Laser tube cutting machines represent a groundbreaking technology that has revolutionized the way industries approach metal fabrication. In today’s fast-paced manufacturing environment, precision, speed, and efficiency are paramount. Laser cutting technology provides all three, enabling manufacturers to produce intricate cuts with minimal waste and maximum accuracy.

The ability of laser tube cutting machines to make precise cuts in a variety of materials has made them an indispensable tool in numerous industries, including aerospace, automotive, construction, and more.

As businesses seek to innovate and streamline their manufacturing processes, laser cutting has emerged as the clear leader in providing high-quality results with unmatched precision.

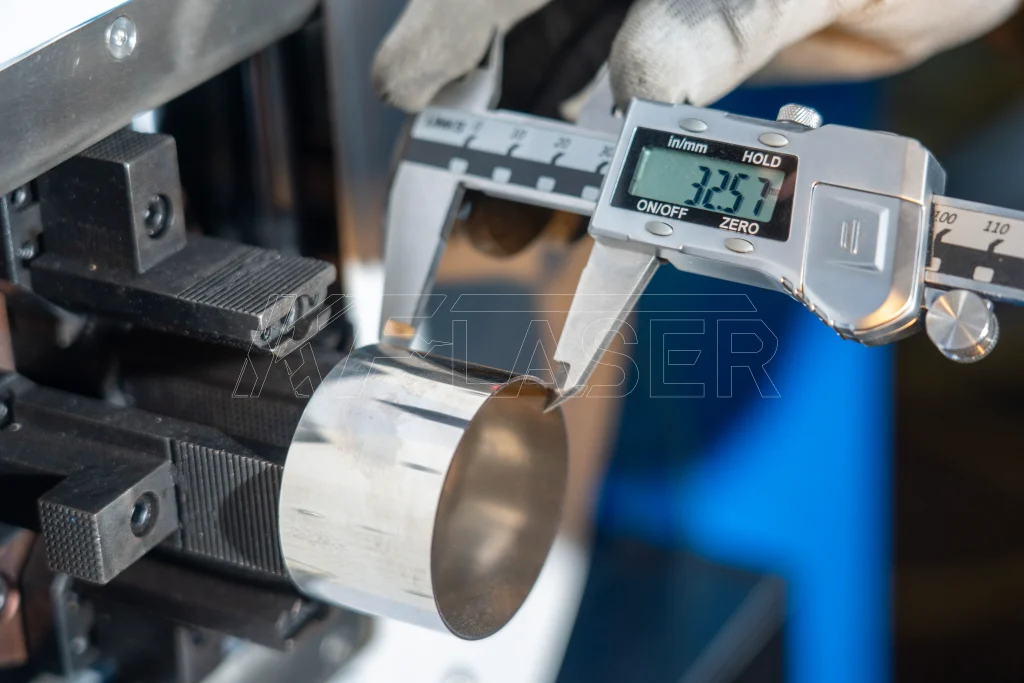

Laser tube cutting machines use a focused laser beam to cut through metal tubes with extreme accuracy. The process involves directing the laser at the tube surface, which then heats and melts the material, creating a cut. The technology is capable of producing both simple and complex cuts in a wide range of materials, including steel, aluminum, and copper.

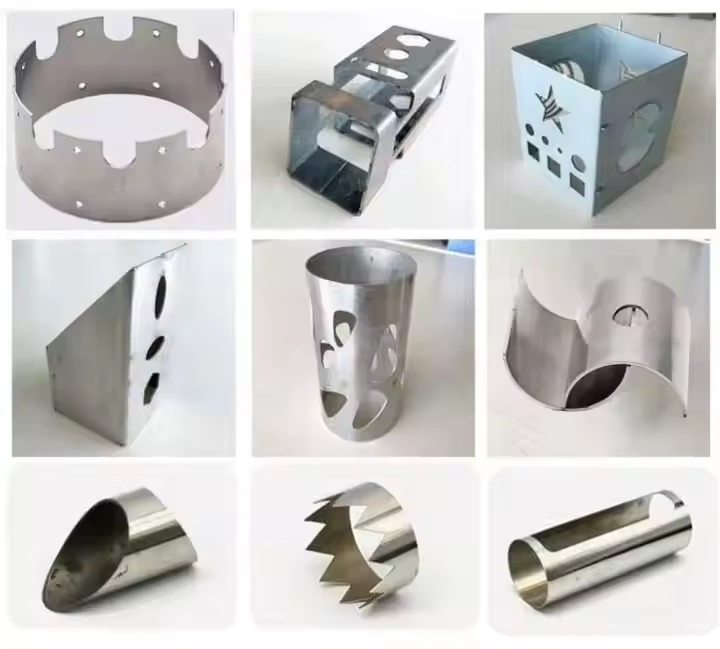

This precision cutting method allows for the creation of intricate patterns, shapes, and designs that are not possible with traditional cutting methods. The automated nature of the process also reduces human error, ensuring consistency and accuracy across every cut.

One of the standout features of laser tube cutting machines is their ability to make incredibly precise cuts. Whether the job requires straight lines or intricate shapes, laser cutting ensures that each cut meets the exact specifications required.

Laser tube cutting machines are known for their speed. Unlike traditional methods, which may require multiple stages of cutting and finishing, laser cutting can achieve clean cuts in a single pass. This results in faster production times and greater efficiency.

The narrow focus of the laser beam ensures minimal material waste, making it a more economical choice for many manufacturers. This is particularly important in industries where the material cost is high, and maximizing the use of raw materials can significantly reduce costs.

Laser tube cutting machines are capable of cutting a wide variety of materials, from thick metals to thin-walled tubing. This versatility makes them ideal for industries that require diverse materials to be processed, such as automotive or construction.

Laser cutting allows manufacturers to create intricate designs and cuts that would be difficult, if not impossible, with conventional cutting methods. Whether it’s making holes, angled cuts, or complex patterns, laser cutting technology can handle it all.

The advantages of laser tube cutting machines extend across many different industries, each benefiting from the speed, precision, and versatility offered by this cutting-edge technology.

In the aerospace industry, where precision is critical, laser tube cutting machines are used extensively to fabricate high-precision components. These machines are capable of cutting intricate shapes and patterns in materials like titanium, stainless steel, and aluminum – materials that are often used in aircraft construction. The ability to cut complex geometries and ensure structural integrity is crucial in this industry.

The automotive industry has embraced laser tube cutting machines for their ability to produce high-precision components quickly and efficiently. Whether it’s for cutting exhaust pipes, structural parts, or custom automotive designs, laser cutting offers speed, accuracy, and minimal material waste, which are essential in automotive manufacturing.

In construction, laser tube cutting machines are used to fabricate structural steel components. The precision of the cuts ensures that the pieces fit together perfectly, reducing the need for further adjustments and making the construction process smoother and more efficient. Additionally, the ability to cut complex shapes and sizes enhances the versatility of laser cutting in building design and construction projects.

Laser tube cutting machines are widely used in metalworking and fabrication shops to process tubes and pipes with high precision. Whether it’s for creating complex pipework or metal furniture, laser cutting enables fabricators to produce parts that meet exact specifications. The technology also helps to reduce finishing time, as the cuts made by laser machines often require minimal post-processing.

In the energy sector, particularly in oil and gas, laser tube cutting machines are used for creating intricate parts for machinery and pipelines. The high precision of the cuts is essential in ensuring the safety and efficiency of components in this critical industry.

While traditional cutting methods, such as saw cutting and punching, are still in use, laser tube cutting machines offer several advantages that make them the preferred choice for modern manufacturing.

Higher Efficiency: Laser cutting is faster than traditional methods, reducing production time and allowing manufacturers to meet tight deadlines. The automated nature of the process also reduces the need for manual labor, saving on labor costs.

Cleaner Cuts with Less Finishing: Traditional cutting methods often require additional steps, such as grinding or deburring, to achieve smooth edges. Laser cutting, on the other hand, produces clean, smooth cuts that require minimal finishing, saving both time and money.

Greater Flexibility: Laser tube cutting machines can handle a wide range of tube sizes and materials, offering flexibility in production. Whether it’s a small batch of custom parts or a large-scale production run, laser cutting technology can accommodate a variety of requirements.

Improved Safety: Traditional cutting methods often pose safety risks due to sharp edges or the need for heavy machinery. Laser cutting eliminates these risks, providing a safer working environment for operators.

Cost Savings: Despite the initial investment in laser cutting technology, the long-term cost savings are significant. With faster processing times, reduced waste, and minimal post-processing, laser tube cutting machines can ultimately help businesses save money.

As technology continues to advance, the future of laser tube cutting machines looks even brighter. Innovations in laser sources, such as fiber lasers, are increasing cutting speeds, improving material efficiency, and further reducing operating costs. The integration of artificial intelligence (AI) and automation into laser cutting systems is also helping to streamline the production process, allowing for even greater precision and faster turnaround times.

In the coming years, we can expect laser tube cutting machines to become even more integral to industries that rely on precision and efficiency. The technology will continue to evolve, offering new solutions to meet the ever-growing demands of modern manufacturing.

By investing in laser tube cutting machines, manufacturers can remain competitive, reduce production times, and enhance the overall quality of their products.