News

The Revolutionary World of Laser Steel Cutting Machines

Imagine a technology so precise it can slice through steel with the finesse of a surgeon’s scalpel. A machine so versatile it powers industries ranging from aerospace to fine jewelry. A process so efficient it reduces waste while maximizing productivity. Welcome to the captivating universe of laser steel cutting machines. These marvels of modern engineering are not just tools; they are a symbol of industrial transformation, driving precision, speed, and innovation to unparalleled heights.

In this comprehensive guide, we delve deep into the intricacies of laser steel cutting machines, exploring their mechanisms, applications, benefits, and essential considerations. Whether you’re an industry professional, a small business owner, or simply curious about the technology, this article offers a detailed exploration that reveals the limitless potential of laser steel cutting.

1.What Is a Laser Steel Cutting Machine?

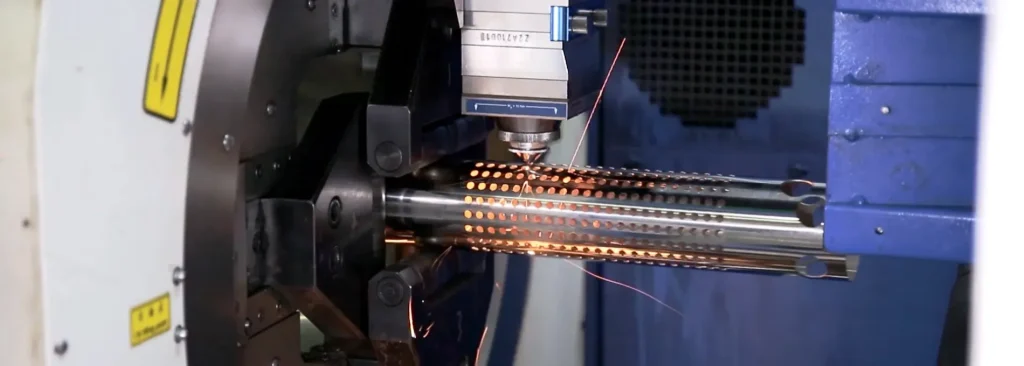

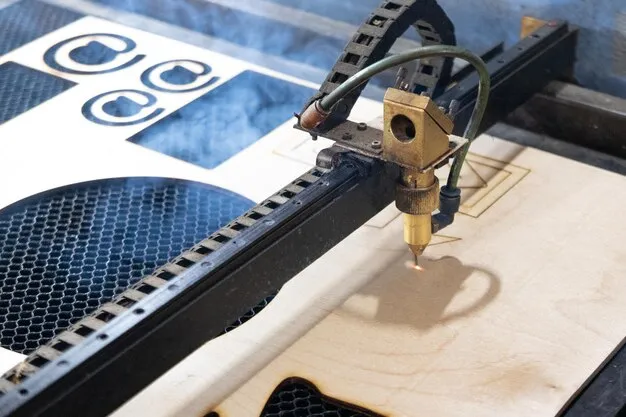

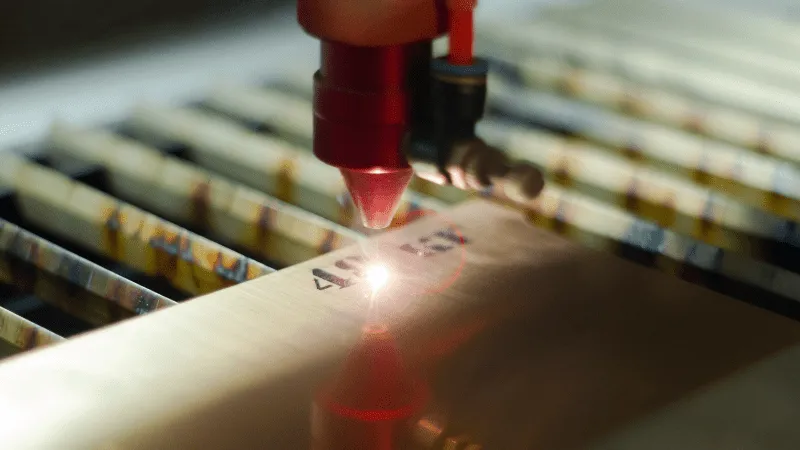

At its core, a laser steel cutting machine is a device that uses high-powered lasers to cut, engrave, or shape steel and other materials with extraordinary accuracy. The key to its effectiveness lies in the concentrated laser beam, which generates heat intense enough to melt or vaporize steel. Controlled by computer numerical control (CNC) systems, these machines execute intricate designs and precise cuts with unmatched consistency.

The term “laser” stands for Light Amplification by Stimulated Emission of Radiation. Laser cutting machines employ this principle by generating a focused beam of light that, when directed onto a material, produces a highly localized and efficient cutting process.

☟ The following video can help you better understand the laser cutting process.

2.Why Are Laser Steel Cutting Machines Revolutionizing Industries?

1. Unmatched Precision

Laser steel cutting machines offer sub-millimeter accuracy, making them ideal for industries where precision is paramount. From intricate automotive parts to detailed architectural designs, these machines can deliver flawless results consistently.

2. Incredible Speed

Time is money, and laser steel cutting machines are among the fastest cutting tools available. With speeds ranging from hundreds to thousands of inches per minute, they significantly reduce production times, enabling industries to meet tight deadlines.

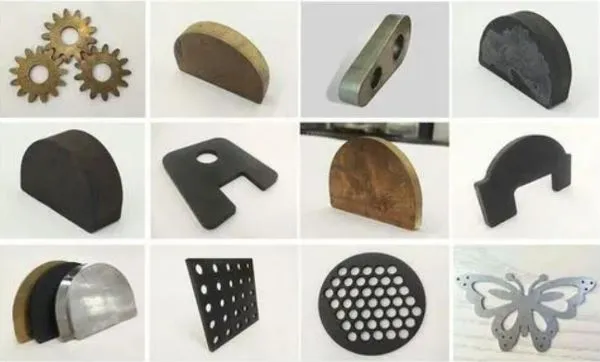

3. Versatility Across Materials

While primarily designed for steel, these machines are capable of cutting a wide range of materials, including stainless steel, aluminum, brass, copper, and more. This versatility makes them indispensable across multiple industries.

4. Energy Efficiency and Cost-Effectiveness

Modern laser steel cutting machines, especially fiber lasers, are highly energy-efficient, consuming less power compared to traditional cutting methods. They also minimize material wastage, resulting in significant cost savings.

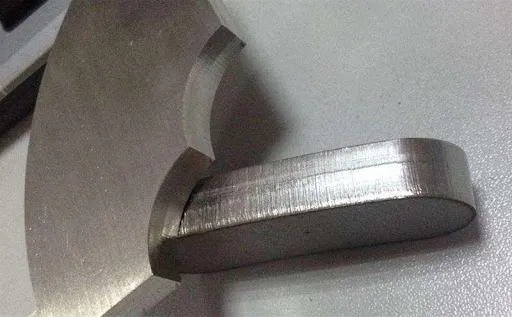

5. Non-Contact Cutting

Unlike mechanical cutting tools, laser cutting is a non-contact process. This means there is minimal wear and tear on the machine and no physical damage to the material being cut. The result is clean, burr-free edges.

3.How Do Laser Steel Cutting Machines Work?

The process of laser steel cutting involves several carefully coordinated steps, each crucial to achieving precision and efficiency:

1. Laser Beam Generation

The machine generates a laser beam using a laser source. Depending on the type of machine, this could be a fiber, CO2, or diode laser. The laser is amplified and directed through a series of mirrors or optical fibers.

2. Beam Focusing

The laser beam is then focused to a fine point using lenses within the cutting head. This concentration of energy ensures that the laser has enough power to melt, vaporize, or ablate the steel.

3. Material Interaction

As the laser beam hits the steel surface, the heat melts or vaporizes the material along the cutting path. Assist gases like nitrogen or oxygen are often used to blow away molten metal and ensure a clean cut.

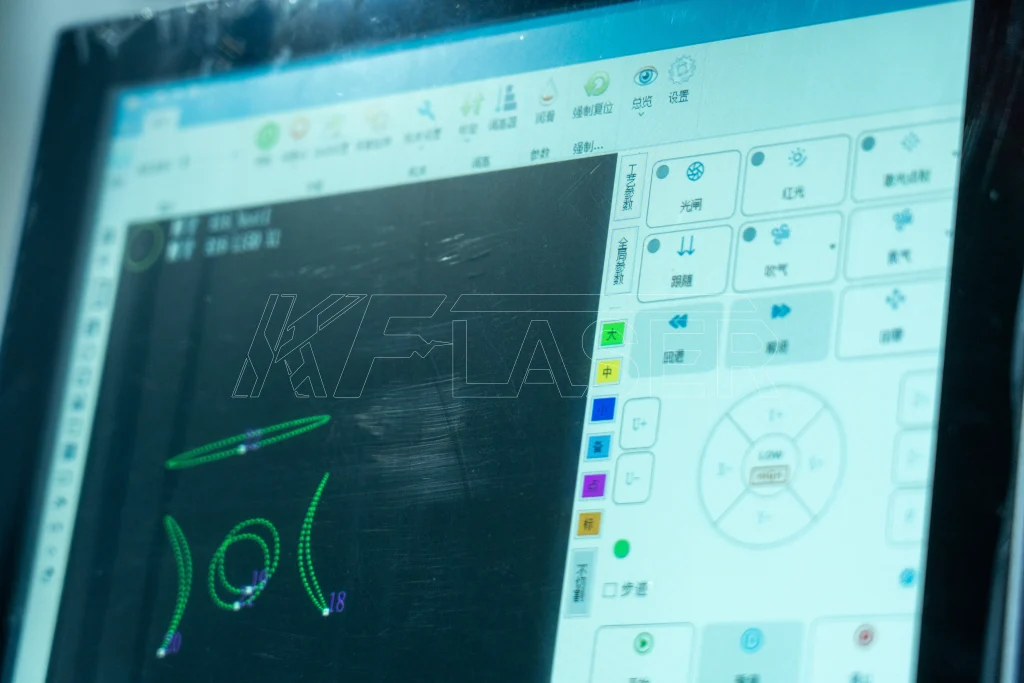

4. Computerized Control

CNC systems guide the cutting head along the predetermined path. These systems use CAD (Computer-Aided Design) files to execute precise and intricate cuts, ensuring minimal human error.

4.Types of Laser Steel Cutting Machines

Laser steel cutting machines can be categorized based on the type of laser they use. Each type has its own strengths and is suited for specific applications.

1. Fiber Laser Cutting Machines

Fiber lasers are the gold standard for cutting metals like steel. They use optical fibers doped with rare earth elements to amplify the laser beam. Their high beam quality and energy efficiency make them ideal for cutting thin and thick metals with precision.

Wavelength: 1.06 μm

Best For: Stainless steel, carbon steel, aluminum, brass, and copper

Advantages: High cutting speed, low maintenance, and excellent energy efficiency

2. CO2 Laser Cutting Machines

CO2 lasers are versatile and cost-effective, making them a popular choice for non-metallic materials and some metal applications. They use a gas mixture of carbon dioxide, nitrogen, and helium to generate the laser.

Wavelength: 10.6 μm

Best For: Non-metals like wood, plastics, and glass; also suitable for mild steel

Advantages: Lower initial cost, high versatility

3. Nd:YAG and Nd:YVO Lasers

These solid-state lasers are known for their durability and precision. They are often used for engraving and marking metals and certain non-metals.

Wavelength: 1.064 μm

Best For: High-precision applications, thin metals, and reflective materials

Advantages: High beam quality, long lifespan

4. Diode Lasers

Diode lasers are compact and energy-efficient but are generally less powerful than fiber or CO2 lasers. They are best suited for light-duty cutting and engraving tasks.

Wavelength: 0.9 to 1.1 μm

Best For: Thin metals, plastics, and composites

Advantages: Compact design, low power consumption

5.Key Parameters to Optimize Laser Steel Cutting

For the best results, operators must carefully control several parameters during the cutting process:

1. Laser Power

The power of the laser determines its ability to cut through materials of varying thickness. Higher power is needed for thicker steels.

2. Cutting Speed

The speed at which the laser moves affects the quality and efficiency of the cut. Faster speeds are ideal for thinner materials, while slower speeds are necessary for thicker metals.

3. Assist Gas Pressure

Assist gases like nitrogen and oxygen improve cut quality by removing molten material and reducing oxidation.

4. Focus Spot Size

A smaller focus spot results in higher precision and cleaner cuts. This parameter is particularly important for intricate designs.

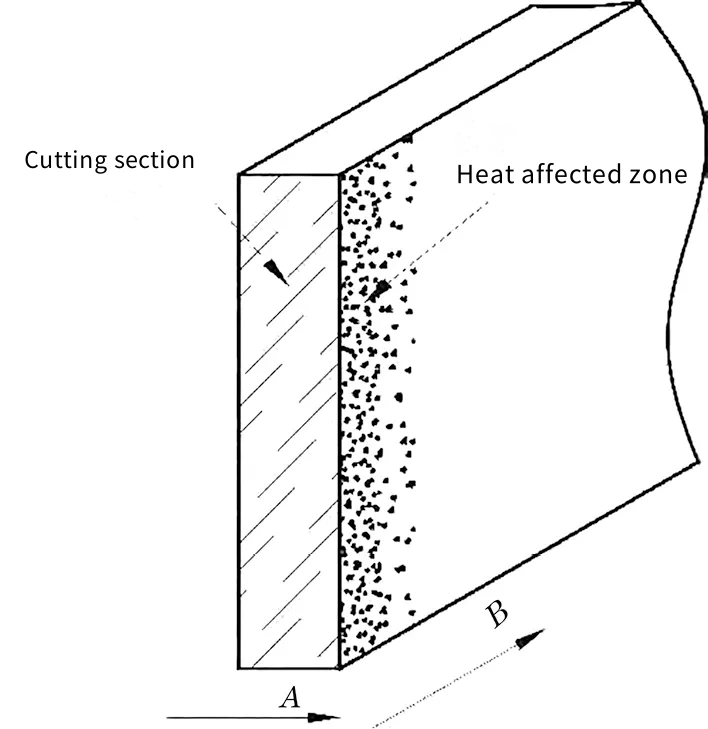

5. Pulse Frequency

The number of laser pulses per second influences the heat affected zone (HAZ) and overall cut quality.

6.Applications of Laser Steel Cutting Machines

The versatility of laser steel cutting machines makes them invaluable across a wide range of industries:

Automotive: For cutting engine components, body panels, and intricate designs

Aerospace: For manufacturing lightweight, high-strength parts

Construction: For creating steel frames, facades, and custom designs

Medical: For producing surgical instruments and medical implants

Electronics: For cutting precision parts for circuit boards and devices

Jewelry: For crafting intricate and detailed designs

7.What to Consider When Choosing a Laser Steel Cutting Machine

Investing in a laser steel cutting machine is a significant decision. Here are some factors to keep in mind:

1.Material Compatibility: Ensure the machine is suitable for the types of steel and other materials you’ll be cutting.

2.Work Area Size: Choose a machine with a bed size that accommodates your typical projects.

3.Power Requirements: Higher power machines can cut thicker materials but come at a higher cost.

4.Precision Needs: Opt for machines with high beam quality for intricate designs.

5.Budget: Factor in both initial costs and ongoing expenses like maintenance and power consumption.

8.The Future of Laser Steel Cutting Machines

As industries evolve, so do the technologies that support them. Laser steel cutting machines are becoming smarter, faster, and more energy-efficient. Innovations like AI-driven CNC systems, advanced nesting software, and hybrid laser technologies are pushing the boundaries of what these machines can achieve. Companies like KF LASER are at the forefront of this revolution, delivering cutting-edge solutions tailored to modern manufacturing needs.

Whether you’re looking to streamline your production processes, enhance precision, or reduce costs, a laser steel cutting machine is an investment in efficiency and innovation. As this technology continues to advance, its applications will only grow, solidifying its place as an indispensable tool in the world of manufacturing and beyond.

Explore the possibilities, embrace the precision, and harness the power of laser steel cutting to elevate your projects to new heights.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine