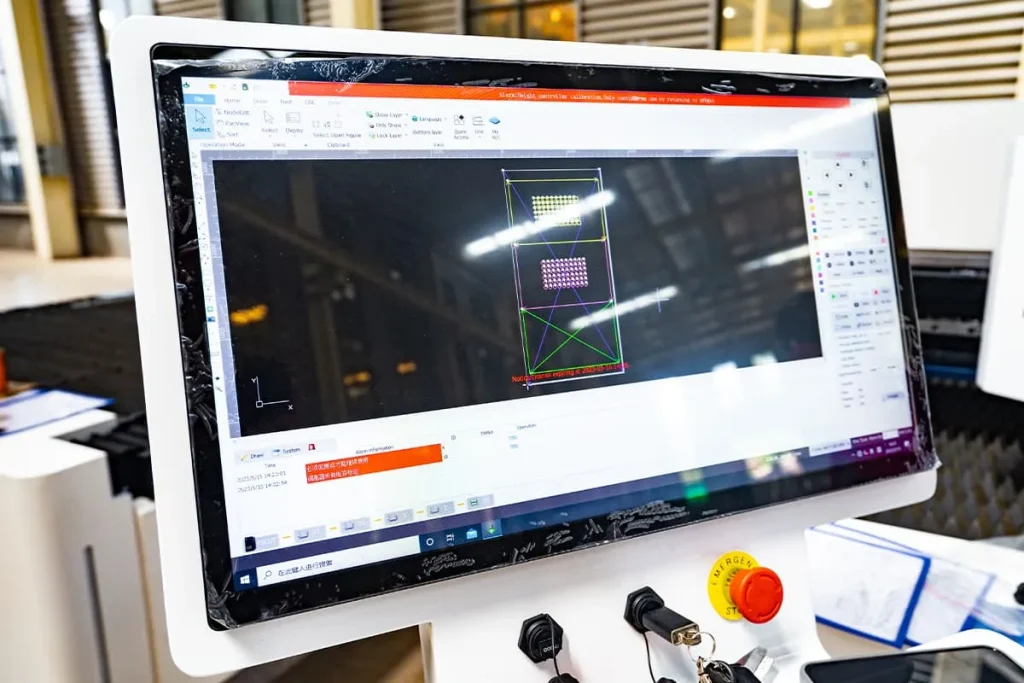

– Controle numérico do computador (CNC) Guidance: The CNC system guides the laser beam along pre-programmed paths, ensuring accurate and repeatable cuts.

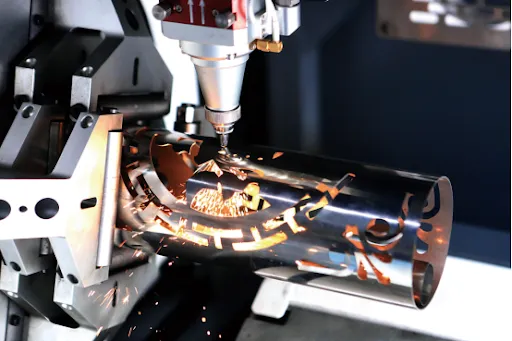

– Use of Chucks: These machines often use chucks to hold and rotate the tube, allowing the laser beam to access all sides and make intricate cuts.

3. Key Features of Fiber Laser Tube Cutting Machines

The efficiency of a fiber laser tube cutting machine lies in its sophisticated features, designed to handle a wide range of cutting tasks with ease. Here are some of the standout attributes that make these machines indispensable:

- High Precision Cutting

Fiber laser tube cutting machines are known for their ability to make precise cuts with minimal tolerance levels. This precision is essential for industries where even small deviations can lead to significant issues, such as in aerospace and medical equipment manufacturing. The focused laser beam ensures clean, cortes suaves, reducing the need for additional finishing processes.

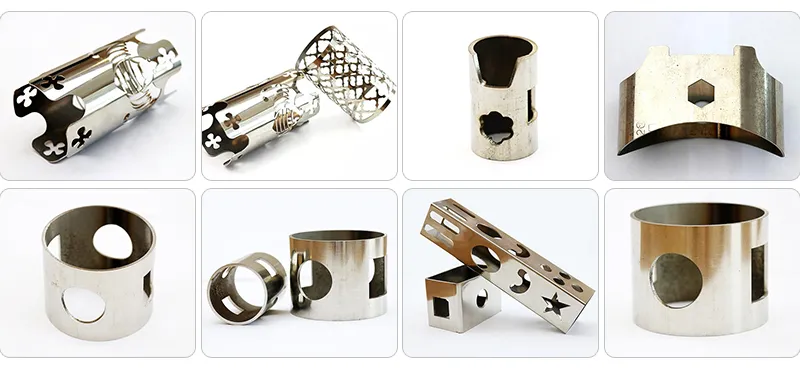

- Versatility in Tube Shapes and Materials

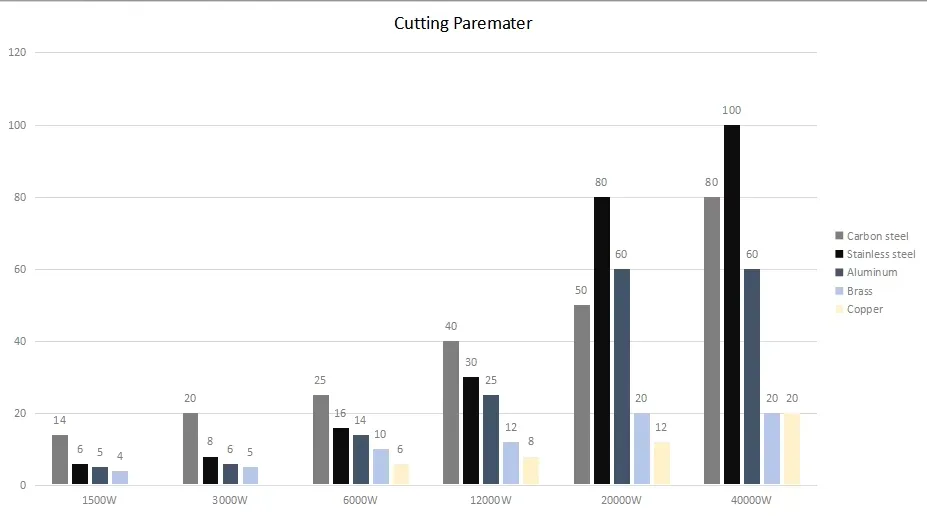

One of the greatest strengths of fiber laser tube cutting machines is their ability to cut various shapes, incluindo redondo, square, retangular, and oval tubes. They can handle materials like stainless steel, aço carbono, alumínio, e mais. This versatility enables manufacturers to meet diverse customer demands and produce complex designs.

- Velocidade e eficiência

Fiber laser tube cutting machines are renowned for their speed. They can handle high-volume production runs without compromising on quality. The fast processing speed allows manufacturers to reduce production time, increasing overall efficiency. The speed advantage is particularly notable when working with thinner materials.

- Corte sem contato

Unlike traditional methods that involve direct contact with the material, fiber laser tube cutting is a non-contact process. This feature eliminates mechanical wear and tear, reducing maintenance needs and preventing damage to delicate workpieces. The laser beam can cut through materials without physically touching them, which helps in maintaining the integrity of the tubes.

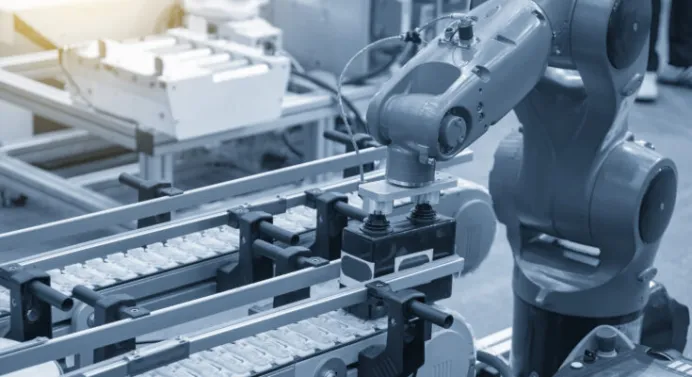

- Capacidades de automação

Many modern fiber laser tube cutting machines come equipped with advanced automation features, including automatic loading and unloading systems. Automation not only boosts productivity but also ensures consistent quality by reducing human error. This makes these machines suitable for integration into larger production lines, further enhancing their utility in industrial manufacturing.

4. Advantages of Fiber Laser Tube Cutting Machines

Fiber laser tube cutting machines offer numerous benefits over other cutting technologies, making them a preferred choice in many industries. Here’s a closer look at their key advantages:

- Reduced Operational Costs

Fiber lasers are known for their high wall plug efficiency, often exceeding 40%. This means they convert more of the electrical energy into laser light, reducing power consumption. Em contraste, Lasers de CO2, which have lower efficiency, consume more energy and require larger cooling systems. Como resultado, fiber lasers help manufacturers save on energy costs and minimize the need for frequent maintenance.

- Enhanced Cutting Quality

The high power density of a fiber laser ensures that the material being cut is quickly melted or vaporized, leading to clean cuts without burrs or rough edges. This results in a superior surface finish, reducing the need for secondary processes like deburring or grinding. This quality is crucial for industries where surface integrity is critical, como fabricação de dispositivos médicos.

- Adaptability to Reflective Materials

Fiber laser tube cutting machines are particularly adept at cutting reflective metals like brass, cobre, e alumínio. Unlike CO2 lasers, which can be damaged by back-reflected light, fiber lasers handle these materials with ease due to their shorter wavelength, which is more easily absorbed by the reflective surfaces.

- Long Lifespan and Minimal Maintenance

Fiber lasers have a longer operational life compared to other laser types, often lasting over 25,000 hours without needing significant maintenance. This longevity is due to the absence of delicate mirrors or gases that require regular replacement. The maintenance primarily involves keeping the cooling system functional and replacing air filters, making these machines more cost-effective over time.

5. Applications of Fiber Laser Tube Cutting Machines

Fiber laser tube cutting machines are versatile enough to be used across various sectors, providing precision and efficiency where traditional methods fall short.

- Indústria automobilística

No setor automotivo, these machines are used to fabricate exhaust systems, componentes do chassi, and other structural parts. The ability to cut tubes with tight tolerances ensures that each component fits perfectly, contributing to vehicle safety and performance.

- Indústria aeroespacial

The aerospace industry demands high precision and lightweight components. Fiber laser tube cutting machines are ideal for producing aircraft structures, peças do motor, and landing gear. Their ability to cut complex shapes with minimal tolerance is crucial for maintaining the structural integrity of aerospace components.

- Construção e Arquitetura

Na construção, laser tube cutting is used for creating structural elements like railings, staircases, and architectural facades. The precision and speed of these machines enable builders to create intricate designs that enhance the aesthetic appeal of structures without compromising on strength.

- Fabricação de equipamentos médicos

The medical industry relies on high-precision tools and components that must meet strict regulatory standards. Fiber laser tube cutting machines are used to produce parts for surgical instruments, implantes, e outros dispositivos médicos, ensuring that each piece meets the necessary specifications for safe use.

- Furniture Design

As the demand for custom-designed furniture grows, fiber laser tube cutting machines offer designers the ability to create intricate frames and structures. The machines’ ability to cut complex shapes allows for innovative designs, meeting consumer demand for aesthetically pleasing and functional furniture.

6. Choosing the Right Fiber Laser Tube Cutting Machine

Selecting the right machine for your specific needs requires careful consideration of several factors. Here’s what to keep in mind:

- Compatibilidade de materiais

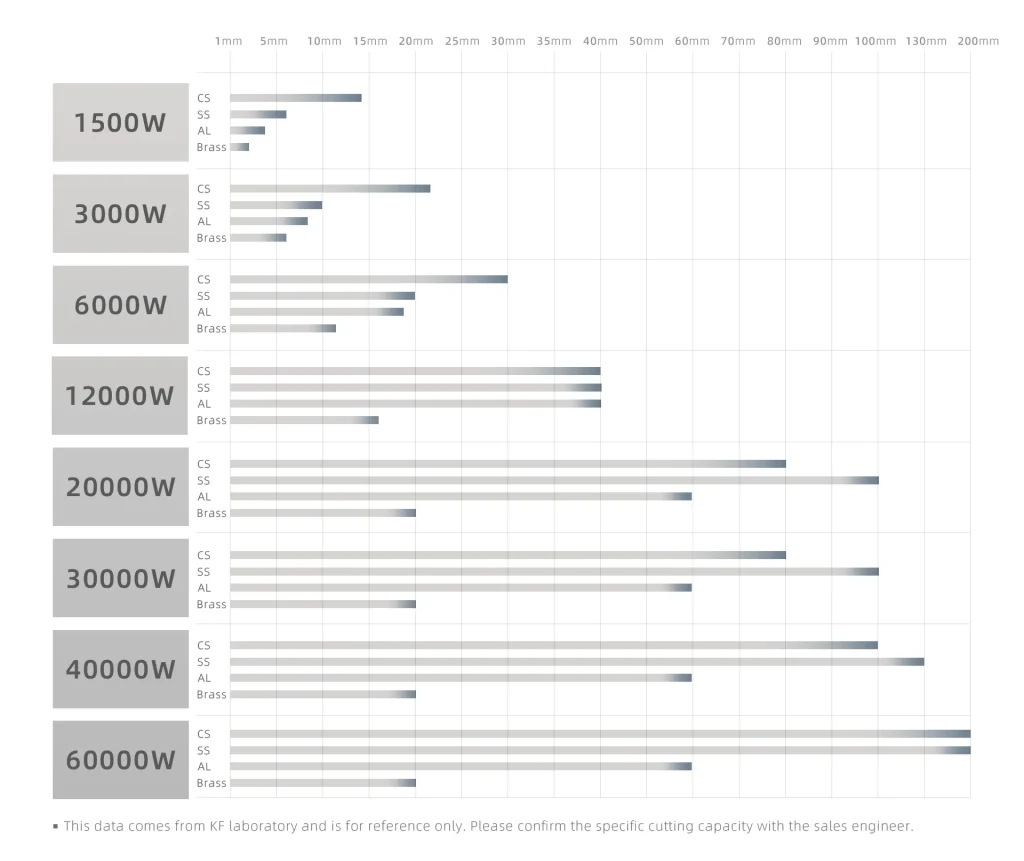

Different materials require different laser power and settings. Ensure that the machine you choose is compatible with the types of metals you intend to cut, such as stainless steel, aço carbono, or aluminum. The machine’s ability to adjust to different material thicknesses is also crucial for diverse cutting needs.

- Recursos de automação

Automation can significantly boost productivity by minimizing manual intervention. Look for features such as automatic loading and unloading, monitoramento em tempo real, and user-friendly CNC interfaces. These capabilities can streamline your production process and improve overall efficiency.

- Cutting Precision and Speed

Evaluate the machine’s precision levels and cutting speed. High precision ensures that your finished products meet exact specifications, while faster cutting speeds can enhance production throughput. No entanto, it is important to balance speed with accuracy to maintain the desired quality.

- Manutenção e Suporte

Regular maintenance is necessary to keep the machine in optimal working condition. Choose a manufacturer that offers robust after-sales support, including easy access to spare parts and technical assistance. A good support system ensures that any downtime is minimized, maintaining smooth production.

7. Future Trends in Fiber Laser Tube Cutting Technology

The field of laser cutting is constantly evolving, with new advancements making machines faster, mais preciso, and easier to use. Here are some trends that are shaping the future of fiber laser tube cutting machines:

- Integration of AI and Machine Learning

Artificial intelligence (IA) and machine learning are being integrated into fiber laser cutting systems to optimize cutting parameters automatically. These technologies can adjust the focus, poder, and speed based on real-time data, reducing the need for manual adjustments and ensuring consistent cutting quality.

- Eco-Friendly Cutting Solutions

As industries shift towards more sustainable practices, the development of energy-efficient laser systems is becoming a priority. Lasers de fibra, known for their high energy efficiency, are being further enhanced to reduce their environmental impact, making them an ideal choice for manufacturers looking to lower their carbon footprint.

- 3D Cutting Capabilities

The ability to cut in three dimensions is becoming more prevalent in fiber laser tube cutting machines. This allows manufacturers to produce more complex geometries and parts without needing additional equipment, expanding the range of potential applications in various sectors.

8. Maximizing the Potential of Your Fiber Laser Tube Cutting Machine

To get the best results from your fiber laser tube cutting machine, follow these tips:

– Regular Calibration: Ensuring the machine is properly calibrated is key to maintaining precision. Regularly check the alignment of the laser and the positioning system.

– Proper Material Setup: Correctly positioning the tube within the chucks and ensuring it is free from contaminants like oil or rust can prevent cutting issues.

– Optimizing Cutting Parameters: Adjust parameters such as laser power, velocidade, and focus for different materials to achieve the cleanest cuts.

By investing in the right machine and leveraging its full capabilities, manufacturers can stay competitive in an ever-evolving market, achieving both efficiency and quality in their production processes.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa