Notícias

Tube Laser Cutting Machine Price: What to Expect and How to Choose the Best Option

Introduction: Understanding the Value of Tube Laser Cutting Machines

When it comes to investing in cutting-edge technology for precision and efficiency, o tube laser cutting machine price is a major factor to consider. For businesses in industries like automotive, aeroespacial, e fabricação, these machines represent the future of high-quality cutting. The ability to process tubes and pipes with intricate designs and exact precision makes tube laser cutting machines indispensable.

But while the benefits are clear, the price of these machines varies greatly depending on several factors. Então, what should you expect when considering the tube laser cutting machine price? How can you ensure you’re getting the best deal while still meeting your operational needs? Neste artigo, we break down everything you need to know to make an informed decision.

1. What is a Tube Laser Cutting Machine?

◆ The Basics of Tube Laser Cutting

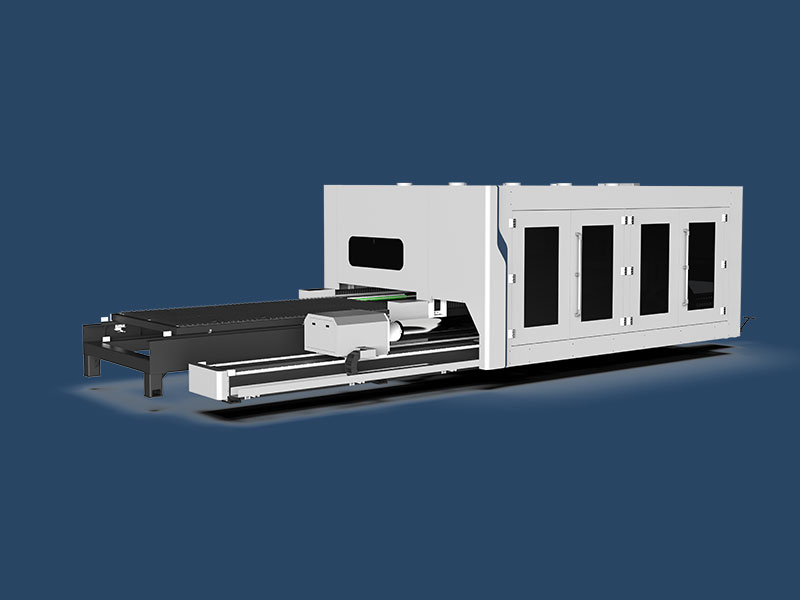

UM tube laser cutting machine is a powerful tool designed to cut various shapes and sizes of tubes, tubos, and profiles with exceptional precision. These machines use fiber laser technology, which is known for its high efficiency and ability to deliver clean, precise cuts at high speeds. Ao contrário dos métodos de corte tradicionais, tube laser cutting offers flexibility in handling complex geometries and materials, from stainless steel to aluminum.

◆ How Do Tube Laser Cutting Machines Work?

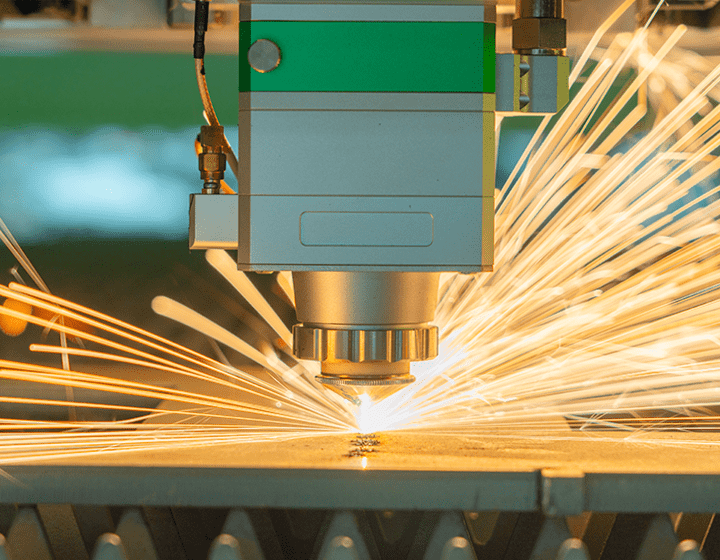

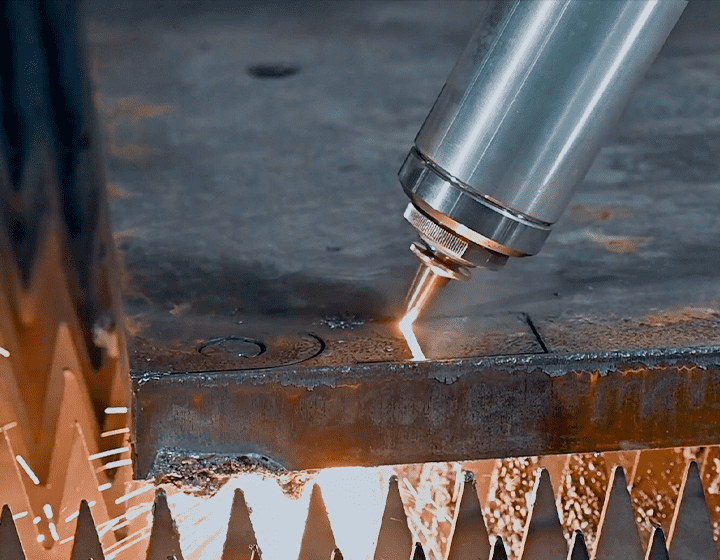

These machines work by focusing a high-powered laser beam onto a tube or pipe, melting the material at the point of contact. The machine’s software controls the cutting path, ensuring precise, clean cuts. The key advantages of this method include:

● Higher accuracy for intricate designs

● Minimal waste due to the narrow beam

● Reduced operational costs thanks to faster cutting speeds

The video below will help you understand the working principle of the laser tube cutting machine more intuitively.

2. Factors Affecting Tube Laser Cutting Machine Price

◆ Machine Power and Capabilities

O power of the laser is a significant factor in determining the price of tube laser cutting machines. More powerful machines can handle thicker and more varied materials, which makes them suitable for demanding applications. As expected, higher power machines come with a higher price tag.

◆ Material Compatibility

Different machines are designed to handle specific types of materials. Some machines excel in cutting Aço suave, while others are optimized for aço inoxidável, alumínio, or even titânio. The more materials a machine can process, the higher its price tends to be.

◆ Cutting Speed and Precision

Machines that offer velocidades de corte mais rápidas e better precision typically come at a premium price. For industries where time and accuracy are critical, these features are essential, but they will reflect in the cost.

◆ Machine Size and Cutting Capacity

Larger machines with extended cutting beds and capabilities for handling bigger tubes or pipes will generally be more expensive. The price varies based on the size of the workpieces they can process.

◆ Software and Automation Features

O automation level of the machine also affects the price. Machines with advanced CNC controllers or automated features, como automatic loading and unloading, are often more expensive but provide better operational efficiency.

3. Tube Laser Cutting Machine Price: What Can You Expect?

◆ Budget Options

For small to medium-sized businesses that don’t require high-powered cutting, basic models start at a lower price range. These machines typically offer power levels between 500W and 1000W and can handle basic cutting jobs efficiently. Prices for these models usually range from $50,000 para $150,000.

◆ Mid-Range Machines

Machines with higher power (1000W-3000W) and more advanced features, such as improved precision, velocidades de corte mais rápidas, and a larger material handling capacity, fall into the mid-range price category. These machines are suitable for industries with higher demands, such as the automotive or aerospace sectors. The cost for these models ranges from $150,000 para $350,000.

◆ High-End Machines

At the top of the price spectrum, you’ll find machines designed for heavy-duty cutting, capable of handling a wide variety of materials at extremely fast cutting speeds. These models often come with advanced features like AI-based cutting optimization, multi-axis cutting heads, e high-speed automation. Expect to pay $350,000 and above for these state-of-the-art machines.

4. Como obter o melhor valor para o seu dinheiro

◆ Assess Your Needs

Before making a purchase, carefully evaluate your business’s cutting needs. Consider factors such as material types, tube sizes, volume de produção, and required precision. By understanding what you truly need, you can select a machine that fits your budget without compromising on essential features.

◆ Consider Long-Term Costs

While the initial purchase price is important, consider the total cost of ownership. Isto inclui manutenção, consumo de energia, e potencial tempo de inatividade. Machines that require less maintenance and have lower operating costs can offer a better return on investment over time.

◆ Look for Financing Options

If the upfront cost of a tube laser cutting machine seems out of reach, many suppliers offer financing options or leasing agreements, which can make the investment more affordable for businesses on a budget.

5. Future Trends in Tube Laser Cutting Machines

The tube laser cutting market continues to evolve with technological advancements that drive performance and affordability. Innovations in laser sources, cutting heads, e software are making these machines more efficient, faster, and easier to operate. As prices continue to decrease over time, small businesses will have more opportunities to invest in these high-tech solutions.

Incorporating a tube laser cutting machine into your production line can provide eficiência, precisão, e relação custo-benefício. By understanding the factors that impact tube laser cutting machine price and assessing your specific needs, you can make a more informed decision and find a solution that offers the best value for your business. Whether you’re just starting or upgrading your existing equipment, the right tube laser cutting machine can make all the difference in enhancing your productivity and competitiveness.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa