News

CNC Laser Metal Cutting Machine: Precision and Efficiency in Modern Manufacturing

The CNC laser metal cutting machine has taken the manufacturing world by storm, offering unmatched precision, speed, and versatility. These machines have revolutionized how industries approach metal fabrication, from automotive production to aerospace engineering. As manufacturers demand higher quality and faster production times, the CNC laser metal cutting machine has proven to be an essential tool for cutting, engraving, and shaping metal with precision.

In today’s competitive market, manufacturers must keep up with technological advances to stay ahead. The CNC laser metal cutting machine represents one of the most significant advancements in modern manufacturing, offering several key advantages over traditional cutting methods.

1.What is a CNC Laser Metal Cutting Machine?

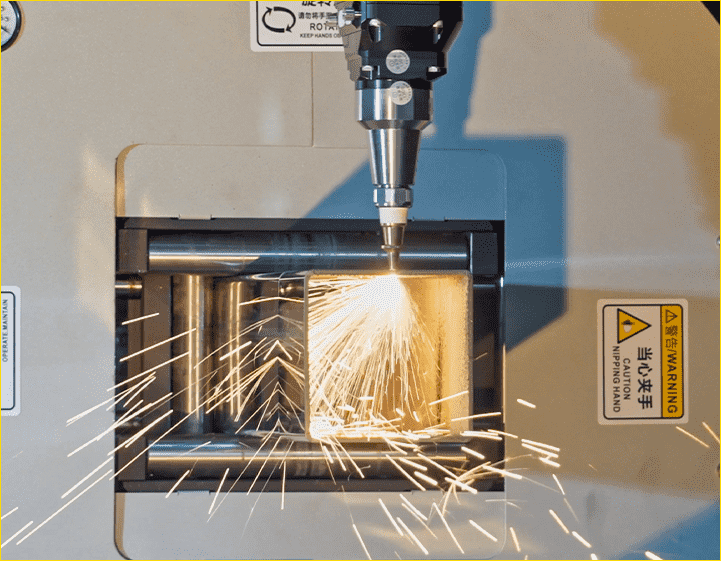

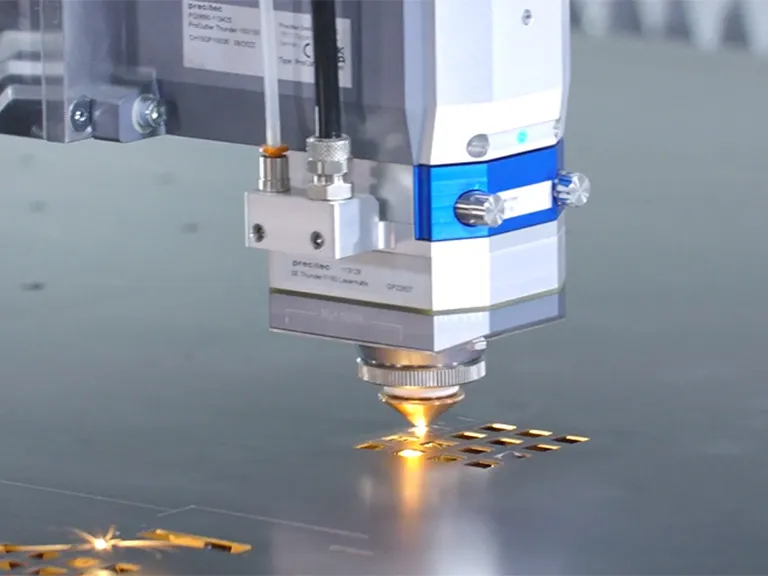

A CNC laser metal cutting machine is a sophisticated tool used for cutting and engraving metal sheets with laser technology. The term “CNC” refers to computer numerical control, which allows for highly automated and precise cutting. The machine utilizes a focused laser beam that melts, burns, or vaporizes the material to create clean, accurate cuts. The process is extremely precise, making it ideal for applications that require high-quality, intricate designs.

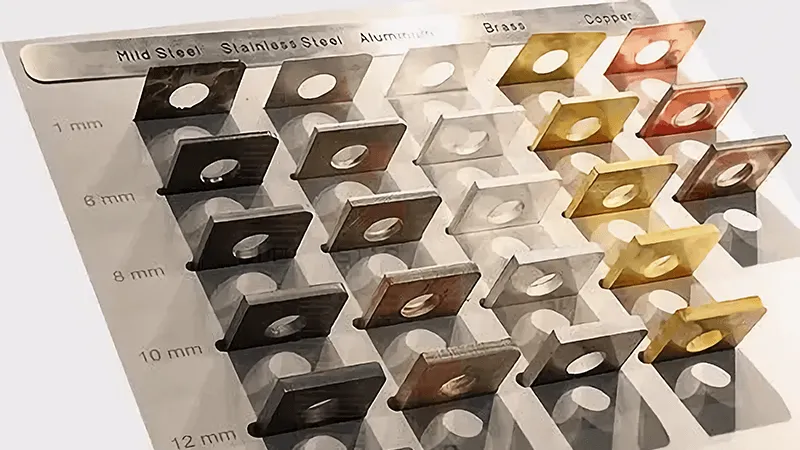

These machines can cut a wide variety of metals, including steel, aluminum, and brass, and they come in different configurations to handle various thicknesses of material. Whether you need to cut thick metal sheets or intricate patterns, the CNC laser cutting machine offers unmatched performance and flexibility.

2.Key Advantages of CNC Laser Metal Cutting Machines

When it comes to metal cutting, the CNC laser metal cutting machine offers several advantages that set it apart from traditional methods such as punching, sawing, or water jet cutting.

Unmatched Precision and Accuracy

The most significant advantage of the CNC laser metal cutting machine is its ability to produce extremely precise cuts. Unlike mechanical cutting tools that can cause wear and tear over time, the laser beam offers consistent, repeatable cuts with minimal deviation. The precision is essential for industries that require tight tolerances and intricate designs, such as aerospace or electronics.

Increased Speed and Productivity

Laser cutting machines can operate at speeds much higher than traditional cutting methods. The combination of precision and speed means manufacturers can produce more parts in less time, significantly increasing overall productivity. This is especially valuable in industries like automotive manufacturing, where high-volume production is critical.

Minimal Material Waste

The CNC laser metal cutting machine produces narrower cuts compared to mechanical cutting, which reduces material wastage. The laser beam is incredibly fine, and the precise cutting reduces the need for additional processing steps. This not only saves on raw materials but also improves the overall efficiency of the manufacturing process.

Flexibility and Versatility

CNC laser machines are highly versatile. They can cut a wide range of metals, from stainless steel to non-ferrous metals like aluminum, copper, and brass. Additionally, they can handle different thicknesses of metal, making them adaptable for a variety of manufacturing needs. Whether you’re cutting flat metal sheets or working with complex 3D parts, a CNC laser cutting machine can handle it.

No Need for Tool Changes

Unlike traditional cutting methods that require tooling changes between different types of cuts, the CNC laser metal cutting machine can handle multiple tasks without the need for physical tool changes. This reduces setup time and ensures smoother transitions between tasks.

Cleaner and Safer Operation

Laser cutting is a non-contact process, meaning the cutting head never physically touches the metal. This results in cleaner edges and less material distortion. Furthermore, the non-contact nature of the cutting reduces wear and tear on the machine, ensuring longer operational life. The use of CNC technology also minimizes human error, leading to safer and more efficient operations.

3.Applications of CNC Laser Metal Cutting Machines

The versatility of the CNC laser metal cutting machine makes it suitable for a wide range of industries and applications. Here are some of the key sectors that benefit from laser metal cutting:

Automotive Industry

The automotive sector relies heavily on precision manufacturing to produce components such as body panels, chassis, and exhaust systems. The CNC laser metal cutting machine plays a critical role in the efficient and accurate production of these parts. By enabling manufacturers to produce intricate designs quickly and with high precision, laser cutting technology has become indispensable in automotive manufacturing.

Aerospace Industry

In the aerospace industry, parts must meet strict safety and performance standards. The CNC laser metal cutting machine ensures that components such as engine parts, wing sections, and other critical elements are cut with the utmost precision. Laser cutting allows manufacturers to meet the stringent tolerance requirements of the aerospace sector.

Electronics and Electrical Equipment

The electronics industry uses laser cutting for precise cutting of enclosures, connectors, and other components made from thin metals. The CNC laser metal cutting machine provides the necessary accuracy for these delicate parts while ensuring minimal material loss and a high level of repeatability.

Construction Industry

In construction, CNC laser metal cutting machine technology is employed to fabricate structural elements, including beams, columns, and girders. Laser cutting provides the accuracy needed for these large-scale components, ensuring that each part fits perfectly within the building’s framework.

4.How to Choose the Right CNC Laser Metal Cutting Machine

Selecting the right CNC laser metal cutting machine depends on several factors that influence performance and cost-effectiveness.

Material Type and Thickness: Different machines are designed to handle specific materials and thicknesses. Consider the type of metal you’ll be cutting and ensure that the machine is capable of handling it. For example, fiber lasers are ideal for cutting thin metals, while CO2 lasers are better for cutting thicker materials.

Cutting Speed and Efficiency: Speed is a crucial factor, especially for high-volume production. However, it’s important to balance speed with precision to ensure that quality is not compromised. Choose a machine that offers the optimal combination of speed and accuracy for your specific needs.

Automation and Software Integration: Advanced CNC systems offer sophisticated automation and software options that help optimize the cutting process. Look for machines with intuitive interfaces and robust software that can integrate easily into your existing manufacturing process.

Maintenance and Support: Choose a machine that comes with strong technical support and service options. Regular maintenance is key to keeping your CNC laser cutting machine in optimal condition, reducing downtime and improving longevity.

5.The Future of CNC Laser Metal Cutting Machines

As technology continues to evolve, CNC laser metal cutting machines will see even more advancements. Some trends to watch out for include:

Increased Automation: As industries push for more efficiency, automation will continue to play a significant role. Fully automated CNC laser cutting systems will streamline the entire process, from design to production.

Improved Energy Efficiency: With growing concerns about environmental impact, manufacturers are looking for ways to reduce energy consumption. Newer laser cutting machines are being designed to be more energy-efficient, reducing operational costs.

Integration with AI and Machine Learning: Artificial intelligence and machine learning will soon be integrated into CNC laser cutting machines to improve the cutting process. These technologies will optimize the cutting paths, reduce errors, and enhance overall productivity.

The CNC laser metal cutting machine is undeniably a powerful tool in the modern manufacturing world, offering unmatched precision, versatility, and speed. As industries demand higher quality and greater efficiency, this technology will continue to shape the future of manufacturing, providing solutions that drive innovation and excellence. Whether it’s for automotive, aerospace, or construction, the CNC laser cutting machine remains at the forefront of the metal cutting revolution.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine